Professional Documents

Culture Documents

Sugar Quality in Soft Drink Manufacture The Acid Beverage Floc Problem

Sugar Quality in Soft Drink Manufacture The Acid Beverage Floc Problem

Uploaded by

Vanessa Alexandra Soria DicioccioOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sugar Quality in Soft Drink Manufacture The Acid Beverage Floc Problem

Sugar Quality in Soft Drink Manufacture The Acid Beverage Floc Problem

Uploaded by

Vanessa Alexandra Soria DicioccioCopyright:

Available Formats

SUGAR QUALITY IN SOFT DRINK MANUFACTURE:

THE ACID BEVERAGE FLOC PROBLEM

Les A. Edye *

1. INTRODUCTION

A floc or floccule is a small portion ofmatter resembling a tuft of wool or a wispy cloud .

In soft drink or acidic beverage manufacture the term is used to describe a visible defect in

the produc t. This visible defect may be particulate and sedimentary or tuft-like and

suspended in the beverage, and may be attributed to microbial contamination or to water and

sugar ingredients that are of unsuitable quality for beverage manufacture. Microb ial

contamination of soft drinks is considered to be outside the scope ofthis review. Simple tests

of microbial contamination and a review of the microbiology of soft drinks are described by

Ashurst (1998) .

The emphasis in this contribution is focused on floc in soft drinks that is not a result of

microbial contamination. This type of floc is referred to by the sugar and beverage

manufacturing industries as acid beverage floc (ABF) . While ABF is harmless, it is

nevertheless a visible defect and consumers reject the soft drink product for aesthetic reasons .

Since in many parts of the world soft drink manufactur ers are large consumers of sugar

(sucrose) and sugar is implicated in ABF formation , the issue of ingredient quality and ABF

is a major concern to both soft drink and sugar manufacturers.

In the late 70's, 25% ofUS sugar production was consumed by soft drink manufacturers,

and consequently, ABF was a major issue to the US industry . During this time researchers

at the Sugar Processing Research Institute Inc. (SPRI , then the Cane Sugar Refining Research

Project Inc.) conducted extensive research on the nature and cause of ABF in soft drinks

manufactured from cane sugar. Clarke , Godshall, Roberts, and Carpenter are the author s of

work produced by the SPRI during this period. Their published work is a major part of

literature on this subje ct and is given coverage here. In the early 80's, high fructose com

syrup (HFCS) consumption by US soft drink manufacturers increased from 0.8 to over 3

million tons, with a consequent decrease in sucrose consumption to less than 300,000 tons

(ca . 5% of production). In November 1984, major US soft drink companies announced that

100% HFCS would be used in their products (Moore et al., 1991). ABF was no longer an

issue to the US sugar industry and research in the US on this subject, previously conside red

essential, effectively ceased .

Both beet and cane sugar are reported to form ABF. The similarities and differences

between ABF from cane and beet sugar are discussed. Where sugar is implicated in ABF

formation , it is principally through the precipitation ofpolysaccharide impuri ties in sugar that

are sparingly soluble in the acidic beverage . Therefore, the nature of polysaccharide

'Sugar Research Institute. Mackay, Austral ia

Quality of Fresh and Processed Foods, edited by Shah idi et al.

Kluwer Academic/Plenum Publishers , 200·t 317

318 EDYE

impurities in sugar is considered. Chill haze in alcoholic beverages, caused by the interaction

of polyphenols and proteins, also is relevant to ABF and is discus sed here .

2. THE SOFT DRINK MANUFACTURER'S PERSPECTIVE

From the perspective of the soft drink manufacturer, the appearance of ABF in soft

drinks is a qualit y problem that is not easil y managed. There is no easy, quick and reliable

test for ABF in the sugar ingredient. When ABF is manifest in soft drinks the product is

usually at the point of retail. While there is a strong link between ABF and sugar quality,

ABF is a complex coacervate containing material from the sugar, water and most likely also

the flavored syrup ingredients. Furthermore, the mechanism of ABF formation is still not

well established. While to some extent water quality plays a role in ABF formation,

nevertheless, no floc guarantees in sugar purchase contracts are often required by soft drink

manufacturers. When ABF appears in soft drink , the sugar manufacturer is quickly blamed

and compensation is sought.

