Professional Documents

Culture Documents

Production Management I

Production Management I

Uploaded by

bhaveshCopyright:

Available Formats

You might also like

- Full Download Solution Manual For Discrete Mathematics With Applications 5th Edition Susanna S Epp PDF Full ChapterDocument36 pagesFull Download Solution Manual For Discrete Mathematics With Applications 5th Edition Susanna S Epp PDF Full Chapterrabate.toiler.vv5s092% (24)

- Opera Cloud User ManualDocument1,018 pagesOpera Cloud User ManualRooban GNo ratings yet

- BA 7201 Operations ManagementDocument10 pagesBA 7201 Operations ManagementSam RenuNo ratings yet

- OM Study Guide Lessons 1-12Document122 pagesOM Study Guide Lessons 1-12bingyang75% (4)

- OM Question Bank I BADocument8 pagesOM Question Bank I BAS Gayathri Vels UniversityNo ratings yet

- BUS 301 Lecture NoteDocument35 pagesBUS 301 Lecture NoteAlo EbenezerNo ratings yet

- POM - Question BankDocument2 pagesPOM - Question BankDarshan PandyaNo ratings yet

- Module-1 Chapter-1Document3 pagesModule-1 Chapter-1Megha100% (1)

- Operation Management Ignou NotesDocument165 pagesOperation Management Ignou NotesanandNo ratings yet

- Applied Operation ResearchDocument340 pagesApplied Operation Researchfuad abduNo ratings yet

- RB NIE OM Unit 6 2020-21Document54 pagesRB NIE OM Unit 6 2020-21RajajiNo ratings yet

- Week 4: Operations Management and Inventory Management: Foundations of Management 2 (MG 459)Document46 pagesWeek 4: Operations Management and Inventory Management: Foundations of Management 2 (MG 459)jie.ji3No ratings yet

- تطبيقات ادارة الانتاج انجليزىDocument7 pagesتطبيقات ادارة الانتاج انجليزىobadfaisal24No ratings yet

- Dps 502 Inventory Management Feb 23 2012Document153 pagesDps 502 Inventory Management Feb 23 2012jaminkwadNo ratings yet

- Operation Management NotesDocument29 pagesOperation Management NotesAbhishek PathakNo ratings yet

- Mba-Question PapersDocument33 pagesMba-Question PaperspawanNo ratings yet

- Production and Operation ManagementDocument2 pagesProduction and Operation ManagementGokul KabaraNo ratings yet

- Production Management Complete Notes-1Document92 pagesProduction Management Complete Notes-1divya08kapoorNo ratings yet

- BUS2113 OM Module Book (Oct 22)Document125 pagesBUS2113 OM Module Book (Oct 22)Haymant Srivastava100% (1)

- PNOM Final Rsaghu SlovedDocument38 pagesPNOM Final Rsaghu SlovedGokul KarwaNo ratings yet

- DOM102 Principles of Operations ManagementDocument68 pagesDOM102 Principles of Operations ManagementALEX ONGERENo ratings yet

- Faculty of Mechanical and Industrial EngineeringDocument10 pagesFaculty of Mechanical and Industrial EngineeringSalvatore PapaNo ratings yet

- Mba236: Operations Management: S. No Topic NoDocument26 pagesMba236: Operations Management: S. No Topic Noanonymousfan101No ratings yet

- OM Question BankDocument5 pagesOM Question BankViraja GuruNo ratings yet

- Operation Management Notes 130126072649 Phpapp02 PDFDocument30 pagesOperation Management Notes 130126072649 Phpapp02 PDFBalu ANo ratings yet

- First Chapter: IntroductionDocument3 pagesFirst Chapter: IntroductionMominul MominNo ratings yet

- Questions 5105Document3 pagesQuestions 5105Mominul MominNo ratings yet

- Sample Plan1Document6 pagesSample Plan1htjritNo ratings yet

- Ie8693 Production Planning and Control Reg 17 Question BankDocument9 pagesIe8693 Production Planning and Control Reg 17 Question BankSathya prakashNo ratings yet

