Professional Documents

Culture Documents

Stepper Motor Interfacing With 8051 MC

Stepper Motor Interfacing With 8051 MC

Uploaded by

dishantgoel2019Copyright:

Available Formats

You might also like

- 312C - Esquema EletricoDocument2 pages312C - Esquema EletricoMarco OlivettoNo ratings yet

- 2W Switch Catalog 2022 LRDocument124 pages2W Switch Catalog 2022 LRRamkinkar Guru100% (1)

- Digital Lab Report 3Document8 pagesDigital Lab Report 3علي عليNo ratings yet

- HOLGAGONDocument8 pagesHOLGAGONRisky HidayatNo ratings yet

- 8051 Lab Stepper Motor InterfacingDocument5 pages8051 Lab Stepper Motor InterfacingGirish ChapleNo ratings yet

- Exp 7Document3 pagesExp 7Ashwini KothavaleNo ratings yet

- Topics Included: Introduction To Stepper Motors & Rotation Sequences Interfacing and Isolating Circuitry Industrial ApplicationsDocument20 pagesTopics Included: Introduction To Stepper Motors & Rotation Sequences Interfacing and Isolating Circuitry Industrial ApplicationsGA16DETNo ratings yet

- Stepper MotorDocument4 pagesStepper Motor1020-Santhosh kumar. JNo ratings yet

- CountersDocument14 pagesCountersMs.DEVI P100% (17)

- Asynchronous and Synchronous Counters: Week 10 and Week 11 (Lecture 1 of 2)Document46 pagesAsynchronous and Synchronous Counters: Week 10 and Week 11 (Lecture 1 of 2)sweethari20009No ratings yet

- Stepper MotorDocument6 pagesStepper MotorSiddharth MishraNo ratings yet

- Stepper Motor Controller Using 8051Document37 pagesStepper Motor Controller Using 8051gutzz0079197100% (2)

- CountersDocument47 pagesCountersAnonymous iQVjcOhNo ratings yet

- The Ring CounterDocument4 pagesThe Ring CounterPraveen KumarNo ratings yet

- Experiment 8: Counting Circuits: (Assignment)Document3 pagesExperiment 8: Counting Circuits: (Assignment)AL Asmr YamakNo ratings yet

- Stepper MotorDocument6 pagesStepper MotorSuganthi EvangelineNo ratings yet

- Digital Design Lab: Snehangshu Bhattacharya 33 A 10900316057 4thDocument7 pagesDigital Design Lab: Snehangshu Bhattacharya 33 A 10900316057 4thJohn DoeNo ratings yet

- Mendoza - Experiment No.14Document3 pagesMendoza - Experiment No.14Aldrin MndzNo ratings yet

- Ovi 5Document6 pagesOvi 5Naimur Asif BornoNo ratings yet

- Name: Izaan Ahmed Khan STD ID: FA19-BSCS-0049 COURSE: DLD Theory Assignment # 03Document10 pagesName: Izaan Ahmed Khan STD ID: FA19-BSCS-0049 COURSE: DLD Theory Assignment # 03Izaan Ahmed KhanNo ratings yet

- 3 Bit Synchronous Up CounterDocument15 pages3 Bit Synchronous Up CounterMaruf MorshedNo ratings yet

- Digital Circuits - Application of Shift RegistersDocument4 pagesDigital Circuits - Application of Shift RegistersB.Prashant JhaNo ratings yet

- Massachusetts Institute of TechnologyDocument3 pagesMassachusetts Institute of TechnologyJack SoNo ratings yet

- EE3101 Communication Engineering: Chapter 3-2, SynchronizationDocument15 pagesEE3101 Communication Engineering: Chapter 3-2, SynchronizationfishkantNo ratings yet

- Counter Circuits: ObjectivesDocument9 pagesCounter Circuits: ObjectivesRuhul Amin Khalil100% (1)

- 08 Shift RegisterDocument12 pages08 Shift RegisterChen ShyanNo ratings yet

- Experiment 2 SALAZARDocument9 pagesExperiment 2 SALAZARgerand salazarNo ratings yet

