Professional Documents

Culture Documents

New Braking System For Electric Vehicles

New Braking System For Electric Vehicles

Uploaded by

acajevtic94Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

New Braking System For Electric Vehicles

New Braking System For Electric Vehicles

Uploaded by

acajevtic94Copyright:

Available Formats

194 ELECTRONICS & POWER MARCH 1977

Industry

Engineering Services delivers the goods

Engineering Services, an 'inhouse' service CEGB construction and repair-and- lines solely on income from clients within the

company within the Central Electricity maintenance divisions as well as other clients in CEGB and elsewhere. The services offered

Generating Board, recently held an exhibition the UK and overseas. cover production assurance, quality assurance,

at the CEGB Headquarters in London. The In conjunction with British Electricity technical documentation and field services,

exhibition showed how the organisation International, the organisation recently with activities incorporated into packages as

operates as an independent company, provid- reached agreement with the Atomic Energy consultancy services, plant procurement, site

ing quality- and production-assurance services Organisation of Iran for the supply of a services and specialist services. The packages

to CEGB departments and external clients. complete package of specialist and consultancy are available individually or as a total service.

The organisation employs 600 staff, mostly services associated with the 23 GW Iranian At the exhibition, the first certificates of

qualified engineers, and its work is mainly nuclear-power programme. The package will compliance were awarded to a representative

concerned with mechanical and electrical plant include supervision of quality control and sample of manufacturing organisations which

for conventional and nuclear power stations. inspection at site and at manufacturers, have demonstrated that their systems meet the

The expertise available within the organisation, production assurance to ensure delivery to

programme of plant ordered, and complemen- relevant section of CEGB QA Standard 42

and on call from the CEGB resources, enables (Quality assurance system requirements

it also to undertake comprehensive contract tary technical documentation, design and

training facilities. applicable to CEGB contracts).

consultancy and supervision services on a

variety of high-technology process plant for the Engineering Services is run on commercial Encircle 75

New braking system for

electric vehicles

The economic viability of battery electric would effectively short circuit the battery and

vehicles of all types from buses to forklift blow the traction fuses) and were not capable

trucks depends to a considerable extent on the of operation at low road speeds.

size, weight and cost of the battery necessary Now, as a result of a programme of

to achieve the required range and on reducing development funded jointly by the UK

maintenance requirements to a minimum. Any Department of Industry and Cableform Ltd., a

reduction in battery weight will not only new system of regenerative braking has been

correspondingly reduce its cost, which is a introduced. This system is claimed to have

significant fraction of the total cost of the advantages over earlier designs in that it is

vehicle, but will also enable the vehicle to be simple, can be produced at low cost, will

more lightly built and materially reduce its provide regenerative braking almost to a

energy consumption per kilometre. standstill and requires no critical adjustments.

One approach, known as 'regenerative

braking', is to use the traction motor as a For many years, the well known Pulsomatic

dynamo to feed some of the energy normally Mk 10 controller manufactured by Cableform

wasted in braking back into the battery. This Ltd. has been fitted to battery electric vehicles

will not only reduce the size of battery both in the UK and abroad. This system uses a

necessary, but will also eliminate most of the combination of variable pulse-repetition fre-

wear on the normal brakes, since they will quency and variable pulse width to give

need to be used only for emergencies and for minimum ripple over the whole speed range.

The new system, for which patent action is Integrated circuits mounted in the 'win-

parking, and cut down maintenance quite dows' of a super-8 film, with the terminal

significantly. pending, uses the same driving circuit to

provide smooth and effective braking, and wires functioning both as conductor and

Up to the present time, regenerative braking support, can now be supplied by Siemens.

systems have required a considerable number hence requires only a very small number of

additional components. It can be applied very The starting material for the new circuits is

of additional components in the control circuit a polyimide ribbon cut and perforated

and hence have been costly, have necessitated cheaply to any battery electric vehicle using a

thyristor controller. analogously to a super-8 film. Manufacturer

critical adjustments to provide the requisite and user can thus fall back on the drive and

safety margin against miscommutation (which Encircle 76 transportation technologies of the film

industry for the production facilities they

require. Before the chips are mounted, the

Ferranti expands Argus range film surface is coated with copper, tinned

and etched to produce conductors and

Two new processors to supplement the highly that of the lower end of the 700S range. Like terminal points for the chips. The inner

successful Argus 700 range have been the 700S, it supports 256k of memory, 2 or 4 ends of the conductors protrude into the

announced by Ferranti. At the same time, the word floating point and virtual addressing. 'windows' of the film to provide both

