Professional Documents

Culture Documents

100VV-TD-ITE-HS0001-00 - Lifting - Systems - Certifications

100VV-TD-ITE-HS0001-00 - Lifting - Systems - Certifications

Uploaded by

emiletoumaCopyright:

Available Formats

You might also like

- Torque Wrench Settings: History of This DocumentDocument35 pagesTorque Wrench Settings: History of This Documentpatrick crowley100% (1)

- S4965V2166 FS Preliminary PDFDocument20 pagesS4965V2166 FS Preliminary PDFmartinuruguayNo ratings yet

- Prosurge - CE CertificationDocument3 pagesProsurge - CE CertificationSamuel RoxasNo ratings yet

- Fire Protection Standard For Vehicles and Moving MachineryDocument39 pagesFire Protection Standard For Vehicles and Moving Machineryjonodo89100% (1)

- Super 456Document70 pagesSuper 456Alem LoajnerNo ratings yet

- CAIRN TSG Y SP 0013 B1 Specification For External Coating of Line PipesDocument23 pagesCAIRN TSG Y SP 0013 B1 Specification For External Coating of Line PipesKRUNAL SHAHNo ratings yet

- Marine Electrical Practice: Marine Engineering SeriesFrom EverandMarine Electrical Practice: Marine Engineering SeriesRating: 4 out of 5 stars4/5 (8)

- HSE Information Sheet Ageing Semi-Submersible Installations Offshore Information Sheet No 5 2007Document5 pagesHSE Information Sheet Ageing Semi-Submersible Installations Offshore Information Sheet No 5 2007Saeed JabbariNo ratings yet

- Newtons 2nd Law Practice ProblemsDocument3 pagesNewtons 2nd Law Practice ProblemsJehmmaRosalesCarpisoNo ratings yet

- D Ti SPC Psi Protct 7101Document80 pagesD Ti SPC Psi Protct 7101MECHANICAL DESIGNNo ratings yet

- Specification For Motor Operated Valve (MOVs)Document9 pagesSpecification For Motor Operated Valve (MOVs)prabha haranNo ratings yet

- Draft Spec. For Set of Panels For LHB Non AC EOG Coaches PDFDocument27 pagesDraft Spec. For Set of Panels For LHB Non AC EOG Coaches PDFVishal Kinikar0% (1)

- Delivery Programme: IVS Mounting Rail Adapter Part No. M22-IVS Article No. 216400 Catalog No. M22-IVSQDocument1 pageDelivery Programme: IVS Mounting Rail Adapter Part No. M22-IVS Article No. 216400 Catalog No. M22-IVSQRamius HamdaniNo ratings yet

- Draft Spect No Ti-Psi-Hvcb-0121Document38 pagesDraft Spect No Ti-Psi-Hvcb-0121Lanka SatyavathiNo ratings yet

- New Emv550Document62 pagesNew Emv550Rajan Mullappilly100% (1)

- RDSO Specification For RelayDocument58 pagesRDSO Specification For RelayTarun Bhateja100% (2)

- Data Sheet CMCE HOME - 2020 - ENGDocument2 pagesData Sheet CMCE HOME - 2020 - ENGlumoodleyNo ratings yet

- Job Specification For CMSDocument12 pagesJob Specification For CMSTauqueerAhmadNo ratings yet

- Cable TrayDocument6 pagesCable TrayMuralimohan Pandian100% (2)

- TI STR 024 Rev 3Document3 pagesTI STR 024 Rev 3Snzy DelNo ratings yet

- SC-CH4 Manual - Eng - 25 - 09 - 2012Document29 pagesSC-CH4 Manual - Eng - 25 - 09 - 2012Lý Chính ĐạoNo ratings yet

- 1 Wellhead - SolutionsDocument4 pages1 Wellhead - SolutionsMarwen GataaNo ratings yet

- Arlv 0000 PisDocument1 pageArlv 0000 PisBruno CunhaNo ratings yet

- Quality Control Procedure Installation of Switchgears, Motor Control Centers and Bus Ducts (Guideline)Document9 pagesQuality Control Procedure Installation of Switchgears, Motor Control Centers and Bus Ducts (Guideline)Muralimohan PandianNo ratings yet

