Professional Documents

Culture Documents

HEC WORKFLOW - 20231107 - v0 - Amjad

HEC WORKFLOW - 20231107 - v0 - Amjad

Uploaded by

Usama RahatOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HEC WORKFLOW - 20231107 - v0 - Amjad

HEC WORKFLOW - 20231107 - v0 - Amjad

Uploaded by

Usama RahatCopyright:

Available Formats

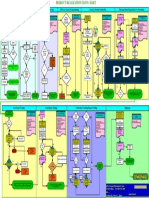

POWER TRANSFORMER MANUFACTURING LAYOUT

Query From

Industrial

Sector

Query From

Private HEC. Participate in ( 90% share )

Sector Disco Tenders.

Cost estimation

Participate

in Disco Tenders

* Submissions of quotation.

Receipt of purchase order from customer.

placement of queries as per BOQ.

Technical verification and vetting of quoted materials

Placement of purchase order to venders / supplaier

Local and foregin.

Matarial receving and quality check.

material will be issued by

Production Planning and Control (PPC) as per manufacturing

Stock in Store order / layout

( Manufacturing )

Fabrication

Insulation Core manufacturing Coil Winding

core clamp, tank body and conservator.

HV

LV

RV

Quality check and inspector Culting Winding Vendor In House

Core Clamp Inspection

Core Assembly Sizing an press.

Drying in auto clave .

Drying in auto clave

Active Part Assembly

On Load Tap Changer (OLTC)

Leads Concestions

Oil purchasing

Testing.

Oil processing to improve dielectric strength.

Vapour Phase Drying (VPD) Process Time 72 Hrs

Tanking

Final Assembly with in 08 Hrs Auxiliary Components i.e Bushings, Bucholz Relays, Temprature Instruments, Aux. & OLTC Control Boxes.

Rechecking Connection Oil circulation and dehydration

In House testing

FAT

Routine,type and special ( if any ) tests.

NTDCLab Rawat (High Voltage & Short Circuit La) test ( impulse test )

Transport to customer store

Goods receipt note ( GRN )

From customer

Payment

You might also like

- 201485-25000-QP-01-B Inspection Test Plan (ITP) For FRP Tank R0Document1 page201485-25000-QP-01-B Inspection Test Plan (ITP) For FRP Tank R0muchamad yasin100% (1)

- Pany ProfileDocument31 pagesPany ProfilehungleteNo ratings yet

- Process Flow Chart - Smart MeterDocument4 pagesProcess Flow Chart - Smart MeterQAD LotusNo ratings yet

- SOP Flow ChartDocument3 pagesSOP Flow Chartuniformwork draftingNo ratings yet

- Sample Manufacturing Quality Plan Format: (Logo of Manufacturer)Document12 pagesSample Manufacturing Quality Plan Format: (Logo of Manufacturer)P.Manna100% (1)

- Inspection & Test Plan Advance Valves Butterfly ValvesDocument2 pagesInspection & Test Plan Advance Valves Butterfly Valvessyed jafarNo ratings yet

- Work FlowDocument1 pageWork FlowWaseem AshrafNo ratings yet

- Check Point For RebberizingDocument1 pageCheck Point For RebberizingDilnesa EjiguNo ratings yet

- ITP AND Reports Only ApprovedDocument18 pagesITP AND Reports Only Approvedb.l.narayana0307No ratings yet

- 08.QA-NPD-08 - Sani Mold - Cover Timer Side - 32981-EDocument6 pages08.QA-NPD-08 - Sani Mold - Cover Timer Side - 32981-EdelightplasticsNo ratings yet

- Quality Dashboard - 28 October To 03 November 2017Document22 pagesQuality Dashboard - 28 October To 03 November 2017Wilson Sombrio100% (3)

- 04 - Push Pull StrategiesDocument22 pages04 - Push Pull StrategiesDiack TchicayaNo ratings yet

- Material Safety Data Sheet FOR Co2 Recovery UnitDocument6 pagesMaterial Safety Data Sheet FOR Co2 Recovery Unitgudapati9No ratings yet

- Production Approval ProcessDocument23 pagesProduction Approval ProcessCuenta PokemonNo ratings yet

- Adobe Scan 01 Apr 2021Document1 pageAdobe Scan 01 Apr 2021Syafinah WahdahNo ratings yet

- Control Plan - 608 2RS C3Document28 pagesControl Plan - 608 2RS C3trandangbkNo ratings yet

- Production Flow ChartDocument1 pageProduction Flow ChartAmeer uddinNo ratings yet

- QAP1Document2 pagesQAP1akshaymehra2354No ratings yet

- Battery? BankDocument2 pagesBattery? Bankrajabharath12No ratings yet

- Quality Alert 4 - Revised 2017Document2 pagesQuality Alert 4 - Revised 2017Faraj Khan100% (1)

- Quality PlanDocument1 pageQuality PlandewayantiputriNo ratings yet

- Inspection Test PlanDocument36 pagesInspection Test PlanShahid IqbalNo ratings yet

- Inspection Test Plan - MechanicalDocument2 pagesInspection Test Plan - MechanicalsahilNo ratings yet

- Checklist For Rebar and Concrete WorkDocument4 pagesChecklist For Rebar and Concrete WorkDwinto RachmadNo ratings yet

