Professional Documents

Culture Documents

BBQ Chicken Nustar KFSS A1

BBQ Chicken Nustar KFSS A1

Uploaded by

agflamesengineering.salesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BBQ Chicken Nustar KFSS A1

BBQ Chicken Nustar KFSS A1

Uploaded by

agflamesengineering.salesCopyright:

Available Formats

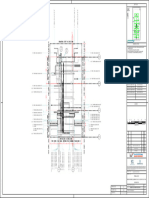

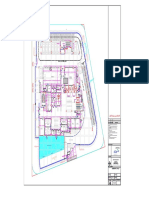

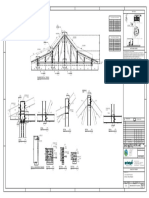

THIS SITE

FRYER)

2-FLOW

ADP (ELECTRIC

NOZZLE FRYER)

05 2-FLOW

ADP (ELECTRIC

2-FLOW ADP NOZZLE FRYER)

NOZZLE (DUCT 5) 06 2-FLOW

OFFICE ADP

NOZZLE (ELECTRIC

07 FRYER)

FUSIBLE LINK & 2-FLOW

LOCKER BRACKET 5

AREA ADP (ELECTRIC

NOZZLE FRYER)

08 2-FLOW

VIP 2-FLOW ADP

DINING NOZZLE (DUCT 4) ADP

LE

800X1200 800X1200

NOZZLE

AB

ET

WASH

IC

09

RV

AREA COMMON FUSIBLE LINK &

SE

TOILET

X12

00 2-FLOW ADP BRACKET 4

00

8

TR

1200*500 NOZZLE (DUCT 1)

BBQ CHICKEN, NUSTAR

AS

HC

TR

AS

HC

AN

AN

2-FLOW ADP

DISHWASHING

NOZZLE (DUCT 3)

AREA

BANQUET

FP-05 SEATING

P

FUSIBLE LINK &

HA

ND

BRACKET 3

05 NOT TO SCALE

WA

SIN SHIN

K G FUSIBLE LINK &

12

00

*50

0

BRACKET 1 2-FLOW ADP

12

NOZZLE (DUCT 2)

LE

00

*50

AB

0

ET

0

IC

*50

12

RV

00

R

*50

00

OO

SE

0

ENT.

12

PD

DISPATCH

LL-U

RO

AREA

COLD 15

00

*50

(10 BURNER

LE

0

STORAGE FUSIBLE LINK &

AB

15

00

.T

*50

GAS RANGE)

EP

0

PR

BRACKET 2

LE

AB

ET

DINING 2-FLOW

IC

0

*50

RV

AREA

00

SE

12

KITCHEN

PR

EP ADP

R

TA

OO

B LE

ENT.

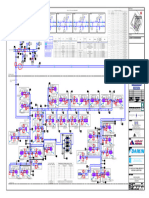

GENERAL NOTES:

P

NOZZLE

PD

(10 BURNER

LL-U

RO

01 GAS RANGE)

2-FLOW

E

BL

TA

1. ALL INSTALLATION SHALL MEET THE UL300 STANDARD AND

00

.

ER

0*7

ADP

PR

67

(10 BURNER

80

0*8 NOZZLE

NFPA 17A AND NFPA 96. 00

GAS RANGE)

R

02

OO

ENT. 10

PD

00

*65

2-FLOW

LL-U

0

ZE P

O

R

FR LE T

RO

2. ALL PIPES TO BE USED INCLUDING FITTINGS FOR THE WET CHEMICAL DISTRIBUTION

EE

ADP

B

TA

(10 BURNER

NOZZLE GAS RANGE)

LINE SHALL BE STAINLESS STEEL OR B.I. PIPE. BAR 03 2-FLOW

AREA

3. ALL MATERIALS TO BE USED SHALL BE NEW AND APPROVED TYPE FOR LOCATION AND PR

EP

TA

BL

ADP

R

E

NOZZLE

OO

ENT.

PD

LL-U

PURPOSES. 04

RO

0

*50

12

00

*50

00

0

4. A FUSIBLE LINK SHALL BE PROVIDED ABOVE EACH APPLIANCE OR GROUP OF DINING

12

AREA

DRY 12

00

*50

APPLIANCES PROTECTED BY A NOZZLE (1-FLOW OR 2-FLOW). STORAGE 0

R

OO

ENT.

PD

1500*500

5. MANUAL PULL STATION SHALL BE LOCATED IN A PATH EGRESS.

L-U

L

SERVICE

RO

ENT.

6. LOCATION OF DEVICE ARE INDICATIVE ONLY LOCATION SHALL BE PROVIDED UPON P

ENT. ENT. 1200*500 1200*500

INSTALLATION.

