Professional Documents

Culture Documents

US4707035

US4707035

Uploaded by

aungkyawzore0 ratings0% found this document useful (0 votes)

8 views5 pagesThis patent describes a synthetic resin vehicle wheel cover with integrated mounting elements. The wheel cover has cylindrical projections on the inner surface that fit over and grasp the wheel nuts. It also has inward projecting elements along the periphery that engage with the tire rim to securely mount the cover. The integrated mounting elements eliminate the need for separate spring mechanisms and allow the cover to be fixedly mounted without risk of rotation.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis patent describes a synthetic resin vehicle wheel cover with integrated mounting elements. The wheel cover has cylindrical projections on the inner surface that fit over and grasp the wheel nuts. It also has inward projecting elements along the periphery that engage with the tire rim to securely mount the cover. The integrated mounting elements eliminate the need for separate spring mechanisms and allow the cover to be fixedly mounted without risk of rotation.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

8 views5 pagesUS4707035

US4707035

Uploaded by

aungkyawzoreThis patent describes a synthetic resin vehicle wheel cover with integrated mounting elements. The wheel cover has cylindrical projections on the inner surface that fit over and grasp the wheel nuts. It also has inward projecting elements along the periphery that engage with the tire rim to securely mount the cover. The integrated mounting elements eliminate the need for separate spring mechanisms and allow the cover to be fixedly mounted without risk of rotation.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 5

United States Patent (19) 11 Patent Number: 4,707,035

Kondo et al. (45) Date of Patent: Nov. 17, 1987

54 SYNTHETIC RESIN VEHICLE WHEEL 4,457,560 7/1984 Rowe et al. ....................... 301/37 P

COVER 4,457,561 7/1984. Whitmarsh ..... ... 301/37 PX

4,458,952 7/1984 Foster et al. .................. 301/37 PX

75 Inventors: Isao Kondo; Yasuyuki Koguro, both

of Kanagawa, Japan FOREIGN PATENT DOCUMENTS

73 Assignee: Marui Industry Co., Ltd., Tokyo, 2451071 4/1976 Fed. Rep. of Germany ... 301/37 P

Japan 2511306 2/1983 France ............................ 301/37 TP

81 15770 2/1983 France ............................ 301/37 TP

(21) Appl. No.: 894,391 55102702 6/1980 Japan .............................. 301/37 TP

499887 1/1939 United Kingdom .............. 301/37 C

22 Filed: Aug. 12, 1986

Primary Examiner-David A. Scherbel

Related U.S. Application Data Assistant Examiner-Carol L. Olson

Attorney, Agent, or Firm-Wenderoth, Lind & Ponack

63 Continuation of Ser. No. 706,887, Mar. 1, 1985, aban

doned. 57 ABSTRACT

30 Foreign Application Priority Data A synthetic resin vehicle wheel cover includes first and

Apr. 14, 1984 JP Japan ............................. 59-54127(U second mounting elements integrally formed with the

cover. The first mounting elements include at least two

51 Int. Cl. ................................................ B60B 7/02 cylindrical projections which project from the inner

52 U.S. C. .............. ... 301/37 P; 301/37 S surface of the cover with the projections positioned

58) Field of Search ............................. 301/37 P, 37 S along a circle about the center axis of the cover so that

56 References Cited the projections are adapted to fit over and firmly grasp

U.S. PATENT DOCUMENTS wheel fastening nuts. The second mounting means in

cludes projections which project inwardly from the

2,624,626 l/1953 Lyon ................................. 301/37 C periphery of the cover so that the projections are

3,876,257 4/1975 Buerger ............................ 301/37 C adapted to fixedly engage with the tire receiving rim.