Taylor (1998) describes the ingredi ents of soft drinks and briefly mentions an unsightly

precipitate in soft drinks resulting from algal polysaccharides and polypeptides, and humic

acids in the water supply . Taylor (1998) failed to acknowledge the contribution of sugar

products to soft drink floc and this may be part of the parley between beverage and sugar

manufacturers.

Taylor ( 1998), however, described the contents of soft drink syrup formulations . Food

grade saponins are used to improve the foaming characteristics of cola and other

formulations, and stabilizers, such as alginates, carrageen, vegetable gums, pectin, acacia ,

guar, tragacanth, xanthan and carboxymethylcellulose are used to improve mouthfeel,

increase viscosity, and stabili ze natural cloudiness (and in fruit drinks to disperse fruit

solids). It is not surprising that it has been difficult to elucidate the chemistry of acid

beverage floc formation and the contribution of sugar impurities to its cause , given that

polysaccharides and saponins may be present in the syrup formulations as well as in the sugar

as impurities (albeit at mg/kg quantities in both cases) .

The section on carbonated beverages (Jones, 1978) in the Kirk-Othmer Encyclopaedia

of Chemical Technology also lists and describ es the ingredients of soft drinks . Poor quality

sugar is noted to have extremely detrimental effects on beverage taste , odor and stability.

Quality control is discussed and the effects of algae in the water supply mentioned to cause

a sediment. No mention is made of ABF . However, in terms of quality control there is very

little the beverage manufa cturer can do about ABF, as the beverage would likely be on the

retail shelf before the problem is manifest.

Hammond (1998) also states, 'The most common cause for floc formation in clear soft

drinks is microbial growth .' He also attributes another cause of floc to algal polysaccharides

in the water supply. Certainly, these possibilities should be eliminated before the sugar

supply is implicated in floc formation.

3. FLOC IN SOFT DlUNKS FROM BEET SUGARS

As early as 1952, researchers at Spreckels Sugar Company, a Californian beet processor.

had isolated floc from simulated acid beverages and found the floc to contain saponins and

small amounts ofhigh molecular weight materials (most likely pectin) (Eis et a!., 1952) . The

saponins were determined to be the glycosides of the triterpene oleanolic acid . Subsequent

to this work , Ridout et al., (1994) elucidated the structures of three beet saponins (all were

You might also like

- Project Report On Soft Drinks ManufacturingDocument9 pagesProject Report On Soft Drinks ManufacturingEIRI Board of Consultants and PublishersNo ratings yet

- LG Mj2887bfumDocument112 pagesLG Mj2887bfummohan S0% (1)

- World Central Kitchen - Karla's Creamy Curry PastaDocument1 pageWorld Central Kitchen - Karla's Creamy Curry PastaHere & NowNo ratings yet

- A Critical Review of Published Literature On Acid Beverage FlocDocument18 pagesA Critical Review of Published Literature On Acid Beverage FlocVanessa Alexandra Soria DicioccioNo ratings yet

- Chapter 2Document54 pagesChapter 2NeerajKPNo ratings yet

- Fermented Beverages - Issues Paper AustraliaDocument12 pagesFermented Beverages - Issues Paper AustraliaEvangelina RivarolaNo ratings yet

- VinegarDocument17 pagesVinegardeepikaNo ratings yet

- Soft Drink ProjectDocument54 pagesSoft Drink ProjectZubair Shaik75% (4)

- IJCRT1134528Document7 pagesIJCRT1134528Kapil Mohan SharmaNo ratings yet

- The Impact of Hop Bitter Acid and Polyphenol Profiles On The PerceivedDocument9 pagesThe Impact of Hop Bitter Acid and Polyphenol Profiles On The PerceivedDavid AndrésNo ratings yet

