Professional Documents

Culture Documents

25C-D1P4N114 Product Profile

25C-D1P4N114 Product Profile

Uploaded by

đức lêCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

25C-D1P4N114 Product Profile

25C-D1P4N114 Product Profile

Uploaded by

đức lêCopyright:

Available Formats

Allen-Bradley PowerFlex 527 AC Drive

A New Spin on Motor Control

PowerFlex® 527 AC drives are ideal for

machines that use a combination of

servo drives and AC drives and would

benefit from a common user experience

for configuration and programming

within the Rockwell Software Studio

5000 Logix Designer™ environment.

• Power ratings of 0.4 to 22 kW/ 0.5

to 30 Hp in global voltage classes

from 100-600V to meet a wide range

of applications

• New level of integration uses the

pre-defined motion instruction sets

within Studio 5000® for machine

control and motor synchronization Are you looking for ways to improve machine performance while

• Once programmed, drive reducing costs and complexity? You’re not alone. That’s why Rockwell

configuration files can more easily be Automation has developed the new Allen-Bradley® PowerFlex 527 AC

transferred to a new machine without drive, with features that help you simplify how you design, develop and

painstaking line-by-line copying deliver your machines.

• Logix Programmable Automation

Controllers (PACs) can automatically

detect a replaced drive and A New Level of Premier Integration

download all configuration The PowerFlex 527 AC drive takes a new approach to integration. This is the

settings over EtherNet/IP™,

first AC drive completely integrated with Allen-Bradley Logix controllers

helping reduce downtime.

and exclusively configured and programmed in the Rockwell Software®

• Built-in dual-port EtherNet/IP

Studio 5000 environment. Using a single software tool, this combination of

provides topology flexibility and

products allows you to reduce cost and engineering time while developing

Device Level Ring functionality

a more competitive machine.

• A choice of safety options for

hardwired or network Safe Torque-Off The PowerFlex 527 Variable Frequency Drive is an ideal complement

helps protect personnel and assets to machines using Allen-Bradley CompactLogix™, ControlLogix®

or GuardLogix® PACs and Allen-Bradley Kinetix® servo drives. The

Integrated Safety on PowerFlex 527 AC drive uses embedded motion instructions that are

EtherNet/IP shared with Kinetix servo drives, providing the same user experience for

configuration, programming and control of both types of drives, helping

• Helps reduce the hardware, save valuable engineering time.

wiring and labor costs associated

with implementing a SIL 3/PLe PowerFlex 527 drives offer a lower-cost solution for machines and

safety solution applications – such as pumps, fans, infeed and outfeed conveyors – that need

simple speed control for induction motors. The servo drives handle the more

• Reduces panel space and allows

precise control operations involving speed, torque and position control.

access to more diagnostic data on

machine safety faults and causes,

without requiring contactors or relays

Integrated Safety Enhances Diagnostics

For years, Rockwell Automation has been providing safety To further simplify use, the PowerFlex 527 AC drive and

solutions that help you protect personnel and assets as Kinetix 5500 servo drive have identical safety interfaces

well as reduce machine downtime. Now, we’re offering within the Studio 5000 Logix environment. This commonality

the expanded benefits of an advanced type of safety – helps reduce engineering time.

Integrated Safety – for both the PowerFlex 527 AC drive and

Kinetix 5500 servo drive.

With Integrated Safety, the drives receive safety commands

from an Allen-Bradley GuardLogix PAC via EtherNet/IP.

Having the controller manage safety helps reduce

the hardware, wiring and labor costs associated with

implementing a SIL 3/PLe safety solution.

The use of integrated – over the network – safety also

reduces panel space and allows access to more diagnostic

data on machine safety faults and causes, without requiring

contactors or relays. The detailed diagnostics help to

streamline the commissioning and troubleshooting of

safety-related faults. In addition, Integrated Safety helps

you save time and reduce labor costs by allowing you to

seamlessly implement and change safety zoning in

Studio 5000 Logix Designer software. Leveraging Studio 5000 Logix Designer as the single software package to configure and program motion,

drive and safety control helps you reduce commissioning time, training costs and time to market.

