Professional Documents

Culture Documents

08.03.04-Quality Assurance of Materials - Approval of Source-R2

08.03.04-Quality Assurance of Materials - Approval of Source-R2

Uploaded by

tanmayascribdOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

08.03.04-Quality Assurance of Materials - Approval of Source-R2

08.03.04-Quality Assurance of Materials - Approval of Source-R2

Uploaded by

tanmayascribdCopyright:

Available Formats

Quality Assurance of Materials - Approval of

Tata Projects Limited Source

L3 E

OBJECTIVE:

To ensure the Quality of Materials sourced locally at site (Fine & Course Aggregate, Ballast and Blanket

Material etc.,) at the Source and conforming to the requirements as per customer specifications / relevant

standards as a pre-purchase activity.

SCOPE:

Applicable to all project sites.

PROCESS OWNERSHIP:

Head QSS-Quality

REPORTING & MEASURES

Who will Review

What will be measured Description of Measure How Often?

measure Forum

% of inspections attended Material Inspections SBU Quality

within stipulated time (as per attended for source Lead Monthly DRM

Internal norms) approval QSS-Quality

% of inspections attended by Material Inspections SBU Quality

Customer within stipulated time attended by Customer for Lead Monthly DRM

(as per Contract) source approval QSS-Quality

SBU Quality

RFICs rejected by

% of RFICs rejected Lead Monthly DRM

Customer

QSS-Quality

Efficiency Measure Effectiveness Measure

Process No: 08.03.04/R1 Ver date: 24.11.21 Page no.: 1 of 4

Format No. 02.01.01 F-05 R2

Tata Projects Limited Quality Assurance of Materials - Approval of Source

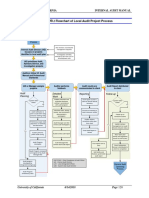

PROCESS FLOWCHART & ACTIVITY: (L3 Level)

Flow Chart Activity Owner

Start

Cust Specs,

relevant Receipt of Request for Inspection & Clearance SCM/ Projects /

Codes / Receipt of RFIC

Standards (RFIC) from SCM / Projects / Vendor / Vendor/

Manufacturer by FQE Manufacturer

B

Customer

Approved List

FQE shall check the availability of Customer

D and source approved list including the Name of the proposed FQE

NO Name is source

available?

Yes

NO Customer FQE shall check whether Joint inspection along

FQE

C inspection with Customer is required or not

required

Yes

Coordinate for FQE shall coordinate with Customer and

Customer's Visit FQE

organize customer's visit.

FQE shall coordinate with Projects for inspection

documents and visit Vendor / Manufacturer place

C Conduct Inspection for Joint inspection with Customer. If Customer FQE

inspection is not required, carry out physical

inspection

Reject

Inform SCM /

Inspection

On completion of physical inspection, FQE shall

Projects with generate Inspection Report (IR) with conclusion FQE

Reasons

Result

(Accepted / Rejected).

IR Accept

FQE shall coordinate for collection of samples

Arrange for testing and arrange for testing at Internal / Third Party FQE

Labs

Process No: 08.03.04/R1 Ver date: 24.11.21 Page no.: 2 of 4

Format No. 02.01.01 F-05 R2

Tata Projects Limited Quality Assurance of Materials - Approval of Source

PROCESS FLOWCHART & ACTIVITY :

Flow Chart Activity Owner

Inform SCM / Reject

On completion of the testing, FQE shall generate

Projects with Test Result

Reasons Inspection Report (IR) with conclusion (Accepted FQE

/ Rejected).

Accept

IR

FQE shall forward the IR along with closed RFIC

Forward the IR along to SCM / Projects for enabling procurement of the

with closed RFIC to FQE

SCM / Projects material and updating the master list of approved

sources.

End

FQE shall Obtain provisional approval for

Obtain provisional approval carrying out inspection of proposed new source FQE

for carrying out inspection

of proposed new source

FQE shall coordinate with Customer for Joint

Cancel inspection inspection if the acceptance is received. In

Client's

call and inform No

acceptance case of rejection FQE shall communicate to SCM FQE

SCM / Project to

for Joint / Projects for cancelling the inspection call and

raise fresh

inspection call

Inspection identify alternate source

Yes

Process No: 08.03.04/R1 Ver date: 24.11.21 Page no.: 3 of 4

Format No. 02.01.01 F-05 R2

Tata Projects Limited Quality Assurance of Materials - Approval of Source

CRITERIA / GUIDELINES / CHECKLIST USED IN THIS PROCESS:

Customer Specifications

Relevant Codes / Standards

FORMATS / REPORTS MAINTAINED:

Format No.08-03-05-FMT-G-QAC-QC-004-R00 - REQUEST FOR INSPECTION & CLERANCE (RFIC)

Note: Any revision / addition in the formats shall be updated and communicated promptly

SIPOC Table:

Supplier EPM

Supplier Input Output Customer Customer EPM

Process No.

