Professional Documents

Culture Documents

Information Sheet 351-450

Information Sheet 351-450

Uploaded by

Suri LopezCopyright:

Available Formats

You might also like

- Deluxe Active Jazz Bass VDocument2 pagesDeluxe Active Jazz Bass VTom Keyte100% (1)

- How To Integrate Literacy and Numeracy Skills inDocument26 pagesHow To Integrate Literacy and Numeracy Skills inJudith Abogada92% (13)

- ENGR135 - LAB05 Stephan Boltzmann's LawDocument12 pagesENGR135 - LAB05 Stephan Boltzmann's Lawgigabyte3235840No ratings yet

- SpecificationDocument66 pagesSpecificationsohaibNo ratings yet

- Geospatial JeopardyDocument54 pagesGeospatial JeopardyrunnealsNo ratings yet

- Ficha Tecnica Desconectador Fusible 25 KVDocument14 pagesFicha Tecnica Desconectador Fusible 25 KVOscar diazNo ratings yet

- CP Cc5010-Eng-300saDocument2 pagesCP Cc5010-Eng-300saTR JJNo ratings yet

- Fuse SelectionDocument10 pagesFuse SelectionPushpraj GaikwadNo ratings yet

- Capacitor Exp Fuses 24037Document12 pagesCapacitor Exp Fuses 24037tableman.test9000No ratings yet

- IEC Miniature Contactors: Bulletin 100-K, 104-KDocument1 pageIEC Miniature Contactors: Bulletin 100-K, 104-KmagicalspellsNo ratings yet

- 172 Bbls (6000 IG) VAC SEMI TR OBM (40 Psi ASME) : NeededDocument3 pages172 Bbls (6000 IG) VAC SEMI TR OBM (40 Psi ASME) : Neededmesut ekşiNo ratings yet

- PURCHASE5Document83 pagesPURCHASE5kishore.raju1999No ratings yet

- Io PanelDocument26 pagesIo PanelakramNo ratings yet

- 33kV O/H Line Rerouting: S/No Description Qty %age Supply CompletedDocument2 pages33kV O/H Line Rerouting: S/No Description Qty %age Supply CompletedFelix MgimbaNo ratings yet

- EL EL EL EL Elastimold Astimold Astimold Astimold Astimold: 15kV Loadbreak Reducing Tap Plug 650ETPDocument2 pagesEL EL EL EL Elastimold Astimold Astimold Astimold Astimold: 15kV Loadbreak Reducing Tap Plug 650ETPJonnyRcNo ratings yet

- PURCHASEDocument6 pagesPURCHASEkishore.raju1999No ratings yet

- Chardon 600 A Deadbreak Junction 25DJ600Document4 pagesChardon 600 A Deadbreak Junction 25DJ600Eduardo FloresNo ratings yet

- Catalog Ky Thuat Ray Dien An Toan PDFDocument20 pagesCatalog Ky Thuat Ray Dien An Toan PDFDuctoanNo ratings yet

- CSII N-Series SwitchesDocument10 pagesCSII N-Series Switchespaul reyesNo ratings yet

- High Speed Fuses BussmannDocument82 pagesHigh Speed Fuses BussmannmimIX0No ratings yet

- Solar Meter Box: 100A 25ka 4P MCCB Set at 80ADocument1 pageSolar Meter Box: 100A 25ka 4P MCCB Set at 80APraveenNo ratings yet

- BushingDocument4 pagesBushingomar_cohen_1No ratings yet

- 800SADocument2 pages800SALucas TavaresNo ratings yet

- Ex9m1 5 Eu en 20180727Document28 pagesEx9m1 5 Eu en 20180727khkalpaNo ratings yet

- FS&SF Havells PDFDocument6 pagesFS&SF Havells PDFSureshNo ratings yet

- S&C Type XS Fuse Cutouts: Complete UnitsDocument1 pageS&C Type XS Fuse Cutouts: Complete Unitsjosgba2002No ratings yet

- DS VSP MOV Fuses MersenDocument2 pagesDS VSP MOV Fuses Mersenessen999No ratings yet

- V Series EDO (Cut Out)Document4 pagesV Series EDO (Cut Out)mrhomNo ratings yet

- SUPERTYFON AT 150-200 With Valve Unit TV 784Document6 pagesSUPERTYFON AT 150-200 With Valve Unit TV 784Dimitry SilinshNo ratings yet

- 107 HP, 380V, 3Ø, Y-D Duplex, Sump Pump, 208amp.1 UnitDocument2 pages107 HP, 380V, 3Ø, Y-D Duplex, Sump Pump, 208amp.1 UnitJose Lorenzo RefelinoNo ratings yet

