Professional Documents

Culture Documents

JTA7 CE 4219 Research FINAL Poster

JTA7 CE 4219 Research FINAL Poster

Uploaded by

JB RSNJNOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JTA7 CE 4219 Research FINAL Poster

JTA7 CE 4219 Research FINAL Poster

Uploaded by

JB RSNJNCopyright:

Available Formats

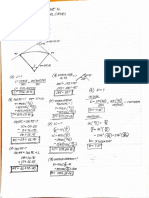

Properties of Human Hair-Reinforced Concrete with the

addition of Superplasticizer in terms of Mechanical Properties

(Compressive Strength and Tensile Strength), Workability

and Water Absorption

Neil Myco D. Sarsalejo, Jims Bryll Senajon, & Jovell Carloise B. Manalili

Department of Civil Engineering, University of San Carlos, Nasipit, Talamban, Cebu City 6000

INTRODUCTION RESULTS AND DISCUSSION

Human hair is one of our environment's most common

residual wastes, which can cause floods and clogs if In Figure 7, on the 10th day, NC outperformed

disposed of improperly. The hair neither decays nor leaves 0.5% SP and 1.0% SP, but 1.5% SP achieved the

intact for safe reuse or recycling. Some applications involve highest value. By the 28th day, all samples

either contamination of the hair with toxic chemicals or surpassed NC, with a slight decrease in 1.0% SP

irreversible blending with certain non-biodegradable or compared to 0.5% SP, while 1.5% SP exhibited

the highest strength. These fluctuations are

ecologically unsafe materials. attributed to the consistent w/c ratio, causing

The concrete industry, on the other hand, has been working varying superplasticizer interactions with the

same water quantity and resulting in distinct

on producing concrete with fiber fillers as reinforcement to strength outcomes.

make it much more durable. One example is using hair as a

fiber filler for concrete to enhance its physical and Figure 7. Average compressive strength of each batch

mechanical properties. after 10-day and 28-day curing

Human hair is good in tension; hence it can be used as a In figure 8, the splitting tensile strength

fiber-reinforcing material. Hair fiber, an alternate non- Figure 1. Hair- r einforced concrete consistently decreases without a superplasticizer,

degradable matter, is available in abundance and at a very with superplasticizer samples aligning with Ravikumar's findings, emphasizing

cheap cost. that excess superplasticizer compromises

concrete cohesiveness, resulting in strength

reduction [4]. The 0.5% SP enhances workability,

OBJECTIVES providing an initial tensile strength boost.

[1] To determine the 10-day and 28-day mechanical properties [compressive (ASTM However, the 1.0% dosage falls short of 28-day

C39), tensile (ASTM C496), and water absorption) of normal concrete, 0.5%, 1%, and compressive strength, and the 1.5% dosage

1.5% addition of superplasticizer by weight of cement with hair of 3% by weight of cement exhibits a significant decline in tensile strength,

deviating from the intended goal.

[2] To the workability of the normal concrete and concrete mixture with 3% hair fiber Figure 8. Average split tensile strength of each batch

added with 0.5%, 1.0%, and 1.5% superplasticizer by using ASTM C143-90 after 10-day and 28-day curing

Figure 9 shows normal concrete with the highest

MATERIALS AND METHODS slump, indicating superior workability, followed by

the 1.5% superplasticizer mixture. Higher

Materials plasticizer doses correlate with increased slump

• Waste Hair values, highlighting a direct link to workability. The

• Coarse slump test emphasizes the substantial impact of

Aggregates adding superplasticizer on mixture workability,

• Fine Aggregates with the average slump of the 1.5% mixture

• Portland Cement comparable to normal concrete and other

• Water Figure 9. Comparison of average slump for four different mixtures also showing improved slump.

concrete mixtures

Methods In Figure 10, water absorption percentages vary

Figure 2. Schematic Framework

Waste Human Hair significantly, influenced by overall sample

outcomes. The 10-day strength of 1.5% with SP

Collected hair wastes from barbershops and cut to 0.75 inches. Cleaned with shampoo and

displays elevated water absorption due to cracks

rinsed twice which was sun-dried after. Mixed into concrete as per the required percentage

and holes from uneven settling. Yet, it's crucial to

by weight of cement and transferred into 150 mm x 300 mm cylindrical molds.

note that overall water absorption for each sample

Mixture Proportion remains within the acceptable range, below the

Mix design followed ACI 211.1 standards which was calculated manually (refer to Table 1). standard's 7% threshold for satisfactory levels.