Argus 700 range has been boosted by the Both computers utilise the wide range of physical support and electronic bonding.

introduction of a bipolar memory which microprogrammed input-output processors, Once the chips have been inserted, the film

increases the power of the top of the range backing stores, peripherals, displays and inter- strips are rolled on to reels. About 1000

Argus 700S by 50%, a new low-priced m.o.s. face equipment already available. integrated circuits can be rolled up in this

memory, a range of advanced monitors, The new 150 ns bipolar memory upgrades way on one film. The user of these flat

including an extremely powerful c.r.t.-based the Argus 700S so that it can easily achieve circuits can cut the circuits individually and

monitor for use in system commissioning and about 1 000 000 instructions per second, a install them directly in his equipment.

improved systems control panels. boost of 50% over the performance of the Electronically controlled cameras and flat

The new processors — the Argus 700F and same processor with core memory. This desktop computers have so far been the

700G — are claimed to bridge the power gap operation complements the ported architec- main fields of application, but small

between the existing Argus 700E and Argus ture of the Argus 700S, which allows measuring instruments in which optimum

700S. The Argus 700F operates with an m.o.s. independent input-output processors to oper- space utilisation is a prime consideration

memory of 500 ns cycle time; the maximum ate with time parallel memory access for the are now also utilising the new circuits

memory capacity is 64k 16 bit words. The most demanding data rate applcations.

Argus 700G has a performance approaching Encircle 77 Encircle 78

You might also like

- Diseño y Fabricación de Hologramas Con MatlabDocument273 pagesDiseño y Fabricación de Hologramas Con MatlabEder Manuel Alfaro Alfaro estNo ratings yet

- Ciena 6500 PDFDocument5 pagesCiena 6500 PDFClaudia Dombroski50% (2)

- External Dimensions and Piping Details: PX Pressure Exchanger Energy Recovery DeviceDocument2 pagesExternal Dimensions and Piping Details: PX Pressure Exchanger Energy Recovery Deviceprasad5034No ratings yet

- Fortress Square MallDocument5 pagesFortress Square MallUmair Hassan100% (3)

- Catalogue Automation Kingstar 2021 C500 R1 en WebDocument16 pagesCatalogue Automation Kingstar 2021 C500 R1 en WebFrancisco Blanco FernandezNo ratings yet

- Medium and High Voltage Generators For Steam and Gas TurbinesDocument4 pagesMedium and High Voltage Generators For Steam and Gas TurbinesJose Gabriel Torrico LandaetaNo ratings yet

- Perkins 400 Series 403D-11Document2 pagesPerkins 400 Series 403D-11Juan henaoNo ratings yet

- Perkins 400 Series 404D-22Document2 pagesPerkins 400 Series 404D-22Brayan Enrique Senk TiznadoNo ratings yet

- Day One Green Cloud Metro ArchitectureDocument15 pagesDay One Green Cloud Metro ArchitectureEmil KatzarskiNo ratings yet

- PT - AtT - Egatrol Gas Turbine Solutions - E - Rev1Document4 pagesPT - AtT - Egatrol Gas Turbine Solutions - E - Rev1rafik1995No ratings yet

- Catalogue Automation Kingstar 2020 enDocument16 pagesCatalogue Automation Kingstar 2020 enFrancisco Blanco FernandezNo ratings yet

- Ubiquiti PBE-5AC-500 Data SheetDocument11 pagesUbiquiti PBE-5AC-500 Data SheetJMAC SupplyNo ratings yet

- Acs800multidrives en RevfDocument48 pagesAcs800multidrives en RevfSukhendu MaityNo ratings yet

