Professional Documents

Culture Documents

PVC Color Master Batch V3

PVC Color Master Batch V3

Uploaded by

Mohmed GamalOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PVC Color Master Batch V3

PVC Color Master Batch V3

Uploaded by

Mohmed GamalCopyright:

Available Formats

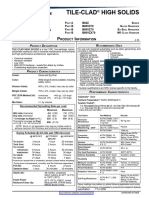

Material Technical Standard of: WD-TE-361

PVC color master batch Issue Date

2 11/11/2008

Distribution MR, MM, MT, FN, PR, QP, TE

1. Material Description:

It's coloring pigment used for coloring of self curing skin PVC insulation.

2. Material Code:

ESC Code: PMB*** (PVC color master batch, *** color) Example: PMBRED.

3. Material Properties:

PVC color master batch has the following properties:

Color Color code Heat stability Light fastness Heavy metals free Diarylide free

Red RAL 3000 <200 0C 6-7 YES YES

Pink RAL 3015 <200 0C 6-7 YES YES

Orange RAL 2011 <200 0C 6 YES YES

Yellow RAL 1018 <200 0C 7 YES YES

Green RAL 6029 <200 0C 7-8 YES YES

Blue RAL 5017 <200 0C 7 YES YES

Violet RAL 4005 <200 0C 7-8 YES YES

Brown RAL 8002 <200 0C 7-8 YES YES

Gray RAL 7012 <200 0C 7-8 YES YES

Black RAL 9005 <200 0C 8 YES YES

White RAL 9016 <200 0C 8 YES YES

Carrier PVC

% of use ≤1%

Hardness 85 ± 5 Shore A

Dispersion factor 2

Volume resistivity >1E+13 ohm.cm

o The master batch must be suitable for PVC compound.

o The master batch shall be tested when mixed with the base natural PVC.

o The material shall not affect the insulation properties of PVC base material.

o The granulates must be free-flowing and free from any contamination.

4. Packing conditions:

4.1 25 kg bags should be synthetic resin or polymer / paper laminated. The packing shall be heat resistant up to 60°C.

4.2 10 bags should be packed in boxes, protected with foils welded, sufficient desiccant and

corrugated paper.

5. Material acceptance criteria:

5.1 Packing conditions.

5.2 Test certificate (Supplier should provide quality control certificate with test results for each batch as per DIN

50049 in English).

Name Position Signature

Prepared by: Mohamed Abd Elaziz Section Head

Approved by: Hesham El Awady Technical Manager

Page 1 / 1

You might also like

- Belex Wireline LubricantDocument2 pagesBelex Wireline LubricantdhowardjNo ratings yet

- 3.HDPE Pipes Catalogue PDFDocument30 pages3.HDPE Pipes Catalogue PDFZain Zulfiqar100% (3)

- HFFR (Thermoset) Color Master BatchDocument1 pageHFFR (Thermoset) Color Master BatchMohmed GamalNo ratings yet

- Color Master Batch V3Document1 pageColor Master Batch V3Mohmed GamalNo ratings yet

- Upvc Solvent CementsDocument1 pageUpvc Solvent CementsMathi Vinoth PillaiNo ratings yet

- Technical Data Sheet: Loxeal Instant Adhesive 43SDocument2 pagesTechnical Data Sheet: Loxeal Instant Adhesive 43SaliNo ratings yet

- STATE OF CALIFORNIA. Department of Transportation Specification. White Tintable Finish Paint Waterborne Acrylic Latex Vehicle (Formula PWB-174A)Document5 pagesSTATE OF CALIFORNIA. Department of Transportation Specification. White Tintable Finish Paint Waterborne Acrylic Latex Vehicle (Formula PWB-174A)Long An ĐỗNo ratings yet

- Ivan Wan ResinDocument3 pagesIvan Wan ResinmuhannadNo ratings yet

- NC-558 TDS enDocument2 pagesNC-558 TDS enniteshacharya100% (1)