Hair percentage derived from Santos, F.D. et al. (2020), and superplasticizer dosage from

M.A.O. Ahmed (2018). Figure 10. Average weight comparison of four concrete

mixtures (compressive and tension) after 10 -day and

Table 1. Hair fiber-reinforced pervious concrete design mix proportions (kg) 28-day curing periods

Dosage No. of Volum

3

Water Cement Sand Gravel Hair SP CONCLUSIONS and RECOMMENDATIONS

of SP Samples e (m ) (kg) (kg) (kg) (kg) (g) (g) • 1.5% SP was the strongest among the three levels, with the least compressive strength found at 1% SP on

average. Notably, 0.5% SP produced the highest individual sample results at 28.08 MPa and 27.41 MPa.

NC (0%) 3 0.018 3.708 7.416 13.31 15.85 0 0 The 0.5% dosage emerges as the optimal choice, showing a significant improvement in tensile strength from

2.19 MPa at 10 days to 2.59 MPa at 28 days, surpassing specified criteria and achieving a favorable balance

0.5% 3 0.018 3.708 7.416 13.31 15.85 222.48 37.08 between compressive and tensile strength. Neither the 1.0% nor the 1.5% dosage is fully suitable due to

limitations in achieving the desired balance between compressive and tensile strength. The optimal choice

1.0% 3 0.018 3.708 7.416 13.31 15.85 222.48 74.15

for hair-reinforced concrete is the 0.5% superplasticizer dosage, consistently surpassing specified criteria

1.5% 3 0.018 3.708 7.416 13.31 15.85 222.48 111.24 and striking a favorable balance in both compressive and tensile strength.

• The slump test highlights the profound effect of adding superplasticizer on mixture workability. Notably, the

1.5% superplasticizer mixture proves to be the most effective, closely matching the workability standard of

Test Methods normal concrete. Contrary to the expected correlation between lower water absorption and higher durability,

A total of 48 specimens was generated to investigate the three properties including our samples, particularly the 1.5% SP mixture with the highest absorption at 0.9%, exhibited superior

compressive strength, split tensile strength, and water absorption after 10 and 28 days of durability with an average MPa of 22.16. The varying outcomes suggest potential influences from factors like

curing. The workability was tested before the sample were transferred to molds which was sample cracking during curing.

Researchers recommend further steps to take to improve and understand more of this study:

done by a slump test.

• Pay careful attention to hair placement challenges in future research due to its abundance and tendency to

Statistical Treatment of Data clump when water is introduced.

Tables and graphs were presented to describe the properties of concrete that were • Explore diverse mix designs (aggregates, cement type, and water-to-cement ratio) when studying the impact

observed by the three experimental mixes of concrete tested at the 10th and 28th-day state of superplasticizer on hair-reinforced concrete.

• Conduct a comprehensive analysis of long-term durability and weathering effects, as our study primarily

after curing. The results presented primarily focused on compressive strength, tensile focused on short-term strength characteristics.

strength, workability test (slump), and water absorption, REFERENCES

[1] Santos, F D; Taguba, M A M; Alzona, A R; Basada, R C S; Elbit, J M A; et al. (Mar 2020) Optimization of the Compressive

Strength of Hair Fiber Reinforced Concrete Using Central Composite Design. IOP Conference Series. Materials Science and

Engineering; Bristol Vol. 771, Iss. 1.H. Zhu, C. Wen, Z. Wang, and L. Li, “Study on the permeability of recycled aggregate

pervious concrete with fibers,” Materials, vol. 13, no. 2, Jan. 2020, doi: 10.3390/ma13020321.

