Professional Documents

Culture Documents

Gassonic Article Replacement PG 34

Gassonic Article Replacement PG 34

Uploaded by

tdyjOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gassonic Article Replacement PG 34

Gassonic Article Replacement PG 34

Uploaded by

tdyjCopyright:

Available Formats

034_PIN_OCT_10:Layout 1 19/10/10 14:17 Page 34

34 Safety

Fixed Gas Detectors –

Total Speed Of Response

By Mads Kornbech, Area Sales And Marketing Manager, and Martin T. Olesen, Managing Director, Gassonic A/S

It is essential to provide a true picture of the actual response time of a gas detection system to understand the

advantages of ultrasonic gas leak detection.

Ultrasonic gas leak detection technology works by listening for ultrasound emitted from pressurized gas leaks.

The detectors do not have to wait until the gas concentration has accumulated to a dangerous gas cloud.

This significantly reduces the response time.

Conventional point gas detectors can be based on at it due to changing wind directions and fast dilution ultrasonic gas detector compared to a conventional

least two different principles. 1) Infrared (IR) sensors of the gas cloud. Tgas is typically measured in minutes gas detector, is that it does not need to wait for a gas

provide a measure for the gas concentration when gas or hours. concentration to accumulate and form a potentially

gets absorbed by the infrared source. 2) Catalytic In a safety system with gas detectors it is inadequate explosive cloud before it can detect the leak.

sensors provide a gas concentration based on a to use Tdetector. Instead, you need to know the total speed The total speed of response for an ultrasonic gas

chemical reaction on the catalytic sensor element. of response (Ttotal), which is the only parameter that leak detector is calculated like this:

provides a true picture of the actual response time of Ttotal = Tdetector + Tultrasound

the gas detection system.

Tdetector for an ultrasonic detector will typically be

equal to the alarm delay time, which is implemented in

Ultrasonic gas leak detectors - the detector to avoid nuisance alarms. The delay is

and response time typically 10-30 seconds.

Tultrasound is typically measured in microseconds since

it is equal to the time it takes for the ultrasonic sound to

travel from the leak spot to the detector. The graph

below shows the Ttotal for an ultrasonic gas leak detector

[UGLD].

Conclusion

When taking into consideration the speed of response

to gas leaks, making ultrasonic gas leak detectors part

of the plant fire and gas detection system adds an

Whereas the point detector needs to be in contact with the alternative or complementary layer of protection, which

gas to detect the leak, the ultrasonic detector immediately

may increase detection efficiency while reducing the

responds to the leak by picking up the ultrasonic leak noise.

need for a high point sensor count. As the technology is

An ultrasonic gas leak detector installed

based on sound propagation instead of the transport of

in a gas plant in Denmark gas molecules, detectors respond to hazards at a

Conventional Gas Detectors – significantly faster rate than concentration-based

and response time sensors. The detectors are unaffected by environmental

Ultrasonic gas leak detectors, such as the Gassonic conditions like wind, leak dilution, and the direction of

Historically, when referring to the response time for

Observer, work by picking up the high-frequency the leak, which indicate that they have high detection

conventional gas detectors, it is often measured in

ultrasonic leak noise, which is generated by all reliability. When a gas leak occurs, the ultrasound

seconds (using the term T90). However, this response

pressurized gas leaks. The performance standard is set generated by the leak travels at the speed of sound

time is based on gas being injected directly into the

according to which mass flow rate (leak rate) that from the source to the detector therefore reacting

sensor head, which is not likely to be the case in an

needs to be detected. The main advantage of an much faster to the dangerous gas leak.

outdoor windy installation where the gas leak will be

several meters away from the gas detector.