- C and R PanelDocument91 pagesC and R PanelMere Thakur JiNo ratings yet

- C&R Panel (Without Automation) - Nov, 2016Document73 pagesC&R Panel (Without Automation) - Nov, 2016Dramebaaz SandeepNo ratings yet

- Control and Relay PanelsDocument122 pagesControl and Relay Panelsmfm tendersNo ratings yet

- AEC Q100 Rev IDocument49 pagesAEC Q100 Rev Ielnaz moghaddamNo ratings yet

- ACS Motion Control - Tech80 SB 1381 ManualDocument183 pagesACS Motion Control - Tech80 SB 1381 ManualPsaNo ratings yet

- PEC-QU-GDE-X-10866 Rev 3, QCP-E-0003Document7 pagesPEC-QU-GDE-X-10866 Rev 3, QCP-E-0003Muralimohan PandianNo ratings yet

- Yanbu Industrial City, KSA: Itp For Hvac (Heating Ventilation and Air Conditioning) System InstallationDocument5 pagesYanbu Industrial City, KSA: Itp For Hvac (Heating Ventilation and Air Conditioning) System InstallationHARSHAL100% (2)

- NR SP CTM 017Document82 pagesNR SP CTM 017omar sarairehNo ratings yet

- C R Panel (With Automation) Nov 2016 - 17.03.2017Document88 pagesC R Panel (With Automation) Nov 2016 - 17.03.2017Ratheesh KumarNo ratings yet

- Draft Spect No. TI-SPC-PSI-LVCBIN-0121Document51 pagesDraft Spect No. TI-SPC-PSI-LVCBIN-0121lovely jiNo ratings yet

- Guide of Methods For Determining The Condition of Stator Winding Insulation - ELT - 270 - 3 PDFDocument4 pagesGuide of Methods For Determining The Condition of Stator Winding Insulation - ELT - 270 - 3 PDFrad1962100% (1)

- ABB SR EnclosuresDocument306 pagesABB SR EnclosuresMuhannadNo ratings yet

- Auxilliary Power, Control and Instrumentation Cable: Technical SpecificationsDocument21 pagesAuxilliary Power, Control and Instrumentation Cable: Technical Specificationsg.HtrughtreNo ratings yet

- NESMA-ITP-ELE-002-Rev.00 Conduit SystemDocument4 pagesNESMA-ITP-ELE-002-Rev.00 Conduit Systemilyas khanNo ratings yet

- Certificate of Compliance: Certificate's Holder: Shanghai Cybervision Tech. Co., LTDDocument1 pageCertificate of Compliance: Certificate's Holder: Shanghai Cybervision Tech. Co., LTDpedro_305054296No ratings yet

- 3KL84213UA00 Datasheet enDocument2 pages3KL84213UA00 Datasheet enE CNo ratings yet

- CAIRN TSG L SP 0009 B1 Specification For General WeldingDocument21 pagesCAIRN TSG L SP 0009 B1 Specification For General WeldingsumeshNo ratings yet

- PQ-TEC-300 - Inspection Procedure of Electrical InspectionDocument13 pagesPQ-TEC-300 - Inspection Procedure of Electrical InspectionTouil Houssem100% (1)

- 9718 0026 Model GEO-FM, WS, PM Frangible Towers and MastsDocument4 pages9718 0026 Model GEO-FM, WS, PM Frangible Towers and MastsHicham RochdiNo ratings yet

- 08.05.15 Draft Spec. For SBC (EDTS 073)Document56 pages08.05.15 Draft Spec. For SBC (EDTS 073)ज्ञानेश्वर जरेNo ratings yet

- EETT Salas ElectricasDocument22 pagesEETT Salas ElectricasleonardoNo ratings yet

- Xh31a 0000 0002 - R1BDocument30 pagesXh31a 0000 0002 - R1Bs07081991100% (1)

- Fs 4031 Eg Package, Rev-0Document16 pagesFs 4031 Eg Package, Rev-0Dinesh RajNo ratings yet

- NORDAC Vector MC: Getriebebau NORD ... NORD GearDocument26 pagesNORDAC Vector MC: Getriebebau NORD ... NORD GearjorgeNo ratings yet