Specifications

100 - 120V: • 0.4...1.1 kW • 0.5...1.5 Hp • 2.5...6 A

200 - 240V: • 0.4...15 kW • 0.5...20 Hp • 2.5...62.1 A

Power Ratings 380 - 480V: • 0.4...22 kW • 0.5...30 Hp • 1.4...43 A

525 - 600V: • 0.4...22 kW • 0.5...30 Hp • 0.9...32 A

Motor Control • Volts per Hertz • Sensorless Vector Control • Closed Loop Velocity Vector Control

Application • Open Loop Speed Regulation • Closed Loop Speed Regulation

• Normal Duty Application: 110% - 60 secs, 150% - 3 secs (For 20 Hp & above)

Overload Capability • Heavy Duty Application: 150% - 60 secs, 180% - 3 secs (200% - 3 secs programmable)

Output Frequency Range • 0….590 Hz

• 5 Digits, 16 segments LCD display with multiple languages and local keypad (IP Address only)

User Interface • Studio 5000 exclusively - Drive is configured via embedded motion instruction

• Internal (1 phase 240V and 3 phase 480V)

EMC Filters • External (1 & 3 phase)

Configuration Studio 5000 Logix Designer™ application

• Built-in Hardwired Safe Torque-Off SIL3/PLe, Cat 3

Safety • Built-in Network Safe Torque-Off SIL3/PLe, Cat 3

Communications Built-in dual-port EtherNet/IP

Frame A: 152 (5.98) H x 72 (2.83) W x 172 (6.77) D

Frame B: 180 (7.08) H x 87 (3.42) W x 172 (6.77) D

Dimensions mm (in) Frame C: 220 (8.66) H x 109 (4.29) W x 184 (7.24) D

Frame D: 260 (10.23) H x 130 (5.11) W x 212 (8.34) D

Frame E: 300 (11.81) H x 185 (7.28) W x 279 (10.98) D

For more information, go to

http://www.ab.rockwellautomation.com/Drives/PowerFlex-527

Allen-Bradley, LISTEN. THINK. SOLVE, CompactLogix, ControlLogix, GuardLogix, Kinetix, PowerFlex, Studio 5000 and Studio 5000 Logix Designer are trademarks of Rockwell Automation, Inc. EtherNet/IP is a

trademark of the ODVA. Trademarks not belonging to Rockwell Automation are property of their respective companies.

Publication Pub 527-PP001B-EN-P – May 2015 Copyright © 2015 Rockwell Automation, Inc. All Rights Reserved. Printed in USA.

You might also like

- Test Bank For Elements of Ecology 8 E by SmithDocument8 pagesTest Bank For Elements of Ecology 8 E by Smitheda100% (1)

- Grade 2 Math Diagnostic Test 2023 - 2024Document3 pagesGrade 2 Math Diagnostic Test 2023 - 2024Rachita Poojari100% (3)

- 7-1 (FIR Filter Design)Document56 pages7-1 (FIR Filter Design)안창용[학생](전자정보대학 전자공학과)No ratings yet

- 1nz FeDocument3 pages1nz FeBilal Khan100% (6)

- PLC Programming from Novice to Professional: Learn PLC Programming with Training VideosFrom EverandPLC Programming from Novice to Professional: Learn PLC Programming with Training VideosRating: 5 out of 5 stars5/5 (1)

- Summary of The Delft University Wind Turbine Dedicated AirfoilsDocument9 pagesSummary of The Delft University Wind Turbine Dedicated AirfoilsDanildo0% (1)

- PowerFlex 527 AC DriveDocument2 pagesPowerFlex 527 AC Drivehammad.scitraNo ratings yet

- Pflex Br008 en PDocument8 pagesPflex Br008 en PMarkNo ratings yet

- Product Profile - Kinetix 5500 - 2198-Pp001 - En-PDocument4 pagesProduct Profile - Kinetix 5500 - 2198-Pp001 - En-PNicolás A. SelvaggioNo ratings yet

- Powerflex 700S High Performance Ac Drive: Technical Data - Phase I ControlDocument76 pagesPowerflex 700S High Performance Ac Drive: Technical Data - Phase I Controlsofiyan hadyNo ratings yet

- NHP Range of PowerFlex Low Voltage DrivesDocument16 pagesNHP Range of PowerFlex Low Voltage DrivesIvan ArdiyanNo ratings yet