7. THE COMPLETE KITCHEN SUPRESSION SYSTEM SHALL BE FURNISHED INSTALLED BY

FIRE PROTECTION KITCHEN SUPRESSION CONTRACTOR COMPLETE SYSTEM FOR

OPERATION INCLUDING MOUNTING AND TERMINATION OF EQUIPMENT DEVICES AND

INTERFACING TO OTHER SYSTEM. FP-1 FP-3 ISOMETRIC DIAGRAM OF AUTOMATIC FIRE SUPPRESSION SYSTEM

SCALE 1:100 METERS

01 03 NOT TO SCALE

SEQUENCE OF OPERATION:

1. SUPPRESSION AGENTS PUT OUT FIRES BY ELIMINATING HEAT OR OXYGEN OR

BY DISRUPTING CHEMICAL REACTIONS.

B

2. WHEN A FLAME OCCURS, THE HEAT OF THE FIRE CAUSES THE FUSIBLE LINK

TO BREAK AT THE HOTTEST POINT APPROXIMATELY 232°C (450°F).

3. THUS, IT RELEASES TENSION ON THE CABLE CREATING A LOADED SPRING

TO ACTUATE THE CYLINDER DISCHARGE VALVE AND INSTANTLY FLOODS THE AB

COOKING AREA WITH CLASS F EXTINGUISHING AGENT.

ET

R VC

I

4. IF NECESSARY USING THE MECHANICAL PULL STATION MANUALLY INITIATE

SE

THE SYSTEM BY REMOVING THE SAFETY PIN AND PULL THE RING. KITCHEN

PR

EP

5 TA

BL

E

6

4

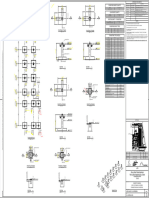

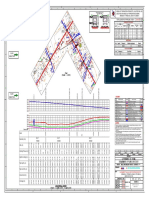

AGENT CAPACITY VS NO. FLOWS MATRIX FUSIBLE LINK & FUSIBLE LINK &

BRACKET 2

FUSIBLE LINK & FUSIBLE LINK &

BRACKET 4

FUSIBLE LINK &

BRACKET 5

4

BRACKET 1 BRACKET 3

4

E

2-FLOW ADP 2-FLOW ADP

L

2-FLOW ADP 2-FLOW ADP 2-FLOW ADP

AB

CAPACITY MAX. ALLOWABLE 5 NOZZLE (DUCT 1) NOZZLE (DUCT 2) NOZZLE (DUCT 3) NOZZLE (DUCT 4) NOZZLE (DUCT 5)

.T

00

BRAND

ER

(GALLONS)

4

0*7

NO. OF FLOWS

PR

67

1.68 5

4

4

4

6

2.3 7

4

LEHAVOT 4.2 12

ZE P

5

EE TO

R

UL 300 Compliance

4

FR LE

5.4 16

B

4

TA

6.8 20 MANUAL

6 MRM PULL STATION

01

4

Wet Chemical

1.25 4

4

2.25 8

4

RANGEGUARD 5 (10 BURNER (10 BURNER (10 BURNER (10 BURNER (ELECTRIC (ELECTRIC (ELECTRIC

FRYER)

(ELECTRIC (ELECTRIC

GAS RANGE) GAS RANGE) GAS RANGE) GAS RANGE) FRYER) FRYER) FRYER) FRYER)

4.0 12 PR 2-FLOW 2-FLOW 2-FLOW 2-FLOW 2-FLOW 2-FLOW

EP 2-FLOW 2-FLOW 2-FLOW

TA ADP ADP ADP ADP ADP ADP ADP ADP ADP

B MECHANICAL

6.0 18 6

LE NOZZLE

01

NOZZLE NOZZLE NOZZLE

04 RELEASE MODULE

NOZZLE NOZZLE NOZZLE

07

NOZZLE

08

NOZZLE

02 03 05 06 09

1.5 5-6

ANSUL

3.0 11-12 2 AGENT CYLINDER

1.6 5 50

3 (COOKING APPLIANCES AREA) WCK 20 LITERS (COOKING APPLIANCES AREA)

0

3.0 10

PYROCHEM 1 12

0 0*5

4.6 15 00

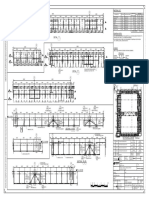

E ELEVATION THRU - A ELEVATION THRU - B

6.0 20

1 MANUAL PULL STATION (MPS)

FLOW NUMBER COMPUTATION

A

2 MECHANICAL RELEASE

NO. OF NOZZLES MODULE (MRM)

