Professional Documents

Culture Documents

Welding Olet As PTS

Welding Olet As PTS

Uploaded by

Mohd Effiezool YaserOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding Olet As PTS

Welding Olet As PTS

Uploaded by

Mohd Effiezool YaserCopyright:

Available Formats

PTS 15.12.

01

WELDING FOR CHEMICAL, OIL AND GAS INDUSTRIES February 2016

(AMENDMENTS / SUPPLEMENTS TO API RP 582)

Page 19 of 102

(v) Toe profile grinding or cosmetic grinding, if restricted by the Owner, shall only be performed

when specified in the design drawings or requested by the Owner.

y

nl

O

se

lU

na

er

nt

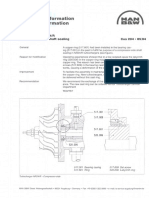

Figure 1: Weld Profile - Weldolets

-I

4.11.4 The first pass of fillet welds in vibrating service shall have a convex profile, meanwhile the final

AS

capping shall have a concave profile. The throat size shall not be less than the size stated in

the design documents. The effective weld size should be used for weld in vibrating service. If

N

required the weld shall be blend ground to achieve this requirement.

O

TR

4.11.5 Stray Arc Strikes

PE

(i) Arc strikes shall be made on the fusion faces or on the previous weld deposit.

(ii) Arc strikes shall be removed by grinding or other appropriate method, and followed by PT or

MT to ensure that there is not defect. The material thickness, to be measured by the

Contractor, after grinding out the arc strike shall not be lower than the minimum required

thickness. Otherwise the component shall be replaced or the weld repaired if permitted by

the Owner.

(iii) Earthing connection shall be check and examine periodically by the Contractor. Arching due

to poor earthing connection shall be considered as stray arc strike.

(iv) Stainless steel clamps shall be used for the connection to the work. Earth cables shall not be

welded to the components.

4.11.6 Records

(i) The Contractor shall maintain daily record of all cut, QSET and repairs. The copies shall be

made available to the Owner if requested.

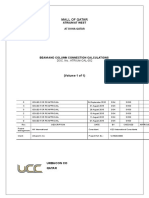

(ii) Detailed records, comprise of (i) weld identification serial numbers, (ii) weld position, (iii)

dates, (iv) WPS number, (v) welder names, and (vi) welder identification number, of all weld

You might also like

- Subsea Rigid Pipelines – Methods of InstallationFrom EverandSubsea Rigid Pipelines – Methods of InstallationRating: 5 out of 5 stars5/5 (1)

- CVC Reading PassagesDocument8 pagesCVC Reading PassagesChase Smythe100% (1)

- Itp 001 PipelineDocument2 pagesItp 001 PipelineMohd Effiezool YaserNo ratings yet

- Project Specification Piping Class SummaryDocument41 pagesProject Specification Piping Class SummaryMohd Effiezool YaserNo ratings yet

- Helicoil Insert - NASADocument8 pagesHelicoil Insert - NASAben100% (1)

- Nes 747Document252 pagesNes 747Soumya Ranjan Subudhi100% (1)

- TGN-BC-01 Tack Welding of Reinforcement BarDocument8 pagesTGN-BC-01 Tack Welding of Reinforcement BarFerhat KahveciNo ratings yet

- F 7 FlangesDocument30 pagesF 7 FlangesAshraf Ismail HassenNo ratings yet

- OCTO 12015 : Department of Public Works and HighwaysDocument8 pagesOCTO 12015 : Department of Public Works and HighwaysFaustino AbadNo ratings yet

- Return To TOC: Dowty Propellers Standard Practices ManualDocument22 pagesReturn To TOC: Dowty Propellers Standard Practices ManualNicolás PiratovaNo ratings yet

- NCCI: Shear Resistance of A Fin Plate Connection SN017a-EN-EUDocument13 pagesNCCI: Shear Resistance of A Fin Plate Connection SN017a-EN-EUMaris VeitsNo ratings yet

- Fabricationandsupplyofteejointforairoutletheader-01 20221218112214.349 XDocument6 pagesFabricationandsupplyofteejointforairoutletheader-01 20221218112214.349 XAbdulrahman EladawyNo ratings yet

