Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

14 viewsMFR-111 - Valve Test Record 01

MFR-111 - Valve Test Record 01

Uploaded by

Rafiq RashidiThis document is a valve test record form used to record the testing of valves. It contains sections to record information about the project, valve details like type and size, test method and pressure, and test results. The test results section documents information like heat number, test pressure, holding time, and whether the valve passed or failed visual inspection at the holding pressure. It provides a standardized way to document valve testing for quality control purposes.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You might also like

- Testing Procedure of Dual Plate Check ValveDocument2 pagesTesting Procedure of Dual Plate Check Valverajesh100% (2)

- SN75 Series - 100 HP 60 HZ Horsepower Rated: Model SN7507 SN7509 SN7510 SN7512 Compressor PerformanceDocument2 pagesSN75 Series - 100 HP 60 HZ Horsepower Rated: Model SN7507 SN7509 SN7510 SN7512 Compressor PerformanceRicardo Guerrero SosaNo ratings yet

- Testing Procedure of Ball ValveDocument2 pagesTesting Procedure of Ball Valverajesh100% (2)

- Komatsu PC200 8 Testing and AdjustingDocument121 pagesKomatsu PC200 8 Testing and Adjustingibnu2malkan100% (6)

- Aerodynamics in Cars SeminarDocument22 pagesAerodynamics in Cars SeminarSwapnil Joshi75% (4)

- Material Test Certificate: To EN 10204 3.1:2004 Traceability Sheets/Mill/PressureDocument1 pageMaterial Test Certificate: To EN 10204 3.1:2004 Traceability Sheets/Mill/PressureMohamed RaafatNo ratings yet

- Table Pengecekan Hydrostatic Pressure Test Product ValvesDocument31 pagesTable Pengecekan Hydrostatic Pressure Test Product ValvesIksan Mustofa50% (2)

- Engineering Specification: ESFU5A-8079-AADocument5 pagesEngineering Specification: ESFU5A-8079-AAjavier ortizNo ratings yet

- Valve Test Record Form: Range Date Calibrated Calibration Certificate NumberDocument1 pageValve Test Record Form: Range Date Calibrated Calibration Certificate NumberAzuwan MohamadNo ratings yet

- APV Test Procedure API 598Document3 pagesAPV Test Procedure API 598Zain AlwaliNo ratings yet

- Pressure & Functional Testing Api 6D Ball Valves: Technical Instruction AP/PT6 00 05/03/19 1/3Document7 pagesPressure & Functional Testing Api 6D Ball Valves: Technical Instruction AP/PT6 00 05/03/19 1/3hari100% (1)

- Shell & Seat Test PressureDocument2 pagesShell & Seat Test PressureHQ EntertainmentNo ratings yet

- Globe Valve LWR 217: Inspection Report Defect-C0LD WorkDocument4 pagesGlobe Valve LWR 217: Inspection Report Defect-C0LD WorkMuhammad ZariqNo ratings yet

- Tubing String Testing (TST) Valve: Provides Tubing Testing Capability With Automatic Fill of The WorkstringDocument2 pagesTubing String Testing (TST) Valve: Provides Tubing Testing Capability With Automatic Fill of The Workstringadi nugroho100% (1)

- Severn Glocon 3Document10 pagesSevern Glocon 3Amit SurtiNo ratings yet

- 1.2. Sample - Datasheet Antisurge ValveDocument1 page1.2. Sample - Datasheet Antisurge ValveMuhammad FauzanNo ratings yet

- Material Test ReportDocument7 pagesMaterial Test Reportjuan carlos suaNo ratings yet

- 4 - Serial 89985-120-63Document7 pages4 - Serial 89985-120-63Katherine Toloza AcostaNo ratings yet

- Satr A 2001Document7 pagesSatr A 2001Naveed ShahNo ratings yet

- IO09 - Hydrostatic Test - R3Document3 pagesIO09 - Hydrostatic Test - R3bafivuitinhNo ratings yet