[2] Ravikumar, C. S., Ramasamy, V., & Thandavamoorthy, T. S. (2015). Effect of fibers in concrete composites. International

Journal of Applied Engineering Research, 10(1), 419-430.

https://www.researchgate.net/publication/282006096_Effect_of_Fibers_In_Concrete_Composites

[[3] Narain das Bheel, Paul Awoyera, Oluwatobi Aluko, Santosh Mahro, Amelec Viloria, Carlos Alberto Severiche Sierra

(2020). Sustainable composite development: Novel use of human hair as fiber in concrete. Case Studies in Construction

Materials, Volume 13, e00412, ISSN 2214-5095

[4] Manaf , A., M V, A., Jomichan, A., & Varghese, G. M. (n.d.). Human hair fibre reinforced concrete - IJERT. Retrieved

October 9, 2022, from https://www.ijert.org/research/human-hair-fibre-reinforced-concrete-IJERTV6IS030528.pdf

ACKNOWLEDGEMENTS

Figure 3. Compressive Figure 4. Split-tensile Figure 5. Slump test Figure 6. Water

Engr. Joey Cyndell T. Atillo-Yu, Engr. Imadyl C. Damuag; Engr. Kathrina Marie Borgonia; Engr. Aida Lebunfacil;

strength test strength test Absorption

Engr. Franklin John T.; Engr. Oliver Dave L. Maguyon; Friends; Family of the Researchers; and to Almighty Father.

UNIVERSITY OF SAN CARLOS

DEPARTMENT OF CIVIL ENGINEERING

You might also like

- Quiz 7 Aw Evaluation Group 4 Es Econ Engineering EconomicsDocument4 pagesQuiz 7 Aw Evaluation Group 4 Es Econ Engineering EconomicsJB RSNJNNo ratings yet

- F1267-12 Standard Specification For Metal, Expanded, SteelDocument8 pagesF1267-12 Standard Specification For Metal, Expanded, Steeltjt4779100% (2)

- Performance Recycled ThermoplasticsDocument6 pagesPerformance Recycled ThermoplasticsEmani V R Murthy100% (1)

- South African Specifications For Laying PipesDocument53 pagesSouth African Specifications For Laying PipesEddiemtongaNo ratings yet

- 126 Ijmperdapr2018126Document10 pages126 Ijmperdapr2018126TJPRC PublicationsNo ratings yet

- Chethana - 2021Document11 pagesChethana - 2021Bibhuti KagyungNo ratings yet

- G2 - Concreto Con Latex - Art.1Document4 pagesG2 - Concreto Con Latex - Art.1Carlos Daniel FontechaNo ratings yet

- Manral 2018 IOP Conf. Ser. Mater. Sci. Eng. 455 012115Document6 pagesManral 2018 IOP Conf. Ser. Mater. Sci. Eng. 455 012115Play PocheNo ratings yet

- An Experimental and Characteristic Study of Abaca Fiber ConcreteDocument10 pagesAn Experimental and Characteristic Study of Abaca Fiber ConcreteAika LorenNo ratings yet

- Tps 381Document34 pagesTps 381Aidil AriefNo ratings yet

- Comparative Study On Durability Properties of Engineered Cementitious Composites With Polypropylene Fiber and Glass FiberDocument19 pagesComparative Study On Durability Properties of Engineered Cementitious Composites With Polypropylene Fiber and Glass Fiberci_balaNo ratings yet

- The Ultimate Strength and Stiffness of Polymers: Annu. Rev. Mater. Sci. 1995. 25: 295-323Document31 pagesThe Ultimate Strength and Stiffness of Polymers: Annu. Rev. Mater. Sci. 1995. 25: 295-323José Roberto LazoNo ratings yet

- Bendable ConcreteDocument7 pagesBendable ConcreteNelly PadriqueNo ratings yet

- Fibra de Vidrio ArticuloDocument8 pagesFibra de Vidrio Articuloangi trujilloNo ratings yet

- Study On Mechanical Behaviour of Sugarcane Bagasse Fiber Reinforced Polymer Matrix CompositesDocument9 pagesStudy On Mechanical Behaviour of Sugarcane Bagasse Fiber Reinforced Polymer Matrix CompositesYasir Aneuk WeldingNo ratings yet

- Mazumder 2018 IOP Conf. Ser. Mater. Sci. Eng. 438 012007Document9 pagesMazumder 2018 IOP Conf. Ser. Mater. Sci. Eng. 438 012007asif mahmudNo ratings yet