4,004,837 1/1977 Main .................................. 301/37 P

4,133,583 1/1979 Spisak ....... . 301/37 PX

4,382,635 5/1983 Brown et al. ................. 301/37 PX 1 Claim, 3 Drawing Figures

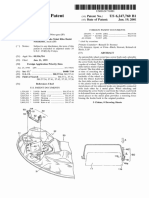

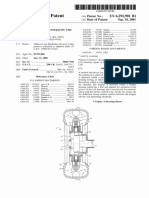

U.S. Patent Nov. 17, 1987 Sheet 1 of 2 4,707,035

U.S. Patent Nov. 17, 1987 Sheet 2 of 2 4,707,035

4,707,035

1. 2

SYNTHETIC RESIN VEHICLE WHEEL COVER BRIEF EXPLANATION OF THE DRAWINGS

FIG. 1 is a front view of a synthetic resin vehicle

This application is a continuation of now abandoned wheel cover in accordance with an embodiment of the

application Ser. No. 706,887, filed Mar. 1, 1985 aban 5 present invention;

doned. FIG. 2 is a cross sectional view of a portion of the

wheel cover of FIG. 1; and

BACKGROUND OF THE INVENTION FIG. 3 is a partial cross-sectional view of a cylindri

This invention relates to a synthetic resin wheel cal member on the wheel cover.

O

cover with integrally formed mounting means for DETAILED DESCRIPTION OF THE

mounting the cover on a vehicle wheel. INVENTION

U.S. Pat. No. 4,093,312 discloses vehicle wheel cov The wheel cover 1 in accordance with an embodi

ers having mounting means which include spring means ment of this invention, as shown, has a first mounting

formed separately from the cover and provided on the 15 means comprising four cylindrical projections 2 pro

outer periphery of the covers, the spring means being vided along a first circle about the center axis of the

adapted to resiliently and firmly engage with a tire cover on the rear surface of the cover 1, and which are

receiving rim so as to fixedly mount the cover on the adapted to fit over and firmly grasp the wheel fastening

wheel. However, since great force is imposed on the nuts N, and a second mounting means comprising eight

spring means when the cover is mounted on the wheel, 20 plate-like rim-engaging projections 3 provided on the

it is required to make the rigidity of the outer periphery rear surface of the cover 1, which are adapted to engage

of the cover supporting the spring means great which with a tire receiving rim R.

thereby limits the freedom of design of the covers. Fur Each cylindrical projection 2 has an annular bulge 2

ther, such spring means tends to damage the rim on the free edge of the inner or tip end thereof, which

whereby the damaged portions will get rusty, and fur 25 is adapted to engage the nut received in the cylindrical

ther to cause injury to a person mounting the cover on projection to prevent the cylindrical projection from

the wheel. Furthermore, such spring means can not slipping off the nut, and an axial direction slit as seen in

prefectly prevent the cover from being rotated relative FIG. 3 extending from the free end toward the cover 1

to the wheel by the torque imposed on the cover during to enable the free end to be expanded when the cylindri

running of the vehicle. 30 cal projection is inserted onto the nut N. Further, the

Japanese Utility Model Public Disclosure No. cylindrical projection has reinforcing ribs 2". The force

53-160138 discloses another type of mounting means for of the cylindrical projection 2 for grasping the nut is

a wheel cover. This mounting means consists of syn determined by the sizes of the nut receiving hole in the

thetic resin cylindrical projections provided on the rear cylindrical projection and slit, hardness and other quali

surface of the cover, which are adapted to receive and

35 ties of the material of the cylindrical projection and so

forth.

firmly grasp nuts which are used to fasten the vehicle The plate-like rim-engaging projections 3 of the sec

wheel and are positioned on the outer surface of the ond mounting means are provided on the periphery of

wheel around the hub of the same, whereby the cover is the cover with the rim-engaging projections being cir

fixedly mounted on the wheel without rotation thereof. 40 cumferentially equally spaced from each other. Each

However, such covers are limited to half size covers rin-engaging projection 3 has a radially outwardly

covering only the radially inner half portion of the projecting engaging portion 3' at the tip end of the

wheel, because these covers do not have means for rim-engaging projection 3, and reinforcing ribs 3". The

fastening the outer periphery of the cover to the rim. rim-engaging projections are radially positioned so that,