- AirSpan BrochureDocument8 pagesAirSpan BrochureMadeline CurryNo ratings yet

- 400 Series: Industrial Open Power UnitDocument2 pages400 Series: Industrial Open Power UnitFaiz FadhillahNo ratings yet

- Servoaccionamientos ACOPOSmultiDocument80 pagesServoaccionamientos ACOPOSmultiayenewNo ratings yet

- Grid Xtreme VR Brochure enDocument9 pagesGrid Xtreme VR Brochure enjeorginagNo ratings yet

- Atasheet: High-Performance Airmax BridgeDocument11 pagesAtasheet: High-Performance Airmax BridgeAmitNo ratings yet

- 1206e-E70tta Iopu PN1962Document4 pages1206e-E70tta Iopu PN1962dmitryiNo ratings yet

- Ceragon RFU-C Product Description PDFDocument45 pagesCeragon RFU-C Product Description PDFEsteban Besso Pianetto100% (1)

- 403D-15 IOPU PN1900 Sept10Document2 pages403D-15 IOPU PN1900 Sept10AngelNo ratings yet

- Ceragon RFU-C Product DescriptionDocument45 pagesCeragon RFU-C Product DescriptionGeiss Hurlo BOUKOU BEJELNo ratings yet

- SICAM A8000 Series - Booklet - II - ENDocument11 pagesSICAM A8000 Series - Booklet - II - ENAnonymous ziKTLim100% (1)

- Product Note Engine Generators 9AKK106094 RevC EN 10-2019 Lowres PDFDocument4 pagesProduct Note Engine Generators 9AKK106094 RevC EN 10-2019 Lowres PDFvogid38712No ratings yet

- GCB - Hecs - 1HC0023255 - en - F24-1Document24 pagesGCB - Hecs - 1HC0023255 - en - F24-1shahzaib.hasnainNo ratings yet

- Alstom Grid Services. GIS Lifecycle Management GRIDDocument16 pagesAlstom Grid Services. GIS Lifecycle Management GRIDSarah VaughanNo ratings yet

- Increase in Global Electricity Generation by 2040: 770 Million PeopleDocument21 pagesIncrease in Global Electricity Generation by 2040: 770 Million PeopleJonson CaoNo ratings yet

- 1VDD006114 Catalogue SR-SP 36kV-EN 12-2019Document100 pages1VDD006114 Catalogue SR-SP 36kV-EN 12-2019ArturNo ratings yet

- IAEN Look Book - 20200603Document23 pagesIAEN Look Book - 20200603dave chaudhuryNo ratings yet

- Rexroth D&C For Wind TurbinesDocument16 pagesRexroth D&C For Wind TurbinesxxshNo ratings yet

- Greater Rotor For Greater Benefit: The New SG 8.0-167 DDDocument2 pagesGreater Rotor For Greater Benefit: The New SG 8.0-167 DDRABIH EL MEDAWARNo ratings yet

- Connecting 5G New Radios: Innovation in Mobile ServicesDocument2 pagesConnecting 5G New Radios: Innovation in Mobile ServicesAmiNo ratings yet

- 6500 Packet-Optical Platform: Enabling A Programmable Infrastructure Foundation For The Adaptive NetworkDocument7 pages6500 Packet-Optical Platform: Enabling A Programmable Infrastructure Foundation For The Adaptive NetworkashishNo ratings yet

- Paper Machine Drive System PMC800: Engineered Solutions For SuccessDocument12 pagesPaper Machine Drive System PMC800: Engineered Solutions For SuccessvictorhugomunozhNo ratings yet

- Heavy Duty Rectifier Broschuere Chlor 020 FINALDocument6 pagesHeavy Duty Rectifier Broschuere Chlor 020 FINALdwijanuarpribadiNo ratings yet

- Abb - Catalogo ACS355 PDFDocument56 pagesAbb - Catalogo ACS355 PDFRodrigo Jacy Monteiro MartinsNo ratings yet

- 6500 Packet Optical Platform PBDocument7 pages6500 Packet Optical Platform PBsatyvan2003No ratings yet

- Siemens Fpso Offshore Production PDFDocument4 pagesSiemens Fpso Offshore Production PDFsstrattonNo ratings yet