- Gpe-Fat OverviewDocument5 pagesGpe-Fat Overviewn.hartonoNo ratings yet

- Inspection and Test Plan Supply, Fabrication, & Galvanizing of Fence and GatesDocument7 pagesInspection and Test Plan Supply, Fabrication, & Galvanizing of Fence and GatesAzhar ShaikhNo ratings yet

- Control PlanDocument4 pagesControl PlanJosué PérezNo ratings yet

- Sewing Room GuidelinesDocument56 pagesSewing Room Guidelinesmalikzeeshanaliawan100% (6)

- 15.QA NPD 15 Sani Mold Defrost Arm Plastic Ace16!01!01Document16 pages15.QA NPD 15 Sani Mold Defrost Arm Plastic Ace16!01!01delightplasticsNo ratings yet

- Collab07AutomatingProcuretoPayProcess PDFDocument46 pagesCollab07AutomatingProcuretoPayProcess PDFsaif22sNo ratings yet

- CP ProductionDocument7 pagesCP Productionsandeep.pantNo ratings yet

- Sales: Submit Faulty Material To Quality DeptDocument1 pageSales: Submit Faulty Material To Quality DeptYash DudaniNo ratings yet

- Complete Flow Chart - RevBDocument1 pageComplete Flow Chart - RevBanushaNo ratings yet

- Henan Bebon Iron & Steel Co., LTDDocument3 pagesHenan Bebon Iron & Steel Co., LTDRajNo ratings yet

- CX R&D Spe 000122Document62 pagesCX R&D Spe 000122Adel IbrahimNo ratings yet

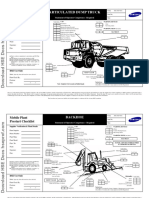

- Heavy Equipment ChecklistDocument18 pagesHeavy Equipment Checklistfullbar9No ratings yet

- Mps-Hsaw Qa Awwa 001Document9 pagesMps-Hsaw Qa Awwa 001Armando BiringkanaeNo ratings yet

- VCDP V7Document1 pageVCDP V7Artur GerasimovNo ratings yet

- EPM 9 Supply Chain Management PURCHASEDocument14 pagesEPM 9 Supply Chain Management PURCHASEsharanNo ratings yet

- Paper TubeDocument1 pagePaper TubeRashedul islam ReazNo ratings yet

- Flow ProcessDocument5 pagesFlow ProcessDaffa AjiNo ratings yet

- Asitp P 001 02Document2 pagesAsitp P 001 02MosabAhmedNo ratings yet

- Henan Bebon Iron & Steel Co., LTDDocument3 pagesHenan Bebon Iron & Steel Co., LTDRajNo ratings yet

- Merchandising Flow ChartDocument1 pageMerchandising Flow ChartshahinrezaNo ratings yet

- Heavy Equipment HSE ChecklistDocument18 pagesHeavy Equipment HSE Checklistanoopanil16No ratings yet

- Prepare An Equipment Package and Package Technical DocumentsDocument48 pagesPrepare An Equipment Package and Package Technical DocumentsAleksandar SpasojevicNo ratings yet

- Dec For RaghavDocument22 pagesDec For RaghavVivek SagayarajNo ratings yet

- JAPL-F-HE-019 Scraper CheckDocument1 pageJAPL-F-HE-019 Scraper CheckAli HassanNo ratings yet

- 1000-90-0911 - 03 Fabricator Packing and Shipping ProcedureDocument6 pages1000-90-0911 - 03 Fabricator Packing and Shipping ProcedureprasongNo ratings yet

- Quality Control Plan CoatingDocument3 pagesQuality Control Plan CoatingtonierlandaNo ratings yet

- Flow DownDocument1 pageFlow DownTeresaNo ratings yet

- Deva, Becoman, Yiti DCP (HSC Vs De-Vil)Document24 pagesDeva, Becoman, Yiti DCP (HSC Vs De-Vil)Omar MuqtharNo ratings yet

- Presentation of GeneratorDocument18 pagesPresentation of Generatorapi-3834081100% (1)

- TEC-032111 - PQF-CLT-Rev01 - Prequalification Checklist For Cut & Bent Factory PDFDocument4 pagesTEC-032111 - PQF-CLT-Rev01 - Prequalification Checklist For Cut & Bent Factory PDFtrndemNo ratings yet

- Etihad Towers Project: Inspection & Test Plan - Sub Structure Waterproofing SystemDocument3 pagesEtihad Towers Project: Inspection & Test Plan - Sub Structure Waterproofing SystemSagar AliasjackeyNo ratings yet

- SATIP-P-104-07 Rev 7 FinalDocument4 pagesSATIP-P-104-07 Rev 7 FinalHatemS.MashaGbehNo ratings yet

- Control of Non-Conforming ProductsDocument10 pagesControl of Non-Conforming ProductsSachin KumbharNo ratings yet

- 00.tender Itinerary - Dec2022Document1 page00.tender Itinerary - Dec2022shardultagalpallewarNo ratings yet

- HSCM-BRL-ITP-004 Sanitary İnstallation WorksDocument1 pageHSCM-BRL-ITP-004 Sanitary İnstallation WorksHabib BagciNo ratings yet

- Service-Oriented Modeling: Service Analysis, Design, and ArchitectureFrom EverandService-Oriented Modeling: Service Analysis, Design, and ArchitectureNo ratings yet