- Leak Class TestsDocument12 pagesLeak Class TestsZain AlwaliNo ratings yet

- Zdocs - Hu 773007136-ADocument1 pageZdocs - Hu 773007136-AMohamed RaafatNo ratings yet

- APV Test Procedure API 6DDocument7 pagesAPV Test Procedure API 6Ddevadoss kishoreNo ratings yet

- GMDSB Station Checklist 2020Document7 pagesGMDSB Station Checklist 2020Shah Mind YunusNo ratings yet

- Test Procedure API 598Document3 pagesTest Procedure API 598Raktim DasNo ratings yet

- TS 90 100 01Document4 pagesTS 90 100 01Lakee911No ratings yet

- Desmet Ballestra India PVT LTD: Inspection Test PlanDocument2 pagesDesmet Ballestra India PVT LTD: Inspection Test Plansameer patilNo ratings yet

- 3230F250 DATA CatalogDocument1 page3230F250 DATA CatalogLIONN TESTE2021No ratings yet

- Severn Glocon Lot2Document5 pagesSevern Glocon Lot2Amit SurtiNo ratings yet

- (°F) (Psi (G) ) (Psi (G) ) (Galus/Min) (MMSCFD) (CP) (Psi (A) )Document16 pages(°F) (Psi (G) ) (Psi (G) ) (Galus/Min) (MMSCFD) (CP) (Psi (A) )Elias EliasNo ratings yet

- CM 470Document4 pagesCM 470Chachou MohamedNo ratings yet

- Zamil 250Document13 pagesZamil 250Zaid Samha100% (1)

- Radiator Cap InspectionDocument7 pagesRadiator Cap InspectionTung NguyenNo ratings yet

- Wimpey - Wacg-22-222-5Document6 pagesWimpey - Wacg-22-222-5jaas jawadNo ratings yet

- NITON - HYDRO TEST PROCEDURE - Rev.0Document6 pagesNITON - HYDRO TEST PROCEDURE - Rev.0PRASHANT100% (2)

- 3dd028-N12-Api 6fa Fire Safe Test Procedure For High and Low Pressure Ball ValvesDocument7 pages3dd028-N12-Api 6fa Fire Safe Test Procedure For High and Low Pressure Ball ValvesPrathik Yeresh ReddyNo ratings yet

- Leser Certificate For Global ApplicationDocument3 pagesLeser Certificate For Global ApplicationErikikoNo ratings yet

- GSL Test Procedure API 598 PDFDocument3 pagesGSL Test Procedure API 598 PDFParag S. DicholkarNo ratings yet

- 108622-2371 TDDocument4 pages108622-2371 TDririnmars22No ratings yet

- CQ68894 Spec Sheet Rev-ADocument1 pageCQ68894 Spec Sheet Rev-AQichiix KiciNo ratings yet

- d200318x012 PDFDocument12 pagesd200318x012 PDFLimuel EspirituNo ratings yet

- Mod 80 UlDocument4 pagesMod 80 UlJUAN PABLO VELA GUIMACNo ratings yet

- QP07.01 Testing Procedure For Ball ValveDocument15 pagesQP07.01 Testing Procedure For Ball ValveAnanm NaimNo ratings yet

- Flow Control Valves Pressure Compensated Cartridge TypeDocument6 pagesFlow Control Valves Pressure Compensated Cartridge TypevrgohilNo ratings yet

- Equivalent Length TableDocument18 pagesEquivalent Length TablenguyenmainamNo ratings yet

- Komatsu - Pc220lc-8 - Excavator - Service - Testing and AdjustingDocument65 pagesKomatsu - Pc220lc-8 - Excavator - Service - Testing and Adjustingjuanchis650No ratings yet

- Modelo Nuevo - 4509B / COMPRESOR SULLAIRDocument2 pagesModelo Nuevo - 4509B / COMPRESOR SULLAIRLenin CastilloNo ratings yet