- 20a td001 - en PDocument48 pages20a td001 - en PAlejandro HernandezNo ratings yet

- InfoPLC Net PowerFlex 525 AC DrivesDocument34 pagesInfoPLC Net PowerFlex 525 AC DrivesgodoyunipNo ratings yet

- Pflex sg002 - en PDocument123 pagesPflex sg002 - en PGhassan MansourNo ratings yet

- Bien Tan RockwelDocument157 pagesBien Tan RockwelThanhVuongNguyenNo ratings yet

- Brochure - PowerFlex 520-Series AC Drives - 520-BR001D-En-P - June 2015Document24 pagesBrochure - PowerFlex 520-Series AC Drives - 520-BR001D-En-P - June 2015Nicolás A. SelvaggioNo ratings yet

- PowerFlex LV Drives - News (FUNCTION)Document46 pagesPowerFlex LV Drives - News (FUNCTION)Helio DautoNo ratings yet

- PowerFlex AC Drives Family MigrationDocument13 pagesPowerFlex AC Drives Family MigrationGermán MoralesNo ratings yet

- Allen-Bradley Powerflex 525 Ac Drives: The Next Generation of Powerful Performance and Flexible ControlDocument36 pagesAllen-Bradley Powerflex 525 Ac Drives: The Next Generation of Powerful Performance and Flexible ControlPhillip BuchananNo ratings yet

- RSLogix 5000 V20 ExternalDocument29 pagesRSLogix 5000 V20 Externalruben dario0% (1)

- VariadorDocument120 pagesVariadoripy45101No ratings yet

- Powerflex® 525 Ac Drive: Enhanced Versatility Comes in An Innovative New DesignDocument1 pagePowerflex® 525 Ac Drive: Enhanced Versatility Comes in An Innovative New DesigntrandanhhaiNo ratings yet

- L09 - Drive Configuration and Programming Lab: PublicDocument133 pagesL09 - Drive Configuration and Programming Lab: PubliccuongvcsNo ratings yet

- PowerFlex Digital DC Drive Technical DataDocument86 pagesPowerFlex Digital DC Drive Technical Datahartman_mdNo ratings yet

- PowerFlex® 755 On-Machine™ DriveDocument4 pagesPowerFlex® 755 On-Machine™ Drivevoltampere03No ratings yet

- Catalogue Pflex VariateurDocument94 pagesCatalogue Pflex VariateurRedouaneNo ratings yet

- 525 pp001 - en PDocument2 pages525 pp001 - en PdanceNo ratings yet

- Abb Acs380 Acs880 Catalog en Reva 3aua0000187460 0106Document36 pagesAbb Acs380 Acs880 Catalog en Reva 3aua0000187460 0106Er Amandeep SinghNo ratings yet

- PowerFlex Low Voltage Drives Selection GuideDocument100 pagesPowerFlex Low Voltage Drives Selection GuideMarius GligorNo ratings yet

- Catalog Altivar Process ATV600 Variable Speed DrivesDocument133 pagesCatalog Altivar Process ATV600 Variable Speed Drivesrabia akramNo ratings yet

- InfoPLC Net Studio5000 V21 KTACDocument51 pagesInfoPLC Net Studio5000 V21 KTACReynan Giacomin Borlini100% (1)

- Pflex-Sg002 - En-P Guide of Selection Drive Low VoltajeDocument60 pagesPflex-Sg002 - En-P Guide of Selection Drive Low VoltajeJuan Carlos LópezNo ratings yet

- PowerFlex 70Document48 pagesPowerFlex 70Daniel PuenteNo ratings yet

- Product Profile: Powerflex® DC DriveDocument4 pagesProduct Profile: Powerflex® DC Drivedhananjaymohapatra2009No ratings yet

- VLT Automation Drive FC 360 PDFDocument16 pagesVLT Automation Drive FC 360 PDFMinh NguyễnNo ratings yet

- Iasimp qr009 en P PDFDocument10 pagesIasimp qr009 en P PDFToni PrattNo ratings yet

- Powerflex 700S Drives With Phase Ii Control: Technical DataDocument118 pagesPowerflex 700S Drives With Phase Ii Control: Technical DataJosmar DuqueNo ratings yet

- Drive Emerson DatasheetDocument12 pagesDrive Emerson DatasheetArmando JuarezNo ratings yet