- Electric Bill Checking Store As BuiltDocument9 pagesElectric Bill Checking Store As BuiltSyed Adnan AqibNo ratings yet

- MCCB WiNbreak1Document16 pagesMCCB WiNbreak1ceracalNo ratings yet

- 132kV Substation Accessories BOQ-20231101Document2 pages132kV Substation Accessories BOQ-20231101sparkCENo ratings yet

- EM Shielded Surge Arresters CPDocument27 pagesEM Shielded Surge Arresters CPgabriel molinaNo ratings yet

- Select 90c d2Document1 pageSelect 90c d2nateNo ratings yet

- CP Ac3050-Eng-200srDocument2 pagesCP Ac3050-Eng-200srAduldech SrasamranNo ratings yet

- Bill of MAterialsDocument2 pagesBill of MAterialsKaori Miyazono (Kobe)No ratings yet

- Flexible Busbar Tie Distance 2Document2 pagesFlexible Busbar Tie Distance 2m.ramadanNo ratings yet

- Marechal DS2 Decontactor Range enDocument4 pagesMarechal DS2 Decontactor Range enManuel HernandezNo ratings yet

- Aluma FormDocument14 pagesAluma FormRONALD HIDROBO CASTELLANONo ratings yet

- Koolwal MATERIALDocument2 pagesKoolwal MATERIALSunil KoolwalNo ratings yet

- Spares Estimation Elect Line1Document10 pagesSpares Estimation Elect Line1Muhammad NabeelNo ratings yet

- LARCE TERASAKI E160-SF Data SheetDocument4 pagesLARCE TERASAKI E160-SF Data SheetCamilo SepulvedaNo ratings yet

- Xpulse 200 2V BSVI (Jun, 2020)Document172 pagesXpulse 200 2V BSVI (Jun, 2020)Kishonkumar KishonNo ratings yet

- 110 TR Chiller & CT Offer (Only For Pumps)Document2 pages110 TR Chiller & CT Offer (Only For Pumps)vaibhavi.dhaneshwarNo ratings yet

- Cable JointsDocument4 pagesCable JointsRaod2No ratings yet

- Bussmann Series Full Line Catalog 1007 - Electronic - PCB and Small Dimension FusesDocument14 pagesBussmann Series Full Line Catalog 1007 - Electronic - PCB and Small Dimension FusesNickal Kosmas SiregarNo ratings yet

- 3MW - RBA Ground Mount - FinalDocument3 pages3MW - RBA Ground Mount - FinalMagesh SNo ratings yet

- Electronic Fuses: Section ContentsDocument14 pagesElectronic Fuses: Section ContentsdeepakNo ratings yet

- SV Series - Special Medium Voltage Leaded Varistors: DescriptionDocument4 pagesSV Series - Special Medium Voltage Leaded Varistors: DescriptionIgor PNo ratings yet

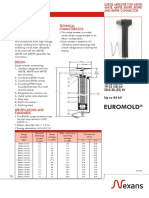

- Application: Slip-On Outdoor TerminationDocument2 pagesApplication: Slip-On Outdoor Terminationlatif100% (1)

- BSM100C 3150aaDocument10 pagesBSM100C 3150aaEduardo GarciaNo ratings yet

- Maya Tech.-Pricelist-01-10-2022Document7 pagesMaya Tech.-Pricelist-01-10-2022Neil TamayoNo ratings yet

- Elastimold 156LR Catalog + Installation InstructionDocument6 pagesElastimold 156LR Catalog + Installation InstructionJoseph JoeNo ratings yet

- Eklavya Rudra 31-08-20Document309 pagesEklavya Rudra 31-08-20Ajay YadavNo ratings yet

- Bill of Mat 203Document36 pagesBill of Mat 203DinoNo ratings yet

- Serie 602Document4 pagesSerie 602Jmanuel AvalosNo ratings yet

- Elastimold 156LRDocument2 pagesElastimold 156LRTamer AlahmedNo ratings yet

- 20 VLDocument5 pages20 VLUmair RaisNo ratings yet

- CGK064-MTO For Cable Ladder Tray - Rev.CDocument7 pagesCGK064-MTO For Cable Ladder Tray - Rev.CSuryanaNo ratings yet

- Maclean - Isoladores de Suspensão e Line PostDocument23 pagesMaclean - Isoladores de Suspensão e Line PostGuilherme LinharesNo ratings yet

- Atx 100 Sub: Service ManualDocument11 pagesAtx 100 Sub: Service ManualShankar DhanpalNo ratings yet

- QA-QC Inspection Request FormDocument1 pageQA-QC Inspection Request FormShaikh Ubaid Ur RehmanNo ratings yet