- Cardolite Ultra LITE 513: Epoxy Reactive Diluent Technical DatasheetDocument2 pagesCardolite Ultra LITE 513: Epoxy Reactive Diluent Technical Datasheettrường phạmNo ratings yet

- 2020 2000 Eng TM PDFDocument2 pages2020 2000 Eng TM PDFJordanNo ratings yet

- VELVEX-Light White Oil / White Mineral Oils (Technical)Document4 pagesVELVEX-Light White Oil / White Mineral Oils (Technical)Varadrajan jothiNo ratings yet

- Technical Specifications: 1. Technical Specifications For Wear Resistive Metallic Putty/pasteDocument2 pagesTechnical Specifications: 1. Technical Specifications For Wear Resistive Metallic Putty/pasteSiddharth DasNo ratings yet

- Poster Heat Tints-Stainless Steel A3-WEB-PDocument1 pagePoster Heat Tints-Stainless Steel A3-WEB-ParunkumarNo ratings yet

- Pintura Epoxica Sherwin Willians Hoja SeguridadDocument4 pagesPintura Epoxica Sherwin Willians Hoja Seguridad1No ratings yet

- White Oil PDS - TechnicalDocument2 pagesWhite Oil PDS - TechnicalArjunNo ratings yet

- Loctite 495Document3 pagesLoctite 495Rammstein GottNo ratings yet

- PDS - ETRO 6plus - 2022.01Document1 pagePDS - ETRO 6plus - 2022.01Sawan TaylorNo ratings yet

- Sikafloor - 264 EngDocument5 pagesSikafloor - 264 Engbassem kooliNo ratings yet

- Maincote™ Hg-31: Waterborne Acrylic Resin For Water and Corrosion-Resistant Industrial CoatingsDocument7 pagesMaincote™ Hg-31: Waterborne Acrylic Resin For Water and Corrosion-Resistant Industrial CoatingsLong An DoNo ratings yet

- Sher-Tile HS - SHERWIN WILLIAMSDocument4 pagesSher-Tile HS - SHERWIN WILLIAMSJoão Gilberto Vedana JúniorNo ratings yet

- Everlube 9002 TDSDocument2 pagesEverlube 9002 TDSValentin100% (1)

- Cssbi S8 2018Document3 pagesCssbi S8 2018bpengineerNo ratings yet

- P004100 Top Tec 6200 SAE 0W 20 46 en - USDocument1 pageP004100 Top Tec 6200 SAE 0W 20 46 en - USAXIS LUBRIFICANTESNo ratings yet

- Cardolite NX-2007: Epoxy Curing Agent Technical DatasheetDocument2 pagesCardolite NX-2007: Epoxy Curing Agent Technical Datasheettrường phạmNo ratings yet

- Bpcoat Pe Series Tds EngDocument2 pagesBpcoat Pe Series Tds EngBRAH100% (1)

- sikafloor_-262_asnDocument5 pagessikafloor_-262_asnferoz khanNo ratings yet

- 29f44e12-20dc ZA Sasolwax C80 en-ZADocument1 page29f44e12-20dc ZA Sasolwax C80 en-ZAchinmaydabkeNo ratings yet

- UCON LB-525 Spec Sheet - 230822 - 152524Document1 pageUCON LB-525 Spec Sheet - 230822 - 152524alfa_ohmNo ratings yet

- Top Tec 6200 0W-20: Product InformationDocument1 pageTop Tec 6200 0W-20: Product Informationهيوا گورانNo ratings yet

- 3 4 TDS Black770B-CarbonBlack IronOxide Pigment-GreefieldDocument1 page3 4 TDS Black770B-CarbonBlack IronOxide Pigment-GreefieldGreefield JasonNo ratings yet

- 2310 Eng TM PDFDocument1 page2310 Eng TM PDFJordanNo ratings yet

- Cardolite NX 2016Document2 pagesCardolite NX 2016Lê TiếnNo ratings yet

- 2015 1800 Eng TM PDFDocument2 pages2015 1800 Eng TM PDFJordanNo ratings yet

- Lead Free GuideDocument2 pagesLead Free Guidebeach_lover_1970No ratings yet

- Laminate PETG CatalogueDocument26 pagesLaminate PETG CatalogueDewanshi KalwarNo ratings yet