- Actuator InformationDocument4 pagesActuator InformationFajar DwikurniaNo ratings yet

- Side Pocket Mandral PDFDocument27 pagesSide Pocket Mandral PDFwajihhasnainNo ratings yet

- AAA Installation & Service ManualDocument36 pagesAAA Installation & Service ManualEurekia EvolutionNo ratings yet

- CM 470iiDocument4 pagesCM 470iiChachou MohamedNo ratings yet

- Flow Meter Data SheetDocument2 pagesFlow Meter Data SheetjlirazuritaNo ratings yet

- Data Sheets-T220425-499Document9 pagesData Sheets-T220425-499pedro torresNo ratings yet

- Data Sheet 2 Less 800#-BV - FB - SW - NT-76 PDFDocument1 pageData Sheet 2 Less 800#-BV - FB - SW - NT-76 PDFSachin KumarNo ratings yet

- Control Valve Data SheetDocument6 pagesControl Valve Data Sheetsiseset100% (1)

- Model S1F Metallic Design Level 1: Service & Operating ManualDocument31 pagesModel S1F Metallic Design Level 1: Service & Operating ManualGonzalo IñiguezNo ratings yet

- Sizing Sheet Dengan Cv. 133 PDFDocument3 pagesSizing Sheet Dengan Cv. 133 PDFJoko WisnugrohoNo ratings yet

- Belinda-MAQ-300-25BA-C Computer Control Safety Valve Test Bench R.1Document10 pagesBelinda-MAQ-300-25BA-C Computer Control Safety Valve Test Bench R.1ahsun habibNo ratings yet

- Tube Comp J00Document1 pageTube Comp J00Dudi SolehudinNo ratings yet

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsFrom EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsRating: 5 out of 5 stars5/5 (1)

- 863-863h 6900648 SM 10-98 PDFDocument3 pages863-863h 6900648 SM 10-98 PDFPepe AlNo ratings yet

- Hydraulic Ram SlideshowDocument26 pagesHydraulic Ram SlideshowAbhishek Patil100% (1)

- CE2102 - Fluid Mechanics Lab ManualDocument81 pagesCE2102 - Fluid Mechanics Lab ManualFazal E GhafoorNo ratings yet

- 330D 336 PDFDocument2 pages330D 336 PDFRICHARDNo ratings yet

- B.3.8 - Safety Valves SpecDocument8 pagesB.3.8 - Safety Valves SpecEmiel RoestenburgNo ratings yet

- rm69 Marine Toilet Electric Mul PDFDocument16 pagesrm69 Marine Toilet Electric Mul PDFurania22000No ratings yet

- Gear Pumps: Product RangeDocument4 pagesGear Pumps: Product RangeEng-Mohammed SalemNo ratings yet

- 2 - AIAA - Computation of Dynamic Stall of A NACA-0012 AirfoilDocument6 pages2 - AIAA - Computation of Dynamic Stall of A NACA-0012 Airfoilkgb_261No ratings yet

- Gas Pressure Regulators VGBF: Technical InformationDocument25 pagesGas Pressure Regulators VGBF: Technical InformationLuis Enrique Vidal GachaNo ratings yet

- Orifice and Venturi Meter - PrelabDocument6 pagesOrifice and Venturi Meter - Prelableo besaNo ratings yet

- SET31Practice TestDocument25 pagesSET31Practice TestMehrozNo ratings yet

- Pressure Drop TheoryDocument5 pagesPressure Drop Theorykaruna346100% (1)

- AerooDocument35 pagesAerooVinu GNo ratings yet

- ME:5160 (58:160) Intermediate Mechanics of Fluids Fall 2021 - HW6 SolutionDocument6 pagesME:5160 (58:160) Intermediate Mechanics of Fluids Fall 2021 - HW6 SolutionDiki AgungNo ratings yet

- FOV With LockDocument3 pagesFOV With LockBiswanath LenkaNo ratings yet

- Actuator Datasheet Severn GloconDocument1 pageActuator Datasheet Severn GloconQichiix KiciNo ratings yet