SUMMARY OF THE INVENTION

45 when the cover 1 is mounted on the wheel, the rim

engaging projections 3 are inwardly depressed in the

Accordingly, an object of this invention is to provide radial direction by the rim R whereby they firmly en

a synthetic resin vehicle wheel cover which is adapted gage with the rim due to the spring back force thereof.

to cover the whole of the wheel and which eliminates To mount the wheel cover of the present invention, it

the defects as described in connection with the wheel of 50 is only required to press the cover 1 against the wheel

U.S. Pat. No. 4,093,312. W while aligning the cylindrical projections 2 with the

The other object of this invention is to provide a corresponding

What is

nuts N.

claimed is:

vehicle wheel cover which is made from synthetic resin

of a desired color and has first and second mounting 55 a1. generally

A synthetic resin wheel cover comprising:

circular cover body;

means integrally formed with the cover, the first mount a plurality of plate-like rim-engaging projections on

ing means being adapted to firmly grasp at least two the face of said cover body which is to be against a

wheel fastening nuts and the second mounting means wheel, said projections having a free end and being

being adapted to fixedly engage with the tire receiving circumferentially spaced at predetermined dis

rim. s

The synthetic resin vehicle wheel cover in accor

60 tances and integral with and extending from said

cover body for elastically engaging the radial inner

dance with the present invention includes first and sec surface of a wheel rim, each rim-engaging projec

ond mounting means, said first mounting means includ tion having an engaging portion on the free end

ing at least two cylindrical projections which are thereof projecting radially outwardly of said cover

adapted to receive and grasp wheel fastening nuts, and 65 body for engaging a corresponding recess in the

said second mounting means including projections radial inner surfaces of the wheel rim for prevent

which are adapted to fixedly engage with the tire re ing said rim-engaging projection from being easily

ceiving rim. removed from the wheel rim; and

4,707,035 4

3

at least two nut gripping members on the same face of said cover body and extending into the hollow

said cover body as said projections, each consisting interior of said cylindrical projection for prevent

of a cylindrical projection integral with said cover ing said cylindrical projection from being easily

body and having a hollow interior and extending removed from the nut, said cover body, said plate

from said cover body for engaging with nuts on the 5 like rim-engaging projection and said cylindrical

wheel, each of said cylindrical projections being projections being molded of synthetic resin having

resiliently deformable radially outwardly by the sufficient resiliency to provide a spring back force

nuts as the hollow interior of said cylindrical pro of said rim-engaging projections and said cylindri

jection is fitted over the nut and being adapted to cal projections sufficient to cause the projections to

clamp the nut by the resilient force of the cylindri O firmly engage with the wheel rim and the nuts so as

cal projection, each of said cylindrical projections not to come off the wheel.

having an annular bulge at the end remote from sk it k k is

15

20

25

30

35

40

45

55

60

65

You might also like

- Patents - Powerpoint Presentation.Document57 pagesPatents - Powerpoint Presentation.Christopher Arellano100% (1)

- Bayes Rules! An Introduction To Applied Bayesian Modeling - Alicia A. Johnson, Miles Q. Ott, Mine Dogucu (2022)Document544 pagesBayes Rules! An Introduction To Applied Bayesian Modeling - Alicia A. Johnson, Miles Q. Ott, Mine Dogucu (2022)Carola Gauna0% (1)

- Avian Medicine and Surgery in Practice Companion and Aviary BirdsDocument384 pagesAvian Medicine and Surgery in Practice Companion and Aviary BirdsDrogaria Econômica0% (2)

- US6247760Document12 pagesUS6247760aungkyawzoreNo ratings yet

- Vernier Caliper PatentDocument9 pagesVernier Caliper Patentmeinard angelesNo ratings yet

- US5820225Document10 pagesUS5820225aungkyawzoreNo ratings yet

- Us 4610182Document7 pagesUs 4610182rohaannn46No ratings yet

- Patent USPTO 4098523 Traction DeviceDocument5 pagesPatent USPTO 4098523 Traction Devicexeron7126No ratings yet