- SPC Ti SPC Psi Protct 7101Document74 pagesSPC Ti SPC Psi Protct 7101Khotokar Venkata Nagaraja RaoNo ratings yet

- Koc e 007 - 1Document58 pagesKoc e 007 - 1inbNo ratings yet

- Technical Specifications For Construction Tower Support 113-Shc-Ta-001 and 113-Sch-Ta-002 at The Coke Handling SystemDocument12 pagesTechnical Specifications For Construction Tower Support 113-Shc-Ta-001 and 113-Sch-Ta-002 at The Coke Handling SystemAna RojasNo ratings yet

- PV1100 Plus CE CERTIFICATEDocument1 pagePV1100 Plus CE CERTIFICATERennerNo ratings yet

- 10 400 KV PANTO Isolator R2 Jan12Document39 pages10 400 KV PANTO Isolator R2 Jan12binodeNo ratings yet

- Vk-A Series Model Vk-202A Transducer Instruction ManualDocument63 pagesVk-A Series Model Vk-202A Transducer Instruction ManualShiva KotamrajuNo ratings yet

- M Storm Drainage System IC M SDS 00Document2 pagesM Storm Drainage System IC M SDS 00achusanachuNo ratings yet

- I-Et-3010.00-1200-200-P4x-116 - 0-Requirements For Bolted JointsDocument21 pagesI-Et-3010.00-1200-200-P4x-116 - 0-Requirements For Bolted JointsMarcelo GardengkiNo ratings yet

- en de 220128Document84 pagesen de 220128MisaelNo ratings yet

- En 3VL9700-4TG30Document2 pagesEn 3VL9700-4TG30marslan7586No ratings yet

- RDSO PE SPEC AC 0138-2009 Rev 2 or LatestDocument23 pagesRDSO PE SPEC AC 0138-2009 Rev 2 or LatestRajnish KumarNo ratings yet

- Instrument Commissioning Checklist PDF FreeDocument13 pagesInstrument Commissioning Checklist PDF FreeVictor CondoriNo ratings yet

- CCTV Surveillance: Video Practices and TechnologyFrom EverandCCTV Surveillance: Video Practices and TechnologyRating: 5 out of 5 stars5/5 (2)

- Module 2 Assessment TaskDocument4 pagesModule 2 Assessment TaskJoner Lauresta GiraoNo ratings yet

- Give Your Recommended Intervention in The Case Study Assigned To Your Division. Case Study 1: Oriental MindoroDocument4 pagesGive Your Recommended Intervention in The Case Study Assigned To Your Division. Case Study 1: Oriental MindoroMark-Christopher Roi Pelobello MontemayorNo ratings yet

- C700D5 - SpecsDocument17 pagesC700D5 - SpecsElias Abou FakhrNo ratings yet

- Checklist For IE - UNESCODocument4 pagesChecklist For IE - UNESCOelaine marieNo ratings yet

- Lecture 7Document28 pagesLecture 7Nkugwa Mark WilliamNo ratings yet

- Garden City MovementDocument13 pagesGarden City MovementLenard O. MelgarNo ratings yet

- Supertronic 0w40 Low SapsDocument1 pageSupertronic 0w40 Low SapsOros FeliciaNo ratings yet

- J6-S9014 DatasheetDocument2 pagesJ6-S9014 DatasheetOreol100% (1)

- IS18005 - Update BIOS Boot Option When Changing Compact Flash Card - Iss1.0Document4 pagesIS18005 - Update BIOS Boot Option When Changing Compact Flash Card - Iss1.0caar100No ratings yet

- TraceDocument2,936 pagesTraceMarisa Tamba.2005No ratings yet

- IE 337 W10 Lecture 1 IntroductionDocument45 pagesIE 337 W10 Lecture 1 IntroductionshanthakumargcNo ratings yet

- FILIPINO Calendar of ActivitiesDocument2 pagesFILIPINO Calendar of ActivitiesMariven NavarroNo ratings yet

- Disability Tax Credit InstructionsDocument12 pagesDisability Tax Credit InstructionsShauna PaynterNo ratings yet