- Oil Pipeline Engineering CourseDocument3 pagesOil Pipeline Engineering CourseKarthik Sundararajan0% (1)

- 10H501 - MTO - Modification of Nozzles and PIPING Rev01 - 14-10-23 New OriginalDocument8 pages10H501 - MTO - Modification of Nozzles and PIPING Rev01 - 14-10-23 New OriginalKasarachi AmadiNo ratings yet

- Ad 1 Unit VIIDocument59 pagesAd 1 Unit VIIOsman KutluNo ratings yet

- Principles of Viscosity MeasurementDocument2 pagesPrinciples of Viscosity MeasurementPedro Sanchez50% (2)

- Safety Valve SizingDocument33 pagesSafety Valve SizingAshok Kumar100% (1)

- Plumbing PIpe SizingDocument12 pagesPlumbing PIpe SizingAwokeNo ratings yet

- BM Hydraulic Calculation Guide HiRes Interactive PagesDocument7 pagesBM Hydraulic Calculation Guide HiRes Interactive PagesKoteswara RaoNo ratings yet

- How To Size A Control Valve For Liquid and Gas Applications Usi PDFDocument4 pagesHow To Size A Control Valve For Liquid and Gas Applications Usi PDFv noteNo ratings yet

- M-54 K4670433 Sewage Treatment SystemDocument8 pagesM-54 K4670433 Sewage Treatment SystemeconmechNo ratings yet

- Property - Mq.edu - Au - Inspection and Test Plans (ITP) - MUM-08 - Valves FORM - 2pDocument2 pagesProperty - Mq.edu - Au - Inspection and Test Plans (ITP) - MUM-08 - Valves FORM - 2pHarumNo ratings yet

- ME2010 Tutorial Govening EquationsDocument2 pagesME2010 Tutorial Govening EquationsTharindu Danushka Nandalal100% (1)

- Actuators and SymbologyDocument18 pagesActuators and SymbologyJimmy KariukiNo ratings yet

- Vickers Valvula DGMFN-3-Z-P2W-41Document3 pagesVickers Valvula DGMFN-3-Z-P2W-41JuanPerezRooneyNo ratings yet

MFR-111 - Valve Test Record 01

MFR-111 - Valve Test Record 01

Uploaded by

Rafiq Rashidi0 ratings0% found this document useful (0 votes)

14 views1 pageThis document is a valve test record form used to record the testing of valves. It contains sections to record information about the project, valve details like type and size, test method and pressure, and test results. The test results section documents information like heat number, test pressure, holding time, and whether the valve passed or failed visual inspection at the holding pressure. It provides a standardized way to document valve testing for quality control purposes.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document is a valve test record form used to record the testing of valves. It contains sections to record information about the project, valve details like type and size, test method and pressure, and test results. The test results section documents information like heat number, test pressure, holding time, and whether the valve passed or failed visual inspection at the holding pressure. It provides a standardized way to document valve testing for quality control purposes.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

0 ratings0% found this document useful (0 votes)

14 views1 pageMFR-111 - Valve Test Record 01

MFR-111 - Valve Test Record 01

Uploaded by

Rafiq RashidiThis document is a valve test record form used to record the testing of valves. It contains sections to record information about the project, valve details like type and size, test method and pressure, and test results. The test results section documents information like heat number, test pressure, holding time, and whether the valve passed or failed visual inspection at the holding pressure. It provides a standardized way to document valve testing for quality control purposes.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

You are on page 1of 1

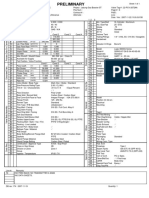

PROJECT:

VALVE TEST RECORD

PART A TO BE FILLED BY MECHANICAL SUPERVISOR

Form No. : TNB-QC-MFR-111 Rev 0

PROJECT : EPCC OF KRP EFFLUENT RECOVERY PROJECT____________ M.O No. ____________________

VALVE : 1. Gate Valve 2. Globe Valve 3. Check Valve 4. Ball Valve 5. Butterfly Valve 6. Plug Valve