- Thermoplastic Road Marking Material: AS PER EN 1871:2000 (Hong Kong)Document4 pagesThermoplastic Road Marking Material: AS PER EN 1871:2000 (Hong Kong)Roanak KhandelwalNo ratings yet

- Ldpe (Boao00101) TdsDocument1 pageLdpe (Boao00101) TdsprsngNo ratings yet

- PDS - EQUINAS 8 - 2023.v3Document1 pagePDS - EQUINAS 8 - 2023.v3Orhan IRMAKNo ratings yet

- HT Swancor 901-Pt-Ve-30Document3 pagesHT Swancor 901-Pt-Ve-30Fernando Cesar PérezNo ratings yet

- P003998 Special Tec F 0W 30 33 en - GBDocument1 pageP003998 Special Tec F 0W 30 33 en - GBAXIS LUBRIFICANTESNo ratings yet

- Everlube 620 ATDSDocument2 pagesEverlube 620 ATDSValentinNo ratings yet

- Bitoner Resin C9 BP-120 TDSDocument2 pagesBitoner Resin C9 BP-120 TDSdamiendamNo ratings yet

- Pondy Oxides & Chemicals LTDDocument16 pagesPondy Oxides & Chemicals LTDab_gutsNo ratings yet

- Carboguard 880 MIO PDSDocument4 pagesCarboguard 880 MIO PDSHerman EngelbrechtNo ratings yet

- Polylon HP PDSDocument4 pagesPolylon HP PDSJose MachadoNo ratings yet

- Apn Knitting Oil 22Document2 pagesApn Knitting Oil 22Elbi SalesTindoNo ratings yet

- Zepoxy REH 140Document2 pagesZepoxy REH 140Aahsan Iqbal احسن اقبالNo ratings yet

- TDS 0038 DisboPOX-230-SF 201908Document7 pagesTDS 0038 DisboPOX-230-SF 201908Insafians PowerNo ratings yet

- Belex Wireline LubricantDocument2 pagesBelex Wireline LubricantdhowardjNo ratings yet

- PVC LS100 by LGDocument1 pagePVC LS100 by LGabhaygupta1No ratings yet

- APP2Document1 pageAPP2thomasNo ratings yet

- Colortrend 871 TDS-aspxDocument2 pagesColortrend 871 TDS-aspxHéctor Blas JuárezNo ratings yet

- Datasheet Novalube Blue 200Document1 pageDatasheet Novalube Blue 200Salvador AdamoNo ratings yet

- SMD291AX50T3Document2 pagesSMD291AX50T3Jonatan SmithNo ratings yet

- 6C44E51A1147D5A6F7998D235159A9Document108 pages6C44E51A1147D5A6F7998D235159A9Ravi SapraNo ratings yet

- 3 2 TDS BlackHM50-CarbonBlack IronOxide Pigment-GreefieldDocument1 page3 2 TDS BlackHM50-CarbonBlack IronOxide Pigment-GreefieldGreefield JasonNo ratings yet

- Safol 23 E-7-90Document3 pagesSafol 23 E-7-90eduardoaffreNo ratings yet

- Sikagard - 63Document5 pagesSikagard - 63dineshNo ratings yet

- 3 1 TDS BlackST50-CarbonBlack IronOxide Pigment-GreefieldDocument1 page3 1 TDS BlackST50-CarbonBlack IronOxide Pigment-GreefieldGreefield JasonNo ratings yet

- CSEC Chem Metals Chemistry of Gardening EtcDocument25 pagesCSEC Chem Metals Chemistry of Gardening Etcdela2100% (2)

- Light Transmitting ConcreteDocument15 pagesLight Transmitting ConcreteAshish TandaleNo ratings yet

- ALP Technical Manual en 2020 WebDocument24 pagesALP Technical Manual en 2020 WebJelak ChandranNo ratings yet