- IARE PPC Lecture NotesDocument65 pagesIARE PPC Lecture NotesJaveed802No ratings yet

- OM-Unit 1 and 2-NotesDocument102 pagesOM-Unit 1 and 2-NotesDEV BHADANANo ratings yet

- Operation Management SyllabusDocument2 pagesOperation Management SyllabusPiyush Singh RajputNo ratings yet

- Faculty E-Notes - Unit 3 Production and Material ManagementDocument32 pagesFaculty E-Notes - Unit 3 Production and Material Managementgargnipun16No ratings yet

- Module 1Document3 pagesModule 1Srinivasan KrishanmoorthyNo ratings yet

- Operations Management Question BankDocument4 pagesOperations Management Question BankViraja Guru50% (2)

- Retail Store ManagementDocument11 pagesRetail Store ManagementTanisha AgarwalNo ratings yet

- e437bPRODUCTION AND OPERATIONS MANAGEMENTDocument2 pagese437bPRODUCTION AND OPERATIONS MANAGEMENTAkhand RanaNo ratings yet

- B.Tech Iv Year-Ii Sem: Malla Reddy College of Engineering &technologyDocument54 pagesB.Tech Iv Year-Ii Sem: Malla Reddy College of Engineering &technologyTinsae AdaneNo ratings yet

- Om & SCM Mba AimsDocument75 pagesOm & SCM Mba Aimsbhupesh joshi100% (1)

- Om & SCM Mba AimsDocument75 pagesOm & SCM Mba Aimsbhupesh joshiNo ratings yet

- Chapter 4 - MATERIALS MANAGEMENTDocument32 pagesChapter 4 - MATERIALS MANAGEMENTMoqsud AminNo ratings yet

- Operation Management NotesDocument30 pagesOperation Management Notesthamizt72% (18)

- Internal Processes Part 1: Managing OperationsDocument13 pagesInternal Processes Part 1: Managing OperationsJedi DuenasNo ratings yet

- Details Module - Production and Operations ManagementDocument113 pagesDetails Module - Production and Operations ManagementTafsir HossainNo ratings yet

- Draft Project Report Dhiraj ChavanDocument63 pagesDraft Project Report Dhiraj ChavanMayuri PotdarNo ratings yet

- Course Pack - Operations ManagementDocument34 pagesCourse Pack - Operations ManagementSARBIKPAUL CHOWDHURYNo ratings yet

- QB PPCDocument45 pagesQB PPCA. ANBU RAJ Mech - Asst.ProfNo ratings yet

- 8509Document8 pages8509Mudassar SaqiNo ratings yet

- OM Notes - FairDocument92 pagesOM Notes - FairPrabhamohanraj MohanrajNo ratings yet

- MBA Sem II-OM-NotesDocument80 pagesMBA Sem II-OM-Notesankitborkar81No ratings yet

- Industrial Management &entrepreneurshipDocument24 pagesIndustrial Management &entrepreneurship17ECER72 DEVI PRASANNANo ratings yet

- Mba 721 Operations ManagementDocument7 pagesMba 721 Operations ManagementAli MohammedNo ratings yet

- Course Outlines For Different SubjectsDocument7 pagesCourse Outlines For Different SubjectsjosephNo ratings yet

- Allama Iqbal Open University Islamabad (Department of Business Administration)Document8 pagesAllama Iqbal Open University Islamabad (Department of Business Administration)lejiy91466No ratings yet

- Allama Iqbal Open University Islamabad (Department of Business Administration)Document8 pagesAllama Iqbal Open University Islamabad (Department of Business Administration)lejiy91466No ratings yet

- Allama Iqbal Open University Islamabad (Department of Business Administration)Document8 pagesAllama Iqbal Open University Islamabad (Department of Business Administration)lejiy91466No ratings yet

- Allama Iqbal Open University Islamabad (Department of Business Administration)Document8 pagesAllama Iqbal Open University Islamabad (Department of Business Administration)lejiy91466No ratings yet