- PMU0037Document58 pagesPMU0037artcav59No ratings yet

- Ensemble Performance: Elaine GoodmanDocument10 pagesEnsemble Performance: Elaine GoodmanizzatbukhoriNo ratings yet

- Color Atlas of Diagnostic MicrobiologyDocument223 pagesColor Atlas of Diagnostic MicrobiologyOana Herea100% (2)

- 2-Tourism and CrimeDocument17 pages2-Tourism and CrimeJohn Melvin AbonitallaNo ratings yet

- Purchasing Process Pt. 2: Laboratory ExerciseDocument6 pagesPurchasing Process Pt. 2: Laboratory ExercisebeverlybandojoNo ratings yet

- DFC20203 Database Design: Topic 3Document7 pagesDFC20203 Database Design: Topic 3Zoro RoNo ratings yet

- Fintech Adoption and Its Impact On Sustainability: Risk Benefit Analysis of An Emerging EconomyDocument32 pagesFintech Adoption and Its Impact On Sustainability: Risk Benefit Analysis of An Emerging EconomyAudit and Accounting ReviewNo ratings yet

- Variable Valve Timing & Acoustic Control Induction Systems: Section 8Document19 pagesVariable Valve Timing & Acoustic Control Induction Systems: Section 8sungjoo75No ratings yet

- Landscape and Urban Planning: Jie Su, Alexandros GasparatosDocument15 pagesLandscape and Urban Planning: Jie Su, Alexandros GasparatosMaria Claudia VergaraNo ratings yet

- Creating Customer Value Developing A Value Proposition and PositioningDocument3 pagesCreating Customer Value Developing A Value Proposition and PositioningЕmil KostovNo ratings yet

- AJP VMFWH 22142Document44 pagesAJP VMFWH 22142mrprem7768No ratings yet

- Skhema Sanyo PDFDocument29 pagesSkhema Sanyo PDFKebon KedolNo ratings yet

- Metamorphism: Directions: The Transformation of A Certain Rock-Type Into A Metamorphic Rock TakesDocument4 pagesMetamorphism: Directions: The Transformation of A Certain Rock-Type Into A Metamorphic Rock TakesLizelle Anie ArcilloNo ratings yet

- Us0ab 21023133 21023133Document1 pageUs0ab 21023133 21023133krish.gkavarapuNo ratings yet

- RT Usersguide PDFDocument36 pagesRT Usersguide PDFRoy RamosNo ratings yet

100VV-TD-ITE-HS0001-00 - Lifting - Systems - Certifications

100VV-TD-ITE-HS0001-00 - Lifting - Systems - Certifications

Uploaded by

emiletoumaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

100VV-TD-ITE-HS0001-00 - Lifting - Systems - Certifications

100VV-TD-ITE-HS0001-00 - Lifting - Systems - Certifications

Uploaded by

emiletoumaCopyright:

Available Formats

ITE

MANDATORY

TECHNICAL INSTRUCTION

No.: 100VV-TD-ITE-HS0001 Date: 10 dic 2019 Rev.: 00

STRUCTURAL BUILDING

DESIGN

How to manage certifications requests for lifting CALCULATION PHYSICS

Title: Discipline:

systems MATERIAL QA/QC HS&E

ABSTRACT

This technical instruction applies to European market and formally defines the product certifications which are

required for the different parts of a panels lifting system.

ISSUE

In order to standardize the topic and Company level, rather than at Group level, Permasteelisa SpA decided to

create this document and track how to manage the certifications requests for lifting systems.

NOTE

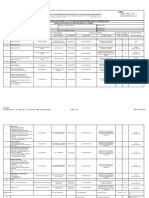

The following table summarizes the elements that might be part of a lifting system and states the required

certification for their use in the European market.

Sketch Element Certification

Lifting beam Machinery Directive,

2006/42/EC

Lifting eyebolts Machinery Directive,

2006/42/EC

Lifting blocks and plates or Machinery Directive,

other temporary elements 2006/42/EC

designed on project

specification

Hook brackets attached to Construction products

mullions regulation, 305/2011 with

reference to curtain wall

system standard, EN 13830

Note: certifications for parts attached to panels are obtained

through PMU and resulting CE certification for the whole

curtain wall system.