- Chockfast ProductDocument12 pagesChockfast ProductanandakoeNo ratings yet

- 101 Oral Viva Questions For Concrete TechnologyDocument3 pages101 Oral Viva Questions For Concrete TechnologyShekhar V kumbarNo ratings yet

- Tubing Capacities DisplacementsDocument2 pagesTubing Capacities DisplacementsIkki Ventrue-100% (1)

- U e T PeshawarDocument36 pagesU e T PeshawarzebmemonNo ratings yet

- TN49 - U-Value of Curtain Walls (5 PP)Document5 pagesTN49 - U-Value of Curtain Walls (5 PP)Steve MarrNo ratings yet

- International Catalogue 2019Document324 pagesInternational Catalogue 2019ag22klaNo ratings yet

- Catálogo Non Automotive 2018Document588 pagesCatálogo Non Automotive 2018Bryan Garcia100% (1)

- Automotive Fuels and Emission SyllabusDocument2 pagesAutomotive Fuels and Emission SyllabusrajeevNo ratings yet

- Trategic Ntervention Aterial: "Periodic Table of Elements"Document8 pagesTrategic Ntervention Aterial: "Periodic Table of Elements"Mira PangilinanNo ratings yet

- Cerium Mischmetal, Cerium Alloys, and Cerium Compounds: Rare Earth Elements)Document16 pagesCerium Mischmetal, Cerium Alloys, and Cerium Compounds: Rare Earth Elements)jaimeNo ratings yet

- PVT OilDocument4 pagesPVT OilHawary Achmadi0% (1)

- Applied Materials Today: SciencedirectDocument29 pagesApplied Materials Today: SciencedirectSamarthya BhagiaNo ratings yet

- 302 Design Criteria Asme b31.3Document2 pages302 Design Criteria Asme b31.3Ton BlokNo ratings yet

- CHRYSO Equalis - 100 - 04092012Document3 pagesCHRYSO Equalis - 100 - 04092012Dileepa DissanayakeNo ratings yet

- Experiment NO. 1-Physical and Chemical ChangeDocument2 pagesExperiment NO. 1-Physical and Chemical ChangeJenniferNo ratings yet

- TDS Rust Killer 3 in 1Document3 pagesTDS Rust Killer 3 in 1Izzuddin IbrahimNo ratings yet

- Acoustic Doors - Hinged Wooden AcoustVVic Door - Acoustic Wooden Door - Sound Proof Doors by Ecotone AcousticsDocument5 pagesAcoustic Doors - Hinged Wooden AcoustVVic Door - Acoustic Wooden Door - Sound Proof Doors by Ecotone AcousticsEdifice Placement SolutionsNo ratings yet

- RCC - SDS Sir Format - 06-Aug-21 (SEP-21)Document15 pagesRCC - SDS Sir Format - 06-Aug-21 (SEP-21)Baladaru Krishna PrasadNo ratings yet

- Arvind Textiles Internship ReportDocument107 pagesArvind Textiles Internship ReportKim hyun Jin16No ratings yet

- Epd Hy 200 R v3 Hse Information Asset Doc 17375524Document12 pagesEpd Hy 200 R v3 Hse Information Asset Doc 17375524gundeskNo ratings yet

- Versatility & Durability: Engineered Liquid Level SolutionsDocument12 pagesVersatility & Durability: Engineered Liquid Level SolutionsJorge JarrinNo ratings yet

- Digital Ultrasonic Thickness Testers Time TT130: SpecificationsDocument2 pagesDigital Ultrasonic Thickness Testers Time TT130: SpecificationsAnonymous PxySJR3HNo ratings yet

- Alofano Como CatalizadorDocument10 pagesAlofano Como CatalizadorRenato Rovere HerreraNo ratings yet

- Homemade PaintDocument16 pagesHomemade PaintGracia AgustinaNo ratings yet

- Bio Plastic From Waste Newspaper IJERTCONV2IS03037Document4 pagesBio Plastic From Waste Newspaper IJERTCONV2IS03037afradina hasnaNo ratings yet

- Cement Follow Up FormulasDocument7 pagesCement Follow Up FormulasSyed Kazam Raza100% (1)