- Ch. 3: Forward and Inverse Kinematics: KON 318E: Introduction To Robotics 1Document79 pagesCh. 3: Forward and Inverse Kinematics: KON 318E: Introduction To Robotics 1Dursun DurmasınNo ratings yet

- P211 OrderForm - v5 - 112019Document6 pagesP211 OrderForm - v5 - 112019keglobalNo ratings yet

- 5.1 Speed Control DC Motor Using PWMDocument3 pages5.1 Speed Control DC Motor Using PWMkrishnaNo ratings yet

- Design of Fuzzy PID Controller For Brushless DC Motor: Research ArticleDocument10 pagesDesign of Fuzzy PID Controller For Brushless DC Motor: Research ArticleadilNo ratings yet

- MODULE 4 - Flip Flop & RegistersDocument27 pagesMODULE 4 - Flip Flop & RegistersChaitanya J S ReddyNo ratings yet

- ENS2456 Solutions 4Document9 pagesENS2456 Solutions 4omairakhtar12345No ratings yet

- 37 DLD Lec 37 Design of Sequential Circuits Example Dated 09 Dec 2022 Lecture SlidesDocument18 pages37 DLD Lec 37 Design of Sequential Circuits Example Dated 09 Dec 2022 Lecture SlidesZuha FatimaNo ratings yet

- Shift Registers: Socketed 74LS164 8-Bit Shift Register ChipDocument46 pagesShift Registers: Socketed 74LS164 8-Bit Shift Register Chipangelgalaxylife87No ratings yet

- CELEBROWDocument16 pagesCELEBROWEpaja Jeremiah JesseNo ratings yet

- 5 - Flip-Flops and Synchronous Sequential CircuitsDocument10 pages5 - Flip-Flops and Synchronous Sequential CircuitsHadeer GamalNo ratings yet

- Lab 10Document7 pagesLab 10Syed Muhammad AhmadNo ratings yet

- Experiment 6 Interfacing of Stepper Motor With 8086: 6.1 Aim(s) / Objective(s) / PurposeDocument4 pagesExperiment 6 Interfacing of Stepper Motor With 8086: 6.1 Aim(s) / Objective(s) / Purposepraveenembd1No ratings yet

- Digital Electronics - Tutorial #1Document3 pagesDigital Electronics - Tutorial #1Dishawn NationNo ratings yet

- Something I Dont Wanna See AgainDocument70 pagesSomething I Dont Wanna See AgainLisaNo ratings yet

- Digital Circuits - CountersDocument6 pagesDigital Circuits - CountersB.Prashant JhaNo ratings yet

- Screenshot 2566-09-08 at 20.27.55Document8 pagesScreenshot 2566-09-08 at 20.27.55dhanabadee.kNo ratings yet

- Lect Register EE208Document16 pagesLect Register EE208Anonymous 001No ratings yet

- Stepper MotorDocument15 pagesStepper MotorsharadaNo ratings yet

- AN-1215 Maze Runner RobotDocument11 pagesAN-1215 Maze Runner RobotMukeshGuptaNo ratings yet

- Theory and Application of Pulse Interpolation To Prover SystemsDocument7 pagesTheory and Application of Pulse Interpolation To Prover SystemsAghil ThayyilNo ratings yet

- Chapter 6Document7 pagesChapter 6DAWA PENJORNo ratings yet

- Arkan Kovan ABudllahDocument13 pagesArkan Kovan ABudllahYasir Yasir KovanNo ratings yet

- GCBs Endurance ABBDocument11 pagesGCBs Endurance ABBFayaz ShaikNo ratings yet

- CounterDocument30 pagesCounterVedantNo ratings yet

- Quiz AnswarDocument10 pagesQuiz AnswarHarshu VagadiyaNo ratings yet

- Lect Register-EE208 2023Document23 pagesLect Register-EE208 2023catdogsunmoon12No ratings yet