- Productions and Opearations BNU V SEM BBA NEP L NEW 1Document20 pagesProductions and Opearations BNU V SEM BBA NEP L NEW 1karthi93002No ratings yet

- Manufacturing Secret : Product Development and Intelligent Manufacturing For Flexible Automation With Odoo 17: odoo consultations, #1.1From EverandManufacturing Secret : Product Development and Intelligent Manufacturing For Flexible Automation With Odoo 17: odoo consultations, #1.1No ratings yet

- Stimulating Innovation in Products and Services: With Function Analysis and MappingFrom EverandStimulating Innovation in Products and Services: With Function Analysis and MappingNo ratings yet

- Table 1: One-Sample Kolmogorov-Smirnov TestDocument6 pagesTable 1: One-Sample Kolmogorov-Smirnov TestbhaveshNo ratings yet

- Logistics of Maruti SuzukiDocument13 pagesLogistics of Maruti SuzukibhaveshNo ratings yet

- 2017 INDIA Investment Outlook: January 2017Document7 pages2017 INDIA Investment Outlook: January 2017bhaveshNo ratings yet

- Defghgife Gqrgersgef Uvwxyz (U) V - VDVW Efgguwxzdexfzeg Efhgghggÿ) JKL Fzoopow Uvwxyz (SDocument1 pageDefghgife Gqrgersgef Uvwxyz (U) V - VDVW Efgguwxzdexfzeg Efhgghggÿ) JKL Fzoopow Uvwxyz (SbhaveshNo ratings yet

- Mukesh AmbaniDocument16 pagesMukesh AmbanibhaveshNo ratings yet

- IA BrochureDocument12 pagesIA BrochureChris WallaceNo ratings yet

- TENSYMP - Special TRACK - Climate SmartDocument1 pageTENSYMP - Special TRACK - Climate SmartMayurkumar patilNo ratings yet

- 2021 YISS - INTRODUCTION TO COMPUTER GRAPHICS - Hyunjung KimDocument3 pages2021 YISS - INTRODUCTION TO COMPUTER GRAPHICS - Hyunjung KimFung AlexNo ratings yet

- ABLRFD v1403 Summary RevisionsDocument2 pagesABLRFD v1403 Summary RevisionsMiguel AngelNo ratings yet

- 100 S Oem S: 102R Low Flow PumpheadDocument2 pages100 S Oem S: 102R Low Flow PumpheadtechniqueNo ratings yet

- PRojectDocument61 pagesPRojectAditya SalunkheNo ratings yet

- Yi PDFDocument2 pagesYi PDFAnonymous La5rPMYNo ratings yet

- Promotion Safe Med ChildrensDocument64 pagesPromotion Safe Med ChildrensAbdul khodir jaelani100% (1)

- 322 Dynamic Demographic Characteristic Slum Population in Nashik City With Special Reference From 2011Document6 pages322 Dynamic Demographic Characteristic Slum Population in Nashik City With Special Reference From 2011B-15 Keyur BhanushaliNo ratings yet

- Solar Power PlantDocument23 pagesSolar Power Plantmadhu_bedi12No ratings yet

- DB Pyranometer SMP10 en 20151208Document2 pagesDB Pyranometer SMP10 en 20151208matefucskoNo ratings yet

- LG 29FG1RL 12950 Chassis CW-62C Manual de ServicioDocument34 pagesLG 29FG1RL 12950 Chassis CW-62C Manual de Serviciopepe sanchezNo ratings yet

- Block 3Document17 pagesBlock 3Dianne ChristineNo ratings yet

- Arnold Schwarzenegger ThesisDocument4 pagesArnold Schwarzenegger Thesislanatedrummondfortwayne100% (2)

- Commercial Paper: Presented by Dharani Dharan.m Vijaya Kumar S.BDocument16 pagesCommercial Paper: Presented by Dharani Dharan.m Vijaya Kumar S.Budaya37No ratings yet

- Nature of Bivariate DataDocument39 pagesNature of Bivariate DataRossel Jane CampilloNo ratings yet