- Jurnal Teknologi: Potential OF Natural AND Synthetic Fibres ON Flexural Performance OF Foamcrete MortarDocument5 pagesJurnal Teknologi: Potential OF Natural AND Synthetic Fibres ON Flexural Performance OF Foamcrete MortarDm EerzaNo ratings yet

- Dhakal2007 ImpDocument9 pagesDhakal2007 ImpKRISHNA VAMSINo ratings yet

- Journal of Applied Polymer Science Volume 98 Issue 2 2005 (Doi 10.1002 - App.22097) Kishore Ravi Shankar S. Sankaran - Short-Beam Three-Point Bend Tests in Syntactic Foams. Part II - Effect of MicroDocument7 pagesJournal of Applied Polymer Science Volume 98 Issue 2 2005 (Doi 10.1002 - App.22097) Kishore Ravi Shankar S. Sankaran - Short-Beam Three-Point Bend Tests in Syntactic Foams. Part II - Effect of MicroPablo OrtegaNo ratings yet

- Mechanical Characterization of NanocelluloseJute Fiber Based CompositesDocument4 pagesMechanical Characterization of NanocelluloseJute Fiber Based CompositesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- 2013xu Refuerzo Con Fibras VegetalesDocument7 pages2013xu Refuerzo Con Fibras VegetalesIsaac Gabriel LarreaNo ratings yet

- Optimization of Sisal Fiber, Glass Fiber and Alumina - Based Hybrid Composite For Flexural Strength Using Taguchi TechniqueDocument12 pagesOptimization of Sisal Fiber, Glass Fiber and Alumina - Based Hybrid Composite For Flexural Strength Using Taguchi TechniqueIJRASETPublicationsNo ratings yet

- Ijaerv10n11spl 13Document6 pagesIjaerv10n11spl 13khm792352No ratings yet

- Results and Observations: Polymer MatrixDocument1 pageResults and Observations: Polymer MatrixDeepak B YNo ratings yet

- 13 Ijmperdaug201813Document7 pages13 Ijmperdaug201813TJPRC PublicationsNo ratings yet

- Characterization of Properties of Epoxy Sisal / Glass Fiber Reinforced Hybrid CompositeDocument7 pagesCharacterization of Properties of Epoxy Sisal / Glass Fiber Reinforced Hybrid CompositeMr. K.S. Raghul Asst Prof MECH100% (1)

- Evaluation of Mechanical Properties of Palm Fiber Glass 2020 Materials TodaDocument4 pagesEvaluation of Mechanical Properties of Palm Fiber Glass 2020 Materials TodaClaudia UngureanuNo ratings yet

- St. Martin'S Engineering College: An Autonomous Institute Nba & Naac A+ AccreditedDocument44 pagesSt. Martin'S Engineering College: An Autonomous Institute Nba & Naac A+ AccreditedPalla ManikantaNo ratings yet

- Mechanical Property of Tailor Made Flax/Glass Fiber Reinforced Hybrid Polyester CompositeDocument4 pagesMechanical Property of Tailor Made Flax/Glass Fiber Reinforced Hybrid Polyester CompositesriyajambukarNo ratings yet

- Mechanical and Thermal Properties of Sugar Palm Yarn Fibre Reinforced Unsaturated Polyester Composites With Different Fibre OrientationDocument7 pagesMechanical and Thermal Properties of Sugar Palm Yarn Fibre Reinforced Unsaturated Polyester Composites With Different Fibre OrientationPrince Ghosh EponNo ratings yet

- Corbin 2018 IOP Conf. Ser. Mater. Sci. Eng. 406 012016Document12 pagesCorbin 2018 IOP Conf. Ser. Mater. Sci. Eng. 406 012016adonaies19No ratings yet

- Youtube Video Stress Strain - Strength Versus Toughness of Emulsion Templated Poly (Dicyclopentadiene) FoamsDocument8 pagesYoutube Video Stress Strain - Strength Versus Toughness of Emulsion Templated Poly (Dicyclopentadiene) FoamsJose Kalanga Jose KalangaNo ratings yet

- IJEAS0305013Document3 pagesIJEAS0305013erpublicationNo ratings yet

- Test Conducted:: Mechanical PropertiesDocument1 pageTest Conducted:: Mechanical PropertiesDeepak B YNo ratings yet

