Professional Documents

Culture Documents

Safety Bulletin 26 NOTES FOR FOREMEN AND SUPERVISORS

Safety Bulletin 26 NOTES FOR FOREMEN AND SUPERVISORS

Uploaded by

Trebor SantosOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Safety Bulletin 26 NOTES FOR FOREMEN AND SUPERVISORS

Safety Bulletin 26 NOTES FOR FOREMEN AND SUPERVISORS

Uploaded by

Trebor SantosCopyright:

Available Formats

SAFETY BULLETIN # 026

NOTES FOR FOREMEN AND SUPERVISORS

PREVENTING ACCIDENTS

Accidents interfere with production. They waste manpower, they spoil material, they

cause disorganization and waste of time.

To the worker, they bring pain and suffering; to his family they sometimes bring tragedy.

Their prevention is vital.

You because of your authority and ability to exercise personal supervision, are in a

specially responsible position for making production as accident-free as possible.

First, you can ensure that the orders you give always contain precise instructions about

the proper way to do the job. Secondly, you can see that the job is actually done the

proper way. Thirdly, you can do a very good deal by your personal influence, to make

the workers under your care keen on accident prevention.

The ideas listed are not safety rules. They are simply suggestions about the various

ways in which you can make best of your personal influence, particularly in regard to

new employees.

Try to carry out the ideas in your daily work.

(1) When you make your daily rounds, make them a hazard inspection as well.

See things which need correcting and have them done.

(2) Warn all the workers of dangers in their work and show them the correct way.

(3) Try to see your work area from the point of view of new workers. What is

familiar to you will be fresh to them and may need explaining.

(4) See that new workers are put in the charge of an experienced man. Some

people are better than others at helping newcomers. Choose the better

ones.

(5) New workers not only need training, but watching as well. They may be

clumsy or awkward, or, being new to the job, may not have grasped the

meaning of instructions. They can be a danger to others as well as

themselves.

(6) See that all workers comply with accident prevention rules. This applies

particularly to such matters as wearing goggles or protective clothing.

(7) Instructions are sometimes disobeyed because people do not understand

the really sound reasons that are behind them. Bear this in mind and be

ready to explain.

Page 1 of 2

SAFETY BULLETIN #026

(8) If a worker in your area is constantly running into danger, consider whether

he could be transferred to work that is less hazardous.

(9) The accident record of your area is your concern. Do all you can to keep

the figures down.

(10) Remember that tidiness is essential for the prevention of accidents.

(11) See that all tools, machinery and equipment are maintained in a safe

condition. Don't let those under you work with defective or unsuitable

equipment. Encourage the reporting of defects by having them put right as

quickly as possible.

(12) See that all guards and safety signs are replaced securely if they have to

be removed.

(13) If there are fire appliances in your area, it is your duty to keep an eye on

them. You are the only person who can ensure that they are always

accessible. If they are only obstructed "for only five minutes", fire is just as

likely to break out during those five minutes as at any other time.

(14) Ordinary and emergency exits and the approaches to them, must always be

kept clear.

(15) See that all workers have all cuts, scratches and punctures dressed at

once. A small wound may be just as dangerous as a large one.

(16) Do not let a worker who feels ill remain at work. Apart from all other

considerations, there is more liability for them to have an accident when

they feel ill.

(17) In the event of a serious accident when no one trained in First Aid is

present, don't let the patient be mauled about. A lot of harm can be done

by unskilled handling however well-intentioned. Serious accidents need

skilled medical attention.

(18) Think of ways of reducing accidents and suggest them to your Safety

Department.

(19) Workers who are actually doing a job can sometimes see hazards or ways

to avoid them. Encourage suggestions and see the worker gets the credit

for them.

(20) The attitude of the workers in your area towards accident prevention

depends upon the example that you set.