- Manual Actuators - F427 Gear Operator: General Purposes Manual Operator For On/off or Throttling DutiesDocument4 pagesManual Actuators - F427 Gear Operator: General Purposes Manual Operator For On/off or Throttling DutiesMuhammad EsamNo ratings yet

- Cus 204 EDocument1 pageCus 204 ECocoi SolisNo ratings yet

- 1357577482393-Revised FBW Manual-Jan 2012 PDFDocument60 pages1357577482393-Revised FBW Manual-Jan 2012 PDFAnirudh PrakashNo ratings yet

- Anchr Bolt RefDocument9 pagesAnchr Bolt ReferleosNo ratings yet

- Is 3063 Spring Washers PDFDocument11 pagesIs 3063 Spring Washers PDFAyman Hamed Malah100% (1)

- Astm A775-A97Document7 pagesAstm A775-A97Артем ТитовNo ratings yet

- OPSS 741 Nov2014Document10 pagesOPSS 741 Nov2014Muhammad UmarNo ratings yet

- Check list _PEB_QualityDocument12 pagesCheck list _PEB_Qualityambar patnaikNo ratings yet

- WEP NormsDocument40 pagesWEP NormskumarNo ratings yet

- AC 43 13 1B Chapter - 07 Pag 1 2Document2 pagesAC 43 13 1B Chapter - 07 Pag 1 2Joel Cordova100% (1)

- UNIT NO. 5.8 Welding of Structural Steel: © Lifting Equipment Engineers Association 2012 - Training/5-8uDocument13 pagesUNIT NO. 5.8 Welding of Structural Steel: © Lifting Equipment Engineers Association 2012 - Training/5-8uYAKUBU A. AROGENo ratings yet

- Hazira-Sor 20200702 181418Document11 pagesHazira-Sor 20200702 181418Suaib VCSNo ratings yet

- Control CablesDocument17 pagesControl CablesNaumaanNo ratings yet

- Welding Processes Investigation SlidesDocument36 pagesWelding Processes Investigation SlidesSwarna LathaNo ratings yet

- AGS033-05 Conveyor IdlersDocument23 pagesAGS033-05 Conveyor IdlersmuzioscarNo ratings yet

- aircraft-fittingsDocument34 pagesaircraft-fittingspkavi2227No ratings yet

- FBW ManualDocument70 pagesFBW ManualSurinderPalSinghGillNo ratings yet

- Pwp0025 r1 Bucket Welding ProcedureDocument11 pagesPwp0025 r1 Bucket Welding ProcedureSidney da SandraNo ratings yet

- Recommended Details Galvanized Steel Structures PDFDocument24 pagesRecommended Details Galvanized Steel Structures PDFPättan DansNo ratings yet

- Chapter 7. Aircraft Hardware, Control Cables, and TurnbucklesDocument74 pagesChapter 7. Aircraft Hardware, Control Cables, and TurnbucklesReza PahleviNo ratings yet

- A775MDocument8 pagesA775M1534520687No ratings yet

- SI1098Q Propeller Flange Bushing LocationDocument12 pagesSI1098Q Propeller Flange Bushing Locationjkloepping_634367970No ratings yet

- Hmu Icc-Es Esr-3878Document10 pagesHmu Icc-Es Esr-3878Koresh KhalpariNo ratings yet

- 14-P-141-80 (TLine Earthwire Fittings)Document13 pages14-P-141-80 (TLine Earthwire Fittings)Ahsan SNNo ratings yet

- AA00220 PC400-6 (Refuerzos PC400-6)Document11 pagesAA00220 PC400-6 (Refuerzos PC400-6)joaquin suarezNo ratings yet

- E00804 Commercial Building For MRCB Technical OfferDocument8 pagesE00804 Commercial Building For MRCB Technical OfferkirubaNo ratings yet

- Welding ManualDocument49 pagesWelding ManualMitesh Kumar100% (1)

- Pig Launchers Recievers PDFDocument9 pagesPig Launchers Recievers PDFgalih santosoNo ratings yet