- FDDGDocument3 pagesFDDGaliffpadziNo ratings yet

- Trajectory Tracking Control of A Differential Wheeled Mobile Robot: A Polar Coordinates Control and LQR ComparisonDocument4 pagesTrajectory Tracking Control of A Differential Wheeled Mobile Robot: A Polar Coordinates Control and LQR ComparisonAntonio MoisesNo ratings yet

- PC200-8 SM - 009 Electrical System PDFDocument64 pagesPC200-8 SM - 009 Electrical System PDFPocilNo ratings yet

- CSE 205: Digital Logic DesignDocument53 pagesCSE 205: Digital Logic DesignAfifa murshida NazinNo ratings yet

- AIAG FMEA TemplateDocument70 pagesAIAG FMEA TemplateBrayan Ruiz Esparza CamposNo ratings yet

- AIAG FMEA TemplateDocument70 pagesAIAG FMEA TemplatepaulNo ratings yet

- Frequency Divider D-Flip-flopsDocument12 pagesFrequency Divider D-Flip-flopsSylvester Delali Dordzi0% (1)

- Fig 1: Half Adder Circuit.: Carry SumDocument3 pagesFig 1: Half Adder Circuit.: Carry SumSiva ArunNo ratings yet

- Digital Logic CounterDocument12 pagesDigital Logic CounterRaziya SultanaNo ratings yet

- Analog Dialogue, Volume 48, Number 1: Analog Dialogue, #13From EverandAnalog Dialogue, Volume 48, Number 1: Analog Dialogue, #13Rating: 4 out of 5 stars4/5 (1)

- Simple Machine: Mechanical AdvantageDocument4 pagesSimple Machine: Mechanical AdvantageTrisson HarteNo ratings yet

- MDV R32 RemoteControllerUsersManual ENGDocument10 pagesMDV R32 RemoteControllerUsersManual ENGtibikomaNo ratings yet

- Differences Between OM1 OM2 OM3 OM4Document3 pagesDifferences Between OM1 OM2 OM3 OM4Alejandro Andres Muñoz EscobarNo ratings yet

- LINEARlight Flex Uniformity Specification Sheet (EN)Document20 pagesLINEARlight Flex Uniformity Specification Sheet (EN)team37No ratings yet

- Fiber Optics Splicing Procedures: Your Source To Fiber Optics, Industrial Datacomm & Fieldbus Products-Solutions-ServicesDocument7 pagesFiber Optics Splicing Procedures: Your Source To Fiber Optics, Industrial Datacomm & Fieldbus Products-Solutions-ServicesHafis Aikal AmranNo ratings yet

- Olympus CX - 21 Manual de Usuario PDFDocument28 pagesOlympus CX - 21 Manual de Usuario PDFApocalipsis2072No ratings yet

- Mac25 Maintenance Section 2Document27 pagesMac25 Maintenance Section 2Wahyu SriharjaNo ratings yet

- G5 IDM Unit Troubleshooting ClassDocument98 pagesG5 IDM Unit Troubleshooting Classsorangel_123No ratings yet

- Valves and LeakagesDocument15 pagesValves and LeakagesCesare Daldossi100% (2)

- Bifacial Module Installation Manual - ENDocument11 pagesBifacial Module Installation Manual - ENGabrielDarienTeporaVillarNo ratings yet

- Installation Procedure T5MaxDocument2 pagesInstallation Procedure T5MaxCarlos Alberto RuedaNo ratings yet

- Yuri - Manual Microtome VCM-202TDocument12 pagesYuri - Manual Microtome VCM-202Tyalva alvarinoNo ratings yet

- Ex. No.: 08: Go-Down WiringDocument5 pagesEx. No.: 08: Go-Down WiringamanNo ratings yet

- Ammeter, Voltmeter Testing Not Applicable For This PanelDocument3 pagesAmmeter, Voltmeter Testing Not Applicable For This Paneleswaran005No ratings yet

- M C 3-35 Philips SON-T 400WDocument3 pagesM C 3-35 Philips SON-T 400WVũ TúNo ratings yet