- 2094 pp004 - en P PDFDocument4 pages2094 pp004 - en P PDFAnindya BasuNo ratings yet

- Commander C Brochure - BenderangDocument28 pagesCommander C Brochure - Benderangfaisal.benderangNo ratings yet

- Its - 04271147Document8 pagesIts - 04271147VladimirKolotNo ratings yet

- Incisive Enterprise PalladiumDocument7 pagesIncisive Enterprise PalladiumSamNo ratings yet

- Industrial Gateway Server From Ge DigitalDocument4 pagesIndustrial Gateway Server From Ge Digitaljahr18No ratings yet

- SMP SG 4250 Substation Gateway Ca912001enDocument20 pagesSMP SG 4250 Substation Gateway Ca912001enNelson Cuevas MojicaNo ratings yet

- x2000 Ac Drive Range CatalogueDocument52 pagesx2000 Ac Drive Range CatalogueDhawal Patel100% (1)

- Controllogix: Selection GuideDocument92 pagesControllogix: Selection GuideneoflashNo ratings yet

- Acs150 Catalog en 3afe68596114 RevhDocument16 pagesAcs150 Catalog en 3afe68596114 Revhnajdo1No ratings yet

- Controllers 60386168Document12 pagesControllers 60386168RICADO LOPEZ OROZCONo ratings yet

- ABB ACS550 DrivesDocument25 pagesABB ACS550 Drivesprasad076No ratings yet

- Commander General Purpose AC Variable Speed Drives BrochureDocument28 pagesCommander General Purpose AC Variable Speed Drives BrochureTraian SerbanNo ratings yet

- Factsheet AVP254 V1.0Document4 pagesFactsheet AVP254 V1.0SamNo ratings yet

- Drive Solutions: We EngineerDocument8 pagesDrive Solutions: We EngineerDoDuyBacNo ratings yet

- Enet pp005 - en eDocument5 pagesEnet pp005 - en eMancamiaicuruNo ratings yet

- Powerflex 700 Adjustable Frequency Ac Drive: Technical DataDocument90 pagesPowerflex 700 Adjustable Frequency Ac Drive: Technical DataЕвгений ЛогиновNo ratings yet

- Switch 5700Document4 pagesSwitch 5700BlAdE 12No ratings yet

- PowerFlex 525 AC Drive Internal PresentationDocument70 pagesPowerFlex 525 AC Drive Internal PresentationJoseph BurgosNo ratings yet

- SMP™ SG-4250 Substation Gateway: Cooper PowerDocument20 pagesSMP™ SG-4250 Substation Gateway: Cooper PowerDavid Lozada TorresNo ratings yet

- PowerFlex 755T Brochure 2022Document14 pagesPowerFlex 755T Brochure 2022beni oscar sNo ratings yet

- Industrial Gateway Server 7.68: From GE DigitalDocument4 pagesIndustrial Gateway Server 7.68: From GE DigitalMurilo GeambastianiNo ratings yet

- NE200 & NE300: High Performance Vector Control DriveDocument20 pagesNE200 & NE300: High Performance Vector Control DriveVũ Duy HảiNo ratings yet

- Cisco 5500 Series Wireless Controllers: Maximum Performance and ScalabilityDocument8 pagesCisco 5500 Series Wireless Controllers: Maximum Performance and ScalabilityarryfakhNo ratings yet

- Control Wave RTUDocument22 pagesControl Wave RTUAnonymous awwd0cnNo ratings yet

- PowerFlex 525 CCW Basic Programming NEWDocument54 pagesPowerFlex 525 CCW Basic Programming NEWOLAWALE100% (1)

- VLSI Design for Video Coding: H.264/AVC Encoding from Standard Specification to ChipFrom EverandVLSI Design for Video Coding: H.264/AVC Encoding from Standard Specification to ChipNo ratings yet

- Next-Generation switching OS configuration and management: Troubleshooting NX-OS in Enterprise EnvironmentsFrom EverandNext-Generation switching OS configuration and management: Troubleshooting NX-OS in Enterprise EnvironmentsNo ratings yet

- Graph of A RelationDocument48 pagesGraph of A RelationHamza KahemelaNo ratings yet

- Past PerfDocument2 pagesPast Perfmilenerato22400% (1)