Page 2 of 2

You might also like

- Do and Dont of Security GuardDocument12 pagesDo and Dont of Security GuardYusuf Kazeem MayowaNo ratings yet

- 20 Workplace Safety Rules and Tips To Know: SafetyinfoDocument5 pages20 Workplace Safety Rules and Tips To Know: Safetyinfogoyalvikas86No ratings yet

- 20 Workplace Safety Rules and Tips To KnowDocument9 pages20 Workplace Safety Rules and Tips To Knowdiomedes pataniNo ratings yet

- 20 Most Important Safety Rules in The Workplace: 1. Follow The Dress CodeDocument4 pages20 Most Important Safety Rules in The Workplace: 1. Follow The Dress CodeajayNo ratings yet

- Safety EngineeringDocument18 pagesSafety EngineeringalbertNo ratings yet

- HSE Procedures & RegulationsDocument26 pagesHSE Procedures & RegulationsCliffordNo ratings yet

- Cis WSH Cet SP1 64019 7Document31 pagesCis WSH Cet SP1 64019 7Gli OxalNo ratings yet

- Workshop Safety RulesDocument2 pagesWorkshop Safety RulesPortia ShilengeNo ratings yet

- Worksheet - 10 Rules For Safety at WorkplaceDocument2 pagesWorksheet - 10 Rules For Safety at WorkplaceGeorgino ValsanNo ratings yet

- + Safestart - Teamwork - EngDocument1 page+ Safestart - Teamwork - Engyusuf.yuzuakNo ratings yet

- 11 Ways To Keep Your Construction SafeDocument14 pages11 Ways To Keep Your Construction SafegirlNo ratings yet

- 14.3. Toolbox Talk RegisterDocument25 pages14.3. Toolbox Talk RegistersimoneNo ratings yet

- Toolbox Talk Topics 1661842015Document25 pagesToolbox Talk Topics 1661842015richard100% (4)

- Carpentry: Practice Occupational Health and Safety ProceduresDocument17 pagesCarpentry: Practice Occupational Health and Safety ProceduresLaurenceFabialaNo ratings yet

- Safety at WorkDocument3 pagesSafety at Workenglishworkphb24No ratings yet

- Woodchuck Construction: Lab Safety ManualDocument23 pagesWoodchuck Construction: Lab Safety Manualapi-359229027No ratings yet

- 5 Min SafeWorkHabits 11Document3 pages5 Min SafeWorkHabits 11SamuelNo ratings yet

- Fire SafteyDocument8 pagesFire SafteyAli HasanNo ratings yet

- Compuwell Project Construction Safety Program - tv5Document23 pagesCompuwell Project Construction Safety Program - tv5Daryl Gomez TimatimNo ratings yet

- General - Safety - Quality ControlDocument137 pagesGeneral - Safety - Quality ControlRandy PedrozaNo ratings yet

- Safety ManualDocument23 pagesSafety ManualM.A.NNo ratings yet

- 3 Lecture 2 N 3-1 Fundamentals of SafetyDocument29 pages3 Lecture 2 N 3-1 Fundamentals of SafetyArjan GhoshNo ratings yet

- Five Steps To Risk AssessmentDocument4 pagesFive Steps To Risk AssessmentIsa GuhilingNo ratings yet

- Ia-Carp Q1 W4 PDFDocument17 pagesIa-Carp Q1 W4 PDFLaurenceFabialaNo ratings yet

- TCE Safety Pocket Manual-11 PDFDocument41 pagesTCE Safety Pocket Manual-11 PDFqamar sayed100% (1)

- Workplace SafetyDocument5 pagesWorkplace Safetyrashikarema17No ratings yet

- Human Resource Management 16Document4 pagesHuman Resource Management 16Noman QureshiNo ratings yet

- 20 Safety Training Topics For Your Workplace - HSDocument2 pages20 Safety Training Topics For Your Workplace - HSiqceastNo ratings yet

- Mechanical Workshop Lab ManualDocument43 pagesMechanical Workshop Lab ManualMuhammad Faiq AliNo ratings yet

- Lesson 3 4Document35 pagesLesson 3 4Alexandra MariNo ratings yet

- Safety TrainingDocument23 pagesSafety Trainingprojit basuNo ratings yet

- New WordDocument22 pagesNew WordJelly Joy CampomayorNo ratings yet

- Toolbox Talk TopicsDocument15 pagesToolbox Talk TopicsEgwonor FestusNo ratings yet

- Site Investigation Report: Mapua Institute of Technology School of Mechanical and Manufacturing EngineeringDocument14 pagesSite Investigation Report: Mapua Institute of Technology School of Mechanical and Manufacturing EngineeringKryzha RemojoNo ratings yet

- Safety Officer Course3Document57 pagesSafety Officer Course3Olatunji OmowunmiNo ratings yet

- DR REYpdfDocument4 pagesDR REYpdfSean Ben KadusaleNo ratings yet

- Safety Handbook EngDocument78 pagesSafety Handbook Engmarkie supieNo ratings yet