- Level Control Loop-1Document8 pagesLevel Control Loop-1Amna liaquatNo ratings yet

- Civil Engineering in Indoor SubstationDocument12 pagesCivil Engineering in Indoor SubstationfarhanNo ratings yet

- Beamex IPRT Probe Brochure ENGDocument1 pageBeamex IPRT Probe Brochure ENGmohamedNo ratings yet

- Standard Spare Parts List JM 1108HD - CJ411Document1 pageStandard Spare Parts List JM 1108HD - CJ411Mf LuiNo ratings yet

- Bravo Radar (BSMT31-B1)Document20 pagesBravo Radar (BSMT31-B1)Christian Felix GuevarraNo ratings yet

- Karabin 98KDocument1 pageKarabin 98KdragoljubNo ratings yet

- TG1YDocument12 pagesTG1Ynicer gutierrez galvezNo ratings yet

- SBJV - Rnav Akseb 2e Rwy 15 - Sid - 20230323Document1 pageSBJV - Rnav Akseb 2e Rwy 15 - Sid - 20230323Alexandre MedeirosNo ratings yet

- MELDAS AC SERVO MDS-B-SVJ2 Series SPECIFICATIONS AND INSTRUCTION MANUAL OSA17Document1 pageMELDAS AC SERVO MDS-B-SVJ2 Series SPECIFICATIONS AND INSTRUCTION MANUAL OSA17jroyal692974No ratings yet

- Drum and Lining Brake 2Document4 pagesDrum and Lining Brake 2albert svensenNo ratings yet

- +metkon Metacut 302 Operation and Instruction Manual Mt18-02Document28 pages+metkon Metacut 302 Operation and Instruction Manual Mt18-02Minh TBB GlobalNo ratings yet

- Komatsu PC200 PC228U - Pins Bushes Seals ShimsDocument12 pagesKomatsu PC200 PC228U - Pins Bushes Seals Shimsmostafa aliNo ratings yet

Stepper Motor Interfacing With 8051 MC

Stepper Motor Interfacing With 8051 MC

Uploaded by

dishantgoel2019Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Stepper Motor Interfacing With 8051 MC

Stepper Motor Interfacing With 8051 MC

Uploaded by

dishantgoel2019Copyright:

Available Formats

10.

6 STEPPER MOTOR INTERFACING

position of a movable part of a

AStepper used to control the

motor is widely

drives, dot matrix printers, and robots

for

18 normally used in floppy disk havea

control of sensor. Stepper motors commonly

P n without the need any

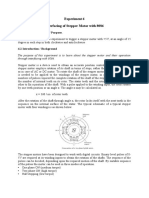

stator normally has

perneent magnet rotor surrounded by stator windings. The

four windings that are paired with a center tapped common as shown in figure 10.8

Red

O0000000 White - Common 1

A

Orange

O0000000

Blue

B

O00000O0 Black -o Common 2

Green

D -

O00000OO

Fig. 10.8 : Stepper Motor Stator Windings Configuration

The stepper motor moves in steps depending upon the pulse sequences given to

its stator windings. The minimum degree of rotation associated with single step is

alled step angle. Stepper motors are available with different step angles like 2,

L18, 0.72° etc. A stepper motor with step angle of 1.8° will rotate by one revolution

09 in 200 steps. Stepper motors can be made to work in half step angle mode. To

nange the direction of rotation, step sequences are to be reversed. To increase the

peed of rotation, the pulse sequence frequency is to be increased. Table 10.4 gives