TEST METHOD : HYDROSTATIC HYDRO-PNEUMATIC PNEUMATIC

PRESSURE GAUGE : RANGE DATE CALIBRATED CALIBRATION CERTIFICATE NUMBER

NAME :_______________________ SIGN :_________________________ DATE :___________________

REMARKS :_________________________________________________________________________________________________________

_________________________________________________________________________________________________________

PART B TO BE FILLED BY INSPECTION

HEAT NUMBER TEST PRESSURE

NO SIZE RATING HOLDING TIME (Sec.) TEST RESULT

BODY BONNET DISC SHELL SEAT BACKSEAT

1

2

3

4

TEST DURATION (Seconds)

TEST PRESSURE (PS1G/Kg /cm) VALVE SHELL CLOSURE (seat) BACKSEAT

SIZE(NPS)

VALVE WATER All Check Valve Other Valve All

RATING GAS

CLOSURE (NOT<)

SHELL (SEAT)

≤ 2 15 60 15 15

150 450/31.6 313/22 80/5.6 2 1/2 to 6 60 60 60 60

300 1125/79 814/57 80/5.6 8 to 12 120 120 120 60

400 1500/106 1089/77 80/5.6 ≥ 14 300 120 120 60

600 2225/157 1628/115 80/5.6

900 3350/236 2442/172 80/5.6 Note : This test pressure is applicable to material

1500 5575/392 4076/287 80/5.6 under Group 1.1 and temperature of 100 Deg.

2500 9275/652 6787/477 80/5.6 F 38(deg C)*Group 1.1 carbon steel (normal), refer

to ansi b16.34

* Other material group, refer ASME B16.34

* Valve rating 800 shall be comply with API 602

REMARKS :_________________________________________________________________________________________________________

_________________________________________________________________________________________________________

_________________________________________________________________________________________________________

Visual inspection at holding pressure of kg/cm².G

Test Result Accepted Rejected

Inspector Name :________________________________________ Date :________________ Signature :___________________

You might also like

- Testing Procedure of Dual Plate Check ValveDocument2 pagesTesting Procedure of Dual Plate Check Valverajesh100% (2)

- SN75 Series - 100 HP 60 HZ Horsepower Rated: Model SN7507 SN7509 SN7510 SN7512 Compressor PerformanceDocument2 pagesSN75 Series - 100 HP 60 HZ Horsepower Rated: Model SN7507 SN7509 SN7510 SN7512 Compressor PerformanceRicardo Guerrero SosaNo ratings yet

- Testing Procedure of Ball ValveDocument2 pagesTesting Procedure of Ball Valverajesh100% (2)

- Komatsu PC200 8 Testing and AdjustingDocument121 pagesKomatsu PC200 8 Testing and Adjustingibnu2malkan100% (6)

- Aerodynamics in Cars SeminarDocument22 pagesAerodynamics in Cars SeminarSwapnil Joshi75% (4)

- Material Test Certificate: To EN 10204 3.1:2004 Traceability Sheets/Mill/PressureDocument1 pageMaterial Test Certificate: To EN 10204 3.1:2004 Traceability Sheets/Mill/PressureMohamed RaafatNo ratings yet

- Table Pengecekan Hydrostatic Pressure Test Product ValvesDocument31 pagesTable Pengecekan Hydrostatic Pressure Test Product ValvesIksan Mustofa50% (2)

- Engineering Specification: ESFU5A-8079-AADocument5 pagesEngineering Specification: ESFU5A-8079-AAjavier ortizNo ratings yet

- Valve Test Record Form: Range Date Calibrated Calibration Certificate NumberDocument1 pageValve Test Record Form: Range Date Calibrated Calibration Certificate NumberAzuwan MohamadNo ratings yet