DESCRIPTION QTY. (1 per coverage)

3 PLAN

EQUIPMENTS 2 9

AGENT CYLINDER WCK 16 LITERS

FP-2 AUTOMATIC FIRE SUPPRESSION SYSTEM LAYOUT FP-4 ELEVATION - AUTOMATIC FIRE SUPPRESSION SYSTEM

4

PLENUM X X 2-FLOW ADP NOZZLE 02 SCALE 1:30 04 SCALE 1:30 METERS

DUCT 5 5 5 FUSIBLE LINK & BRACKET

TOTAL 14 6 EXHAUST DUCT

R. A. 9 2 6 6 JIM

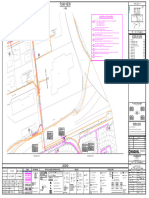

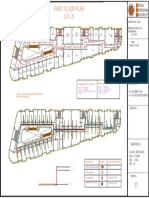

BBQ CHICKEN-NUSTAR ELECTRONNICS AND COMMUNICATION LAYOUT

GPD

JIM 00 FP-01 01

RESORT AND CASINO GPD

NUSTAR RESORT AND CASINO, KAWIT ISLAND, A1

CEBU CITY, 6000 CEBU X 1:50 MTRS. FRESH AIR AND EXHAUST

VENTILATION SYSTEM

FOR CONSTRUCTION 12/11/2023

You might also like

- EX1200-Electrical Circuit Diagram (Cummins Engine Specification)Document1 pageEX1200-Electrical Circuit Diagram (Cummins Engine Specification)Norman CoetzeeNo ratings yet

- DD13 Engine Harness PDFDocument2 pagesDD13 Engine Harness PDFalejandro calixtoNo ratings yet

- Sejmste1 19Document1 pageSejmste1 19hal9000_mark1No ratings yet

- Irrigation Control Cable LayoutDocument4 pagesIrrigation Control Cable Layoutalivesince1091No ratings yet

- Drp001-Puc-330000-P-Gad-005-5 (Y)Document1 pageDrp001-Puc-330000-P-Gad-005-5 (Y)John AlmasNo ratings yet

- Council DWG-01Document1 pageCouncil DWG-01Janitha SandaruwanNo ratings yet

- 250 KVA Genset Wiring PDFDocument1 page250 KVA Genset Wiring PDFSZANo ratings yet

- Approved by Bhubaneswar Development AuthorityDocument1 pageApproved by Bhubaneswar Development AuthorityAkash MohantyNo ratings yet

- Floor Plan - Em-Schematic RiserDocument1 pageFloor Plan - Em-Schematic Riserisyed1948No ratings yet

- Cat 3412Document4 pagesCat 3412hoseinNo ratings yet

- KJ 117 o en Sac 00 Zme 0303Document1 pageKJ 117 o en Sac 00 Zme 0303Abdullah ObeidatNo ratings yet

- Fire Water NetworkDocument1 pageFire Water NetworkKhuda BukshNo ratings yet

- Sector-6 (Palm Wood Enclave) Size 194 SQRDDocument1 pageSector-6 (Palm Wood Enclave) Size 194 SQRDWave cityNo ratings yet

- 9m Ev Electrical LV SchematicDocument1 page9m Ev Electrical LV SchematicShankar NaiduNo ratings yet

- DD13 Engine Harness PDFDocument2 pagesDD13 Engine Harness PDFalejandro sanchezNo ratings yet

- Door DetailsDocument1 pageDoor DetailsSOUNDARYA CHOTHENo ratings yet

- Syracuse Council Districts MapDocument1 pageSyracuse Council Districts MapTim KnaussNo ratings yet

- Terminal Penumpang-UMUM 02Document4 pagesTerminal Penumpang-UMUM 02ph03y3nkNo ratings yet

- Sheraton Boh Ugf PowerDocument1 pageSheraton Boh Ugf PowerEbênNo ratings yet

- PLANS - Architectural-Structural-Plumbing-ElectricalDocument30 pagesPLANS - Architectural-Structural-Plumbing-ElectricalAngelica Dacuycuy100% (1)

- Os00002 T Bw31.za3.um02&ez18453 R03-SHT1Document1 pageOs00002 T Bw31.za3.um02&ez18453 R03-SHT1Gopalakrishnan DhandapaniNo ratings yet

- 313 312 315 MergedDocument3 pages313 312 315 MergedDenzo RyugaNo ratings yet

- Circuit Diagrams: MAIN PWB CIRCUIT DIAGRAM (AV-29B316/B) (1/4) (2/4) SHEET1Document4 pagesCircuit Diagrams: MAIN PWB CIRCUIT DIAGRAM (AV-29B316/B) (1/4) (2/4) SHEET1Fede DiNo ratings yet