- Protection Coordination Rev03 by STL Power SolutionDocument168 pagesProtection Coordination Rev03 by STL Power Solutionalf sunflower100% (1)

- Sl. No. Scholar Name Guide Name Research Field Month & Year of Regn. AwardedDocument4 pagesSl. No. Scholar Name Guide Name Research Field Month & Year of Regn. AwardedSamuel Pakianathan EEENo ratings yet

- Delhi Technological University: (Formerly Delhi College of Engineering) Result NotificationDocument8 pagesDelhi Technological University: (Formerly Delhi College of Engineering) Result NotificationShubham AgarwalNo ratings yet

- Bimetal Dial ThermometerDocument2 pagesBimetal Dial ThermometerAnonymous edvYngNo ratings yet

- Commscope Andew VHLP2-80-XXXDocument5 pagesCommscope Andew VHLP2-80-XXXАлександр КNo ratings yet

- DLP PolgovDocument2 pagesDLP PolgovJuna Silawan Babatu-onNo ratings yet

- iCE40UltraFamilyDataSheet PDFDocument42 pagesiCE40UltraFamilyDataSheet PDFson_gotenNo ratings yet

- Assessment 1Document27 pagesAssessment 1Joan PangyanNo ratings yet

- Quasi TurbineDocument29 pagesQuasi TurbineArun N MukundanNo ratings yet

- Gabions For Streambank Erosion Control PDFDocument9 pagesGabions For Streambank Erosion Control PDFTriayudha WahyuNo ratings yet

- MicrosoftDocument20 pagesMicrosoftSagar PatelNo ratings yet

- Lesson 1 Recognizing and Using Nouns CompressedDocument16 pagesLesson 1 Recognizing and Using Nouns CompressedJian DeluanaNo ratings yet

- The Autocar HandbookDocument228 pagesThe Autocar HandbookRahul SinghNo ratings yet

- BATCH 1 PPT Major Project AykDocument18 pagesBATCH 1 PPT Major Project AykAliseriyashwanth24No ratings yet

- Week 3-Tals: 1. The Student Learning MovementDocument5 pagesWeek 3-Tals: 1. The Student Learning MovementPrincess PauleNo ratings yet

- Social Learning Theories: Albert Bandura, Julian Rotter, Walter MischelDocument13 pagesSocial Learning Theories: Albert Bandura, Julian Rotter, Walter MischelnickcupoloNo ratings yet

- OLGA Link User GuideDocument51 pagesOLGA Link User GuideekabudiartiNo ratings yet

- 2021 Main Residency Match® by The Numbers: PositionsDocument1 page2021 Main Residency Match® by The Numbers: Positionsyogitha dadiNo ratings yet

- Stresses in SoilDocument37 pagesStresses in SoilRadhaAnanthalekshmiNo ratings yet

- TikTok Article & Questions (PART 1)Document4 pagesTikTok Article & Questions (PART 1)AqeelALTNo ratings yet

- Design Practices in Design Thinking Kimbell 2009Document24 pagesDesign Practices in Design Thinking Kimbell 2009subirNo ratings yet

- Using The Word Mapping Strategy in English Vocabulary DevelopmentDocument23 pagesUsing The Word Mapping Strategy in English Vocabulary DevelopmentJennilyn Estacio ZarateNo ratings yet

- Advent 7109 User ManualDocument73 pagesAdvent 7109 User ManualDaveW1958No ratings yet

- IMS Abend CodesDocument23 pagesIMS Abend Codesparvathy88No ratings yet

- Conceptual FrameworkDocument20 pagesConceptual FrameworkWZ HakimNo ratings yet

- Dr.R.A.Mashelkar Bio-DataDocument43 pagesDr.R.A.Mashelkar Bio-DatacalpineNo ratings yet

Information Sheet 351-450

Information Sheet 351-450

Uploaded by

Suri LopezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Information Sheet 351-450

Information Sheet 351-450

Uploaded by

Suri LopezCopyright:

Available Formats

S&C Type XS Fuse Cutouts Detailed Functional Specification Guide

Outdoor Distribution (4.16 kV through 25 kV)

1. General

1.1 The fuse cutout shall conform to the following specification.

1.2 The fuse cutout shall consist of a mounting, a fuse tube or disconnect blade, connectors, and

optionally, a mounting bracket. The distribution fuse link used in the fuse cutout is not covered

by this specification.