- APV Test Procedure API 598Document3 pagesAPV Test Procedure API 598Zain AlwaliNo ratings yet

- Pressure & Functional Testing Api 6D Ball Valves: Technical Instruction AP/PT6 00 05/03/19 1/3Document7 pagesPressure & Functional Testing Api 6D Ball Valves: Technical Instruction AP/PT6 00 05/03/19 1/3hari100% (1)

- Shell & Seat Test PressureDocument2 pagesShell & Seat Test PressureHQ EntertainmentNo ratings yet

- Globe Valve LWR 217: Inspection Report Defect-C0LD WorkDocument4 pagesGlobe Valve LWR 217: Inspection Report Defect-C0LD WorkMuhammad ZariqNo ratings yet

- Tubing String Testing (TST) Valve: Provides Tubing Testing Capability With Automatic Fill of The WorkstringDocument2 pagesTubing String Testing (TST) Valve: Provides Tubing Testing Capability With Automatic Fill of The Workstringadi nugroho100% (1)

- Severn Glocon 3Document10 pagesSevern Glocon 3Amit SurtiNo ratings yet

- 1.2. Sample - Datasheet Antisurge ValveDocument1 page1.2. Sample - Datasheet Antisurge ValveMuhammad FauzanNo ratings yet

- Material Test ReportDocument7 pagesMaterial Test Reportjuan carlos suaNo ratings yet

- 4 - Serial 89985-120-63Document7 pages4 - Serial 89985-120-63Katherine Toloza AcostaNo ratings yet

- Satr A 2001Document7 pagesSatr A 2001Naveed ShahNo ratings yet

- IO09 - Hydrostatic Test - R3Document3 pagesIO09 - Hydrostatic Test - R3bafivuitinhNo ratings yet

- Leak Class TestsDocument12 pagesLeak Class TestsZain AlwaliNo ratings yet

- Zdocs - Hu 773007136-ADocument1 pageZdocs - Hu 773007136-AMohamed RaafatNo ratings yet

- APV Test Procedure API 6DDocument7 pagesAPV Test Procedure API 6Ddevadoss kishoreNo ratings yet

- GMDSB Station Checklist 2020Document7 pagesGMDSB Station Checklist 2020Shah Mind YunusNo ratings yet

- Test Procedure API 598Document3 pagesTest Procedure API 598Raktim DasNo ratings yet

- TS 90 100 01Document4 pagesTS 90 100 01Lakee911No ratings yet

- Desmet Ballestra India PVT LTD: Inspection Test PlanDocument2 pagesDesmet Ballestra India PVT LTD: Inspection Test Plansameer patilNo ratings yet

- 3230F250 DATA CatalogDocument1 page3230F250 DATA CatalogLIONN TESTE2021No ratings yet

- Severn Glocon Lot2Document5 pagesSevern Glocon Lot2Amit SurtiNo ratings yet

- (°F) (Psi (G) ) (Psi (G) ) (Galus/Min) (MMSCFD) (CP) (Psi (A) )Document16 pages(°F) (Psi (G) ) (Psi (G) ) (Galus/Min) (MMSCFD) (CP) (Psi (A) )Elias EliasNo ratings yet

- CM 470Document4 pagesCM 470Chachou MohamedNo ratings yet

- Zamil 250Document13 pagesZamil 250Zaid Samha100% (1)

- Radiator Cap InspectionDocument7 pagesRadiator Cap InspectionTung NguyenNo ratings yet

- Wimpey - Wacg-22-222-5Document6 pagesWimpey - Wacg-22-222-5jaas jawadNo ratings yet

- NITON - HYDRO TEST PROCEDURE - Rev.0Document6 pagesNITON - HYDRO TEST PROCEDURE - Rev.0PRASHANT100% (2)

- 3dd028-N12-Api 6fa Fire Safe Test Procedure For High and Low Pressure Ball ValvesDocument7 pages3dd028-N12-Api 6fa Fire Safe Test Procedure For High and Low Pressure Ball ValvesPrathik Yeresh ReddyNo ratings yet