p sequence for full step movement and Table 10.5 gives step sequences for half

ep movement. StePRer t r

h epene

e =o 6r fulLStePlig 36

s afe 3sY =

ISHAN'S Programmable Logic ntrollers and rocontrollers

246 Sequences

Full Step

Table 10.4: FelClockwise

D

C

B

Step A 1o

0

1 0 oh

0 1

1 1 h

0

1

0 0 Anti-Clockwise

Sequences

Table 10.5: Half Step

B C D

Step A

0 0 1

Clockwisee

0

1 0 0 Cip

0 1 0 0 o4h

1 0 o6h

0 1 0

0 0 1 1 3 Anti-Clockwise

8 0 0 1

0 0 1

Figure 10.9 shows interfacing of

stepper motor with 8051. Buffers are usea u

provide sufficient base current for the transistor

drivers. Transistors are sti cted

according to the current rating of the

stepper

path for energy dissipation due to stored motors. Diodes are used to pewhen

OvIde

transistors are turned off. magnetic energy in the col

Buffers

P1.2 Transistors

P1.0 000

P1.1 O00

Stepper Motor +Vcc

P13 O00

O00

Fig. 10.9:Stepper Motor

Connections with 8051

Designand Interface Using 8051

247

The following program can be used to rotate

directions if input signal on pin 2.0 is low andtheanti

wIse

stepper motor in full step, clock

clock wise direction if pin 2.0

s nigh. Portl (Pi.0 -P1.3) is connected with windings

high.

A, B, C and D of stepper

ntor through buffers and driver transistors. When pin

motor

output is made nign,

ansistor turns ON and current flows through the

tran

winding

ORG 0100H

MOV A, #99H ; Load step 1 sequence

SETB P2.0 Initialize Pin 2.0 as input bit

REP1 JB P2.0, ANTI Jumps if pin 2.0 is high

RR A

MOV P1,A

ACALL DELAY

SJMP REP1

ANTI RLA

MOV P1, A

ACALL DELAY

SJMP REP1

; DELAY SUBROUTINE

; Increase in delay time decreases speed and vice versa

DELAY MOV RO, #20H

REP2 MOV R1, #4EH

REP3 DJNZ R1, REP3

DJNZ RO, REP2

RET

END

10.7 RTC INTERFACE

Time Clock) is used keep track of seconds,

to

In a control system, RTC (Real

date, month and year at an instant. Chip

nutes, hours, days, day of the week,

dual in-line package. A lithium energy

US12C887 is a RTC available in 24-pin

urce, quartz crystal are included in it

S0ur and can maintain time-of-day and memory

a n pin diagram of the

10.10 shows block diagram

the absence of power. figure

TC DS 12c887

You might also like

- 312C - Esquema EletricoDocument2 pages312C - Esquema EletricoMarco OlivettoNo ratings yet

- 2W Switch Catalog 2022 LRDocument124 pages2W Switch Catalog 2022 LRRamkinkar Guru100% (1)

- Digital Lab Report 3Document8 pagesDigital Lab Report 3علي عليNo ratings yet

- HOLGAGONDocument8 pagesHOLGAGONRisky HidayatNo ratings yet

- 8051 Lab Stepper Motor InterfacingDocument5 pages8051 Lab Stepper Motor InterfacingGirish ChapleNo ratings yet

- Exp 7Document3 pagesExp 7Ashwini KothavaleNo ratings yet

- Topics Included: Introduction To Stepper Motors & Rotation Sequences Interfacing and Isolating Circuitry Industrial ApplicationsDocument20 pagesTopics Included: Introduction To Stepper Motors & Rotation Sequences Interfacing and Isolating Circuitry Industrial ApplicationsGA16DETNo ratings yet

- Stepper MotorDocument4 pagesStepper Motor1020-Santhosh kumar. JNo ratings yet

- CountersDocument14 pagesCountersMs.DEVI P100% (17)

- Asynchronous and Synchronous Counters: Week 10 and Week 11 (Lecture 1 of 2)Document46 pagesAsynchronous and Synchronous Counters: Week 10 and Week 11 (Lecture 1 of 2)sweethari20009No ratings yet

- Stepper MotorDocument6 pagesStepper MotorSiddharth MishraNo ratings yet

- Stepper Motor Controller Using 8051Document37 pagesStepper Motor Controller Using 8051gutzz0079197100% (2)