- TCM Torque SB96 7DDocument14 pagesTCM Torque SB96 7DИван КоньковNo ratings yet

- Visual 003 PDFDocument3 pagesVisual 003 PDFashadNo ratings yet

- 1) ATRIUM-CAL-002 - Connection Calculations (23!09!2015 Updated)Document39 pages1) ATRIUM-CAL-002 - Connection Calculations (23!09!2015 Updated)Suresh DNo ratings yet

- FlatLOK TER 1501 08 0719Document10 pagesFlatLOK TER 1501 08 0719Ryan McKinneyNo ratings yet

- SN017 NCCI Shear Resistance of A Fin Plate ConnectionDocument13 pagesSN017 NCCI Shear Resistance of A Fin Plate ConnectionDJordje JovanovicNo ratings yet

- Designandconstructionofroofsusing Precast Reinforced Concrete L-Panels-CodeofpracticeDocument8 pagesDesignandconstructionofroofsusing Precast Reinforced Concrete L-Panels-CodeofpracticeGrv SrmNo ratings yet

- Welding Procedure - A - PDFDocument60 pagesWelding Procedure - A - PDFMade Agus BudiarthaNo ratings yet

- OPSS 919 - Nov11Document17 pagesOPSS 919 - Nov11umerfr2No ratings yet

- Recommended Design Model Beam Welds Design Check No 1 Design Capacity of Flange Welds To Beam - DG11Document6 pagesRecommended Design Model Beam Welds Design Check No 1 Design Capacity of Flange Welds To Beam - DG11perdhana2000No ratings yet

- STPE600 - Dadi A ProiezioneDocument17 pagesSTPE600 - Dadi A ProiezioneLucaNo ratings yet

- Picture Book Index/Checklist For Pipe Handler PH-60 and PH-85Document17 pagesPicture Book Index/Checklist For Pipe Handler PH-60 and PH-85HayLenLeeNo ratings yet

- Recommended Practice FOR Welded Fabrication in Wagons: Government of India Ministry of RailwaysDocument75 pagesRecommended Practice FOR Welded Fabrication in Wagons: Government of India Ministry of RailwaysAMIT KUMAR100% (1)

- FBW Manual-Jan 2012-Revised and Corrected CS2Document68 pagesFBW Manual-Jan 2012-Revised and Corrected CS2Dinesh CandassamyNo ratings yet

- Fabrication and Site Handling of Reinforcing BarsDocument9 pagesFabrication and Site Handling of Reinforcing BarsTiago Lamy SilvaNo ratings yet

- Ancon MBT Couplers International VersionDocument14 pagesAncon MBT Couplers International Versionjcunha4740No ratings yet

- Ancon Tapered Thread Couplers International Version PDFDocument16 pagesAncon Tapered Thread Couplers International Version PDFAhmadHamdyNo ratings yet

- Amcr MidtermsDocument116 pagesAmcr MidtermsTIP EducationNo ratings yet

- 407-19-23 July 2019Document9 pages407-19-23 July 2019turboshaftNo ratings yet

- ASB 412-00-106 - Tail Rotor (T - R) Blade 212-010-750-009 - 011 - 105 - 107 Tip Block Retention Modification Rev. D - 18-Mar-2005Document9 pagesASB 412-00-106 - Tail Rotor (T - R) Blade 212-010-750-009 - 011 - 105 - 107 Tip Block Retention Modification Rev. D - 18-Mar-2005yu gangNo ratings yet

- ADCO Amendments 30-99-12-3207 Rev.1 To DEP 31.38.01.31 Steel Piping 2013...Document22 pagesADCO Amendments 30-99-12-3207 Rev.1 To DEP 31.38.01.31 Steel Piping 2013...aymanNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- 032 - SECTION 5 - WELD MAP Rev01Document5 pages032 - SECTION 5 - WELD MAP Rev01Mohd Effiezool YaserNo ratings yet

- MTW HI-FORCE 201700149 85-525N.m 14 JAN 23Document2 pagesMTW HI-FORCE 201700149 85-525N.m 14 JAN 23Mohd Effiezool YaserNo ratings yet