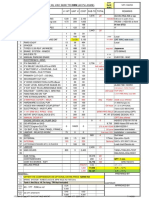

1.3 The ratings of the fuse cutout shall be as designated below. (Select values from one of the rows

shown in the table below.)

kV

Nominal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . _________________

Maximum. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . _________________

BIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . _________________

Amperes, RMS

Continuous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . _________________

Interrupting, Asymmetrical. . . . . . . . . . . . . . . . . . . . . . . _________________

Leakage Distance to Ground. . . . . . . . . . . . . . . . . . . . . . . _________________

kV Amperes, RMS Leakage Fuse Tube or

Distance to

Interr., Asym. Disconnect

Nom. Max BIL Cont. Ground, Blade

60 Hz 50 Hz (Inches mm)

10 000 8 000

14.4 15 110 100 8Z\x (216) Fuse Tube

12 000d 9 600d

25 27 125 100 8 000 6 400 11 (279) Fuse Tube

25 27 150 100 8 000 6 400 17 (432) Fuse Tube

14.4 15 110 100 16 000 12 800 8Z\x (216) Fuse Tube

12 000 9 600

25 27 125 100 11 (279) Fuse Tube

16 000d 12 800d

12 000 9 600

25 27 150 100 17 (432) Fuse Tube

16 000d 12 800d

25 27 150 l 100 12 000 9 600 26 (660)j Fuse Tube

14.4 15 110 200 12 000 9 600 8Z\x (216) Fuse Tube

25 27 125 200 10 000 8 000 11 (279) Fuse Tube

25 27 150 200 10 000 8 000 17 (432) Fuse Tube

14.4 15 110 300 – – 8Z\x (216) Disconnect

25 27 125 300 – – 11 (279) Disconnect

25 27 150 300 – – 17 (432) Disconnect

25 27 150 l 300 – – 26 (660)j Disconnect

d One-shot rating, based on replacement of cutout tube only.

l Meets 170-kV BIL rating requirement of IEC Publication 282-2 with porcelain insulator only.

j Leakage distance to ground is 26 inches (660 mm) for porcelain insulator, 30 inches (762 mm) for polymer insulator.

June 22, 2009 © S&C Electric Company Information Sheet 351-450

S&C Type XS Fuse Cutouts

1.4 Mounting brackets and connectors, as designated below, shall be optionally available. (Select

from the table below.)

Item

Extended Mounting Bracket, for crossarm, pole, or wall mounting of overhead—pole-top style cutouts

NEMA Type “B” Mounting Bracket, for crossarm mounting of overhead—pole-top style cutouts

Accommodating Connectors

Item

Quantity Size and Material

No. 6 solid through No. 2 stranded copper or aluminum in one groove; No. 2

Parallel-Grove Connectors Two solid through 250 kc mil stranded copper or aluminum or 4/0 ACSR in the

other groove

Eye-Bolt Connectors One No. 8 solid through 250 kc mil stranded copper or aluminum, or 4/0 ACSR

1.5 Certification of Ratings

(a) The manufacturer of the fuse cutout shall be solely responsible for the performance of

the complete cutout as rated.

(b) The manufacturer shall furnish, upon request, certification of ratings of the cutout.

1.6 Compliance with Standards and Codes

The fuse cutout shall conform to or exceed all applicable requirements of the following stan

dards and codes:

(a) ANSI/IEEE C37.41-2000 (IEEE Standard Design Tests for High-Voltage Fuses, Distribu

tion Enclosed Single-Pole Air Switches, Fuse Disconnecting Switches, and Accessories).

(b) ANSI C37.42-1996 (Distribution Cutouts and Fuse Links—Specifications).

(c) IEC 60282-2-1997 (High Voltage Fuses—Part 2: Expulsion Fuses).

1.7 Factory Assembly and Adjustment

The cutout shall be completely assembled and adjusted at the factory.

2. Construction

2.1 Mounting

(a) Insulator—Porcelain

(1) The insulator shall be constructed of a single piece of porcelain, free of chips or

blemishes.

(2) There shall be no steel bands around the insulator. (Such bands cause mechani

cal stress concentrations and may subject the insulator to damage over time.)

(3) All openings in the insulator shall be completely potted with an inorganic sulfur

cement that does not deteriorate or absorb moisture over time. No voids or

2 S&C Information Sheet 351-450

S&C Type XS Fuse Cutouts

foreign objects which can contaminate the sulfur cement shall be present.

(4) All exposed areas of the sulfur cement shall be coated with an enamel-based

paint to minimize the ingress of water.

(5) The insulator shall be labeled with the appropriate BIL rating.

Insulator—Polymer

(1) The insulator shall be constructed of a high-strength fiberglass-reinforced

polyester (FRP) core with composite-polymer silicone insulation molded over.

(2) The inserts shall be one piece, having attachment hole for the live parts and

mounting bracket, molded into the FRP core. Two-piece and crimped inserts

shall not be accepted.