- SITXWHS001 Participate in Safe Work Practices Aakash BhattaraiDocument10 pagesSITXWHS001 Participate in Safe Work Practices Aakash Bhattaraisagar chetriNo ratings yet

- 1 Chapter One Engine FundamentalDocument25 pages1 Chapter One Engine FundamentalGebisa TamiruNo ratings yet

- Kesehatan Dan Keselamatan Kerja: Adang DurachimDocument12 pagesKesehatan Dan Keselamatan Kerja: Adang DurachimnisaSitiNo ratings yet

- Amor, Module 3 (BOSH)Document3 pagesAmor, Module 3 (BOSH)jerkNo ratings yet

- Scripts IdolDocument6 pagesScripts IdolRonnick De La TongaNo ratings yet

- Admin Volume FourDocument78 pagesAdmin Volume FourManoranjan RoyNo ratings yet

- Filipino Traits CharacteristicsDocument26 pagesFilipino Traits CharacteristicsJay DexNo ratings yet

- Unit 1 GSMDocument20 pagesUnit 1 GSMBala SbNo ratings yet

- Unsafe Acts and Conditions Bet-Ect 2ADocument16 pagesUnsafe Acts and Conditions Bet-Ect 2AtososNo ratings yet

- Security Supervisor Job DescriptionDocument5 pagesSecurity Supervisor Job DescriptionEmiliano Croes100% (1)

- ToolboxTalk 0715Document2 pagesToolboxTalk 0715Epifanio Jr Lagadan TorresNo ratings yet

- Safety Program SampleDocument3 pagesSafety Program SampleShogun1stNo ratings yet

- Mce-161 Teaching NotesDocument28 pagesMce-161 Teaching Notesomah khemikalNo ratings yet

- Health & Safety HandbookDocument34 pagesHealth & Safety HandbookHariram SNo ratings yet

- REPORT-1Document2 pagesREPORT-1Francine TutaanNo ratings yet

- Basic Occupational Safety and HealthDocument6 pagesBasic Occupational Safety and HealthRonnick De La TongaNo ratings yet

- New Employee OrientationDocument23 pagesNew Employee Orientationvhlactaotao100% (2)

- 2 Health and Safety Practices and ProceduresDocument14 pages2 Health and Safety Practices and ProceduresMuhammed AdemNo ratings yet

- Daily Hse Recap 2Document1 pageDaily Hse Recap 2Collins BrownNo ratings yet

- Safety Training Ideas Worth StealingDocument38 pagesSafety Training Ideas Worth StealingGrace Passini100% (5)

- Industrialsafety HazardsDocument82 pagesIndustrialsafety HazardsalyssaNo ratings yet

- How To Become A Successful Bodyguard: Alternative Careers Series, #6From EverandHow To Become A Successful Bodyguard: Alternative Careers Series, #6No ratings yet

- Safety Bulletin 35 HOT WORKDocument3 pagesSafety Bulletin 35 HOT WORKTrebor SantosNo ratings yet

- Fire Extinguisher ProcedureDocument1 pageFire Extinguisher ProcedureTrebor SantosNo ratings yet

- JSA ManualDocument32 pagesJSA ManualTrebor SantosNo ratings yet

- Christmas Decor Safety CertificateDocument2 pagesChristmas Decor Safety CertificateTrebor SantosNo ratings yet

- 11 Things That Make Up A Perfect Fire Evacuation DrillDocument2 pages11 Things That Make Up A Perfect Fire Evacuation DrillTrebor SantosNo ratings yet

- Safety Bulletin 7 PORTABLE ELECTRICAL EQUIPMENT SAFETYDocument1 pageSafety Bulletin 7 PORTABLE ELECTRICAL EQUIPMENT SAFETYTrebor SantosNo ratings yet

- Job Site Fire PreventionDocument3 pagesJob Site Fire PreventionTrebor SantosNo ratings yet

- EHS-G-22 Guidelines On Confined Spaces - Procedure v.3Document13 pagesEHS-G-22 Guidelines On Confined Spaces - Procedure v.3Trebor SantosNo ratings yet

- Safe Working With Flammable SubstancesDocument5 pagesSafe Working With Flammable SubstancesTrebor SantosNo ratings yet

- FMD-F-11-02.8.2.1 - List of Qualifications For Technical Maintenance PersonnelDocument2 pagesFMD-F-11-02.8.2.1 - List of Qualifications For Technical Maintenance PersonnelTrebor SantosNo ratings yet