- Leser Certificate For Global ApplicationDocument3 pagesLeser Certificate For Global ApplicationErikikoNo ratings yet

- GSL Test Procedure API 598 PDFDocument3 pagesGSL Test Procedure API 598 PDFParag S. DicholkarNo ratings yet

- 108622-2371 TDDocument4 pages108622-2371 TDririnmars22No ratings yet

- CQ68894 Spec Sheet Rev-ADocument1 pageCQ68894 Spec Sheet Rev-AQichiix KiciNo ratings yet

- d200318x012 PDFDocument12 pagesd200318x012 PDFLimuel EspirituNo ratings yet

- Mod 80 UlDocument4 pagesMod 80 UlJUAN PABLO VELA GUIMACNo ratings yet

- QP07.01 Testing Procedure For Ball ValveDocument15 pagesQP07.01 Testing Procedure For Ball ValveAnanm NaimNo ratings yet

- Flow Control Valves Pressure Compensated Cartridge TypeDocument6 pagesFlow Control Valves Pressure Compensated Cartridge TypevrgohilNo ratings yet

- Equivalent Length TableDocument18 pagesEquivalent Length TablenguyenmainamNo ratings yet

- Komatsu - Pc220lc-8 - Excavator - Service - Testing and AdjustingDocument65 pagesKomatsu - Pc220lc-8 - Excavator - Service - Testing and Adjustingjuanchis650No ratings yet

- Modelo Nuevo - 4509B / COMPRESOR SULLAIRDocument2 pagesModelo Nuevo - 4509B / COMPRESOR SULLAIRLenin CastilloNo ratings yet

- Actuator InformationDocument4 pagesActuator InformationFajar DwikurniaNo ratings yet

- Side Pocket Mandral PDFDocument27 pagesSide Pocket Mandral PDFwajihhasnainNo ratings yet

- AAA Installation & Service ManualDocument36 pagesAAA Installation & Service ManualEurekia EvolutionNo ratings yet

- CM 470iiDocument4 pagesCM 470iiChachou MohamedNo ratings yet

- Flow Meter Data SheetDocument2 pagesFlow Meter Data SheetjlirazuritaNo ratings yet

- Data Sheets-T220425-499Document9 pagesData Sheets-T220425-499pedro torresNo ratings yet

- Data Sheet 2 Less 800#-BV - FB - SW - NT-76 PDFDocument1 pageData Sheet 2 Less 800#-BV - FB - SW - NT-76 PDFSachin KumarNo ratings yet

- Control Valve Data SheetDocument6 pagesControl Valve Data Sheetsiseset100% (1)

- Model S1F Metallic Design Level 1: Service & Operating ManualDocument31 pagesModel S1F Metallic Design Level 1: Service & Operating ManualGonzalo IñiguezNo ratings yet

- Sizing Sheet Dengan Cv. 133 PDFDocument3 pagesSizing Sheet Dengan Cv. 133 PDFJoko WisnugrohoNo ratings yet

- Belinda-MAQ-300-25BA-C Computer Control Safety Valve Test Bench R.1Document10 pagesBelinda-MAQ-300-25BA-C Computer Control Safety Valve Test Bench R.1ahsun habibNo ratings yet

- Tube Comp J00Document1 pageTube Comp J00Dudi SolehudinNo ratings yet

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsFrom EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsRating: 5 out of 5 stars5/5 (1)

- 863-863h 6900648 SM 10-98 PDFDocument3 pages863-863h 6900648 SM 10-98 PDFPepe AlNo ratings yet

- Hydraulic Ram SlideshowDocument26 pagesHydraulic Ram SlideshowAbhishek Patil100% (1)

- CE2102 - Fluid Mechanics Lab ManualDocument81 pagesCE2102 - Fluid Mechanics Lab ManualFazal E GhafoorNo ratings yet