- Afrique Du Sud - Natal - Telegraph 1864-1879Document5 pagesAfrique Du Sud - Natal - Telegraph 1864-1879Hervé DenisNo ratings yet

- International Dairy Journal: D.K. Hickey, T.P. Guinee, J. Hou, M.G. WilkinsonDocument6 pagesInternational Dairy Journal: D.K. Hickey, T.P. Guinee, J. Hou, M.G. WilkinsonBianca AndreeaNo ratings yet

- Security ManagementDocument35 pagesSecurity ManagementVanessa CarreteNo ratings yet

- Ateneo Philosophy Club: Project ProposalDocument2 pagesAteneo Philosophy Club: Project ProposalArmando MataNo ratings yet

- An Experiment of DensityDocument4 pagesAn Experiment of DensitySamuel TumewaNo ratings yet

- A Review of Jet Mixing Enhancement For Aircraft Propulsion ApplicationsDocument25 pagesA Review of Jet Mixing Enhancement For Aircraft Propulsion ApplicationsJINU CHANDRANNo ratings yet

- Social Venture Inherent Constitution:: Perceptions of ValueDocument3 pagesSocial Venture Inherent Constitution:: Perceptions of ValuePallavi GuptaNo ratings yet

- Apps SynonymsDocument42 pagesApps SynonymsMuhammad Sumair100% (1)

- Wizard - School of DiabolismDocument1 pageWizard - School of DiabolismHope LaneNo ratings yet

- Intermediate Accounting Reporting and Analysis 3Rd Edition James Wahlen Full ChapterDocument67 pagesIntermediate Accounting Reporting and Analysis 3Rd Edition James Wahlen Full Chapterwilliam.rodriquez579100% (6)

- BTD Course FileDocument23 pagesBTD Course FilePrashant S HadagaliNo ratings yet

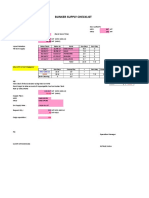

- Bunker & FW Supply ChecklistDocument3 pagesBunker & FW Supply ChecklistSampetua StmrgNo ratings yet

Production Management I

Production Management I

Uploaded by

bhaveshOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Production Management I

Production Management I

Uploaded by

bhaveshCopyright:

Available Formats

Veer N arm ad South Gujarat University

Production Management I

S.Y. B.B.A., Semester 111 Effective from June 2012

Objectives:

To expose students with the basics of Operations Management.. They should understand basic

management of manufacturing processes. They must appreciate that fundamentals of Operations

Management are also applicable to production of services. They should also understand various

aspects of production planning & control techniques. They should know various techniques of

optimum utilization of resources like time, inventory , machine etc. They should also be exposed to

quality assurance techniques.

Pedagogic Tools:

Lectures, Case studies, Practical examples from corporate & business world, assignments & presentations.

Industrial trips

Course Content:

CHAPTER 1. Introduction to Operations Management: ( 20 % )

Sr. No Sub Topic

1. Definition of Production & Introduction to Production Function

2. Definition of Operations Management. Explanation of appropriateness of term “ Operations

Management “ than “ Operations Management “

3. Scope of Operations Management at macro level. How Operations Management covers

manufacture of tangible products & also of services. Difference between tangible products

and services.

4. Scope of Operations Management at micro level or within an organization ( Responsibilities

of Production Manager )

5. Importance of Operations Management.

6. Inter-action of Operations Management with other functional areas viz. Marketing

Management, Finance Management, Personnel Management and Quality Assurance

department

7. Types of production systems. Intermittent & continuous production systems & their sub

classes

CHAPTER 2. Plant site Selection ( 20 % )

Sr. No Sub Topic

1. General idea of Plant site / location selection decision

2. Stages of Plant site selection process

3. Factors affecting plant site selection

4. Techniques & models of plant site selection.

5. Industrial concentration & its merits & de-merits. Government measures to control industrial

concentration

6. Comparison or Urban sites ( Developed areas ) & Rural sites ( Backward areas )

CHAPTER 3. Design of Plant lay-out & material handling systems (20 % )