- Introduction To System Identification: Jan Swevers July 2006Document74 pagesIntroduction To System Identification: Jan Swevers July 2006Amino fileNo ratings yet

- 1.1 Introduction To TrainingDocument35 pages1.1 Introduction To TrainingArpan SoniNo ratings yet

- Bayley DevelopmentMotorAbilities 1936Document29 pagesBayley DevelopmentMotorAbilities 1936Ave BellowsNo ratings yet

- (B) Projectile Motion (Exercise) PDFDocument38 pages(B) Projectile Motion (Exercise) PDFdevansh dewanNo ratings yet

- 00 Shut Down 2018 - Presentation Wafa Field 18 March - Rev1Document29 pages00 Shut Down 2018 - Presentation Wafa Field 18 March - Rev1بريجينيف خروتشوفNo ratings yet

- 3 Statistical ConceptsDocument34 pages3 Statistical ConceptsP.T. SaleendranNo ratings yet

- Tiktoksellercenter Batchupload 20240130 TemplateDocument23 pagesTiktoksellercenter Batchupload 20240130 TemplateHakim AzisonNo ratings yet

- Exercises of Trigometric Function and Coordinates GeometryDocument13 pagesExercises of Trigometric Function and Coordinates GeometryKuen Jian LinNo ratings yet

- ASPECTOS GEOTECNICOS EN INTERVENTORIA - Ing. Ruben Dario Tovar ValenciaDocument62 pagesASPECTOS GEOTECNICOS EN INTERVENTORIA - Ing. Ruben Dario Tovar ValenciaAndres SobrinoNo ratings yet

- A Recommended Practice Design, Manufacture and Installation of Glass Reinforced Concrete (GRC)Document92 pagesA Recommended Practice Design, Manufacture and Installation of Glass Reinforced Concrete (GRC)cbler100% (2)

- Aleksey - Baldygin - 201501 - PHD - Oil Recovery in Porous Media Using Emulsion FloodingDocument362 pagesAleksey - Baldygin - 201501 - PHD - Oil Recovery in Porous Media Using Emulsion FloodingGerardo San Luis PotosiNo ratings yet

- CATOLOGO EASY ScheniderDocument78 pagesCATOLOGO EASY ScheniderVladimir Santos Mariano OrtegaNo ratings yet

- Ball-Bearing Motor: Joseph Henry Laboratories, Princeton University, Princeton, NJ 08544Document5 pagesBall-Bearing Motor: Joseph Henry Laboratories, Princeton University, Princeton, NJ 08544Gabriel AlesNo ratings yet

- Laplace QB - DSEDocument1 pageLaplace QB - DSEmirek22938No ratings yet

- HP Device Manager Administrator Guide en USDocument91 pagesHP Device Manager Administrator Guide en USYorick VeldscholtenNo ratings yet

- MELNICENKO Patent WO2007069936A1 enDocument12 pagesMELNICENKO Patent WO2007069936A1 enMihai DanielNo ratings yet

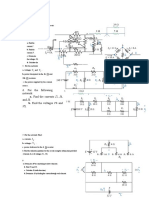

- For The Following Network and I8.: A. Find The Currents I2, I6, B. Find The Voltages V4 andDocument2 pagesFor The Following Network and I8.: A. Find The Currents I2, I6, B. Find The Voltages V4 andعبدالله عبدالحكيم عامرNo ratings yet

- Online Handwriting Recognition SystemDocument31 pagesOnline Handwriting Recognition SystemRakesh AhujaNo ratings yet

- Flex Pak 3000Document24 pagesFlex Pak 3000Maitry ShahNo ratings yet

- Initial Analysis of PCM Integrated Solar CollectorsDocument5 pagesInitial Analysis of PCM Integrated Solar CollectorsTushar Kant SwainNo ratings yet

- Neuroscience Ii: Summary: Nationality (Will Tell You Incidence, For Example, AsiansDocument29 pagesNeuroscience Ii: Summary: Nationality (Will Tell You Incidence, For Example, AsiansAngelaTrinidad100% (2)

- String Operations in PythonDocument6 pagesString Operations in PythonShubhraNo ratings yet

- Tai Lieu Xi MangDocument207 pagesTai Lieu Xi MangthanhNo ratings yet