- Artigo Tpa 2Document13 pagesArtigo Tpa 2Josenildo Alves da SilvaNo ratings yet

- Beverages 08 00006Document13 pagesBeverages 08 00006Waleed FahmyNo ratings yet

- Estudo Do Perfil Químico de Cervejas Brasileiras Uma Avaliação Entre As BebidasDocument13 pagesEstudo Do Perfil Químico de Cervejas Brasileiras Uma Avaliação Entre As BebidasCaio DiasNo ratings yet

- Invitro Evaluation of Microbial Content in Bottled Soft Drinks, Fruit Flavored Juices and Fruit JuicesDocument5 pagesInvitro Evaluation of Microbial Content in Bottled Soft Drinks, Fruit Flavored Juices and Fruit JuicesEditor IJTSRDNo ratings yet

- Métodos Analiticos para Los Compuestos Del Corcho en El VinoDocument13 pagesMétodos Analiticos para Los Compuestos Del Corcho en El VinoErika SolísNo ratings yet

- An Overview On The Biological Production of Vinegar: December 2014Document18 pagesAn Overview On The Biological Production of Vinegar: December 2014Bad lipzNo ratings yet

- Beverage Market in BangladeshDocument71 pagesBeverage Market in BangladeshMollah Md NaimNo ratings yet

- Chem ProjectDocument28 pagesChem ProjectPrashant KhatriNo ratings yet

- Carbonated BeveragesDocument6 pagesCarbonated BeveragesVasu ShashankNo ratings yet

- Degradation of Ascorbic Acid in Ethanolic Solutions - J Agric Food Chem., 2012 60 (42), 10696-701 PDFDocument6 pagesDegradation of Ascorbic Acid in Ethanolic Solutions - J Agric Food Chem., 2012 60 (42), 10696-701 PDFnonameNo ratings yet

- The Potential Of: ToothwearDocument6 pagesThe Potential Of: Toothwearasti findaNo ratings yet

- Zhong 2021Document9 pagesZhong 2021Jose perezNo ratings yet

- Alcoholic BeverageDocument6 pagesAlcoholic Beverageadebowale adejengbeNo ratings yet

- CHEMISTRY PROJECT On Content of Cold Drinks Available in The MarketDocument5 pagesCHEMISTRY PROJECT On Content of Cold Drinks Available in The MarketKiran ShajiNo ratings yet

- Carbonated BeveragesDocument7 pagesCarbonated BeveragesKapithas EswaranNo ratings yet

- Chemrj 2016 01 04 100 104Document5 pagesChemrj 2016 01 04 100 104editor chemrjNo ratings yet

- 2 1 Preparation of Wine Through Simple Fermentation Process: 3 I. Background of The ExperimentDocument5 pages2 1 Preparation of Wine Through Simple Fermentation Process: 3 I. Background of The ExperimentrickiegasparNo ratings yet

- CBSE Class XII Chemistry ProjectDocument23 pagesCBSE Class XII Chemistry Projecttrishabhagawati93% (14)

- Investigation Into The Potential of Lachancea Strain KBI 12.1 For Low Alcohol Beer BrewingDocument14 pagesInvestigation Into The Potential of Lachancea Strain KBI 12.1 For Low Alcohol Beer BrewingSandra Paola Moreno RNo ratings yet

- Fermentation 08 00273 v3Document32 pagesFermentation 08 00273 v3Raul BarradasNo ratings yet

- Soft Drink: How Products Are MadeDocument11 pagesSoft Drink: How Products Are MadeChetan Ganesh RautNo ratings yet

- Blanco Etal 2016 CRFSNDocument12 pagesBlanco Etal 2016 CRFSNBarohNo ratings yet

- Coca Cola and Carbonated BeveragesDocument7 pagesCoca Cola and Carbonated BeveragesAndry PrasetyaNo ratings yet

- Modeling and Optimization of Lactic Acid Production Using Cashew Apple Juice As SubstrateDocument18 pagesModeling and Optimization of Lactic Acid Production Using Cashew Apple Juice As SubstrateAlex Pari FarfanNo ratings yet

- Comparative Study of Different Types of Cold DrinksDocument17 pagesComparative Study of Different Types of Cold DrinksdiyaNo ratings yet