- CountersDocument47 pagesCountersAnonymous iQVjcOhNo ratings yet

- The Ring CounterDocument4 pagesThe Ring CounterPraveen KumarNo ratings yet

- Experiment 8: Counting Circuits: (Assignment)Document3 pagesExperiment 8: Counting Circuits: (Assignment)AL Asmr YamakNo ratings yet

- Stepper MotorDocument6 pagesStepper MotorSuganthi EvangelineNo ratings yet

- Digital Design Lab: Snehangshu Bhattacharya 33 A 10900316057 4thDocument7 pagesDigital Design Lab: Snehangshu Bhattacharya 33 A 10900316057 4thJohn DoeNo ratings yet

- Mendoza - Experiment No.14Document3 pagesMendoza - Experiment No.14Aldrin MndzNo ratings yet

- Ovi 5Document6 pagesOvi 5Naimur Asif BornoNo ratings yet

- Name: Izaan Ahmed Khan STD ID: FA19-BSCS-0049 COURSE: DLD Theory Assignment # 03Document10 pagesName: Izaan Ahmed Khan STD ID: FA19-BSCS-0049 COURSE: DLD Theory Assignment # 03Izaan Ahmed KhanNo ratings yet

- 3 Bit Synchronous Up CounterDocument15 pages3 Bit Synchronous Up CounterMaruf MorshedNo ratings yet

- Digital Circuits - Application of Shift RegistersDocument4 pagesDigital Circuits - Application of Shift RegistersB.Prashant JhaNo ratings yet

- Massachusetts Institute of TechnologyDocument3 pagesMassachusetts Institute of TechnologyJack SoNo ratings yet

- EE3101 Communication Engineering: Chapter 3-2, SynchronizationDocument15 pagesEE3101 Communication Engineering: Chapter 3-2, SynchronizationfishkantNo ratings yet

- Counter Circuits: ObjectivesDocument9 pagesCounter Circuits: ObjectivesRuhul Amin Khalil100% (1)

- 08 Shift RegisterDocument12 pages08 Shift RegisterChen ShyanNo ratings yet

- Experiment 2 SALAZARDocument9 pagesExperiment 2 SALAZARgerand salazarNo ratings yet

- Ch. 3: Forward and Inverse Kinematics: KON 318E: Introduction To Robotics 1Document79 pagesCh. 3: Forward and Inverse Kinematics: KON 318E: Introduction To Robotics 1Dursun DurmasınNo ratings yet

- P211 OrderForm - v5 - 112019Document6 pagesP211 OrderForm - v5 - 112019keglobalNo ratings yet

- 5.1 Speed Control DC Motor Using PWMDocument3 pages5.1 Speed Control DC Motor Using PWMkrishnaNo ratings yet

- Design of Fuzzy PID Controller For Brushless DC Motor: Research ArticleDocument10 pagesDesign of Fuzzy PID Controller For Brushless DC Motor: Research ArticleadilNo ratings yet

- MODULE 4 - Flip Flop & RegistersDocument27 pagesMODULE 4 - Flip Flop & RegistersChaitanya J S ReddyNo ratings yet

- ENS2456 Solutions 4Document9 pagesENS2456 Solutions 4omairakhtar12345No ratings yet

- 37 DLD Lec 37 Design of Sequential Circuits Example Dated 09 Dec 2022 Lecture SlidesDocument18 pages37 DLD Lec 37 Design of Sequential Circuits Example Dated 09 Dec 2022 Lecture SlidesZuha FatimaNo ratings yet

- Shift Registers: Socketed 74LS164 8-Bit Shift Register ChipDocument46 pagesShift Registers: Socketed 74LS164 8-Bit Shift Register Chipangelgalaxylife87No ratings yet

- CELEBROWDocument16 pagesCELEBROWEpaja Jeremiah JesseNo ratings yet

- 5 - Flip-Flops and Synchronous Sequential CircuitsDocument10 pages5 - Flip-Flops and Synchronous Sequential CircuitsHadeer GamalNo ratings yet