(b) Loadbuster® Attachment Hooks

(1) There must be attachment hooks at the upper (jaw) end of the fuse cutout, over

which Loadbuster’s anchor can be hooked; and a pull ring on the fuse tube which

can be readily engaged with Loadbuster’s pull-ring hook and held fast by the pull-

ring latch.

(2) The fuse cutout must be capable of easy, positive manipulation with Loadbuster

from all practical angles and directions, while maintaining the minimum mechan-

ical and electrical requirements specified by the manufacturer of the loadbreak

tool.

(3) The fuse cutout must mechanically coordinate with Loadbuster’s operating

sequence such that (a) engagement of Loadbuster will not cause or allow the

fuse tube to drop open prematurely and (b) the attachment hooks will keep

Loadbuster positively anchored until tripping occurs, while (c) permitting easy

removal of Loadbuster whether the opening stroke has been completed or

whether, for any reason, the fuse cutout has been reclosed after partial (incom

plete) opening.

(4) The Loadbuster attachment hooks shall be constructed of galvanized steel, not

less than 3/80 in diameter. The ends of the hooks shall be rounded off or trimmed

to effect easy attachment of Loadbuster and to prevent damage to the carton

during shipment.

(5) The Loadbuster attachment hooks shall be resistance-welded to the upper

contact assembly. (Spot welding, which can produce localized rust and weaken

the hooks, shall not be acceptable.)

(c) Sleet Shield

(1) The sleet shield shall protect the upper contacts against direct exposure to sleet,

snow, and ice.

(2) The sleet shield shall be robust enough to prevent the upper contact from flexing

during high-current interruptions.

S&C Information Sheet 351-450 3

S&C Type XS Fuse Cutouts

(d) Upper Contact Assembly

(1) The current transfer strap shall consist of a single piece of copper. A secondary

shunt, which will increase the number of current transfer points and possible hot

spots, shall not be acceptable.

(2) The upper contact assembly shall include a firm spring that applies a constant

pressure of between 25 and 50 pounds to the fuse-tube cap, thus minimizing the

possibility of arcing.

(3) The required pull-out force for the fuse tube shall be between 30 and 40 pounds,

applied perpendicular to the axis of the fuse tube.

(4) The detent-type latch shall have silver-clad embossed surfaces that produce a

built-in wiping action on opening and closing.

(5) The upper contact shall be coated with Sanchem Incorporated No-Ox-Id “A”

lubricant (or equivalent).

(e) Hinge and Lower Contact Assembly

(1) The lower contacts shall be silver-clad and have an embossed feature for built-in

wiping action by the fuse-tube trunnion during closing.

(2) The lower contacts shall utilize stainless-steel backup springs to prevent arcing

that may occur as the fuse tube rises slightly in the hinge during operation.

(3) The hinge and lower contact assembly shall be permanently labeled with the

manufacturer’s name.

(4) The lower contacts shall be coated with Sanchem Incorporated No-Ox-Id “A”

lubricant (or equivalent).

2.2 Fuse Tube Assembly

(a) Fuse Tube

(1) The arc-extinguishing liner of the fuse tube shall consist of a non-bone-fiber (or

horn-fiber) material with the following properties:

(i) Less than 0.5% moisture absorption by weight per ASTM D570 Long-Term

Immersion Test Method (Clause 6.4).

(ii) No (0.0%) swelling of the inner diameter of the fuse tube after being sub

jected to a 3-week water-submersion test.

(2) The lower end of the fuse tube shall be counter-bored to promote efficient

expulsion of exhaust gases during high-magnitude operations.

(3) The fuse tube shall be coated with a UV-resistant polyethylene enamel to a

thickness of 0.002-0.005, +/- 0.001 inches. The surface of the fuse tube shall be

smooth, hard, and durable. The standard color shall be ASA61 Gray.

(4) The fuse tube shall be labeled with the nominal and maximum voltage ratings,

the continuous-current rating, and the asymmetrical interrupting current rating

of the fuse cutout.

4 S&C Information Sheet 351-450

S&C Type XS Fuse Cutouts

(b) Fuse-Tube Cap

(1) The fuse-tube cap shall have four large flats to ensure convenient tightening with

a wrench. (The cap shall not be knurled to encourage simple hand tightening,

which can result in a high-resistance joint and overheating.)

(2) The fuse-tube cap shall be silver plated.

(c) Upper Ferrule

(1) The upper ferrule of the fuse tube shall include a heavy pull ring that cannot be

easily bent by a hookstick during normal handling.

(2) The ferrule shall be attached with two through-pins. (Push pins are less secure

and shall not be acceptable.)

(d) Lower Ferrule

The lower ferrule of the fuse tube shall be attached with a single through-pin. (Push pins

are less secure and shall not be acceptable.)