- Job Pack Standardized Format Rev2 - SF Duct Burner View Port Repair InsulationDocument14 pagesJob Pack Standardized Format Rev2 - SF Duct Burner View Port Repair InsulationMohd Effiezool YaserNo ratings yet

- Proposed PipeDocument1 pageProposed PipeMohd Effiezool YaserNo ratings yet

- Stiffener ProposalDocument2 pagesStiffener ProposalMohd Effiezool YaserNo ratings yet

- B Detail: Piping Isometric BuildingDocument1 pageB Detail: Piping Isometric BuildingMohd Effiezool YaserNo ratings yet

- New Stiffener Size - 01Document1 pageNew Stiffener Size - 01Mohd Effiezool YaserNo ratings yet

- 5S4 Pipe Support DrawingDocument1 page5S4 Pipe Support DrawingMohd Effiezool YaserNo ratings yet

- PTS Vs IP & JotunDocument8 pagesPTS Vs IP & JotunMohd Effiezool YaserNo ratings yet

- MTW KING TOYO 438745 50-300N.m 14 JAN 23Document2 pagesMTW KING TOYO 438745 50-300N.m 14 JAN 23Mohd Effiezool YaserNo ratings yet

- Pipe Bend ReportDocument1 pagePipe Bend ReportMohd Effiezool Yaser100% (1)

- Bfja Tag Critical A4Document2 pagesBfja Tag Critical A4Mohd Effiezool YaserNo ratings yet

- MTW NOVATORK AR040983 20-100N.m 12 OCT 22Document2 pagesMTW NOVATORK AR040983 20-100N.m 12 OCT 22Mohd Effiezool YaserNo ratings yet

- 001-FP 001Document2 pages001-FP 001Mohd Effiezool YaserNo ratings yet

- NRF 002Document1 pageNRF 002Mohd Effiezool YaserNo ratings yet

- 30lbe51br001-Rev 2 - 2Document1 page30lbe51br001-Rev 2 - 2Mohd Effiezool YaserNo ratings yet

- PCP Sag Pip DWG 480460Document2 pagesPCP Sag Pip DWG 480460Mohd Effiezool YaserNo ratings yet

- 30LBF11BR411 - 1Document1 page30LBF11BR411 - 1Mohd Effiezool YaserNo ratings yet

- TP1 - 04464539030100 - PCP Sag Pip DWG Lbe 47109001Document1 pageTP1 - 04464539030100 - PCP Sag Pip DWG Lbe 47109001Mohd Effiezool YaserNo ratings yet

- 30lbf11br001-Rev 2Document1 page30lbf11br001-Rev 2Mohd Effiezool YaserNo ratings yet

- 30lae25br005-Rev 2Document1 page30lae25br005-Rev 2Mohd Effiezool YaserNo ratings yet

- Markup Finding CCC (Insulated)Document1 pageMarkup Finding CCC (Insulated)Mohd Effiezool YaserNo ratings yet

- Markup Finding PCC (Insulated)Document1 pageMarkup Finding PCC (Insulated)Mohd Effiezool YaserNo ratings yet

- Jotun LatterDocument1 pageJotun LatterMohd Effiezool YaserNo ratings yet

- Markup Finding PL (Insulated)Document1 pageMarkup Finding PL (Insulated)Mohd Effiezool YaserNo ratings yet

- Welding Olet As ASME B31.3Document1 pageWelding Olet As ASME B31.3Mohd Effiezool YaserNo ratings yet

- SCH PipeDocument1 pageSCH PipeMohd Effiezool YaserNo ratings yet

- Mandatory Appendix 5 - Guideline On The Approval of New Materials Under The ASME BPV CodeDocument4 pagesMandatory Appendix 5 - Guideline On The Approval of New Materials Under The ASME BPV CodeMohd Effiezool YaserNo ratings yet

- Yellow Illustrative Digital Education For Children InfographicDocument1 pageYellow Illustrative Digital Education For Children InfographicNur Azimah AzibNo ratings yet

- Item Part No Location No - Available No. Used Remaining Min No. Required Reordered No Cost Per Item Total CostDocument1 pageItem Part No Location No - Available No. Used Remaining Min No. Required Reordered No Cost Per Item Total CostRockyNo ratings yet