Form: 100VV-TD-ITE rev.00 dated 05 Oct 2017

Prepared by: C. Bergamin Checked by: M. Dal Cin Approved by: G. Franceschet

P. F. Marton P. Quaia

File: 100VV-TD-ITE-HS0001-00 _ Lifting_systems_certifications Page 1 / 2

ITE

MANDATORY

TECHNICAL INSTRUCTION

Alloy steel bow shackles with Screw pin shackles

screw pin EN 13889

Note: only EN 13889 certifies that screw pin shackles are

suitable for both static and dynamic loads; shackles certified

according to different regulations cannot be used for lifting

operations.

Additional lifting accessories: Machinery Directive,

chains, belts, straps, slings, 2006/42/EC

hooks

ACTION

PDM, PE

Define the elements of the lifting system: designed on purpose or chosen from technical catalog (in this case,

make sure their available certification corresponds to the required one).

Explicit the working load limit (WLL), the required certification and the part surface color (preferable: yellow,

orange) in the fabrication drawing of each designed element; e.g.:

In case there is no fabrication drawing for the part, WLL, certification and additional characteristics shall be

indicated in the material request (in the “Description” field).

In case of extra-European market, ask the Client’s consultant to clarify the necessary certifications in the

reference market

BUYER

Submit the elements drawings to suppliers and issue a purchase order line for the requests of certificates.

Make sure the supplier delivers the proper certificates in the language of the project country and, once received,

forward them to the project team so that they can be inserted in the dedicated project folder.

SITE MANAGER

Before using the lifting system elements delivered to site verify they are properly marked according to the

corresponding certifications and make sure their certificates are available; in case of missing marking or

certificate the element shall be put in quarantine and cannot be used before receiving it.

Example of marking on bespoke temporary lifting element

Pemasteelisa fabrication drawing code Working Load Limit

Unique part serial number

Form: 100VV-TD-ITE rev.00 dated 05 Oct 2017

Prepared by: C. Bergamin Checked by: M. Dal Cin Approved by: G. Franceschet

P. F. Marton P. Quaia

File: 100VV-TD-ITE-HS0001-00 _ Lifting_systems_certifications Page 2 / 2

You might also like

- Torque Wrench Settings: History of This DocumentDocument35 pagesTorque Wrench Settings: History of This Documentpatrick crowley100% (1)

- S4965V2166 FS Preliminary PDFDocument20 pagesS4965V2166 FS Preliminary PDFmartinuruguayNo ratings yet

- Prosurge - CE CertificationDocument3 pagesProsurge - CE CertificationSamuel RoxasNo ratings yet

- Fire Protection Standard For Vehicles and Moving MachineryDocument39 pagesFire Protection Standard For Vehicles and Moving Machineryjonodo89100% (1)

- Super 456Document70 pagesSuper 456Alem LoajnerNo ratings yet

- CAIRN TSG Y SP 0013 B1 Specification For External Coating of Line PipesDocument23 pagesCAIRN TSG Y SP 0013 B1 Specification For External Coating of Line PipesKRUNAL SHAHNo ratings yet

- Marine Electrical Practice: Marine Engineering SeriesFrom EverandMarine Electrical Practice: Marine Engineering SeriesRating: 4 out of 5 stars4/5 (8)

- HSE Information Sheet Ageing Semi-Submersible Installations Offshore Information Sheet No 5 2007Document5 pagesHSE Information Sheet Ageing Semi-Submersible Installations Offshore Information Sheet No 5 2007Saeed JabbariNo ratings yet

- Newtons 2nd Law Practice ProblemsDocument3 pagesNewtons 2nd Law Practice ProblemsJehmmaRosalesCarpisoNo ratings yet

- D Ti SPC Psi Protct 7101Document80 pagesD Ti SPC Psi Protct 7101MECHANICAL DESIGNNo ratings yet

- Specification For Motor Operated Valve (MOVs)Document9 pagesSpecification For Motor Operated Valve (MOVs)prabha haranNo ratings yet

- Draft Spec. For Set of Panels For LHB Non AC EOG Coaches PDFDocument27 pagesDraft Spec. For Set of Panels For LHB Non AC EOG Coaches PDFVishal Kinikar0% (1)