- 330D 336 PDFDocument2 pages330D 336 PDFRICHARDNo ratings yet

- B.3.8 - Safety Valves SpecDocument8 pagesB.3.8 - Safety Valves SpecEmiel RoestenburgNo ratings yet

- rm69 Marine Toilet Electric Mul PDFDocument16 pagesrm69 Marine Toilet Electric Mul PDFurania22000No ratings yet

- Gear Pumps: Product RangeDocument4 pagesGear Pumps: Product RangeEng-Mohammed SalemNo ratings yet

- 2 - AIAA - Computation of Dynamic Stall of A NACA-0012 AirfoilDocument6 pages2 - AIAA - Computation of Dynamic Stall of A NACA-0012 Airfoilkgb_261No ratings yet

- Gas Pressure Regulators VGBF: Technical InformationDocument25 pagesGas Pressure Regulators VGBF: Technical InformationLuis Enrique Vidal GachaNo ratings yet

- Orifice and Venturi Meter - PrelabDocument6 pagesOrifice and Venturi Meter - Prelableo besaNo ratings yet

- SET31Practice TestDocument25 pagesSET31Practice TestMehrozNo ratings yet

- Pressure Drop TheoryDocument5 pagesPressure Drop Theorykaruna346100% (1)

- AerooDocument35 pagesAerooVinu GNo ratings yet

- ME:5160 (58:160) Intermediate Mechanics of Fluids Fall 2021 - HW6 SolutionDocument6 pagesME:5160 (58:160) Intermediate Mechanics of Fluids Fall 2021 - HW6 SolutionDiki AgungNo ratings yet

- FOV With LockDocument3 pagesFOV With LockBiswanath LenkaNo ratings yet

- Actuator Datasheet Severn GloconDocument1 pageActuator Datasheet Severn GloconQichiix KiciNo ratings yet

- Oil Pipeline Engineering CourseDocument3 pagesOil Pipeline Engineering CourseKarthik Sundararajan0% (1)

- 10H501 - MTO - Modification of Nozzles and PIPING Rev01 - 14-10-23 New OriginalDocument8 pages10H501 - MTO - Modification of Nozzles and PIPING Rev01 - 14-10-23 New OriginalKasarachi AmadiNo ratings yet

- Ad 1 Unit VIIDocument59 pagesAd 1 Unit VIIOsman KutluNo ratings yet

- Principles of Viscosity MeasurementDocument2 pagesPrinciples of Viscosity MeasurementPedro Sanchez50% (2)

- Safety Valve SizingDocument33 pagesSafety Valve SizingAshok Kumar100% (1)

- Plumbing PIpe SizingDocument12 pagesPlumbing PIpe SizingAwokeNo ratings yet

- BM Hydraulic Calculation Guide HiRes Interactive PagesDocument7 pagesBM Hydraulic Calculation Guide HiRes Interactive PagesKoteswara RaoNo ratings yet

- How To Size A Control Valve For Liquid and Gas Applications Usi PDFDocument4 pagesHow To Size A Control Valve For Liquid and Gas Applications Usi PDFv noteNo ratings yet

- M-54 K4670433 Sewage Treatment SystemDocument8 pagesM-54 K4670433 Sewage Treatment SystemeconmechNo ratings yet

- Property - Mq.edu - Au - Inspection and Test Plans (ITP) - MUM-08 - Valves FORM - 2pDocument2 pagesProperty - Mq.edu - Au - Inspection and Test Plans (ITP) - MUM-08 - Valves FORM - 2pHarumNo ratings yet

- ME2010 Tutorial Govening EquationsDocument2 pagesME2010 Tutorial Govening EquationsTharindu Danushka Nandalal100% (1)

- Actuators and SymbologyDocument18 pagesActuators and SymbologyJimmy KariukiNo ratings yet

- Vickers Valvula DGMFN-3-Z-P2W-41Document3 pagesVickers Valvula DGMFN-3-Z-P2W-41JuanPerezRooneyNo ratings yet