Therefore, when it comes to the total speed

response time for a conventional gas detection system,

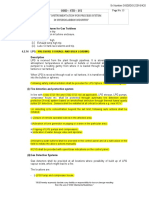

it is important to also include the factor that the gas Total Speed of Response for Fixed Gas Detectors

needs to accumulate and get from the leak point to the

detector. Total speed of response for conventional gas 90% response

detectors should therefore be calculated like this: Tdetector UGLD

nsor

Ttotal = Tdetector + Tgas ntional se

gas to r e ach conve

me for

nknown ti

un

50% response Tgas conventional

‘Tdetector’ can also be referred to as T90 (or T50) and it gas detector

simply tells how long time it takes for the gas detector

to reach 90% (or 50%) of the correct reading when

a well-defined gas concentration is injected directly

into the sensor-head of the detector. Tdetector is normally Tdetector

conventional

10-20 seconds1. gas detector

‘Tgas’ tells how long time it takes for a certain gas

concentration to travel from the leak spot to the T50 T90 Time

detector. This parameter is not very often taken into Ttotal UGLD

consideration simply because it is very difficult to predict

Ttotal conventional gas detectors

1 varies for different models and detector types (IR, catalytic, toxic)

October/November 2010

You might also like

- PTW Questions & AnswersDocument11 pagesPTW Questions & AnswersDijith Jhansi0% (1)

- Marine Department - MCVS&RDocument5 pagesMarine Department - MCVS&REliza's Soothing Sounds100% (1)

- E 685 - 93 R00 - Rty4nqDocument7 pagesE 685 - 93 R00 - Rty4nqpechugonisNo ratings yet

- Smoke Detector Technology Research - Chief Jay FlemingDocument15 pagesSmoke Detector Technology Research - Chief Jay FlemingThe World Fire Safety FoundationNo ratings yet

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- CSE Presentation For Lead Worker Updated Aug 7 2019Document92 pagesCSE Presentation For Lead Worker Updated Aug 7 2019Engr Bilal Ali Rajput100% (3)

- Layered Gas & Flame MonitoringDocument4 pagesLayered Gas & Flame MonitoringMuhammad FerialNo ratings yet

- Photoacoustic Infrared TechnologyDocument7 pagesPhotoacoustic Infrared TechnologyZada BandiNo ratings yet

- 6b OpticalDocument13 pages6b OpticalHüseyin YükselNo ratings yet

- Particulate Entry Lag in Spot-Type Smoke Detectors'Document12 pagesParticulate Entry Lag in Spot-Type Smoke Detectors'hyesquen8781No ratings yet

- Baliga2014 - Expanding - The - Use - of - Ultrasonic - Gas - Leak - Detectors - A Review of Gas Release Characteristics For Adequate DetectionDocument7 pagesBaliga2014 - Expanding - The - Use - of - Ultrasonic - Gas - Leak - Detectors - A Review of Gas Release Characteristics For Adequate DetectionHenriqueNo ratings yet

- Beam Detectors Application Guide: System Sensor EuropeDocument12 pagesBeam Detectors Application Guide: System Sensor EuropeMohamed AdelNo ratings yet

- Gas Phase Ftir Spectroscopy Introduction BR52338Document9 pagesGas Phase Ftir Spectroscopy Introduction BR52338MelixaxNo ratings yet

- Gassonic Observer-I Brochure - ENDocument8 pagesGassonic Observer-I Brochure - ENsafie147No ratings yet

- Ultrasound Distance Measurement and Ultrasonic Doppler EffectDocument4 pagesUltrasound Distance Measurement and Ultrasonic Doppler EffectA N ArunkumarNo ratings yet

- 07 8313 MC UltrasonicgasleakdetectwpDocument8 pages07 8313 MC Ultrasonicgasleakdetectwpykresna1631No ratings yet

- Open Path Toxic Gas Detectors-Key To An Integrated Strategy For Worker SafetyDocument11 pagesOpen Path Toxic Gas Detectors-Key To An Integrated Strategy For Worker SafetyOsiris LimonNo ratings yet

- Capstone Project 2 FinalDocument35 pagesCapstone Project 2 FinalAmarjeet SinghNo ratings yet