- Delivery Programme: IVS Mounting Rail Adapter Part No. M22-IVS Article No. 216400 Catalog No. M22-IVSQDocument1 pageDelivery Programme: IVS Mounting Rail Adapter Part No. M22-IVS Article No. 216400 Catalog No. M22-IVSQRamius HamdaniNo ratings yet

- Draft Spect No Ti-Psi-Hvcb-0121Document38 pagesDraft Spect No Ti-Psi-Hvcb-0121Lanka SatyavathiNo ratings yet

- New Emv550Document62 pagesNew Emv550Rajan Mullappilly100% (1)

- RDSO Specification For RelayDocument58 pagesRDSO Specification For RelayTarun Bhateja100% (2)

- Data Sheet CMCE HOME - 2020 - ENGDocument2 pagesData Sheet CMCE HOME - 2020 - ENGlumoodleyNo ratings yet

- Job Specification For CMSDocument12 pagesJob Specification For CMSTauqueerAhmadNo ratings yet

- Cable TrayDocument6 pagesCable TrayMuralimohan Pandian100% (2)

- TI STR 024 Rev 3Document3 pagesTI STR 024 Rev 3Snzy DelNo ratings yet

- SC-CH4 Manual - Eng - 25 - 09 - 2012Document29 pagesSC-CH4 Manual - Eng - 25 - 09 - 2012Lý Chính ĐạoNo ratings yet

- 1 Wellhead - SolutionsDocument4 pages1 Wellhead - SolutionsMarwen GataaNo ratings yet

- Arlv 0000 PisDocument1 pageArlv 0000 PisBruno CunhaNo ratings yet

- Quality Control Procedure Installation of Switchgears, Motor Control Centers and Bus Ducts (Guideline)Document9 pagesQuality Control Procedure Installation of Switchgears, Motor Control Centers and Bus Ducts (Guideline)Muralimohan PandianNo ratings yet

- C and R PanelDocument91 pagesC and R PanelMere Thakur JiNo ratings yet

- C&R Panel (Without Automation) - Nov, 2016Document73 pagesC&R Panel (Without Automation) - Nov, 2016Dramebaaz SandeepNo ratings yet

- Control and Relay PanelsDocument122 pagesControl and Relay Panelsmfm tendersNo ratings yet

- AEC Q100 Rev IDocument49 pagesAEC Q100 Rev Ielnaz moghaddamNo ratings yet

- ACS Motion Control - Tech80 SB 1381 ManualDocument183 pagesACS Motion Control - Tech80 SB 1381 ManualPsaNo ratings yet

- PEC-QU-GDE-X-10866 Rev 3, QCP-E-0003Document7 pagesPEC-QU-GDE-X-10866 Rev 3, QCP-E-0003Muralimohan PandianNo ratings yet

- Yanbu Industrial City, KSA: Itp For Hvac (Heating Ventilation and Air Conditioning) System InstallationDocument5 pagesYanbu Industrial City, KSA: Itp For Hvac (Heating Ventilation and Air Conditioning) System InstallationHARSHAL100% (2)

- NR SP CTM 017Document82 pagesNR SP CTM 017omar sarairehNo ratings yet

- C R Panel (With Automation) Nov 2016 - 17.03.2017Document88 pagesC R Panel (With Automation) Nov 2016 - 17.03.2017Ratheesh KumarNo ratings yet

- Draft Spect No. TI-SPC-PSI-LVCBIN-0121Document51 pagesDraft Spect No. TI-SPC-PSI-LVCBIN-0121lovely jiNo ratings yet

- Guide of Methods For Determining The Condition of Stator Winding Insulation - ELT - 270 - 3 PDFDocument4 pagesGuide of Methods For Determining The Condition of Stator Winding Insulation - ELT - 270 - 3 PDFrad1962100% (1)

- ABB SR EnclosuresDocument306 pagesABB SR EnclosuresMuhannadNo ratings yet

- Auxilliary Power, Control and Instrumentation Cable: Technical SpecificationsDocument21 pagesAuxilliary Power, Control and Instrumentation Cable: Technical Specificationsg.HtrughtreNo ratings yet