(S) (I) (O) (C) Process No.

(P)

Vendor/

End Customer /

Manufacturer / RFIC 08.03.04 RFIC & IR 14.02.02/ 09.01

Projects

Projects / SCM

Process No: 08.03.04/R1 Ver date: 24.11.21 Page no.: 4 of 4

Format No. 02.01.01 F-05 R2

You might also like

- C1 (1 - Storey Roof Sheets)Document11 pagesC1 (1 - Storey Roof Sheets)John Michael TalanNo ratings yet

- 5.7 - Non-Conforming Material & Product Control Procedure.Document1 page5.7 - Non-Conforming Material & Product Control Procedure.Md.Akidul Islam AkidNo ratings yet

- ANPQP - Supplier Feasibility Commitment: Renault Project: Document Reference No / VersionDocument1 pageANPQP - Supplier Feasibility Commitment: Renault Project: Document Reference No / Versionjefry sitorusNo ratings yet

- Halonix Technologies Private Limited Supplier Audit Check SheetDocument1 pageHalonix Technologies Private Limited Supplier Audit Check Sheetatul sachanNo ratings yet

- Estimating Process Section 11: Quality Assurance ManualDocument4 pagesEstimating Process Section 11: Quality Assurance ManualNgonidzashe ZvarevasheNo ratings yet

- Audit Planning Matrix: PT EssentraDocument4 pagesAudit Planning Matrix: PT EssentraHerik RenaldoNo ratings yet

- BRSM Form 009 QMSMDD PazDocument17 pagesBRSM Form 009 QMSMDD PazAnonymous q8lh3fldWMNo ratings yet

- Audit Check List WP 16 WI 01Document11 pagesAudit Check List WP 16 WI 01milind bedarkarNo ratings yet

- Jipl CL Pur 10 Testing Lab AuditDocument8 pagesJipl CL Pur 10 Testing Lab AuditMeghna SharmaNo ratings yet

- MSP - MR - 03 Internal AuditDocument6 pagesMSP - MR - 03 Internal AuditsharanNo ratings yet

- Process Check ListDocument5 pagesProcess Check Listapi-338883409No ratings yet

- 2016 Functional ObjectivesDocument8 pages2016 Functional ObjectivesHILLARY YOLANDANo ratings yet

- 9001 Audit Checklist - Quality Planning and DesignDocument14 pages9001 Audit Checklist - Quality Planning and DesignAmer RahmahNo ratings yet

- Management Review Meeting Report - 03Document2 pagesManagement Review Meeting Report - 03Claire TanNo ratings yet

- System Audit Check SheetDocument8 pagesSystem Audit Check SheetFINAL QUALITYNo ratings yet

- Audit ItineraryDocument1 pageAudit Itinerarytony sNo ratings yet

- ISO 9001:2008 ISO/TS 16949:2009 Added Requirement: 0.5 Goal of This Technical SpecificationDocument52 pagesISO 9001:2008 ISO/TS 16949:2009 Added Requirement: 0.5 Goal of This Technical Specificationsupady5751No ratings yet

- Process Audit VDA-6 3-2010 - enDocument40 pagesProcess Audit VDA-6 3-2010 - enRohini GadhaweNo ratings yet

- Management Review Agenda and Minutes: M: Name Title Here Name Title HereDocument5 pagesManagement Review Agenda and Minutes: M: Name Title Here Name Title HereTrivesh SharmaNo ratings yet

- Lab Audit ChecklistDocument1 pageLab Audit ChecklistPon ShanmugakumarNo ratings yet

- Notes Taken During 3 July APQP PPAP ClassDocument2 pagesNotes Taken During 3 July APQP PPAP Classrosemarie tolentinoNo ratings yet

- 6000 Appendix 6000.: 2 Flowchart of Local Audit Project ProcessDocument1 page6000 Appendix 6000.: 2 Flowchart of Local Audit Project ProcessNiken RindasariNo ratings yet

- Process Flow ChartDocument2 pagesProcess Flow ChartBASAVA ENGINEERINGNo ratings yet

- CounterfeitDocument5 pagesCounterfeitVivek GoudNo ratings yet

- APP I Customer Satisfaction Survey - v0 - Syafik ReviewDocument1 pageAPP I Customer Satisfaction Survey - v0 - Syafik ReviewSyafik JaafarNo ratings yet

- Documents File IndexDocument1 pageDocuments File IndexMeet VermaaNo ratings yet

- Anicon Flowcontrols LLP Procedure: Procedure Name Department Responsibility Clause NO Target DateDocument9 pagesAnicon Flowcontrols LLP Procedure: Procedure Name Department Responsibility Clause NO Target DateAnicon Flowcontols llpNo ratings yet

