Professional Documents

Culture Documents

HS84218-00-CIV-STN-0006-0000 Rev1 Standard Details For Circular Auxiliary Platforms

HS84218-00-CIV-STN-0006-0000 Rev1 Standard Details For Circular Auxiliary Platforms

Uploaded by

Fatih ÜnlüOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HS84218-00-CIV-STN-0006-0000 Rev1 Standard Details For Circular Auxiliary Platforms

HS84218-00-CIV-STN-0006-0000 Rev1 Standard Details For Circular Auxiliary Platforms

Uploaded by

Fatih ÜnlüCopyright:

Available Formats

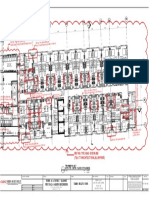

TYP PLAN FOR PLTFORM (1300<L<1800) DETAIL OF BRACKET ON GRID-1(BKT-1) TYP BOLT DETAIL DETAIL OF BRACKET ON GRID-2 (BKT-2)

DETAIL OF BRACKET ON GRID-1(BKT-1) TYP BOLT DETAIL DETAIL OF BRACKET ON GRID-2 (BKT-2) DETAIL OF (BKT-1) AT SPLICE LOCATION ( IF APPLICABLE )

(SCALE 1:10)

90

13 50 13

B

5

A

3

3

HANDRAIL (TYP)

HANDRAIL (TYP) REF NOTE 3 TK01-AI-DX-000053 6

1SIDES

1300<L<1800

C VESSEL 1300<L<1800

40 20 A 65

L 1 1 INNER RING L150X100X10 TOS

80

WIDTH INNER RING L150X100X10 35

2 45

0.4L A 65 4 4

0.6L

35

.)

2 IN GRATING 30 THK (TYP)

0

GRATING 30 THK (TYP)

1500 (MAX)

(M 45 REFER NOTE 7

3 00 REFER NOTE 7

R2 C VESSEL

R2

OUTER RING L150X100X10 IPE200

OUTER RING L150X100X10 6

75

R1 R1 100 6 3 SIDE

TOS 6 3 SIDE 6

TOS == 100

75

R1 R1

R2 R2 6 ==

1 SIDE

1 1 UPN200 1

16 16

IPE200 1 M12 BOLTS

VESSEL OUTER DIA

VESSEL OUTER DIA WITH WASHERS, NUT & LOCK NUT

M12 BOLTS

CLEARENCE 0.5mm BETWEEN SECTION 13-13

11

WITH WASHERS, NUT & LOCK NUT

A

CLEARENCE 0.5mm BETWEEN 16 16 STRUCTURE & WASHER (SCALE 1:10)

16 16

STRUCTURE & WASHER INSULATION THICKNESS

B

5

INSULATION THICKNESS

3

1 700 (MIN.) 1

12

12 THK. SPLICE PLATE

REF NOTE 4. 2 2 (TYP)

45

2

OPENING FOR LADDER WHERE APPLICABLE DETAIL 'X' SECTION 4-4

WHERE APPLICABLE (SCALE 1:10) 45

(SCALE 1:20)

HANDRAIL HEIGHT TO BE ADJUSTED

60

REFER NOTE 9

60

IPE200

SECTION A-A SECTION B-B SECTION 1-1 REF. LINE

(SCALE 1:20)

10 R1 R3

C

(SCALE 1:10) (SCALE 1:10)

SPACER

60

60

B

50X200X10 THK PLATE

35

SPACER (PITCH MAX 500) 10

600 MAX.

15 MIN.

50X200X10 THK PLATE

8 THK. PLATE 30 30 25 8 THK. PLATE 30 30 25

A

(PITCH MAX 500) L150X100X10

15

WELDEED ON BRACKET MIN. WELDEED ON BRACKET MIN.