- Artigo Sobre Organica 3Document9 pagesArtigo Sobre Organica 3antoniofamorimNo ratings yet

- Mechatronics Notes22Document23 pagesMechatronics Notes22Arun KumarNo ratings yet

- IOT Unit02 L12 Humidity and Ultrasonic SensorDocument6 pagesIOT Unit02 L12 Humidity and Ultrasonic Sensorfakenoddy07No ratings yet

- Paper Velocimeter SPIE RS07Document12 pagesPaper Velocimeter SPIE RS07Mounika ReddyNo ratings yet

- Single-Ended Reflected Beam Smoke Detector: Applications GuideDocument8 pagesSingle-Ended Reflected Beam Smoke Detector: Applications GuideAnonymous 8RFzObvNo ratings yet

- A Portable Laser-Based Sensor For Detecting H2S in Domestic Natural GasDocument6 pagesA Portable Laser-Based Sensor For Detecting H2S in Domestic Natural Gaslaoying qdNo ratings yet

- Ultrasonics: Nacef Ghodhbani, Pierre Marechal, Hugues Du oDocument10 pagesUltrasonics: Nacef Ghodhbani, Pierre Marechal, Hugues Du oEl Mehdi AkhatarNo ratings yet

- D D U M D: Esign and Evelopment of An Ltrasonic Otion EtectorDocument13 pagesD D U M D: Esign and Evelopment of An Ltrasonic Otion EtectorKatamba RogersNo ratings yet

- Smoke Detector FdsDocument2 pagesSmoke Detector Fdshyesquen8781No ratings yet

- Liyingsun2010 - Acoustic Emission Sound Source Localization For Crack in The PipelineDocument4 pagesLiyingsun2010 - Acoustic Emission Sound Source Localization For Crack in The PipelineHenriqueNo ratings yet

- Sensors Accurate Estimation of Airborne Ultrasonic Time-Of-flight For Overlapping Echoes-13-15465-V2Document24 pagesSensors Accurate Estimation of Airborne Ultrasonic Time-Of-flight For Overlapping Echoes-13-15465-V2A N ArunkumarNo ratings yet

- Murphy Usound DocDocument7 pagesMurphy Usound DocThaddée Lumbu LuhagaNo ratings yet

- Sensors: Gas Leak Detection by Dilution of Atmospheric OxygenDocument14 pagesSensors: Gas Leak Detection by Dilution of Atmospheric OxygenKhoirul HudaNo ratings yet

- Beam Detection Systems: Application GuideDocument12 pagesBeam Detection Systems: Application GuidekktayNo ratings yet

- Smoke Sensor PDFDocument14 pagesSmoke Sensor PDFSyed Sabir AhmedNo ratings yet

- Ultrasonic Sensing BasicsDocument15 pagesUltrasonic Sensing BasicsEdsonNo ratings yet

- Acoustic LidarDocument4 pagesAcoustic LidardrphysicsNo ratings yet

- ASTM D7653 gas-phase-ftir-spectroscopy-introduction-BR52338Document8 pagesASTM D7653 gas-phase-ftir-spectroscopy-introduction-BR52338Treerat VacharanukrauhNo ratings yet

- Application of Ultrasonic Sensor For Measuring DisDocument10 pagesApplication of Ultrasonic Sensor For Measuring Discristian123100% (1)

- Guided Wave Pipe Inspection and Monitoring SystemDocument5 pagesGuided Wave Pipe Inspection and Monitoring SystemGreen MichaelsNo ratings yet

- Ultrasonic Sensors in AirDocument12 pagesUltrasonic Sensors in AirkumargpalaniNo ratings yet

- Scatter Response Time AN060Document4 pagesScatter Response Time AN060Rahmat AdiatamaNo ratings yet

- Rapid Firing Scheme For Ultrasonic Sensors Used in Mobile RobotsDocument10 pagesRapid Firing Scheme For Ultrasonic Sensors Used in Mobile RobotsRavindra KumarNo ratings yet