- NESMA-ITP-ELE-002-Rev.00 Conduit SystemDocument4 pagesNESMA-ITP-ELE-002-Rev.00 Conduit Systemilyas khanNo ratings yet

- Certificate of Compliance: Certificate's Holder: Shanghai Cybervision Tech. Co., LTDDocument1 pageCertificate of Compliance: Certificate's Holder: Shanghai Cybervision Tech. Co., LTDpedro_305054296No ratings yet

- 3KL84213UA00 Datasheet enDocument2 pages3KL84213UA00 Datasheet enE CNo ratings yet

- CAIRN TSG L SP 0009 B1 Specification For General WeldingDocument21 pagesCAIRN TSG L SP 0009 B1 Specification For General WeldingsumeshNo ratings yet

- PQ-TEC-300 - Inspection Procedure of Electrical InspectionDocument13 pagesPQ-TEC-300 - Inspection Procedure of Electrical InspectionTouil Houssem100% (1)

- 9718 0026 Model GEO-FM, WS, PM Frangible Towers and MastsDocument4 pages9718 0026 Model GEO-FM, WS, PM Frangible Towers and MastsHicham RochdiNo ratings yet

- 08.05.15 Draft Spec. For SBC (EDTS 073)Document56 pages08.05.15 Draft Spec. For SBC (EDTS 073)ज्ञानेश्वर जरेNo ratings yet

- EETT Salas ElectricasDocument22 pagesEETT Salas ElectricasleonardoNo ratings yet

- Xh31a 0000 0002 - R1BDocument30 pagesXh31a 0000 0002 - R1Bs07081991100% (1)

- Fs 4031 Eg Package, Rev-0Document16 pagesFs 4031 Eg Package, Rev-0Dinesh RajNo ratings yet

- NORDAC Vector MC: Getriebebau NORD ... NORD GearDocument26 pagesNORDAC Vector MC: Getriebebau NORD ... NORD GearjorgeNo ratings yet

- SPC Ti SPC Psi Protct 7101Document74 pagesSPC Ti SPC Psi Protct 7101Khotokar Venkata Nagaraja RaoNo ratings yet

- Koc e 007 - 1Document58 pagesKoc e 007 - 1inbNo ratings yet

- Technical Specifications For Construction Tower Support 113-Shc-Ta-001 and 113-Sch-Ta-002 at The Coke Handling SystemDocument12 pagesTechnical Specifications For Construction Tower Support 113-Shc-Ta-001 and 113-Sch-Ta-002 at The Coke Handling SystemAna RojasNo ratings yet

- PV1100 Plus CE CERTIFICATEDocument1 pagePV1100 Plus CE CERTIFICATERennerNo ratings yet

- 10 400 KV PANTO Isolator R2 Jan12Document39 pages10 400 KV PANTO Isolator R2 Jan12binodeNo ratings yet

- Vk-A Series Model Vk-202A Transducer Instruction ManualDocument63 pagesVk-A Series Model Vk-202A Transducer Instruction ManualShiva KotamrajuNo ratings yet

- M Storm Drainage System IC M SDS 00Document2 pagesM Storm Drainage System IC M SDS 00achusanachuNo ratings yet

- I-Et-3010.00-1200-200-P4x-116 - 0-Requirements For Bolted JointsDocument21 pagesI-Et-3010.00-1200-200-P4x-116 - 0-Requirements For Bolted JointsMarcelo GardengkiNo ratings yet

- en de 220128Document84 pagesen de 220128MisaelNo ratings yet

- En 3VL9700-4TG30Document2 pagesEn 3VL9700-4TG30marslan7586No ratings yet

- RDSO PE SPEC AC 0138-2009 Rev 2 or LatestDocument23 pagesRDSO PE SPEC AC 0138-2009 Rev 2 or LatestRajnish KumarNo ratings yet

- Instrument Commissioning Checklist PDF FreeDocument13 pagesInstrument Commissioning Checklist PDF FreeVictor CondoriNo ratings yet

- CCTV Surveillance: Video Practices and TechnologyFrom EverandCCTV Surveillance: Video Practices and TechnologyRating: 5 out of 5 stars5/5 (2)

- Module 2 Assessment TaskDocument4 pagesModule 2 Assessment TaskJoner Lauresta GiraoNo ratings yet