Sr. No Sub Topic

1. Definition of Plant-layout.

2. Process of plant lay-out design

3. Various types of plant lay-outs

4. Various factors affecting the lay-out

5. Techniques of plant lay-out design

6. Definition of material handling. Four functions of material handling.

7. Factors affecting selection of material handling equipments

8 Different types of material handling equipments.

Chapter 4. Inventory Management: ( 40 % )

Sr. No Sub Topic

1. Definition of Inventory. Types of Inventory

2. Useful applications of Inventory ( Purposes of Inventory )

3. Definition of Inventory Control

4. Concept of selective inventory control & ABC analysis. Advantages & Limitations of ABC

analysis

5. VED analysis, FSN analysis & ABC X VED matrix

6. Various costs associated with acquiring & keeping inventory.

7. The concept of Economic Order Quantity to minimize total cost of Inventory. Formula of

Economic Order Quantity ( EOQ ) for basic model of Economic Order Quantity

8. Numerical problems of basic EOQ model

9. EOQ model with price discounts

10. Numerical model for EOQ with price discounts

11. EOQ model with separate consideration for storage cost & interest cost. Need to consider

storage cost & interest cost separately.

12. Need to consider storage cost & interest cost separately. Numerical problems for EOQ

model with separate consideration for storage cost & interest cost.

13 EOQ model with shortage cost.

14 Numerical problems for EOQ model with shortage

15. The concept of Economic Run Length ( ERLQ ) when item is supplied at uniform rate rather

than instantaneous supply in one lot. ERL formula derivation

16 Numerical problems for ERLQ model

17. The concept of lead time of purchasing. Understanding of Internal & External lead time

18. Concept of various stock levels viz. Re-Order Level (ROL), Safety stock, Buffer stock,

Maximum Level, Minimum Level etc.

19. Composite numerical problems with practical data. Concept of service level and probabilistic

demand. Numerical examples based on these theories.

Note:

From Chapter No. 4 Only numerical problems should be asked in final

exam.

Reference Books:

1. Operations Management- By Joseph Monks , McGraw Hill

2. Operations management - B y Everett Adams, PHI

3. Operations Management - By Martinich, PHI

4. Operations Management - By Krajewski, PHI

5. Operations Management - By William Stevenson , McGraw Hill

6. Operations Management - By Russell & Taylor

You might also like

- Full Download Solution Manual For Discrete Mathematics With Applications 5th Edition Susanna S Epp PDF Full ChapterDocument36 pagesFull Download Solution Manual For Discrete Mathematics With Applications 5th Edition Susanna S Epp PDF Full Chapterrabate.toiler.vv5s092% (24)

- Opera Cloud User ManualDocument1,018 pagesOpera Cloud User ManualRooban GNo ratings yet

- BA 7201 Operations ManagementDocument10 pagesBA 7201 Operations ManagementSam RenuNo ratings yet

- OM Study Guide Lessons 1-12Document122 pagesOM Study Guide Lessons 1-12bingyang75% (4)

- OM Question Bank I BADocument8 pagesOM Question Bank I BAS Gayathri Vels UniversityNo ratings yet

- BUS 301 Lecture NoteDocument35 pagesBUS 301 Lecture NoteAlo EbenezerNo ratings yet

- POM - Question BankDocument2 pagesPOM - Question BankDarshan PandyaNo ratings yet

- Module-1 Chapter-1Document3 pagesModule-1 Chapter-1Megha100% (1)

- Operation Management Ignou NotesDocument165 pagesOperation Management Ignou NotesanandNo ratings yet

- Applied Operation ResearchDocument340 pagesApplied Operation Researchfuad abduNo ratings yet

- RB NIE OM Unit 6 2020-21Document54 pagesRB NIE OM Unit 6 2020-21RajajiNo ratings yet

- Week 4: Operations Management and Inventory Management: Foundations of Management 2 (MG 459)Document46 pagesWeek 4: Operations Management and Inventory Management: Foundations of Management 2 (MG 459)jie.ji3No ratings yet