- Lab 10Document7 pagesLab 10Syed Muhammad AhmadNo ratings yet

- Experiment 6 Interfacing of Stepper Motor With 8086: 6.1 Aim(s) / Objective(s) / PurposeDocument4 pagesExperiment 6 Interfacing of Stepper Motor With 8086: 6.1 Aim(s) / Objective(s) / Purposepraveenembd1No ratings yet

- Digital Electronics - Tutorial #1Document3 pagesDigital Electronics - Tutorial #1Dishawn NationNo ratings yet

- Something I Dont Wanna See AgainDocument70 pagesSomething I Dont Wanna See AgainLisaNo ratings yet

- Digital Circuits - CountersDocument6 pagesDigital Circuits - CountersB.Prashant JhaNo ratings yet

- Screenshot 2566-09-08 at 20.27.55Document8 pagesScreenshot 2566-09-08 at 20.27.55dhanabadee.kNo ratings yet

- Lect Register EE208Document16 pagesLect Register EE208Anonymous 001No ratings yet

- Stepper MotorDocument15 pagesStepper MotorsharadaNo ratings yet

- AN-1215 Maze Runner RobotDocument11 pagesAN-1215 Maze Runner RobotMukeshGuptaNo ratings yet

- Theory and Application of Pulse Interpolation To Prover SystemsDocument7 pagesTheory and Application of Pulse Interpolation To Prover SystemsAghil ThayyilNo ratings yet

- Chapter 6Document7 pagesChapter 6DAWA PENJORNo ratings yet

- Arkan Kovan ABudllahDocument13 pagesArkan Kovan ABudllahYasir Yasir KovanNo ratings yet

- GCBs Endurance ABBDocument11 pagesGCBs Endurance ABBFayaz ShaikNo ratings yet

- CounterDocument30 pagesCounterVedantNo ratings yet

- Quiz AnswarDocument10 pagesQuiz AnswarHarshu VagadiyaNo ratings yet

- Lect Register-EE208 2023Document23 pagesLect Register-EE208 2023catdogsunmoon12No ratings yet

- FDDGDocument3 pagesFDDGaliffpadziNo ratings yet

- Trajectory Tracking Control of A Differential Wheeled Mobile Robot: A Polar Coordinates Control and LQR ComparisonDocument4 pagesTrajectory Tracking Control of A Differential Wheeled Mobile Robot: A Polar Coordinates Control and LQR ComparisonAntonio MoisesNo ratings yet

- PC200-8 SM - 009 Electrical System PDFDocument64 pagesPC200-8 SM - 009 Electrical System PDFPocilNo ratings yet

- CSE 205: Digital Logic DesignDocument53 pagesCSE 205: Digital Logic DesignAfifa murshida NazinNo ratings yet

- AIAG FMEA TemplateDocument70 pagesAIAG FMEA TemplateBrayan Ruiz Esparza CamposNo ratings yet

- AIAG FMEA TemplateDocument70 pagesAIAG FMEA TemplatepaulNo ratings yet

- Frequency Divider D-Flip-flopsDocument12 pagesFrequency Divider D-Flip-flopsSylvester Delali Dordzi0% (1)

- Fig 1: Half Adder Circuit.: Carry SumDocument3 pagesFig 1: Half Adder Circuit.: Carry SumSiva ArunNo ratings yet

- Digital Logic CounterDocument12 pagesDigital Logic CounterRaziya SultanaNo ratings yet

- Analog Dialogue, Volume 48, Number 1: Analog Dialogue, #13From EverandAnalog Dialogue, Volume 48, Number 1: Analog Dialogue, #13Rating: 4 out of 5 stars4/5 (1)

- Simple Machine: Mechanical AdvantageDocument4 pagesSimple Machine: Mechanical AdvantageTrisson HarteNo ratings yet

- MDV R32 RemoteControllerUsersManual ENGDocument10 pagesMDV R32 RemoteControllerUsersManual ENGtibikomaNo ratings yet

- Differences Between OM1 OM2 OM3 OM4Document3 pagesDifferences Between OM1 OM2 OM3 OM4Alejandro Andres Muñoz EscobarNo ratings yet