- SYS Procedure - Internal Quality Audit P1Document1 pageSYS Procedure - Internal Quality Audit P1sumanNo ratings yet

- Qa QC File IndexDocument1 pageQa QC File IndexAthma SNo ratings yet

- Post DeliveryDocument1 pagePost DeliveryXionNo ratings yet

- ISO 9001:2000 IN A NUTSHELL (First Revision)Document5 pagesISO 9001:2000 IN A NUTSHELL (First Revision)nallasivam v100% (1)

- Stallion Auto Parts PVT - LTD Contingency PlanDocument2 pagesStallion Auto Parts PVT - LTD Contingency PlanStallion Auto Parts P. Ltd.No ratings yet

- 10.1 ImprovementDocument8 pages10.1 ImprovementVijayendran VijayNo ratings yet

- Customer Satisfaction Process PDFDocument1 pageCustomer Satisfaction Process PDFmilou88No ratings yet

- Form - Scar LogDocument18 pagesForm - Scar LogHarie BongkyNo ratings yet

- APS-WP-15 Process Validation ProcedureDocument24 pagesAPS-WP-15 Process Validation Procedureshobha shelarNo ratings yet

- RC 2022 Summary CAFDDocument4 pagesRC 2022 Summary CAFDEjazNo ratings yet

- 14 - P11 Production Scheduling and Planning Process-May'17Document9 pages14 - P11 Production Scheduling and Planning Process-May'17Rohini GadhaweNo ratings yet

- Risk Register Template 47Document9 pagesRisk Register Template 47shinto LawrenceNo ratings yet

- 12 MGD MRM Report Jan-2020Document156 pages12 MGD MRM Report Jan-2020Manish KaushikNo ratings yet

- SQMP ManualDocument81 pagesSQMP ManualAnkita DwivediNo ratings yet

- QMS-SOP-F15 - Procedure For Control of Document InformationDocument4 pagesQMS-SOP-F15 - Procedure For Control of Document InformationPINTU RAJNo ratings yet

- 04 Control of Calibrated Equipment SOPDocument8 pages04 Control of Calibrated Equipment SOPKamalakar KaramchetiNo ratings yet

- KerepeanDocument12 pagesKerepeansyeila_elmiaNo ratings yet

- Self Evaluation Form - FY19 - FinalDocument3 pagesSelf Evaluation Form - FY19 - FinalVijay TamboliNo ratings yet

- IMS-FM013-02 OHSE Risk Assessment FormDocument4 pagesIMS-FM013-02 OHSE Risk Assessment FormYounisQamarNo ratings yet

- QSP 415 01 CommunicationDocument7 pagesQSP 415 01 CommunicationMacelNo ratings yet

- P-03 Procedure For Rework 2Document2 pagesP-03 Procedure For Rework 2sharif1974No ratings yet

- (QSP-MR-02) Control RecordsDocument2 pages(QSP-MR-02) Control RecordsBASAVA ENGINEERING100% (1)

- Title: Context of The Organisation Requirements (Issues/Needs/Expectations)Document2 pagesTitle: Context of The Organisation Requirements (Issues/Needs/Expectations)rohini kadamNo ratings yet

- Dell QSA Audit Checklist - CNDocument52 pagesDell QSA Audit Checklist - CNMichael WuNo ratings yet

- CSL P5-007229 AuditReportDocument5 pagesCSL P5-007229 AuditReportIdrus IsmailNo ratings yet

- Quality Policy and Quality ObjectivesDocument2 pagesQuality Policy and Quality ObjectivesrabiulfNo ratings yet

- RMR-HSMS-P-014 OHS Management System Internal AuditDocument5 pagesRMR-HSMS-P-014 OHS Management System Internal AuditkamranNo ratings yet

- Procedure For Material Requirement Planning & PurchasingDocument1 pageProcedure For Material Requirement Planning & PurchasingHarkesh KumarNo ratings yet

- Request For Inspection:: EmployerDocument2 pagesRequest For Inspection:: Employerhovael laboratoryNo ratings yet

- PUR-F-SPR - Supplier Performance RatingDocument4 pagesPUR-F-SPR - Supplier Performance RatingRajkumar PrajapatiNo ratings yet

- 9.3 Procedure For Management ReviewDocument7 pages9.3 Procedure For Management ReviewValantina JamilNo ratings yet

- Job & ResponsibilityDocument9 pagesJob & ResponsibilityKerri Unklebeach100% (1)

- ASP-NPD-04 (Process of Product Safety)Document5 pagesASP-NPD-04 (Process of Product Safety)akash.vd.1603No ratings yet

- HSE Checks-Management CriteriaDocument9 pagesHSE Checks-Management CriteriatanmayascribdNo ratings yet