- تطبيقات ادارة الانتاج انجليزىDocument7 pagesتطبيقات ادارة الانتاج انجليزىobadfaisal24No ratings yet

- Dps 502 Inventory Management Feb 23 2012Document153 pagesDps 502 Inventory Management Feb 23 2012jaminkwadNo ratings yet

- Operation Management NotesDocument29 pagesOperation Management NotesAbhishek PathakNo ratings yet

- Mba-Question PapersDocument33 pagesMba-Question PaperspawanNo ratings yet

- Production and Operation ManagementDocument2 pagesProduction and Operation ManagementGokul KabaraNo ratings yet

- Production Management Complete Notes-1Document92 pagesProduction Management Complete Notes-1divya08kapoorNo ratings yet

- BUS2113 OM Module Book (Oct 22)Document125 pagesBUS2113 OM Module Book (Oct 22)Haymant Srivastava100% (1)

- PNOM Final Rsaghu SlovedDocument38 pagesPNOM Final Rsaghu SlovedGokul KarwaNo ratings yet

- DOM102 Principles of Operations ManagementDocument68 pagesDOM102 Principles of Operations ManagementALEX ONGERENo ratings yet

- Faculty of Mechanical and Industrial EngineeringDocument10 pagesFaculty of Mechanical and Industrial EngineeringSalvatore PapaNo ratings yet

- Mba236: Operations Management: S. No Topic NoDocument26 pagesMba236: Operations Management: S. No Topic Noanonymousfan101No ratings yet

- OM Question BankDocument5 pagesOM Question BankViraja GuruNo ratings yet

- Operation Management Notes 130126072649 Phpapp02 PDFDocument30 pagesOperation Management Notes 130126072649 Phpapp02 PDFBalu ANo ratings yet

- First Chapter: IntroductionDocument3 pagesFirst Chapter: IntroductionMominul MominNo ratings yet

- Questions 5105Document3 pagesQuestions 5105Mominul MominNo ratings yet

- Sample Plan1Document6 pagesSample Plan1htjritNo ratings yet

- Ie8693 Production Planning and Control Reg 17 Question BankDocument9 pagesIe8693 Production Planning and Control Reg 17 Question BankSathya prakashNo ratings yet

- IARE PPC Lecture NotesDocument65 pagesIARE PPC Lecture NotesJaveed802No ratings yet

- OM-Unit 1 and 2-NotesDocument102 pagesOM-Unit 1 and 2-NotesDEV BHADANANo ratings yet

- Operation Management SyllabusDocument2 pagesOperation Management SyllabusPiyush Singh RajputNo ratings yet

- Faculty E-Notes - Unit 3 Production and Material ManagementDocument32 pagesFaculty E-Notes - Unit 3 Production and Material Managementgargnipun16No ratings yet

- Module 1Document3 pagesModule 1Srinivasan KrishanmoorthyNo ratings yet

- Operations Management Question BankDocument4 pagesOperations Management Question BankViraja Guru50% (2)

- Retail Store ManagementDocument11 pagesRetail Store ManagementTanisha AgarwalNo ratings yet

- e437bPRODUCTION AND OPERATIONS MANAGEMENTDocument2 pagese437bPRODUCTION AND OPERATIONS MANAGEMENTAkhand RanaNo ratings yet

- B.Tech Iv Year-Ii Sem: Malla Reddy College of Engineering &technologyDocument54 pagesB.Tech Iv Year-Ii Sem: Malla Reddy College of Engineering &technologyTinsae AdaneNo ratings yet

- Om & SCM Mba AimsDocument75 pagesOm & SCM Mba Aimsbhupesh joshi100% (1)

- Om & SCM Mba AimsDocument75 pagesOm & SCM Mba Aimsbhupesh joshiNo ratings yet

- Chapter 4 - MATERIALS MANAGEMENTDocument32 pagesChapter 4 - MATERIALS MANAGEMENTMoqsud AminNo ratings yet

- Operation Management NotesDocument30 pagesOperation Management Notesthamizt72% (18)