- Studies On Relationship Between Compressive and Splitting Tensile Strength of High Performance ConcreteDocument6 pagesStudies On Relationship Between Compressive and Splitting Tensile Strength of High Performance ConcreteSourav BasakNo ratings yet

- Study of The Behaviour of Hybrid Nano Jute Fiber Composite Under Impact LoadsDocument4 pagesStudy of The Behaviour of Hybrid Nano Jute Fiber Composite Under Impact LoadsTJPRC PublicationsNo ratings yet

- Acs Macromol 0c02628Document13 pagesAcs Macromol 0c02628Martin GeorgeNo ratings yet

- JRPC GK - Sathishkumar Article 2017Document15 pagesJRPC GK - Sathishkumar Article 2017Sajailslhuti JilluNo ratings yet

- An Experimental Study On The Mechanical Properties of Basalt and Banana Fiber Reinforced Hybrid Polymer CompositesDocument8 pagesAn Experimental Study On The Mechanical Properties of Basalt and Banana Fiber Reinforced Hybrid Polymer CompositesTJPRC PublicationsNo ratings yet

- Effect of Fiber PDFDocument4 pagesEffect of Fiber PDFAnil Suryawanshi0% (1)

- Lakshmanan 2019 IOP Conf. Ser. Mater. Sci. Eng. 577 012030Document15 pagesLakshmanan 2019 IOP Conf. Ser. Mater. Sci. Eng. 577 012030Midhun RNo ratings yet

- Free Vibration Characteristics of Banana Sisal Natural Fibers Reinforced Hybrid Polymer Composite BeamDocument5 pagesFree Vibration Characteristics of Banana Sisal Natural Fibers Reinforced Hybrid Polymer Composite BeamDr Engr Md Zillur RahmanNo ratings yet

- Introduction !!Document6 pagesIntroduction !!atef.selmi01No ratings yet

- IRJET V8I3425 With Cover Page v2Document8 pagesIRJET V8I3425 With Cover Page v2Avula Siva Rami reddyNo ratings yet

- Effect of Change in Volume Fraction On Mechanical Properties of Glass Fiber-Epoxy Resin CompositesDocument4 pagesEffect of Change in Volume Fraction On Mechanical Properties of Glass Fiber-Epoxy Resin Compositesrahul reddyNo ratings yet

- Mechanical, Thermal and Water Absorption Properties of Woven Okra Fiber Polyester CompositesDocument10 pagesMechanical, Thermal and Water Absorption Properties of Woven Okra Fiber Polyester CompositesDr.D.K.Nageswara RaoNo ratings yet

- Batch 1Document10 pagesBatch 120311a0135No ratings yet

- 1 s2.0 S223878541931124X MainDocument13 pages1 s2.0 S223878541931124X MainSeçkin MartinNo ratings yet

- Study The Effect of Polypropylene FiberDocument4 pagesStudy The Effect of Polypropylene FiberHrishikesh GosaviNo ratings yet

- Delamination Behavior of Dyneema Composite LaminatDocument10 pagesDelamination Behavior of Dyneema Composite Laminatcanvadesigner69No ratings yet

- تأثير محتوى مسحوق الألمنيوم الناعم على بعض الخواص الميكانيكية لمركبات الايبوكسي والبوليسترDocument12 pagesتأثير محتوى مسحوق الألمنيوم الناعم على بعض الخواص الميكانيكية لمركبات الايبوكسي والبوليسترeng.waleedalakhrasNo ratings yet

- 1 s2.0 S2307187723001219 MainDocument10 pages1 s2.0 S2307187723001219 MainFaiz IbrahimNo ratings yet

- Irjet V3i7282Document3 pagesIrjet V3i7282shouvikNo ratings yet

- Fong - 2018 - IOP - Conf. - Ser. - Mater. - Sci. - Eng. - 344 - 012029Document13 pagesFong - 2018 - IOP - Conf. - Ser. - Mater. - Sci. - Eng. - 344 - 012029TIop outNo ratings yet

- Journal of Adhesion Science and TechnologyDocument21 pagesJournal of Adhesion Science and TechnologyTe-greg MillerNo ratings yet