- ABB ACS800 Drives PDFDocument52 pagesABB ACS800 Drives PDFrobertoNo ratings yet

- Enersys 12V Frontal Batteries Info PDFDocument20 pagesEnersys 12V Frontal Batteries Info PDFLuis Fernando Vargas MarihuanNo ratings yet

- Motors and Drives PDFDocument64 pagesMotors and Drives PDFsomeontorrenteNo ratings yet

- Maritime Pce Best Practice GuideDocument15 pagesMaritime Pce Best Practice GuideJorge Agustin Torres CruzNo ratings yet

- Broch Aerial Trans GBDocument8 pagesBroch Aerial Trans GBsuyambu19No ratings yet

- 0 Pro C1370 enDocument6 pages0 Pro C1370 enDaniel GonzalezNo ratings yet

- Elegance-Ducted-19 11 19Document2 pagesElegance-Ducted-19 11 19Tee Shi FengNo ratings yet

- KUKADocument4 pagesKUKAUmesh SNo ratings yet

- COMBIFLEXDocument10 pagesCOMBIFLEXgyanasilutradingNo ratings yet

- ALSTOM Generator Circuit Breakers PDFDocument12 pagesALSTOM Generator Circuit Breakers PDFAnonymous XpGlmaYIXMNo ratings yet

- ARBURG Packaging Technology 680582 en GBDocument16 pagesARBURG Packaging Technology 680582 en GBketan yadavNo ratings yet

- Ciena 6500Document5 pagesCiena 6500Idir BenferhatNo ratings yet

- Suzlon S88 2.1MW Product Brochure PDFDocument4 pagesSuzlon S88 2.1MW Product Brochure PDFvineeshNo ratings yet

- Q-SeabedBenefits 4113924 01Document4 pagesQ-SeabedBenefits 4113924 01Raden TunaNo ratings yet

- Cacfd-1508 Mains Approach-Answer e 2021Document22 pagesCacfd-1508 Mains Approach-Answer e 2021Nikhil Reddy AndruNo ratings yet

- PCS 6000 - Static Frequency ConvertersDocument6 pagesPCS 6000 - Static Frequency ConvertersmpadliNo ratings yet

- AP1000 Plant DescriptionDocument31 pagesAP1000 Plant DescriptionirfelecNo ratings yet

- Actuadores ElectricosDocument24 pagesActuadores ElectricosJUAN GUEVARA SANCHEZNo ratings yet

- TripticoHydro English v01Document6 pagesTripticoHydro English v01Rajkishor YadavNo ratings yet

- Catalogue Pflex VariateurDocument94 pagesCatalogue Pflex VariateurRedouaneNo ratings yet

- Elegance-Open-19 11 19Document2 pagesElegance-Open-19 11 19eajNo ratings yet

- Highly Integrated Gate Drivers for Si and GaN Power TransistorsFrom EverandHighly Integrated Gate Drivers for Si and GaN Power TransistorsNo ratings yet

- University of Cambridge International Examinations International General Certificate of Secondary EducationDocument20 pagesUniversity of Cambridge International Examinations International General Certificate of Secondary Educationluines78No ratings yet

- Lesson Plan CotDocument21 pagesLesson Plan CotJohn Ray SaldeNo ratings yet

- Anna University Disaster Management QUES BANKDocument4 pagesAnna University Disaster Management QUES BANKJunaid Pantheeran78% (9)

- Per. Dev. Week 2Document21 pagesPer. Dev. Week 2Mi ChellNo ratings yet

- RSEGP-2023 Detailed-Programm Final2Document7 pagesRSEGP-2023 Detailed-Programm Final2huilemoteur2020No ratings yet

- Alexander Binzel Schweisstechnik GMBH & Co. KG P.O. Box 10 01 53 D-35331 Gießen Phone: +49 (0) 64 08 / 59-0 Fax: +49 (0) 64 08 / 59-191Document8 pagesAlexander Binzel Schweisstechnik GMBH & Co. KG P.O. Box 10 01 53 D-35331 Gießen Phone: +49 (0) 64 08 / 59-0 Fax: +49 (0) 64 08 / 59-191Arda YazıcıNo ratings yet