50

40

10

15

15

REF. C REF. LINE

50 55 55

50 55 55

20

==

20

10

2-14X38 SLOTTED HOLE

12

160

160

1 IN PLATE AND ANGLE (TYP)

SECTION 10-10 75 BB

GAP

30

30

(SCALE 1:20)

A

10

UPN200 15 2-13X30 SLOTTED HOLE

IPE160 IPE160 IPE160

IN ANGLE FRAME (TYP) 2-14X38 SLOTTED HOLE

11

2-21.5 DIA HOLES 1 IN PLATE AND ANGLE (TYP)

2-21.5 DIA HOLES 4-13X30 SLOTTED HOLE

FOR M20 BOLTS

FOR M20 BOLTS 6 IN ANGLE FRAME (TYP)

6 TYP 3 SIDES 15

IPE200 L150X100X10 1

TYP PLAN FOR PLTFORM (L<1300) DETAIL OF BRACKET ON GRID-1(BKT-1)

1

SECTION 12-12 SECTION 11-11

(SCALE 1:10) (SCALE 1:10)

3

35 75 100 75 35 140 35 75 100 75 35 140

HANDRAIL (TYP) REF NOTE 3 CLIENT APPROVAL

C VESSEL

L<1300 Doc. Rev. Date SKBR/IPMT Approver HAOR Approver

2 30 30 Tarix

6 6

35

40

L

40

300(MIN

2 WIDTH

INNER RING L150X100X10

1500 (MAX)

60 60

60 60

R4

160

R4 C VESSEL A 65

.)

R3 VESSEL OUTER DIA GRATING 30 THK (TYP)

45

50

50

R3 REFER NOTE 7

R3

INSULATION THK.

R3 R4 R4 10 THK. PLATE WITH C POST C POST

8-17X38 SLOTTED HOLE

8-17X38 SLOTTED HOLE

170

OUTER RING L150X100X10 IN PLATE (TYP)

1 1

75

IN PLATE (TYP)

TOS 1. ALL DIMENSIONS AND ELEVATIONS ARE IN MILLIMETERS, COORDINATES ARE IN

6 8-17X38 SLOTTED HOLE METERS (UNLESS NOTED OTHER WISE)

3 SIDE 100 100

6 IN PLATE (TYP) 150 8 THK. PLATE 2. FOR GENERAL NOTES AND MATERIALS REFER DWG. NO. TK01-AI-DX-000051.

1 3. FOR DETAILS OF HANDRAIL REFER DOCUMENT NO TK01-AI-DX-000053.

IPE200 M12 BOLTS 8 THK. STIFFENER PLATE

4. FOR LADDER FIXING DETAILS REFER DOCUMENT NO TK01-AI-DX-000054

1 700(MIN.) 1 WITH WASHERS, NUT & LOCK NUT (TYP.)

5. FOR EL. AT T.O.S REF. INDIVIDUAL PLATFORM DRAWING

CLEARENCE 0.5mm BETWEEN

16 16 TYP 6. ALL WELDS ARE CONTINUOUS WELDS.

8 STRUCTURE & WASHER

2 2 7. FOR GRATING AND CHEQUERED PLATES DETAILS SEE DOC. TK01-AI-DX-000007/000052

3

REF NOTE 2 8. SUPPORT CLIPS DIRECTLY WELDED ON VESSEL WALL SHALL BE SUPPLIED

DETAIL OF BRACKET ON GRID-2 (BKT-2) ND WELDED TO SHELL/HEAD/SKIRT BY VESSEL MANUFACTURER MATERIAL FOR

EXTERNAL SUPPORTS AND CLIPS WELDED TO VESSEL SHALL BE THE SAME GRADE

SECTION 6-6 MATERIAL AS VESSEL

5

3

(SCALE 1:20) 9. FOR INDICATED LENGTH TOE PLATE SHALL BE ADDED ON HANDRAIL. HANDRAIL

HEIGHT SHALL BE ADJUSTED TO MATCH WITH HANDRAILS ON PERIPHERY.