(e) Fuse-Tube Trunnion and Flipper Spring

(1) The flipper shall extend far enough over the end of the fuse tube to center the

fuse-link cable in the fuse-tube bore.

(2) The portion of the flipper extending over the end of the fuse tube shall be no

wider than 9/160 to minimize the reflection of gases expelled during operation.

The flipper shall be curved radially (3/160 radius typical) to minimize damage to

the fuse-link cable.

(3) Drop-out of the fuse tube shall be effected solely by the spring-loaded flipper and

collapsible trunnion assembly, and not by the force of the exhaust during opera-

tion.

(4) The flipper shall include a backstop to guard against finger injury if the flipper is

inadvertently released during fuse link installation.

(5) The flipper spring shall be constructed of stainless steel.

(6) The flipper spring shall subject the fuse link to a force of not less than four

pounds, and not more than ten pounds.

(f) Cable-Clamping Bolt

The cable-clamping bolt shall have a 9/160 hex-head bolt with 13/160 diameter shoulder

under the bolt head.

3. Packaging

3.1 The cutout carton shall adequately protect the cutout against damage during shipping.

3.2 The supplier shall be capable of imprinting user bar codes, stock numbers, etc. to the ends of the

carton.

S&C Information Sheet 351-450 5

You might also like

- Deluxe Active Jazz Bass VDocument2 pagesDeluxe Active Jazz Bass VTom Keyte100% (1)

- How To Integrate Literacy and Numeracy Skills inDocument26 pagesHow To Integrate Literacy and Numeracy Skills inJudith Abogada92% (13)

- ENGR135 - LAB05 Stephan Boltzmann's LawDocument12 pagesENGR135 - LAB05 Stephan Boltzmann's Lawgigabyte3235840No ratings yet

- SpecificationDocument66 pagesSpecificationsohaibNo ratings yet

- Geospatial JeopardyDocument54 pagesGeospatial JeopardyrunnealsNo ratings yet

- Ficha Tecnica Desconectador Fusible 25 KVDocument14 pagesFicha Tecnica Desconectador Fusible 25 KVOscar diazNo ratings yet

- CP Cc5010-Eng-300saDocument2 pagesCP Cc5010-Eng-300saTR JJNo ratings yet

- Fuse SelectionDocument10 pagesFuse SelectionPushpraj GaikwadNo ratings yet

- Capacitor Exp Fuses 24037Document12 pagesCapacitor Exp Fuses 24037tableman.test9000No ratings yet

- IEC Miniature Contactors: Bulletin 100-K, 104-KDocument1 pageIEC Miniature Contactors: Bulletin 100-K, 104-KmagicalspellsNo ratings yet

- 172 Bbls (6000 IG) VAC SEMI TR OBM (40 Psi ASME) : NeededDocument3 pages172 Bbls (6000 IG) VAC SEMI TR OBM (40 Psi ASME) : Neededmesut ekşiNo ratings yet

- PURCHASE5Document83 pagesPURCHASE5kishore.raju1999No ratings yet

- Io PanelDocument26 pagesIo PanelakramNo ratings yet

- 33kV O/H Line Rerouting: S/No Description Qty %age Supply CompletedDocument2 pages33kV O/H Line Rerouting: S/No Description Qty %age Supply CompletedFelix MgimbaNo ratings yet

- EL EL EL EL Elastimold Astimold Astimold Astimold Astimold: 15kV Loadbreak Reducing Tap Plug 650ETPDocument2 pagesEL EL EL EL Elastimold Astimold Astimold Astimold Astimold: 15kV Loadbreak Reducing Tap Plug 650ETPJonnyRcNo ratings yet

- PURCHASEDocument6 pagesPURCHASEkishore.raju1999No ratings yet

- Chardon 600 A Deadbreak Junction 25DJ600Document4 pagesChardon 600 A Deadbreak Junction 25DJ600Eduardo FloresNo ratings yet

- Catalog Ky Thuat Ray Dien An Toan PDFDocument20 pagesCatalog Ky Thuat Ray Dien An Toan PDFDuctoanNo ratings yet

- CSII N-Series SwitchesDocument10 pagesCSII N-Series Switchespaul reyesNo ratings yet

- High Speed Fuses BussmannDocument82 pagesHigh Speed Fuses BussmannmimIX0No ratings yet

- Solar Meter Box: 100A 25ka 4P MCCB Set at 80ADocument1 pageSolar Meter Box: 100A 25ka 4P MCCB Set at 80APraveenNo ratings yet

- BushingDocument4 pagesBushingomar_cohen_1No ratings yet

- 800SADocument2 pages800SALucas TavaresNo ratings yet

- Ex9m1 5 Eu en 20180727Document28 pagesEx9m1 5 Eu en 20180727khkalpaNo ratings yet