- Chem ProjectDocument18 pagesChem Projectsroy191006No ratings yet

- Soft Drinks Industry: Presented by Vishnupriya.GDocument29 pagesSoft Drinks Industry: Presented by Vishnupriya.Gpriyaleo_19894819No ratings yet

- Microbiology of Soft Drinks and Fruit JuicesDocument38 pagesMicrobiology of Soft Drinks and Fruit JuicesAbdur RafeyNo ratings yet

- Use of Saccharomyces Boulardii in Alcohol-Free Beer ProductionDocument10 pagesUse of Saccharomyces Boulardii in Alcohol-Free Beer ProductionMinh AnhNo ratings yet

- Ifrj261 217 224Document9 pagesIfrj261 217 224Ghene PinonNo ratings yet

- Niedzwiedz 2022 - Red WineDocument10 pagesNiedzwiedz 2022 - Red WineIoana LețiNo ratings yet

- Yeo Et Al-2014-International Journal of Food Science & TechnologyDocument12 pagesYeo Et Al-2014-International Journal of Food Science & Technology_juliogsNo ratings yet

- CHM144L Experiment 5Document4 pagesCHM144L Experiment 5zidrick benjaminNo ratings yet

- Divita 1Document14 pagesDivita 1Riya GoelNo ratings yet

- World Market SugarDocument60 pagesWorld Market SugarCarlos TomeyNo ratings yet

- Coffee FermentationDocument6 pagesCoffee Fermentationdwiartomoro100% (1)

- 116 Jmbfs Bobkova FBP FDocument11 pages116 Jmbfs Bobkova FBP FMinh Quang HàNo ratings yet

- Analysis of Marketing Strategy of Coca Cola and PepsiDocument49 pagesAnalysis of Marketing Strategy of Coca Cola and PepsiRobin BhardwajNo ratings yet

- Accepted Manuscript: Food and Bioproducts ProcessingDocument32 pagesAccepted Manuscript: Food and Bioproducts ProcessingMarina ButuceaNo ratings yet

- Alcoholic FermentationDocument8 pagesAlcoholic FermentationRohan ChaudhariNo ratings yet

- Analysis of Marketing Strategy of Coca Cola and PepsiDocument48 pagesAnalysis of Marketing Strategy of Coca Cola and Pepsianish_10677953No ratings yet

- Chemistry ProjectDocument19 pagesChemistry ProjectBiswajeet SrichandanNo ratings yet

- Journal Pre-Proof: Trends in Food Science & TechnologyDocument52 pagesJournal Pre-Proof: Trends in Food Science & TechnologyA SierraNo ratings yet

- Chemistry Project On Content of Cold Drinks Available in The MarketDocument5 pagesChemistry Project On Content of Cold Drinks Available in The Marketdaviansec7No ratings yet

- Soft Carbonated BeveragesDocument23 pagesSoft Carbonated BeveragesBikila RusiNo ratings yet

- Doherty2011 - Improved Sugar Cane Juice CL by Understanding CalciumOxide-Phosphate-Sucrose SysDocument8 pagesDoherty2011 - Improved Sugar Cane Juice CL by Understanding CalciumOxide-Phosphate-Sucrose SysMolly0630No ratings yet

- Malaysian Soft Drink MarketDocument14 pagesMalaysian Soft Drink Markethasfanizamhashim100% (1)

- Beverage Market in BangladeshDocument71 pagesBeverage Market in Bangladeshjanu11183% (12)

- Chemistry and Technology of Soft Drinks and Fruit JuicesFrom EverandChemistry and Technology of Soft Drinks and Fruit JuicesRating: 4.5 out of 5 stars4.5/5 (2)

- SITHCCC005 Student LogbookDocument16 pagesSITHCCC005 Student LogbookHussain SubhaniNo ratings yet

- 1st Summative Test - Midterm (Cookery) - 2nd SemDocument2 pages1st Summative Test - Midterm (Cookery) - 2nd SemGloriefe MeniosaNo ratings yet

- Instant Download Wilkins Clinical Assessment in Respiratory Care 7th Edition Heuer Test Bank PDF Full ChapterDocument32 pagesInstant Download Wilkins Clinical Assessment in Respiratory Care 7th Edition Heuer Test Bank PDF Full Chapterkimlovellsotr100% (12)