- Internal Processes Part 1: Managing OperationsDocument13 pagesInternal Processes Part 1: Managing OperationsJedi DuenasNo ratings yet

- Details Module - Production and Operations ManagementDocument113 pagesDetails Module - Production and Operations ManagementTafsir HossainNo ratings yet

- Draft Project Report Dhiraj ChavanDocument63 pagesDraft Project Report Dhiraj ChavanMayuri PotdarNo ratings yet

- Course Pack - Operations ManagementDocument34 pagesCourse Pack - Operations ManagementSARBIKPAUL CHOWDHURYNo ratings yet

- QB PPCDocument45 pagesQB PPCA. ANBU RAJ Mech - Asst.ProfNo ratings yet

- 8509Document8 pages8509Mudassar SaqiNo ratings yet

- OM Notes - FairDocument92 pagesOM Notes - FairPrabhamohanraj MohanrajNo ratings yet

- MBA Sem II-OM-NotesDocument80 pagesMBA Sem II-OM-Notesankitborkar81No ratings yet

- Industrial Management &entrepreneurshipDocument24 pagesIndustrial Management &entrepreneurship17ECER72 DEVI PRASANNANo ratings yet

- Mba 721 Operations ManagementDocument7 pagesMba 721 Operations ManagementAli MohammedNo ratings yet

- Course Outlines For Different SubjectsDocument7 pagesCourse Outlines For Different SubjectsjosephNo ratings yet

- Allama Iqbal Open University Islamabad (Department of Business Administration)Document8 pagesAllama Iqbal Open University Islamabad (Department of Business Administration)lejiy91466No ratings yet

- Allama Iqbal Open University Islamabad (Department of Business Administration)Document8 pagesAllama Iqbal Open University Islamabad (Department of Business Administration)lejiy91466No ratings yet

- Allama Iqbal Open University Islamabad (Department of Business Administration)Document8 pagesAllama Iqbal Open University Islamabad (Department of Business Administration)lejiy91466No ratings yet

- Allama Iqbal Open University Islamabad (Department of Business Administration)Document8 pagesAllama Iqbal Open University Islamabad (Department of Business Administration)lejiy91466No ratings yet

- Productions and Opearations BNU V SEM BBA NEP L NEW 1Document20 pagesProductions and Opearations BNU V SEM BBA NEP L NEW 1karthi93002No ratings yet

- Manufacturing Secret : Product Development and Intelligent Manufacturing For Flexible Automation With Odoo 17: odoo consultations, #1.1From EverandManufacturing Secret : Product Development and Intelligent Manufacturing For Flexible Automation With Odoo 17: odoo consultations, #1.1No ratings yet

- Stimulating Innovation in Products and Services: With Function Analysis and MappingFrom EverandStimulating Innovation in Products and Services: With Function Analysis and MappingNo ratings yet

- Table 1: One-Sample Kolmogorov-Smirnov TestDocument6 pagesTable 1: One-Sample Kolmogorov-Smirnov TestbhaveshNo ratings yet

- Logistics of Maruti SuzukiDocument13 pagesLogistics of Maruti SuzukibhaveshNo ratings yet

- 2017 INDIA Investment Outlook: January 2017Document7 pages2017 INDIA Investment Outlook: January 2017bhaveshNo ratings yet

- Defghgife Gqrgersgef Uvwxyz (U) V - VDVW Efgguwxzdexfzeg Efhgghggÿ) JKL Fzoopow Uvwxyz (SDocument1 pageDefghgife Gqrgersgef Uvwxyz (U) V - VDVW Efgguwxzdexfzeg Efhgghggÿ) JKL Fzoopow Uvwxyz (SbhaveshNo ratings yet

- Mukesh AmbaniDocument16 pagesMukesh AmbanibhaveshNo ratings yet

- IA BrochureDocument12 pagesIA BrochureChris WallaceNo ratings yet

- TENSYMP - Special TRACK - Climate SmartDocument1 pageTENSYMP - Special TRACK - Climate SmartMayurkumar patilNo ratings yet