SECTION 3-3 SECTION 2-2 L<1300 HANDRAIL (TYP) REF NOTE 3

(SCALE 1:20) (SCALE 1:20)

10

GAP

7 A 65 7

50

160 IPE200 45 INNER RING L150X100X10

8 160 == 12 THK. REF. C

TYP 8

==

12 THK. 70 GUSSET PLATE

40

== GRATING 30 THK (TYP)

75

70 GUSSET PLATE (TYP)

40

1 REFER NOTE 7

75

==

TOS

75

==

4-13X30 SLOTTED HOLE

TOS OUTER RING L150X100X10

75

SPACER IN FRAME (TYP)

75

350

195

50X200X10 THK PLATE TOS

350

6

195

6 TYP (PITCH MAX 500c/c) (TYP UNO)

6

TYP

75

6

40

UPN200 1

40

6-21.5 DIA HOLES VESSEL OUTER DIA M12 BOLTS

12 THK.

6-21.5 DIA HOLES 8

TYP 8

FOR M20 BOLTS SECTION 7-7 WITH WASHERS, NUT & LOCK NUT

CLEARENCE 0.5mm BETWEEN

5

FOR M20 BOLTS (SCALE 1:20) 16 16

STIFFNER PLATE (TYP) ON FLANGE INSULATION THICKNESS STRUCTURE & WASHER

3

DETAIL 'C' HANDRAIL HEIGHT TO BE ADJUSTED

C

REFER NOTE 9

(SCALE 1:10) SECTION 5-5

B

(SCALE 1:20)

35

ON MAIN SUPPORT (IPE200/UPN200) ALL AROUND THE WALKWAYS SHELL

0

600 MAX.

15 MIN.

160

HANDRAIL (TYP) == 12 THK.

40 TK01-AI-DX-000053 70 N (+ VE DOWNWARD)

GUSSET PLATE

40

R

75

15

15

35 REF. LINE UPN200

==

TOS

75 UNFACTORED LOADS

350

40

T

195

IPE200

60

75

/UPN200 15 1 NODE HORIZONTAL VERTICAL HORIZONTAL MOMENT

25

60

B

25

6-21.5 DIA HOLES 14X38 SLOTTED HOLE

40

2 M16 BOLTS WITH Rn FR (kN) FN (kN) FT (kN) MR-R (kN-m) MT-T (kN-m)

FOR M20 BOLTS IN FRAME (TYP)

WASHERS, NUT & LOCK NUT +VE/-VE +VE/-VE +VE/-VE +VE/-VE +VE/-VE

6 15 1

TYP 6 8 R1 9 14.5 6 0.5 15.5 1.4

PL 6 THK 2 M16 BOLTS WITH 8

WASHERS, NUT & LOCK NUT R2 9 6.75 3 0.5 7.75 0.7

A = 110MM FOR UNINSULATED EQUIPMENT

R3 9 10.5 3 0.5 9.5 0.7

A = INSUALTION THICKNESS + 40MM OR 110MM

WHICHEVER MAXIMUM FOR INSULATED EQUIPMENT R4 9 5.25 1.5 0.5 4.75 0.35

You might also like

- Zandvoort PalaceDocument2 pagesZandvoort Palacenoe HudNo ratings yet

- Why Is ItDocument2 pagesWhy Is ItVittorio Pagano100% (1)

- In C Major With Strings-PianoDocument2 pagesIn C Major With Strings-PianoKlozeNo ratings yet

- Another Day of Sun Piano-PianoDocument2 pagesAnother Day of Sun Piano-PianoEva YNo ratings yet

- SWR UpdatedDocument1 pageSWR Updatedram prasad meenaNo ratings yet

- 8 Pièces Pour Piano (No. 2) - Conducteur - Et - Parties (Sop - Alt - Ten)Document15 pages8 Pièces Pour Piano (No. 2) - Conducteur - Et - Parties (Sop - Alt - Ten)ZadorxsNo ratings yet