- Bài Tập Bổ Trợ Eveybody Up 2 Bản DemoDocument17 pagesBài Tập Bổ Trợ Eveybody Up 2 Bản DemoNgân NgọcNo ratings yet

- 6 Juice ShotsDocument3 pages6 Juice ShotscraigwanlessNo ratings yet

- Dim Sum BrunchDocument4 pagesDim Sum BrunchLucas YorkshireNo ratings yet

- HappyJoes Aledo MenuDocument6 pagesHappyJoes Aledo MenuTrevor KernanNo ratings yet

- New Primal Protocol Meal PlanDocument30 pagesNew Primal Protocol Meal PlanHibaNo ratings yet

- Karl Antonio Francis Ching PRODUCT or SERVICE PROPOSALDocument6 pagesKarl Antonio Francis Ching PRODUCT or SERVICE PROPOSALBen T OngNo ratings yet

- 03 Laboratory Exercise 1 CostingDocument3 pages03 Laboratory Exercise 1 Costingangelabarron2001No ratings yet

- Task Performance Group 4Document63 pagesTask Performance Group 4algene jovelle evangelistaNo ratings yet

- Raja Wapda Food BillDocument1 pageRaja Wapda Food BillArslan MalikNo ratings yet

- The Falastin Cookbook 16 Most Populor Palestinian Dishes (Dori Dutton (Dutton, Dori) ) (Z-Library)Document66 pagesThe Falastin Cookbook 16 Most Populor Palestinian Dishes (Dori Dutton (Dutton, Dori) ) (Z-Library)mwburaikNo ratings yet

- Noi Dung On Tap Mon Tieng Anh LOP 9 Bai 7Document4 pagesNoi Dung On Tap Mon Tieng Anh LOP 9 Bai 715. Nguyễn Thanh HiềnNo ratings yet

- 5000 Calorie Meal PlanDocument1 page5000 Calorie Meal PlanRISHIKA DHOTENo ratings yet

- Lunch Cicchetti+Menu+Jan+23Document2 pagesLunch Cicchetti+Menu+Jan+23Daniel LongsonNo ratings yet

- GWJ appEN CalculatorDocument10 pagesGWJ appEN CalculatorMesec ZvezdaNo ratings yet

- Semi-Detailed-Lesson - PlanDocument10 pagesSemi-Detailed-Lesson - PlanJudy GarciaNo ratings yet

- X4-Ex Sous Chef Ridwan Rosyad (6805)Document11 pagesX4-Ex Sous Chef Ridwan Rosyad (6805)Leonardo HernandezNo ratings yet

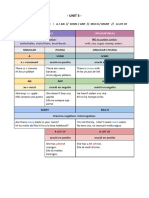

- Unit 5: Countable / Uncountable + A / An // Some / Any // Much / Many // A Lot ofDocument3 pagesUnit 5: Countable / Uncountable + A / An // Some / Any // Much / Many // A Lot ofmghpau98No ratings yet

- CBLM One LO UPDATED 2023Document41 pagesCBLM One LO UPDATED 2023John Ellis LacsamanaNo ratings yet

- Gastronomic Tourism in Ayutthaya, ThailandDocument6 pagesGastronomic Tourism in Ayutthaya, ThailandAndy Monjardin SamaniegoNo ratings yet

- Progress Test 4 B Year 5Document5 pagesProgress Test 4 B Year 5Paula MonteiroNo ratings yet

- FDA Dairy Product Recall Rizo-Lopez Foods IncDocument9 pagesFDA Dairy Product Recall Rizo-Lopez Foods IncWXMINo ratings yet

- Ruby Village TemplateDocument2 pagesRuby Village Templatekomal sharmaNo ratings yet

- Sukiya A3+Menu OldDocument2 pagesSukiya A3+Menu OldpurplevioletviNo ratings yet

- Food Fraud Newsletter 01-2023Document6 pagesFood Fraud Newsletter 01-2023jmmfbeijosNo ratings yet

- RecipeDocument1 pageRecipeKhanjida khanom KeyaNo ratings yet