- US5988762Document15 pagesUS5988762aungkyawzoreNo ratings yet

- US4991909Document10 pagesUS4991909aungkyawzoreNo ratings yet

- US4682820Document12 pagesUS4682820aungkyawzoreNo ratings yet

- United States Patent (19) : 73 Assignee: Monogram Industries, Inc., CulverDocument5 pagesUnited States Patent (19) : 73 Assignee: Monogram Industries, Inc., CulverFayçal MahieddineNo ratings yet

- First: United States PatentDocument7 pagesFirst: United States Patentyraju88No ratings yet

- United States Patent (19) : (11) Patent Number: (45) Date of PatentDocument12 pagesUnited States Patent (19) : (11) Patent Number: (45) Date of PatentOctavio HernandezNo ratings yet

- United States Patent (19) : Aerospatiale, FranceDocument7 pagesUnited States Patent (19) : Aerospatiale, Franceingeniomeca8800No ratings yet

- US4219241Document7 pagesUS4219241aungkyawzoreNo ratings yet

- Us 4476409Document7 pagesUs 4476409Shankar PediredlaNo ratings yet

- United States PatentDocument13 pagesUnited States Patent63No ratings yet

- United States Patent: (12) (10) Patent N0.: US 7,267,030 B2Document15 pagesUnited States Patent: (12) (10) Patent N0.: US 7,267,030 B2cirno9No ratings yet

- US3883181Document8 pagesUS3883181aungkyawzoreNo ratings yet

- US5457886Document9 pagesUS5457886aungkyawzoreNo ratings yet

- Us 4909638Document7 pagesUs 4909638Rohan KulkarniNo ratings yet

- United States Patent 19Document6 pagesUnited States Patent 19mahmoud EissaNo ratings yet

- United States Patent (19) : Helderle Et AlDocument14 pagesUnited States Patent (19) : Helderle Et AlabodolkuhaaNo ratings yet

- United States Patent: (12) (10) Patent N0.: US 6,933,430 B2 Oskorep (45) Date of Patent: Aug. 23, 2005Document14 pagesUnited States Patent: (12) (10) Patent N0.: US 6,933,430 B2 Oskorep (45) Date of Patent: Aug. 23, 2005Walied SamiNo ratings yet

- United States Patent (10) Patent No.: US 6,453,528 B1Document9 pagesUnited States Patent (10) Patent No.: US 6,453,528 B1MahnooshNo ratings yet

- US5368370Document7 pagesUS5368370aungkyawzoreNo ratings yet

- United States Patent: (12) (10) Patent No.: US 7,214,135 B2 Laskey Et Al. (45) Date of Patent: May 8, 2007Document6 pagesUnited States Patent: (12) (10) Patent No.: US 7,214,135 B2 Laskey Et Al. (45) Date of Patent: May 8, 2007Keval Kamani100% (1)

- Anti-Resonance Pipe ClipDocument6 pagesAnti-Resonance Pipe ClipTUNCAY GUMUSNo ratings yet

- US5513743Document6 pagesUS5513743AdailsonNo ratings yet

- United States Patent (10) Patent No.: US 7,032.967 B2: Pyzik Et Al. (45) Date of Patent: Apr. 25, 2006Document10 pagesUnited States Patent (10) Patent No.: US 7,032.967 B2: Pyzik Et Al. (45) Date of Patent: Apr. 25, 2006Muhammad Rifqi fawziNo ratings yet

- Antibacklash Gears Including Rack and Pinion GearsDocument11 pagesAntibacklash Gears Including Rack and Pinion GearsBrian KiddNo ratings yet

- United States Patent: (10) Patent No.: US 6,293,891 B1Document8 pagesUnited States Patent: (10) Patent No.: US 6,293,891 B1Dejan ZdravkovskiNo ratings yet