- Ten Basic Safety RulesDocument1 pageTen Basic Safety RulesTrebor SantosNo ratings yet

- AStAla Tools Inventory & Accountability FormDocument1 pageAStAla Tools Inventory & Accountability FormTrebor SantosNo ratings yet

- TB BrochureDocument20 pagesTB BrochureTrebor SantosNo ratings yet

- FMD-F-11-02.10.1.3 Daily Equipment Inspection FormDocument1 pageFMD-F-11-02.10.1.3 Daily Equipment Inspection FormTrebor SantosNo ratings yet

- Hepatitis B BrochureDocument16 pagesHepatitis B BrochureTrebor SantosNo ratings yet

- Hyundai Elevator Preventive Maintenance ProcedureDocument19 pagesHyundai Elevator Preventive Maintenance ProcedureTrebor Santos100% (3)

- Material Handling & Back Safety 26.09.2014Document28 pagesMaterial Handling & Back Safety 26.09.2014Trebor SantosNo ratings yet

- FMD-F-11-02 10 1 1 2 - Spu - PMDocument1 pageFMD-F-11-02 10 1 1 2 - Spu - PMTrebor SantosNo ratings yet

- FMD-F-11-02 12 2 3 - Generator - DailyDocument2 pagesFMD-F-11-02 12 2 3 - Generator - DailyTrebor SantosNo ratings yet

- Basic Electrical Safety 19.09.2014Document49 pagesBasic Electrical Safety 19.09.2014Trebor SantosNo ratings yet

- Scaffold Safety 2014Document88 pagesScaffold Safety 2014Trebor Santos100% (1)

- FMD-F-11-02 10 16 1 - PumpsDocument1 pageFMD-F-11-02 10 16 1 - PumpsTrebor SantosNo ratings yet

- FMD-F-11-02.12.2.2 Generator No LoadDocument1 pageFMD-F-11-02.12.2.2 Generator No LoadTrebor SantosNo ratings yet

- FMD-F-11-02.10.10.1 - Fire Pump Preventive Maintenance ChecklistDocument3 pagesFMD-F-11-02.10.10.1 - Fire Pump Preventive Maintenance ChecklistTrebor SantosNo ratings yet

- Using Ultrasound For High Voltage Insulation Testing - Maintenance TechnologyDocument7 pagesUsing Ultrasound For High Voltage Insulation Testing - Maintenance TechnologyTrebor SantosNo ratings yet

- Substation Online Partial Discharge Testing (OLPD) Testing Tech. Update and InfoDocument11 pagesSubstation Online Partial Discharge Testing (OLPD) Testing Tech. Update and InfoTrebor SantosNo ratings yet

- FMD-F-11-02.10.10.2 - Jockey Pump Preventive Maintenance ChecklistDocument1 pageFMD-F-11-02.10.10.2 - Jockey Pump Preventive Maintenance ChecklistTrebor SantosNo ratings yet

- PHILIPPINES - Tropical Cyclone KOPPU ("LANDO") : LuzonDocument1 pagePHILIPPINES - Tropical Cyclone KOPPU ("LANDO") : LuzonTrebor SantosNo ratings yet

- Dengue FeverDocument44 pagesDengue FeverTrebor Santos100% (4)

- Training LevelsDocument3 pagesTraining LevelsTrebor SantosNo ratings yet

- Developing An Effective Emergency Management Plan For An Lgu or A Barangay (Considering Covid-19 Safety Protocols)Document29 pagesDeveloping An Effective Emergency Management Plan For An Lgu or A Barangay (Considering Covid-19 Safety Protocols)MARC MARVIN PALOMARESNo ratings yet

- FNAF Seurity Breach OST Happy Ending Theme Piano ScoreDocument4 pagesFNAF Seurity Breach OST Happy Ending Theme Piano Scorecivic kungNo ratings yet

- From Rookie To Reality Case Analysis and RationalDocument6 pagesFrom Rookie To Reality Case Analysis and RationalJoy ColemanNo ratings yet

- Budget of Work Fish Capture: Sptve Specialization: Grade 9Document4 pagesBudget of Work Fish Capture: Sptve Specialization: Grade 9Edgardo De Mesa MalaitNo ratings yet

- Steps To Achieving Better Safety in The Cement IndustryDocument3 pagesSteps To Achieving Better Safety in The Cement IndustryEleanor KhansaNo ratings yet