- Field Quality PlanDocument1 pageField Quality PlantanmayascribdNo ratings yet

- Sizing For CableDocument32 pagesSizing For CabletanmayascribdNo ratings yet

- Jalsu Battery DetailsDocument3 pagesJalsu Battery DetailstanmayascribdNo ratings yet

- Capacitor Bank On THD 1682220893Document3 pagesCapacitor Bank On THD 1682220893tanmayascribdNo ratings yet

- 168 التنمية المستدامةDocument267 pages168 التنمية المستدامةAbdelhafid FerroudjNo ratings yet

- Diagram of 6 Steps in ISO 27001/ISO 27005 Risk ManagementDocument1 pageDiagram of 6 Steps in ISO 27001/ISO 27005 Risk ManagementJosé LagosNo ratings yet

- HEU Water Bags ChinaDocument4 pagesHEU Water Bags ChinaPWkannonNo ratings yet

- Tef Impact Report 2022Document164 pagesTef Impact Report 2022KIEFFOLOH BENJAMINNo ratings yet

- MGT 423Document4 pagesMGT 423Ajmal AftabNo ratings yet

- Procurement Assignment 1Document9 pagesProcurement Assignment 1Muhammad JahenzebNo ratings yet

- CAED101 - DE CASTRO - ACN1 - Network Model Transshipment Problem QuizDocument3 pagesCAED101 - DE CASTRO - ACN1 - Network Model Transshipment Problem QuizIra Grace De CastroNo ratings yet

- Assignment - Quiz (COGS)Document2 pagesAssignment - Quiz (COGS)Mohsin AliNo ratings yet

- Risk Metrics SolvedDocument20 pagesRisk Metrics SolvedHimanshi gargNo ratings yet

- Atalay Et Al (2014)Document77 pagesAtalay Et Al (2014)Taila SouzaNo ratings yet

- Strategy Implementation and Resource AllocationDocument9 pagesStrategy Implementation and Resource AllocationRaj Shravanthi100% (1)

- Nicks (India) Tools Unit-II Khakat: Quality Management System AuditDocument1 pageNicks (India) Tools Unit-II Khakat: Quality Management System Auditrajesh sharmaNo ratings yet

- IAESB International Education Standards BrochureDocument16 pagesIAESB International Education Standards BrochureeveNo ratings yet

- ReFirmance ReviewDocument4 pagesReFirmance ReviewAntonio AbreuNo ratings yet

- MMETitle and Cert Edorsement PageDocument3 pagesMMETitle and Cert Edorsement Pageaeron antonioNo ratings yet

- Chapter 11 Summary OMDocument5 pagesChapter 11 Summary OMKarthik SaiNo ratings yet

- ANSWERS Module 4 - PRACTICE EXAMDocument66 pagesANSWERS Module 4 - PRACTICE EXAMMahesh Chandra DixitNo ratings yet

- A Study On Supply Chain Management in Construction: Literature ReviewDocument5 pagesA Study On Supply Chain Management in Construction: Literature ReviewMoidin AfsanNo ratings yet

- MCDONALDSNEDERLAND Jaarrekening 2021Document34 pagesMCDONALDSNEDERLAND Jaarrekening 2021jackstone35.jsNo ratings yet

- C.V Sukhpal Singh 1.02.21Document5 pagesC.V Sukhpal Singh 1.02.21Issac JohnNo ratings yet

- Principles of Management II: Chapter Nine: Quality Management Lecturer: Dr. Mazen RohmiDocument33 pagesPrinciples of Management II: Chapter Nine: Quality Management Lecturer: Dr. Mazen Rohmihasan jabrNo ratings yet

- 2009 KPI Branch - Meeter GreeterDocument2 pages2009 KPI Branch - Meeter GreeterMohd Jamal Khir IsmailNo ratings yet

- DM 1591541524857400Document17 pagesDM 1591541524857400Maro MeroNo ratings yet

- Entrepreneurship Assessment Week 1 To 4 Q 1Document2 pagesEntrepreneurship Assessment Week 1 To 4 Q 1YricaCastleNo ratings yet

- Kusi 2401-4-PBDocument110 pagesKusi 2401-4-PBkusmanaa64No ratings yet

- Artikel Perusahaan ManufakturDocument9 pagesArtikel Perusahaan ManufakturClone SideNo ratings yet

- Strategy Implementation: Organizing For Action: Powerpoint Slides Anthony F. Chelte Western New England CollegeDocument35 pagesStrategy Implementation: Organizing For Action: Powerpoint Slides Anthony F. Chelte Western New England CollegeshebisanaNo ratings yet

- E - Jurnal Riset Manajemen Fakultas Ekonomi Dan Bisnis Unisma WebsiteDocument13 pagesE - Jurnal Riset Manajemen Fakultas Ekonomi Dan Bisnis Unisma Websitegadis rantiNo ratings yet

- Afar MaterialsDocument4 pagesAfar MaterialsCheese Butter0% (1)