- Footboard Travel Alert SystemDocument40 pagesFootboard Travel Alert SystemSaravanan Viswakarma100% (2)

- เเคตตาล็อค 2024Document4 pagesเเคตตาล็อค 2024pitipat nimnomNo ratings yet

- IEEE Digital Time-Of-Flight Measurement For Ultrasonic-SensorsDocument6 pagesIEEE Digital Time-Of-Flight Measurement For Ultrasonic-SensorsA N ArunkumarNo ratings yet

- Instrument For Real-Time Measurement of Low Turbidity by Using Time-Correlated Single Photon Counting TechniqueDocument9 pagesInstrument For Real-Time Measurement of Low Turbidity by Using Time-Correlated Single Photon Counting TechniqueAgrimart IndonesiaNo ratings yet

- Burglar AlarmDocument5 pagesBurglar AlarmBharath ReddyNo ratings yet

- PHY02Document7 pagesPHY02ben harrisNo ratings yet

- Ultrasonic Distance Meter Embedded System Project Explains About Developing NewDocument63 pagesUltrasonic Distance Meter Embedded System Project Explains About Developing NewSahil SethiNo ratings yet

- Singh 2012Document4 pagesSingh 2012ritu10maliNo ratings yet

- Advance Analytical Instrumentaion TechniqueDocument29 pagesAdvance Analytical Instrumentaion TechniqueRIzwanaNo ratings yet

- Combustible Gases Detection - Catalytic Vs IR Comparison - Specs.etaDocument6 pagesCombustible Gases Detection - Catalytic Vs IR Comparison - Specs.etanazmin77No ratings yet

- Leak DetectionDocument6 pagesLeak DetectionranjitgoparajuNo ratings yet

- Wagner Titanus enDocument16 pagesWagner Titanus enmohamed alghazalyNo ratings yet

- On Tap Phan 2 AEDocument9 pagesOn Tap Phan 2 AEduy.leanh87No ratings yet

- Building and Room Acoustics Measurements With Sine-Sweep TechniqueDocument2 pagesBuilding and Room Acoustics Measurements With Sine-Sweep Techniquejabeur rahmaNo ratings yet

- SPM 70-35-00 (Ut)Document11 pagesSPM 70-35-00 (Ut)Muh SubhanNo ratings yet

- Mapping Fixed Gas Detectors and Flame Detectors: SafetyDocument2 pagesMapping Fixed Gas Detectors and Flame Detectors: SafetybobNo ratings yet

- Martini 2015Document14 pagesMartini 2015Oscar ScusselNo ratings yet

- 0409-0415 (851) Spectrophotometry and Light-ScatteringDocument7 pages0409-0415 (851) Spectrophotometry and Light-ScatteringGYANNo ratings yet

- PHY01Document6 pagesPHY01ben harrisNo ratings yet

- SPE 149602 Distributed Acoustic Sensing - A New Way of Listening To Your Well/ReservoirDocument9 pagesSPE 149602 Distributed Acoustic Sensing - A New Way of Listening To Your Well/ReservoirBolsec14No ratings yet

- 10 3390@mi11080763Document13 pages10 3390@mi11080763MaxiNo ratings yet

- Geophones or Accelerometers BCE Technical Note 10Document3 pagesGeophones or Accelerometers BCE Technical Note 10Tony ChanNo ratings yet

- EDL Upgrading SPBG Bogor - ElectricalDocument63 pagesEDL Upgrading SPBG Bogor - Electrical17crushNo ratings yet

- Infrared Sensors Snaa207Document8 pagesInfrared Sensors Snaa207midi663No ratings yet

- Uniphos Precision Air Sampling Pump Uniphos Precision Air Sampling PumpDocument10 pagesUniphos Precision Air Sampling Pump Uniphos Precision Air Sampling PumpAnticristh6666No ratings yet