- FS&SF Havells PDFDocument6 pagesFS&SF Havells PDFSureshNo ratings yet

- S&C Type XS Fuse Cutouts: Complete UnitsDocument1 pageS&C Type XS Fuse Cutouts: Complete Unitsjosgba2002No ratings yet

- DS VSP MOV Fuses MersenDocument2 pagesDS VSP MOV Fuses Mersenessen999No ratings yet

- V Series EDO (Cut Out)Document4 pagesV Series EDO (Cut Out)mrhomNo ratings yet

- SUPERTYFON AT 150-200 With Valve Unit TV 784Document6 pagesSUPERTYFON AT 150-200 With Valve Unit TV 784Dimitry SilinshNo ratings yet

- 107 HP, 380V, 3Ø, Y-D Duplex, Sump Pump, 208amp.1 UnitDocument2 pages107 HP, 380V, 3Ø, Y-D Duplex, Sump Pump, 208amp.1 UnitJose Lorenzo RefelinoNo ratings yet

- Electric Bill Checking Store As BuiltDocument9 pagesElectric Bill Checking Store As BuiltSyed Adnan AqibNo ratings yet

- MCCB WiNbreak1Document16 pagesMCCB WiNbreak1ceracalNo ratings yet

- 132kV Substation Accessories BOQ-20231101Document2 pages132kV Substation Accessories BOQ-20231101sparkCENo ratings yet

- EM Shielded Surge Arresters CPDocument27 pagesEM Shielded Surge Arresters CPgabriel molinaNo ratings yet

- Select 90c d2Document1 pageSelect 90c d2nateNo ratings yet

- CP Ac3050-Eng-200srDocument2 pagesCP Ac3050-Eng-200srAduldech SrasamranNo ratings yet

- Bill of MAterialsDocument2 pagesBill of MAterialsKaori Miyazono (Kobe)No ratings yet

- Flexible Busbar Tie Distance 2Document2 pagesFlexible Busbar Tie Distance 2m.ramadanNo ratings yet

- Marechal DS2 Decontactor Range enDocument4 pagesMarechal DS2 Decontactor Range enManuel HernandezNo ratings yet

- Aluma FormDocument14 pagesAluma FormRONALD HIDROBO CASTELLANONo ratings yet

- Koolwal MATERIALDocument2 pagesKoolwal MATERIALSunil KoolwalNo ratings yet

- Spares Estimation Elect Line1Document10 pagesSpares Estimation Elect Line1Muhammad NabeelNo ratings yet

- LARCE TERASAKI E160-SF Data SheetDocument4 pagesLARCE TERASAKI E160-SF Data SheetCamilo SepulvedaNo ratings yet

- Xpulse 200 2V BSVI (Jun, 2020)Document172 pagesXpulse 200 2V BSVI (Jun, 2020)Kishonkumar KishonNo ratings yet

- 110 TR Chiller & CT Offer (Only For Pumps)Document2 pages110 TR Chiller & CT Offer (Only For Pumps)vaibhavi.dhaneshwarNo ratings yet

- Cable JointsDocument4 pagesCable JointsRaod2No ratings yet

- Bussmann Series Full Line Catalog 1007 - Electronic - PCB and Small Dimension FusesDocument14 pagesBussmann Series Full Line Catalog 1007 - Electronic - PCB and Small Dimension FusesNickal Kosmas SiregarNo ratings yet

- 3MW - RBA Ground Mount - FinalDocument3 pages3MW - RBA Ground Mount - FinalMagesh SNo ratings yet

- Electronic Fuses: Section ContentsDocument14 pagesElectronic Fuses: Section ContentsdeepakNo ratings yet

- SV Series - Special Medium Voltage Leaded Varistors: DescriptionDocument4 pagesSV Series - Special Medium Voltage Leaded Varistors: DescriptionIgor PNo ratings yet

- Application: Slip-On Outdoor TerminationDocument2 pagesApplication: Slip-On Outdoor Terminationlatif100% (1)

- BSM100C 3150aaDocument10 pagesBSM100C 3150aaEduardo GarciaNo ratings yet

- Maya Tech.-Pricelist-01-10-2022Document7 pagesMaya Tech.-Pricelist-01-10-2022Neil TamayoNo ratings yet

- Elastimold 156LR Catalog + Installation InstructionDocument6 pagesElastimold 156LR Catalog + Installation InstructionJoseph JoeNo ratings yet

- Eklavya Rudra 31-08-20Document309 pagesEklavya Rudra 31-08-20Ajay YadavNo ratings yet