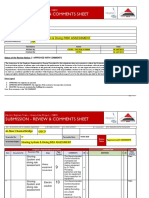

- Shoring Systtem and Diving Riskassesment CommentsDocument5 pagesShoring Systtem and Diving Riskassesment CommentsMohamed Hasafy100% (1)

- VME-HSE-P-41 - Emergency Preparedness and ResponseDocument5 pagesVME-HSE-P-41 - Emergency Preparedness and ResponseM TaufikNo ratings yet

- Investigation Teacher NotesDocument2 pagesInvestigation Teacher NotesJaniceNo ratings yet

- OCD BARMM Annual-Accomplishment-Report-2018 (Information Unit)Document15 pagesOCD BARMM Annual-Accomplishment-Report-2018 (Information Unit)jofel delicanaNo ratings yet

- Submission of BSKE 2023 Incident Monitoring Report October 28,2023Document4 pagesSubmission of BSKE 2023 Incident Monitoring Report October 28,2023pcadgmetromanilaNo ratings yet

- Unit 2 MY FAMILY AND MY COMMUNITYDocument8 pagesUnit 2 MY FAMILY AND MY COMMUNITYLORETO MORALESNo ratings yet

- RiskAssessment FireAlarmInstallationDocument11 pagesRiskAssessment FireAlarmInstallationMd. Shahid HassanNo ratings yet

- Proposed California Captive Orca Welfare and Safety ActDocument7 pagesProposed California Captive Orca Welfare and Safety ActLisa HalverstadtNo ratings yet

- Sa Sunog Hindi Ka Nag-Iisa." With This Year's Theme, It Reminds People ThatDocument2 pagesSa Sunog Hindi Ka Nag-Iisa." With This Year's Theme, It Reminds People ThatLevi LavirezNo ratings yet

- BRC Food Safety Management System Implementation WorkbookDocument36 pagesBRC Food Safety Management System Implementation WorkbookAbdellah Ftouhi100% (1)

- Critique Paper For HACCP, GMP, SSOPDocument2 pagesCritique Paper For HACCP, GMP, SSOPManantan Ma. KatherinaNo ratings yet

- 10 Simple Steps For A Successful Grant ApplicationDocument4 pages10 Simple Steps For A Successful Grant ApplicationGaudencio BoniceliNo ratings yet

- Art3 ISO 22000 2005 PDFDocument1 pageArt3 ISO 22000 2005 PDFRamón G. PachecoNo ratings yet

- IAH White Paper - v9Document2 pagesIAH White Paper - v9June LefflerNo ratings yet

- ICAO and Its FunctionsDocument3 pagesICAO and Its FunctionsMahesh Kumar Sah67% (9)

- MYER ContractorDocument1 pageMYER ContractorRohan Dutt SharmaNo ratings yet

- ED Decision 2012-020-R - Explanatory NoteDocument7 pagesED Decision 2012-020-R - Explanatory NotegordarkoNo ratings yet

- Penyelenggaraan Keamanan Pangan Sebagai Salah Satu Upaya Perlindungan Hak Masyarakat Sebagai KonsumenDocument19 pagesPenyelenggaraan Keamanan Pangan Sebagai Salah Satu Upaya Perlindungan Hak Masyarakat Sebagai Konsumenphintar dellaNo ratings yet

- Implan 2016 (Siniloan)Document4 pagesImplan 2016 (Siniloan)Bfp Siniloan FS LagunaNo ratings yet

- Air and Space Law PaperDocument25 pagesAir and Space Law PaperK.MeghanaNo ratings yet

- Elias Almeida: Personal Details ExpertiseDocument4 pagesElias Almeida: Personal Details ExpertiseElias AlmeidaNo ratings yet

- Golden Bipartisian OSHA LetterDocument6 pagesGolden Bipartisian OSHA LetterNEWS CENTER MaineNo ratings yet

- Chapter 1 FSSC 5.1Document50 pagesChapter 1 FSSC 5.1harshil Kevat100% (1)

- Action Plan For Implementing A HACCP 2Document8 pagesAction Plan For Implementing A HACCP 2mahmoodabdellatifNo ratings yet

- SEC 8 (2) (I) SUPERVISOR APPOINTMENTDocument2 pagesSEC 8 (2) (I) SUPERVISOR APPOINTMENTLwandziso Dlamini100% (2)