- United States Patent (19) : Felix-DalichowDocument5 pagesUnited States Patent (19) : Felix-DalichowBarmak CheraghiNo ratings yet

- US6045195Document30 pagesUS6045195aungkyawzoreNo ratings yet

- patent-US5730647-Apparatus For Fine-Grinding A CrankshaftDocument9 pagespatent-US5730647-Apparatus For Fine-Grinding A CrankshaftMahnooshNo ratings yet

- Wheel PWR GenerationDocument8 pagesWheel PWR GenerationAsad Ahmed KhanNo ratings yet

- United States Patent (19) : GullettDocument7 pagesUnited States Patent (19) : GullettMaJoy GarciaNo ratings yet

- United States PatentDocument7 pagesUnited States PatentBrilliant DavidsonNo ratings yet

- United States Patent (19) (11 3,724,381: Assignee: Dynamit Nobel AktiengesellschaftDocument4 pagesUnited States Patent (19) (11 3,724,381: Assignee: Dynamit Nobel AktiengesellschaftSmokeNo ratings yet

- US4392295Document14 pagesUS4392295chahineNo ratings yet

- US460Document5 pagesUS460bbNo ratings yet

- US4893426Document7 pagesUS4893426Jean DelaronciereNo ratings yet

- PatentDocument13 pagesPatenteuontyNo ratings yet

- Phy 2Document38 pagesPhy 2AlvianiNo ratings yet

- United States Patent: Chang Et AlDocument9 pagesUnited States Patent: Chang Et AlEric Manuel Mercedes AbreuNo ratings yet

- Slurry Reaction AgitatorsDocument10 pagesSlurry Reaction AgitatorsManoj BNo ratings yet

- US5931543Document12 pagesUS5931543aungkyawzoreNo ratings yet

- Patent DocumentDocument14 pagesPatent Documentcmhg1982No ratings yet

- United States Patent (10) Patent No.: US 8.414,195 B2Document6 pagesUnited States Patent (10) Patent No.: US 8.414,195 B2Anshumaan Pratap BhagatNo ratings yet

- Drudy (45) Apr. 27, 1982: ,. L ' - T 1) Ate States Ate E (191 (111 4,326,560Document7 pagesDrudy (45) Apr. 27, 1982: ,. L ' - T 1) Ate States Ate E (191 (111 4,326,560Daniel ZabalaNo ratings yet

- Patent 2Document11 pagesPatent 2PankajNo ratings yet

- United States Patent (19) : (54) Coating Device For Coating OfaDocument10 pagesUnited States Patent (19) : (54) Coating Device For Coating OfaNiccolast Adnandito SaputraNo ratings yet

- US6103347 XXXXXXXXXXXXXXDocument12 pagesUS6103347 XXXXXXXXXXXXXXfrancisco perezNo ratings yet

- US5180284Document7 pagesUS5180284vishal pandeyNo ratings yet

- Us 6012901Document8 pagesUs 6012901B Bala Venkata GaneshNo ratings yet

- Camerastructure For Single LensDocument11 pagesCamerastructure For Single LensGibral AnugrahNo ratings yet

- United States Patent (19) : GlockDocument19 pagesUnited States Patent (19) : GlockJay MasonNo ratings yet

- NasaDocument6 pagesNasaKevin DominichNo ratings yet

- Us4036274 Safety Cage For InflationDocument5 pagesUs4036274 Safety Cage For InflationJimmy Cuevas MonsalveNo ratings yet

- United States Patent (10) Patent No.: US 6,527,353 B1: Bradfish Et Al. (45) Date of Patent: Mar. 4, 2003Document9 pagesUnited States Patent (10) Patent No.: US 6,527,353 B1: Bradfish Et Al. (45) Date of Patent: Mar. 4, 2003Renato GavanNo ratings yet

- US3667570Document7 pagesUS3667570Ger Adinolfi-FebreNo ratings yet

- Engineered Rubber Products: Introduction to Design, Manufacture and TestingFrom EverandEngineered Rubber Products: Introduction to Design, Manufacture and TestingNo ratings yet