- Florovsky Georges, RedemptionDocument59 pagesFlorovsky Georges, RedemptionStefan MilanovicNo ratings yet

- c5 Conc1 EnergeticsDocument7 pagesc5 Conc1 EnergeticsAlexandra AlexandraNo ratings yet

- TexturingDocument25 pagesTexturingRtr Hasan MahmudNo ratings yet

- SelectaDocument55 pagesSelectaHuong Cam ThuyNo ratings yet

- Troubleshooting Manual For I/O Link Communication Alarm: (System Alarm PC050/PC150/971)Document22 pagesTroubleshooting Manual For I/O Link Communication Alarm: (System Alarm PC050/PC150/971)huutan12345No ratings yet

- Food Microbiology Laboratory For The Food Science Student: Cangliang Shen Yifan ZhangDocument164 pagesFood Microbiology Laboratory For The Food Science Student: Cangliang Shen Yifan ZhangQonita RachmahNo ratings yet

- Bowaon and TotoonDocument1 pageBowaon and TotoonKharine Grace Ursal100% (1)

- M.E VlsiDocument25 pagesM.E VlsiDurai SelvanNo ratings yet

- Presentación Difusión PREXORDocument16 pagesPresentación Difusión PREXORTomas Masquimillan Peñailillo100% (1)

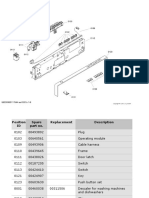

- ΕΓΧΕΙΡΙΔΙΟ ΠΛΥΝΤΗΡΙΟΥ ΠΙΑΤΩΝ - ΑΝΤΑΛΛΑΚΤΙΚΑDocument16 pagesΕΓΧΕΙΡΙΔΙΟ ΠΛΥΝΤΗΡΙΟΥ ΠΙΑΤΩΝ - ΑΝΤΑΛΛΑΚΤΙΚΑΤΣΙΜΠΙΔΗΣ ΠΑΝΑΓΙΩΤΗΣNo ratings yet

- 5 - Introduction To Psychology by James W. Kalat 5Document1 page5 - Introduction To Psychology by James W. Kalat 5Chester ChesterNo ratings yet

- Demand Forecasting and Estimating Methods ProblemsDocument22 pagesDemand Forecasting and Estimating Methods ProblemsNagarjuna ReddyNo ratings yet

- 5WG1527 1AB41 Siemens PDFDocument2 pages5WG1527 1AB41 Siemens PDFsamim_khNo ratings yet

- Plum Concrete WallsDocument4 pagesPlum Concrete WallsnileshNo ratings yet

- Mpman High-Tech Mini Electric Scooter User Manual Model: TR800Document18 pagesMpman High-Tech Mini Electric Scooter User Manual Model: TR800ChrisNo ratings yet

- Handout 3 - BT làm trong tg nghỉ dịch (làm bài)Document10 pagesHandout 3 - BT làm trong tg nghỉ dịch (làm bài)Tuấn Anh NguyễnNo ratings yet

- Super Duper MoxonDocument8 pagesSuper Duper Moxonrus comaresNo ratings yet

- Troubleshooting The Stencil Printing Process: Chrys Shea, Shea Engineering ServicesDocument44 pagesTroubleshooting The Stencil Printing Process: Chrys Shea, Shea Engineering ServicesXuan HoangNo ratings yet

- DC DC: Table 5.13: Overhead Line Conductor - Hard Drawn CopperDocument8 pagesDC DC: Table 5.13: Overhead Line Conductor - Hard Drawn CopperVino VinoNo ratings yet

- Supply Chain Management: Junaid Jamshaid (J.)Document18 pagesSupply Chain Management: Junaid Jamshaid (J.)Mansoor ZainNo ratings yet

- Torr and Li 1993 Gravitoelectric-Electric CouplingDocument13 pagesTorr and Li 1993 Gravitoelectric-Electric Couplingjmulder1No ratings yet

- HarvestlandDocument687 pagesHarvestlandJanetNo ratings yet