- Demography Is The: Statistical Study Human PopulationDocument17 pagesDemography Is The: Statistical Study Human PopulationYash SejpalNo ratings yet

- 10 1039@d0mh00081gDocument20 pages10 1039@d0mh00081gHuấn BùiNo ratings yet

- Spare Parts Catalogue: AXLE 26.18 - (CM8118) REF: 133821Document8 pagesSpare Parts Catalogue: AXLE 26.18 - (CM8118) REF: 133821Paulinho InformáticaNo ratings yet

- 13.4.2 WBS 6.6 Cerberus Corperation Case Study Managing Stakeholder ConflictDocument7 pages13.4.2 WBS 6.6 Cerberus Corperation Case Study Managing Stakeholder ConflictJorge Alejandro Betancur JaramilloNo ratings yet

- Solution To Microwave Engineering Pozar Chapter 14 Exercise 17 With MATLABDocument3 pagesSolution To Microwave Engineering Pozar Chapter 14 Exercise 17 With MATLABJohn Bofarull GuixNo ratings yet

- Flood Precast - Super Wideslab Load Span TablesDocument1 pageFlood Precast - Super Wideslab Load Span TablesRaymond KinnairdNo ratings yet

- Analiza C. Cortes 20 ItemsDocument6 pagesAnaliza C. Cortes 20 ItemsEngel AlardeNo ratings yet

- Interactive Physics ManualDocument13 pagesInteractive Physics ManualMarciano SantamaríaNo ratings yet

- RFQ-97 For Supply of Biscuit & Soap-2Document1 pageRFQ-97 For Supply of Biscuit & Soap-2Prodip Debnath NayanNo ratings yet

- Chechk List Fokker 50Document1 pageChechk List Fokker 50Felipe PinillaNo ratings yet

- Process Flow ChartDocument22 pagesProcess Flow ChartKumar Ashutosh100% (1)

- SociologyDocument185 pagesSociologyHansraj shahNo ratings yet

- Zen and The ArtDocument3 pagesZen and The ArtMaria GonzálezNo ratings yet

- ECE 5325/6325 Fall 2009: Exam 1 SolutionsDocument2 pagesECE 5325/6325 Fall 2009: Exam 1 Solutionswilfred godfreyNo ratings yet

- Be RealDocument3 pagesBe RealТатьяна СоколоваNo ratings yet

- 11th English BE Confident 5 Test Questions With Answer PDF DownloadDocument57 pages11th English BE Confident 5 Test Questions With Answer PDF Downloadbsai2749No ratings yet

- 13-GB 50018-2002-EnDocument109 pages13-GB 50018-2002-Enyyyy071220100% (1)

- Lab6 Phase Locked LoopsDocument20 pagesLab6 Phase Locked Loopsuitce2011No ratings yet

- Os Past Papers' Solutions 2017Document4 pagesOs Past Papers' Solutions 2017zainab tehreemNo ratings yet

- Razones de CambioDocument1 pageRazones de CambioCarlos FloresNo ratings yet

- Solution of Assignment 5Document5 pagesSolution of Assignment 5Reza Borah100% (1)

- Free - Space W - Band Setup For The Electrical Characterization of Materials and MM - Wave ComponentsDocument44 pagesFree - Space W - Band Setup For The Electrical Characterization of Materials and MM - Wave ComponentsthomasNo ratings yet

- Newsela - A New Boredom Study Is Anything But BoringDocument3 pagesNewsela - A New Boredom Study Is Anything But Boringafolden91683No ratings yet

- SCIETECHNODocument19 pagesSCIETECHNOChini ChanNo ratings yet

- Application of Irradiation For Food Preservation: Seminar ONDocument19 pagesApplication of Irradiation For Food Preservation: Seminar ONPrashant KumarNo ratings yet

- GeoGauge - Verifier Mass GuideDocument4 pagesGeoGauge - Verifier Mass GuideOmar CarlosNo ratings yet

- RRLsDocument6 pagesRRLsRobot RobotNo ratings yet