- Kitsch v. Deejayzoo - Markman OrderDocument17 pagesKitsch v. Deejayzoo - Markman OrderSarah BursteinNo ratings yet

- Condition Classification For New GST ConditionsDocument3 pagesCondition Classification For New GST ConditionsVenugopal PNo ratings yet

- Dwnload Full College Algebra Real Mathematics Real People 7th Edition Larson Solutions Manual PDFDocument23 pagesDwnload Full College Algebra Real Mathematics Real People 7th Edition Larson Solutions Manual PDFodileamanda5ns4q3100% (18)

- D4123 Resilient ModulusDocument4 pagesD4123 Resilient ModulusNurul RizalNo ratings yet

- Intellectual PropertyDocument26 pagesIntellectual PropertyANKIT ARORANo ratings yet

- Social Media and Depression Symptoms A Network PerspectiveDocument10 pagesSocial Media and Depression Symptoms A Network PerspectiveLê HằngNo ratings yet

- Chicken BluesDocument18 pagesChicken BluesumitNo ratings yet

- BurberryDocument6 pagesBurberryEegii ZazolNo ratings yet

- Cornell: Pump CompanyDocument2 pagesCornell: Pump CompanyJavier AffifNo ratings yet

- DeFries v. MSB Trade - ComplaintDocument55 pagesDeFries v. MSB Trade - ComplaintSarah BursteinNo ratings yet

- IPL Cases Part2Document4 pagesIPL Cases Part2Jerald-Edz Tam Abon67% (3)

- 2 01-CopyrightDocument10 pages2 01-Copyrightapi-298810403No ratings yet

- Preserving Intellectual Property RightsDocument8 pagesPreserving Intellectual Property RightsPankaj NishadNo ratings yet

- Alignment TrainingDocument59 pagesAlignment TrainingNasrul100% (1)

- 727 PosrvDocument7 pages727 Posrvtxlucky80No ratings yet

- Study On Consumer Preference in Regard With Horlicks and CadburyDocument3 pagesStudy On Consumer Preference in Regard With Horlicks and CadburyM.E. PrakashNo ratings yet

- NHSLeadership Framework LeadershipFramework Summary PDFDocument20 pagesNHSLeadership Framework LeadershipFramework Summary PDFSudhakar Singh100% (1)

- Steel Castings, Surface Acceptance Standards, Visual ExaminationDocument3 pagesSteel Castings, Surface Acceptance Standards, Visual ExaminationRamzi BEN AHMEDNo ratings yet

- 2 Ride My Bear Jenika Snow Jordan MarieDocument110 pages2 Ride My Bear Jenika Snow Jordan MarieNazaa Guedez100% (2)

- Burnish Resistance of Latex Paints: Standard Test Method ForDocument3 pagesBurnish Resistance of Latex Paints: Standard Test Method ForProvocateur Samara100% (1)

- Detail TV Wall at Living RoomDocument1 pageDetail TV Wall at Living RoomSuth KimseangNo ratings yet

- Pe 1998 01Document104 pagesPe 1998 01Benjamin DoverNo ratings yet

- 2016 KS1 English Reading Paper 1 Reading Prompt and Answer Booklet PDFADocument20 pages2016 KS1 English Reading Paper 1 Reading Prompt and Answer Booklet PDFABernard Chan100% (1)

- Defining Line Styles in Outfitting Draft Rev1Document8 pagesDefining Line Styles in Outfitting Draft Rev1Sanja BarabaNo ratings yet

- Directional Astrology by SepharialDocument217 pagesDirectional Astrology by SepharialAnthony Louis100% (1)

- Provisional Application For Patent - BrochureDocument2 pagesProvisional Application For Patent - BrochureJames LindonNo ratings yet

- Patented Algorithm With Software Release AgreementDocument2 pagesPatented Algorithm With Software Release AgreementUmer WaheedNo ratings yet