- Give Your Recommended Intervention in The Case Study Assigned To Your Division. Case Study 1: Oriental MindoroDocument4 pagesGive Your Recommended Intervention in The Case Study Assigned To Your Division. Case Study 1: Oriental MindoroMark-Christopher Roi Pelobello MontemayorNo ratings yet

- C700D5 - SpecsDocument17 pagesC700D5 - SpecsElias Abou FakhrNo ratings yet

- Checklist For IE - UNESCODocument4 pagesChecklist For IE - UNESCOelaine marieNo ratings yet

- Lecture 7Document28 pagesLecture 7Nkugwa Mark WilliamNo ratings yet

- Garden City MovementDocument13 pagesGarden City MovementLenard O. MelgarNo ratings yet

- Supertronic 0w40 Low SapsDocument1 pageSupertronic 0w40 Low SapsOros FeliciaNo ratings yet

- J6-S9014 DatasheetDocument2 pagesJ6-S9014 DatasheetOreol100% (1)

- IS18005 - Update BIOS Boot Option When Changing Compact Flash Card - Iss1.0Document4 pagesIS18005 - Update BIOS Boot Option When Changing Compact Flash Card - Iss1.0caar100No ratings yet

- TraceDocument2,936 pagesTraceMarisa Tamba.2005No ratings yet

- IE 337 W10 Lecture 1 IntroductionDocument45 pagesIE 337 W10 Lecture 1 IntroductionshanthakumargcNo ratings yet

- FILIPINO Calendar of ActivitiesDocument2 pagesFILIPINO Calendar of ActivitiesMariven NavarroNo ratings yet

- Disability Tax Credit InstructionsDocument12 pagesDisability Tax Credit InstructionsShauna PaynterNo ratings yet

- PMU0037Document58 pagesPMU0037artcav59No ratings yet

- Ensemble Performance: Elaine GoodmanDocument10 pagesEnsemble Performance: Elaine GoodmanizzatbukhoriNo ratings yet

- Color Atlas of Diagnostic MicrobiologyDocument223 pagesColor Atlas of Diagnostic MicrobiologyOana Herea100% (2)

- 2-Tourism and CrimeDocument17 pages2-Tourism and CrimeJohn Melvin AbonitallaNo ratings yet

- Purchasing Process Pt. 2: Laboratory ExerciseDocument6 pagesPurchasing Process Pt. 2: Laboratory ExercisebeverlybandojoNo ratings yet

- DFC20203 Database Design: Topic 3Document7 pagesDFC20203 Database Design: Topic 3Zoro RoNo ratings yet

- Fintech Adoption and Its Impact On Sustainability: Risk Benefit Analysis of An Emerging EconomyDocument32 pagesFintech Adoption and Its Impact On Sustainability: Risk Benefit Analysis of An Emerging EconomyAudit and Accounting ReviewNo ratings yet

- Variable Valve Timing & Acoustic Control Induction Systems: Section 8Document19 pagesVariable Valve Timing & Acoustic Control Induction Systems: Section 8sungjoo75No ratings yet

- Landscape and Urban Planning: Jie Su, Alexandros GasparatosDocument15 pagesLandscape and Urban Planning: Jie Su, Alexandros GasparatosMaria Claudia VergaraNo ratings yet

- Creating Customer Value Developing A Value Proposition and PositioningDocument3 pagesCreating Customer Value Developing A Value Proposition and PositioningЕmil KostovNo ratings yet

- AJP VMFWH 22142Document44 pagesAJP VMFWH 22142mrprem7768No ratings yet

- Skhema Sanyo PDFDocument29 pagesSkhema Sanyo PDFKebon KedolNo ratings yet

- Metamorphism: Directions: The Transformation of A Certain Rock-Type Into A Metamorphic Rock TakesDocument4 pagesMetamorphism: Directions: The Transformation of A Certain Rock-Type Into A Metamorphic Rock TakesLizelle Anie ArcilloNo ratings yet

- Us0ab 21023133 21023133Document1 pageUs0ab 21023133 21023133krish.gkavarapuNo ratings yet

- RT Usersguide PDFDocument36 pagesRT Usersguide PDFRoy RamosNo ratings yet