- Saguate Cumbia - Sax1Document1 pageSaguate Cumbia - Sax1thomas castraNo ratings yet

- Sweet Dreams Are Made of This-Trombone 1Document2 pagesSweet Dreams Are Made of This-Trombone 1Lucas OliveiraNo ratings yet

- MuzikaDocument2 pagesMuzikaadomelis2011No ratings yet

- Julia Ben VersionDocument3 pagesJulia Ben VersionNico E MartinezNo ratings yet

- Pilar H.A.:P1 Pilar H.A.:P2: A B C D E FDocument1 pagePilar H.A.:P1 Pilar H.A.:P2: A B C D E FclaudioNo ratings yet

- Planos LA ELSADocument14 pagesPlanos LA ELSAJonevic MolinaNo ratings yet

- Patrones de DanzaDocument1 pagePatrones de DanzaHector Jose Suarez TorresNo ratings yet

- Denah PDF KeseluruhanDocument13 pagesDenah PDF KeseluruhanpoladwipaNo ratings yet

- 薛之谦 演员(伴奏)Document6 pages薛之谦 演员(伴奏)John PeanutbutterNo ratings yet

- Allegretto: César IzurietaDocument3 pagesAllegretto: César IzurietaFelipe BonillaNo ratings yet

- Parcela 29aDocument1 pageParcela 29aLuís G. MorenoNo ratings yet

- WAMozart Symphony No in GM K ST MVTDocument11 pagesWAMozart Symphony No in GM K ST MVTmatthewmensah984No ratings yet

- KA2 KA3 S1a: NotesDocument1 pageKA2 KA3 S1a: NotescristianNo ratings yet

- Ao - Sentir Arranjo-PianoDocument2 pagesAo - Sentir Arranjo-PianoGiovanni PereiraNo ratings yet

- La Trampera Fin de Curso Copia-PianoDocument3 pagesLa Trampera Fin de Curso Copia-Pianomartin buckiNo ratings yet

- Mapa Bogota 4aDocument2 pagesMapa Bogota 4anietocristian4630No ratings yet

- Fire Force OP - InfernoDocument4 pagesFire Force OP - InfernoFederico MartínNo ratings yet

- Fire Force OP - InfernoDocument4 pagesFire Force OP - InfernoFederico MartínNo ratings yet

- LooooooooooooooouiDocument1 pageLooooooooooooooouirim deNo ratings yet

- Rds Ormoc-2f Reflected Ceiling PlanDocument1 pageRds Ormoc-2f Reflected Ceiling PlanAaron JabasNo ratings yet

- DU2103800-N012-N017-Road Cross Sections - StampedDocument6 pagesDU2103800-N012-N017-Road Cross Sections - StampedON ROADING CONTRACTING LLCNo ratings yet

- Eine Kleine Nachtmusik: Reduccion Al PianoDocument2 pagesEine Kleine Nachtmusik: Reduccion Al PianoPedroo Pianista431100% (1)

- Efficiency Rag: James Scott (1917)Document4 pagesEfficiency Rag: James Scott (1917)홍정기No ratings yet

- VP Efficiencyrag PDFDocument4 pagesVP Efficiencyrag PDF홍정기No ratings yet

- A Song For You PianoDocument3 pagesA Song For You PianoBoatman Bill100% (1)

- Pure Sky - Genshin ImpactDocument1 pagePure Sky - Genshin ImpactPipo PhạmNo ratings yet

- 535 (Fá) - Tu És Fiel, SenhorDocument1 page535 (Fá) - Tu És Fiel, SenhorSérgioNo ratings yet

- Finale 2009 - (Over and Out March - R. Beck - Alto Sax. 1Document1 pageFinale 2009 - (Over and Out March - R. Beck - Alto Sax. 1maestro29100% (1)