- PapajDocument5 pagesPapajLiliNo ratings yet

- Minor ProjectDocument35 pagesMinor ProjectNihal BelliappaNo ratings yet

- Composites Part B: D.K.K. Cavalcanti, M.D. Banea, J.S.S. Neto, R.A.A. Lima, L.F.M. Da Silva, R.J.C. CarbasDocument8 pagesComposites Part B: D.K.K. Cavalcanti, M.D. Banea, J.S.S. Neto, R.A.A. Lima, L.F.M. Da Silva, R.J.C. Carbasmohd asrofi muslim0% (1)

- Effect of The Joncryl1 ADR Compatibilizing Agent in Blends of Poly (Butylene Adipate-Co-Terephthalate) / Poly (Lactic Acid)Document6 pagesEffect of The Joncryl1 ADR Compatibilizing Agent in Blends of Poly (Butylene Adipate-Co-Terephthalate) / Poly (Lactic Acid)Alana GabrieliNo ratings yet

- Abhilash Et Al 2021 Development of Bamboo Polymer Composites With Improved Impact ResistanceDocument11 pagesAbhilash Et Al 2021 Development of Bamboo Polymer Composites With Improved Impact ResistancenurizzaatiNo ratings yet

- 16 Influence of Weave Pattern and Composite Thickness On MechanicalDocument13 pages16 Influence of Weave Pattern and Composite Thickness On MechanicalEngr Md. Nayemul IslamNo ratings yet

- 09jamr01 1185Document7 pages09jamr01 1185shahrozaligondalNo ratings yet

- A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessFrom EverandA Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessNo ratings yet

- Unit 2 - Construction Management ContextDocument49 pagesUnit 2 - Construction Management ContextJB RSNJNNo ratings yet

- Activity 1 Hyetographs and Cumulative Precipitation JANINEDocument2 pagesActivity 1 Hyetographs and Cumulative Precipitation JANINEJB RSNJNNo ratings yet

- Lecture 2.b.2 Analysis and Design of RC Beams (Strength Design by (JBM and RLF)Document75 pagesLecture 2.b.2 Analysis and Design of RC Beams (Strength Design by (JBM and RLF)JB RSNJNNo ratings yet

- Gis Lecture 1Document36 pagesGis Lecture 1JB RSNJNNo ratings yet

- Senajon SynthesisDocument2 pagesSenajon SynthesisJB RSNJNNo ratings yet

- 8.2 Average End-Area MethodDocument1 page8.2 Average End-Area MethodJB RSNJNNo ratings yet

- Journal ArticleDocument14 pagesJournal ArticleJB RSNJNNo ratings yet

- 7.2 Horizontal CurvesDocument16 pages7.2 Horizontal CurvesJB RSNJNNo ratings yet

- 7.3 Vertical CurvesDocument8 pages7.3 Vertical CurvesJB RSNJNNo ratings yet

- Assignment 7.1 Horizontal CurvesDocument7 pagesAssignment 7.1 Horizontal CurvesJB RSNJNNo ratings yet

- PRESBITERO Assignment 8.1 EarthworksDocument3 pagesPRESBITERO Assignment 8.1 EarthworksJB RSNJNNo ratings yet

- Taylor Series ExpansionDocument6 pagesTaylor Series ExpansionJB RSNJNNo ratings yet

- Assignment 7.2 Vertical CurvesDocument2 pagesAssignment 7.2 Vertical CurvesJB RSNJNNo ratings yet

- Adrenergic Antagonist: PharmacologyDocument3 pagesAdrenergic Antagonist: PharmacologyJB RSNJNNo ratings yet

- Friday: Data Sheet of Course Time 02:30 ofDocument2 pagesFriday: Data Sheet of Course Time 02:30 ofJB RSNJNNo ratings yet

- Unit:1 (Force System) Assignment-1Document25 pagesUnit:1 (Force System) Assignment-1JB RSNJNNo ratings yet

- The Academy of Political Science Political Science QuarterlyDocument33 pagesThe Academy of Political Science Political Science QuarterlyJB RSNJNNo ratings yet

- Course Syllabus Overview: Readings in Philippine History: C.B.H.DecrepitoDocument23 pagesCourse Syllabus Overview: Readings in Philippine History: C.B.H.DecrepitoJB RSNJNNo ratings yet