- General Monitors S5000 Manual-EnDocument22 pagesGeneral Monitors S5000 Manual-Enمحمد رمضانNo ratings yet

- Catalog SKY2000 C2H4 Gas DetectorsDocument5 pagesCatalog SKY2000 C2H4 Gas Detectorshienluuduc2011_66877No ratings yet

- Report of Initial / Annual / Intermediate / Renewal / General Examination SurveyDocument9 pagesReport of Initial / Annual / Intermediate / Renewal / General Examination SurveyJagjit SinghNo ratings yet

- ALMURBAT General PresentationDocument14 pagesALMURBAT General PresentationalaaNo ratings yet

- Watchgas PDMDocument14 pagesWatchgas PDMNemz CervantesNo ratings yet

- The Ultimate Ultrasonic Diagnostic Tool: ULD-400 Series Ultrasonic Leak DetectorsDocument3 pagesThe Ultimate Ultrasonic Diagnostic Tool: ULD-400 Series Ultrasonic Leak DetectorsLeo RodriguezNo ratings yet

- FGS Mapping ReportDocument4 pagesFGS Mapping ReportHujiLoko100% (2)

- Design and Construction of A GSM Based Gas Leak Alert SystemDocument6 pagesDesign and Construction of A GSM Based Gas Leak Alert SystemGibin GeorgeNo ratings yet

- EuroKlimat 200213 - CRIO - v3 - EN - WebDocument92 pagesEuroKlimat 200213 - CRIO - v3 - EN - Webportocala12No ratings yet

- Metal Oxide DetectorDocument20 pagesMetal Oxide DetectorRizkonNo ratings yet

- Prototype Sistem Kontrol Otomatis Kadar Karbon Monoksida Di Dalam Ruang Parkir BasementDocument8 pagesPrototype Sistem Kontrol Otomatis Kadar Karbon Monoksida Di Dalam Ruang Parkir Basementandhika jayanugrahaNo ratings yet

- Development of Cotton Picker Fire Monitoring SysteDocument13 pagesDevelopment of Cotton Picker Fire Monitoring SysteHarmawan FebriantoNo ratings yet

- New Microsoft Word DocumentDocument3 pagesNew Microsoft Word Documentengineer mrewaNo ratings yet

- LPG Instrumentation SafetyDocument2 pagesLPG Instrumentation SafetySATISHNo ratings yet

- CM-80T4 Datasheet UK 2019Document2 pagesCM-80T4 Datasheet UK 2019iramal nounouNo ratings yet

- F&G DetectorsDocument52 pagesF&G Detectorsrgupta50No ratings yet

- Hazard and Operability Study of Rotary Drum Dryer in Hazardous Waste Management IndustryDocument13 pagesHazard and Operability Study of Rotary Drum Dryer in Hazardous Waste Management IndustryIJRASETPublicationsNo ratings yet

- Gas Detectors: DgtkexDocument2 pagesGas Detectors: DgtkexAltayyeb AlfaryjatNo ratings yet

- S4100C General Monitors Gas Detector Data SheetDocument2 pagesS4100C General Monitors Gas Detector Data SheetmuthuNo ratings yet

- Consilium Guide Maintenance of Fire and Gas Detection SystemsDocument1 pageConsilium Guide Maintenance of Fire and Gas Detection SystemsTURARAMANo ratings yet

- Latest Final Year Electronics andDocument17 pagesLatest Final Year Electronics andPath Finder100% (1)

- Drager XAM 2000 Quick Reference GuideDocument7 pagesDrager XAM 2000 Quick Reference GuideBradNo ratings yet

- Standard Operating Procedure (SOP) Confined Space: Environmental Health & SafetyDocument5 pagesStandard Operating Procedure (SOP) Confined Space: Environmental Health & SafetyrasulyaNo ratings yet

- MQ138Document3 pagesMQ138Anbu OpsNo ratings yet