- LD PC CH.199+590Document4 pagesLD PC CH.199+590Aerotide InfrastructuresNo ratings yet

- Asterix Gallowstreet V1.1-Saxophone BarytonDocument3 pagesAsterix Gallowstreet V1.1-Saxophone Barytonarthurcho72No ratings yet

- Layout BDocument1 pageLayout BMuhammad FauzanNo ratings yet

- Bình Bán - Long Vân - Duyên K NGDocument2 pagesBình Bán - Long Vân - Duyên K NGKim Thoa NguyễnNo ratings yet

- DreadnoughtDocument8 pagesDreadnoughtSTENAFPRO4566No ratings yet

- Flower DanceDocument7 pagesFlower Dancehardworking2310No ratings yet

- Marcha Nupcial WagnerDocument2 pagesMarcha Nupcial WagnerVictoria AcostaNo ratings yet

- OPD 1411 - As-Built PlanDocument1 pageOPD 1411 - As-Built PlanPatbauNo ratings yet

- Fix'd in His Everlasting Seat.Document6 pagesFix'd in His Everlasting Seat.UNAMBA VICTOR100% (1)

- Aria Sopra La Bergamasca - Marco UccelliniDocument7 pagesAria Sopra La Bergamasca - Marco UccelliniDuo Zotti LuppiNo ratings yet

- Finale 2009 - (Over and Out March - R. Beck - Trombone 2Document1 pageFinale 2009 - (Over and Out March - R. Beck - Trombone 2maestro29No ratings yet

- International Developments Power: Turbine ServicesDocument1 pageInternational Developments Power: Turbine ServicesYousefNo ratings yet

- 2C-M002 - Rev 0Document1 page2C-M002 - Rev 0Marco Andres Ortiz TitoNo ratings yet

- AR02-10 - TOWER 6&7 FLOOR PLANS 6th-18thDocument1 pageAR02-10 - TOWER 6&7 FLOOR PLANS 6th-18thJay Berlin EsguerraNo ratings yet

- We All Lie SKY Castle OSTDocument3 pagesWe All Lie SKY Castle OSTEina LeNo ratings yet

- AR02-10 - TOWER 6&7 FLOOR PLANS 5th FloorDocument1 pageAR02-10 - TOWER 6&7 FLOOR PLANS 5th FloorJay Berlin EsguerraNo ratings yet

- C-STR-DWG-000-31008-0 - PR-102 Structural Steel GA - Plan & Det at Base PL LevelDocument1 pageC-STR-DWG-000-31008-0 - PR-102 Structural Steel GA - Plan & Det at Base PL LevelHUSSEIN FNEISHNo ratings yet

- Italia Alto Sax 1Document1 pageItalia Alto Sax 1Cláudio ClementeNo ratings yet

- ML Coral0N IencantadoDocument3 pagesML Coral0N IencantadoGuilherme BarcikNo ratings yet

- ML Coral0N IencantadoDocument3 pagesML Coral0N IencantadoGuilherme BarcikNo ratings yet

- Something's Got A Hold On Me: FreelyDocument2 pagesSomething's Got A Hold On Me: FreelyMezzo ForteNo ratings yet

- Audio Micro: CA+ CA-Vol+ Vol - Tv/Av MenuDocument2 pagesAudio Micro: CA+ CA-Vol+ Vol - Tv/Av MenuJosé Alberto Pérez CabreraNo ratings yet

- 3-MEPs-ELECT-ER-B4&7-0003 (SH 1-1) - R2 (FND Reviewed) - ER-B4-0003Document1 page3-MEPs-ELECT-ER-B4&7-0003 (SH 1-1) - R2 (FND Reviewed) - ER-B4-0003muzeek306No ratings yet

- James Bond: John Barry 120 100Document3 pagesJames Bond: John Barry 120 100ATNo ratings yet

- GrafZeppelin BBDocument53 pagesGrafZeppelin BBTens AiepNo ratings yet