- Bill of Mat 203Document36 pagesBill of Mat 203DinoNo ratings yet

- Serie 602Document4 pagesSerie 602Jmanuel AvalosNo ratings yet

- Elastimold 156LRDocument2 pagesElastimold 156LRTamer AlahmedNo ratings yet

- 20 VLDocument5 pages20 VLUmair RaisNo ratings yet

- CGK064-MTO For Cable Ladder Tray - Rev.CDocument7 pagesCGK064-MTO For Cable Ladder Tray - Rev.CSuryanaNo ratings yet

- Maclean - Isoladores de Suspensão e Line PostDocument23 pagesMaclean - Isoladores de Suspensão e Line PostGuilherme LinharesNo ratings yet

- Atx 100 Sub: Service ManualDocument11 pagesAtx 100 Sub: Service ManualShankar DhanpalNo ratings yet

- QA-QC Inspection Request FormDocument1 pageQA-QC Inspection Request FormShaikh Ubaid Ur RehmanNo ratings yet

- Protection Coordination Rev03 by STL Power SolutionDocument168 pagesProtection Coordination Rev03 by STL Power Solutionalf sunflower100% (1)

- Sl. No. Scholar Name Guide Name Research Field Month & Year of Regn. AwardedDocument4 pagesSl. No. Scholar Name Guide Name Research Field Month & Year of Regn. AwardedSamuel Pakianathan EEENo ratings yet

- Delhi Technological University: (Formerly Delhi College of Engineering) Result NotificationDocument8 pagesDelhi Technological University: (Formerly Delhi College of Engineering) Result NotificationShubham AgarwalNo ratings yet

- Bimetal Dial ThermometerDocument2 pagesBimetal Dial ThermometerAnonymous edvYngNo ratings yet

- Commscope Andew VHLP2-80-XXXDocument5 pagesCommscope Andew VHLP2-80-XXXАлександр КNo ratings yet

- DLP PolgovDocument2 pagesDLP PolgovJuna Silawan Babatu-onNo ratings yet

- iCE40UltraFamilyDataSheet PDFDocument42 pagesiCE40UltraFamilyDataSheet PDFson_gotenNo ratings yet

- Assessment 1Document27 pagesAssessment 1Joan PangyanNo ratings yet

- Quasi TurbineDocument29 pagesQuasi TurbineArun N MukundanNo ratings yet

- Gabions For Streambank Erosion Control PDFDocument9 pagesGabions For Streambank Erosion Control PDFTriayudha WahyuNo ratings yet

- MicrosoftDocument20 pagesMicrosoftSagar PatelNo ratings yet

- Lesson 1 Recognizing and Using Nouns CompressedDocument16 pagesLesson 1 Recognizing and Using Nouns CompressedJian DeluanaNo ratings yet

- The Autocar HandbookDocument228 pagesThe Autocar HandbookRahul SinghNo ratings yet

- BATCH 1 PPT Major Project AykDocument18 pagesBATCH 1 PPT Major Project AykAliseriyashwanth24No ratings yet

- Week 3-Tals: 1. The Student Learning MovementDocument5 pagesWeek 3-Tals: 1. The Student Learning MovementPrincess PauleNo ratings yet

- Social Learning Theories: Albert Bandura, Julian Rotter, Walter MischelDocument13 pagesSocial Learning Theories: Albert Bandura, Julian Rotter, Walter MischelnickcupoloNo ratings yet

- OLGA Link User GuideDocument51 pagesOLGA Link User GuideekabudiartiNo ratings yet

- 2021 Main Residency Match® by The Numbers: PositionsDocument1 page2021 Main Residency Match® by The Numbers: Positionsyogitha dadiNo ratings yet

- Stresses in SoilDocument37 pagesStresses in SoilRadhaAnanthalekshmiNo ratings yet

- TikTok Article & Questions (PART 1)Document4 pagesTikTok Article & Questions (PART 1)AqeelALTNo ratings yet

- Design Practices in Design Thinking Kimbell 2009Document24 pagesDesign Practices in Design Thinking Kimbell 2009subirNo ratings yet

- Using The Word Mapping Strategy in English Vocabulary DevelopmentDocument23 pagesUsing The Word Mapping Strategy in English Vocabulary DevelopmentJennilyn Estacio ZarateNo ratings yet

- Advent 7109 User ManualDocument73 pagesAdvent 7109 User ManualDaveW1958No ratings yet

- IMS Abend CodesDocument23 pagesIMS Abend Codesparvathy88No ratings yet

- Conceptual FrameworkDocument20 pagesConceptual FrameworkWZ HakimNo ratings yet

- Dr.R.A.Mashelkar Bio-DataDocument43 pagesDr.R.A.Mashelkar Bio-DatacalpineNo ratings yet