- LINEARlight Flex Uniformity Specification Sheet (EN)Document20 pagesLINEARlight Flex Uniformity Specification Sheet (EN)team37No ratings yet

- Fiber Optics Splicing Procedures: Your Source To Fiber Optics, Industrial Datacomm & Fieldbus Products-Solutions-ServicesDocument7 pagesFiber Optics Splicing Procedures: Your Source To Fiber Optics, Industrial Datacomm & Fieldbus Products-Solutions-ServicesHafis Aikal AmranNo ratings yet

- Olympus CX - 21 Manual de Usuario PDFDocument28 pagesOlympus CX - 21 Manual de Usuario PDFApocalipsis2072No ratings yet

- Mac25 Maintenance Section 2Document27 pagesMac25 Maintenance Section 2Wahyu SriharjaNo ratings yet

- G5 IDM Unit Troubleshooting ClassDocument98 pagesG5 IDM Unit Troubleshooting Classsorangel_123No ratings yet

- Valves and LeakagesDocument15 pagesValves and LeakagesCesare Daldossi100% (2)

- Bifacial Module Installation Manual - ENDocument11 pagesBifacial Module Installation Manual - ENGabrielDarienTeporaVillarNo ratings yet

- Installation Procedure T5MaxDocument2 pagesInstallation Procedure T5MaxCarlos Alberto RuedaNo ratings yet

- Yuri - Manual Microtome VCM-202TDocument12 pagesYuri - Manual Microtome VCM-202Tyalva alvarinoNo ratings yet

- Ex. No.: 08: Go-Down WiringDocument5 pagesEx. No.: 08: Go-Down WiringamanNo ratings yet

- Ammeter, Voltmeter Testing Not Applicable For This PanelDocument3 pagesAmmeter, Voltmeter Testing Not Applicable For This Paneleswaran005No ratings yet

- M C 3-35 Philips SON-T 400WDocument3 pagesM C 3-35 Philips SON-T 400WVũ TúNo ratings yet

- Level Control Loop-1Document8 pagesLevel Control Loop-1Amna liaquatNo ratings yet

- Civil Engineering in Indoor SubstationDocument12 pagesCivil Engineering in Indoor SubstationfarhanNo ratings yet

- Beamex IPRT Probe Brochure ENGDocument1 pageBeamex IPRT Probe Brochure ENGmohamedNo ratings yet

- Standard Spare Parts List JM 1108HD - CJ411Document1 pageStandard Spare Parts List JM 1108HD - CJ411Mf LuiNo ratings yet

- Bravo Radar (BSMT31-B1)Document20 pagesBravo Radar (BSMT31-B1)Christian Felix GuevarraNo ratings yet

- Karabin 98KDocument1 pageKarabin 98KdragoljubNo ratings yet

- TG1YDocument12 pagesTG1Ynicer gutierrez galvezNo ratings yet

- SBJV - Rnav Akseb 2e Rwy 15 - Sid - 20230323Document1 pageSBJV - Rnav Akseb 2e Rwy 15 - Sid - 20230323Alexandre MedeirosNo ratings yet

- MELDAS AC SERVO MDS-B-SVJ2 Series SPECIFICATIONS AND INSTRUCTION MANUAL OSA17Document1 pageMELDAS AC SERVO MDS-B-SVJ2 Series SPECIFICATIONS AND INSTRUCTION MANUAL OSA17jroyal692974No ratings yet

- Drum and Lining Brake 2Document4 pagesDrum and Lining Brake 2albert svensenNo ratings yet

- +metkon Metacut 302 Operation and Instruction Manual Mt18-02Document28 pages+metkon Metacut 302 Operation and Instruction Manual Mt18-02Minh TBB GlobalNo ratings yet

- Komatsu PC200 PC228U - Pins Bushes Seals ShimsDocument12 pagesKomatsu PC200 PC228U - Pins Bushes Seals Shimsmostafa aliNo ratings yet