- 2021 YISS - INTRODUCTION TO COMPUTER GRAPHICS - Hyunjung KimDocument3 pages2021 YISS - INTRODUCTION TO COMPUTER GRAPHICS - Hyunjung KimFung AlexNo ratings yet

- ABLRFD v1403 Summary RevisionsDocument2 pagesABLRFD v1403 Summary RevisionsMiguel AngelNo ratings yet

- 100 S Oem S: 102R Low Flow PumpheadDocument2 pages100 S Oem S: 102R Low Flow PumpheadtechniqueNo ratings yet

- PRojectDocument61 pagesPRojectAditya SalunkheNo ratings yet

- Yi PDFDocument2 pagesYi PDFAnonymous La5rPMYNo ratings yet

- Promotion Safe Med ChildrensDocument64 pagesPromotion Safe Med ChildrensAbdul khodir jaelani100% (1)

- 322 Dynamic Demographic Characteristic Slum Population in Nashik City With Special Reference From 2011Document6 pages322 Dynamic Demographic Characteristic Slum Population in Nashik City With Special Reference From 2011B-15 Keyur BhanushaliNo ratings yet

- Solar Power PlantDocument23 pagesSolar Power Plantmadhu_bedi12No ratings yet

- DB Pyranometer SMP10 en 20151208Document2 pagesDB Pyranometer SMP10 en 20151208matefucskoNo ratings yet

- LG 29FG1RL 12950 Chassis CW-62C Manual de ServicioDocument34 pagesLG 29FG1RL 12950 Chassis CW-62C Manual de Serviciopepe sanchezNo ratings yet

- Block 3Document17 pagesBlock 3Dianne ChristineNo ratings yet

- Arnold Schwarzenegger ThesisDocument4 pagesArnold Schwarzenegger Thesislanatedrummondfortwayne100% (2)

- Commercial Paper: Presented by Dharani Dharan.m Vijaya Kumar S.BDocument16 pagesCommercial Paper: Presented by Dharani Dharan.m Vijaya Kumar S.Budaya37No ratings yet

- Nature of Bivariate DataDocument39 pagesNature of Bivariate DataRossel Jane CampilloNo ratings yet

- Afrique Du Sud - Natal - Telegraph 1864-1879Document5 pagesAfrique Du Sud - Natal - Telegraph 1864-1879Hervé DenisNo ratings yet

- International Dairy Journal: D.K. Hickey, T.P. Guinee, J. Hou, M.G. WilkinsonDocument6 pagesInternational Dairy Journal: D.K. Hickey, T.P. Guinee, J. Hou, M.G. WilkinsonBianca AndreeaNo ratings yet

- Security ManagementDocument35 pagesSecurity ManagementVanessa CarreteNo ratings yet

- Ateneo Philosophy Club: Project ProposalDocument2 pagesAteneo Philosophy Club: Project ProposalArmando MataNo ratings yet

- An Experiment of DensityDocument4 pagesAn Experiment of DensitySamuel TumewaNo ratings yet

- A Review of Jet Mixing Enhancement For Aircraft Propulsion ApplicationsDocument25 pagesA Review of Jet Mixing Enhancement For Aircraft Propulsion ApplicationsJINU CHANDRANNo ratings yet

- Social Venture Inherent Constitution:: Perceptions of ValueDocument3 pagesSocial Venture Inherent Constitution:: Perceptions of ValuePallavi GuptaNo ratings yet

- Apps SynonymsDocument42 pagesApps SynonymsMuhammad Sumair100% (1)

- Wizard - School of DiabolismDocument1 pageWizard - School of DiabolismHope LaneNo ratings yet

- Intermediate Accounting Reporting and Analysis 3Rd Edition James Wahlen Full ChapterDocument67 pagesIntermediate Accounting Reporting and Analysis 3Rd Edition James Wahlen Full Chapterwilliam.rodriquez579100% (6)

- BTD Course FileDocument23 pagesBTD Course FilePrashant S HadagaliNo ratings yet

- Bunker & FW Supply ChecklistDocument3 pagesBunker & FW Supply ChecklistSampetua StmrgNo ratings yet