- Method of Statement For Concrete WorksDocument15 pagesMethod of Statement For Concrete WorksAhmed Ibrahim100% (1)

- Southco Push To Close Latches: Touch Latch, Large SizeDocument1 pageSouthco Push To Close Latches: Touch Latch, Large SizeCécileNo ratings yet

- Brick Collections: Explore Our Extensive Collection of BricksDocument23 pagesBrick Collections: Explore Our Extensive Collection of BricksadsasdfsdfdsfNo ratings yet

- Assignment 5 1386142Document3 pagesAssignment 5 1386142Duncan100% (1)

- All Fastenal Bolt Torque Chart-2Document9 pagesAll Fastenal Bolt Torque Chart-2rizman123786No ratings yet

- Midal Cable ReportDocument9 pagesMidal Cable ReportFaYzYNo ratings yet

- Harga Dasar Satuan UpahDocument26 pagesHarga Dasar Satuan UpahYogi SugiriNo ratings yet

- Seismic Retrofitting Guidlines of Buildings in NepalDocument444 pagesSeismic Retrofitting Guidlines of Buildings in NepalÖzgür BozdağNo ratings yet

- Fundamentals of Post-Tensioned Concrete Design For BuildingsDocument49 pagesFundamentals of Post-Tensioned Concrete Design For Buildingssalaverria0% (1)

- Effect of Feed Rate On Surface Roughness in Abrasive Waterjet Cutting Applications.Document7 pagesEffect of Feed Rate On Surface Roughness in Abrasive Waterjet Cutting Applications.ronNo ratings yet

- Boysen Plexibond™ Cementitious Waterproofing System #7760: Surface PreparationDocument3 pagesBoysen Plexibond™ Cementitious Waterproofing System #7760: Surface PreparationRL SanNo ratings yet

- Analysis The Effect of Environmental Conditions On Abs Grade A Steel and Bki Grade A Steel Coating On The Resistance Test of Impact CoatingDocument15 pagesAnalysis The Effect of Environmental Conditions On Abs Grade A Steel and Bki Grade A Steel Coating On The Resistance Test of Impact Coatingary rizkiNo ratings yet

- Mix Design For Concrete Roads As Per IRC152011 PDFDocument9 pagesMix Design For Concrete Roads As Per IRC152011 PDFairpavsetNo ratings yet

- Properties of MaterialsDocument1 pageProperties of MaterialsphydotsiNo ratings yet

- RAFT Foundation FDocument30 pagesRAFT Foundation FBhargav BbvsNo ratings yet

- American Welding Society (AWS) Standards: Code DescriptionDocument7 pagesAmerican Welding Society (AWS) Standards: Code DescriptionZainudinNo ratings yet

- Haylu - B+G+4 Apartment - FD - BoQ - Priced - 1911181Document80 pagesHaylu - B+G+4 Apartment - FD - BoQ - Priced - 1911181YosefNo ratings yet

- Mirror E CatalogueDocument16 pagesMirror E CatalogueanadinathNo ratings yet

- MD0311 Ric MAXISTAB 2020Document84 pagesMD0311 Ric MAXISTAB 2020Анатолий РябухаNo ratings yet

- Sampag-Anchor-Channels-and-SectionsDocument40 pagesSampag-Anchor-Channels-and-SectionsPaing Phyo AungNo ratings yet

- Mega Lug - MJ RestraintDocument6 pagesMega Lug - MJ RestraintRogNo ratings yet

- Metallic Coatings For Corrosion PreventionDocument9 pagesMetallic Coatings For Corrosion PreventionDevashish JoshiNo ratings yet

- 12X18H10TDocument3 pages12X18H10TDurga Prasad SharmaNo ratings yet

- 8-IWRE 416-Formwork and FalseworkDocument41 pages8-IWRE 416-Formwork and Falseworkally IsayaNo ratings yet

- 616566Document2 pages616566Neem LalNo ratings yet

- Cemented Carbide Products For Stone Working SpecDocument6 pagesCemented Carbide Products For Stone Working SpecX800XLNo ratings yet

- Rate Analysis-All ActivitiesDocument25 pagesRate Analysis-All ActivitiesmuraliNo ratings yet

- Fasteners Vol1 TocDocument3 pagesFasteners Vol1 TocLucas Willian100% (2)