- Distribution Substation Ss.40462, Fp-04: NotesDocument1 pageDistribution Substation Ss.40462, Fp-04: NotesAnwarologyNo ratings yet

- Lift DetailsDocument1 pageLift DetailsSOUNDARYA CHOTHENo ratings yet

- Keyplan: PT Katalis Sinergi IndonesiaDocument1 pageKeyplan: PT Katalis Sinergi IndonesiaFebry YantaNo ratings yet

- Elevation - A Elevation - B Section - 1: A B C D E F H I G D1Document1 pageElevation - A Elevation - B Section - 1: A B C D E F H I G D1buildings departmentNo ratings yet

- mcc2 PDFDocument1 pagemcc2 PDFSravyaSree100% (2)

- 4355 Aa DC 21i10pr09001 - 0Document1 page4355 Aa DC 21i10pr09001 - 0amit bagchiNo ratings yet

- Steel Column Base Details-ModelDocument1 pageSteel Column Base Details-ModelAhmed SolankiNo ratings yet

- BGLR 1343 Feeder-2Document1 pageBGLR 1343 Feeder-2Mani CadNo ratings yet

- Portfolio - Celestino, RhineDocument8 pagesPortfolio - Celestino, RhineAnonymous 9I5RViWz8UNo ratings yet

- Stilt Plan: Column Number Column SizeDocument1 pageStilt Plan: Column Number Column SizeRHUTI NAIKNo ratings yet

- It ParkDocument1 pageIt ParkJESUS: REPENT MENo ratings yet

- Ground Water Supply & Distribution Layout Second Water Supply & Distribution LayoutDocument1 pageGround Water Supply & Distribution Layout Second Water Supply & Distribution LayoutLyricsNo ratings yet

- 9572-109-PVC-B-XXX (SHT-1) - R0 - Grde Slab LVL - 09042020Document1 page9572-109-PVC-B-XXX (SHT-1) - R0 - Grde Slab LVL - 09042020MRITYUNJOY DUTTANo ratings yet

- Drive Way 5800 Wide: DN From Ground FloorDocument1 pageDrive Way 5800 Wide: DN From Ground FloorEram HashmiNo ratings yet

- Appendik I - Park PB 04-Layout1Document1 pageAppendik I - Park PB 04-Layout1Art Sensation 2019No ratings yet

- Power Layout Circuit-R1 (3F)Document1 pagePower Layout Circuit-R1 (3F)Electrical PCBL TeamNo ratings yet

- Power Layout Circuit-R1 (SF)Document1 pagePower Layout Circuit-R1 (SF)Electrical PCBL TeamNo ratings yet

- Proposed Lay - Out Plan at Nehru Enclave Vaibhav Khand Gomti Nagar, LucknowDocument1 pageProposed Lay - Out Plan at Nehru Enclave Vaibhav Khand Gomti Nagar, LucknowDhananjay SinghNo ratings yet

- G216338-Hmod-Near 80 Black Walnut Dr-Kitchener-DwgDocument5 pagesG216338-Hmod-Near 80 Black Walnut Dr-Kitchener-DwgJhonn StevNo ratings yet

- Condominio Las Lomas de Santo Domingo 2023Document1 pageCondominio Las Lomas de Santo Domingo 2023Alberto LugoNo ratings yet

- Manual de Entrenamiento Cessna 208 (212-217)Document6 pagesManual de Entrenamiento Cessna 208 (212-217)leonardoNo ratings yet

- Fsa 0180 F2Document1 pageFsa 0180 F2Mani CadNo ratings yet

- Span Arrangementpackage-59 - P3L2 PDFDocument23 pagesSpan Arrangementpackage-59 - P3L2 PDFJ. Kumar Infraprojects LtdNo ratings yet

- 30925-01 - 1233 South Grand - Foundation 2021-03-11-Corrección - FadDocument6 pages30925-01 - 1233 South Grand - Foundation 2021-03-11-Corrección - FadRicardo Alejandro Oyarce ArmijoNo ratings yet

- First Floor Plan (LVL 3) : Submitted To:-Ar. Amandeep Kaur Ar - Naveen Suresh ChomalDocument1 pageFirst Floor Plan (LVL 3) : Submitted To:-Ar. Amandeep Kaur Ar - Naveen Suresh ChomalDharaniNo ratings yet

- SCC-3-450-EXB1-7000-0: MV Cable Routing To Drups Area Connection OverallDocument1 pageSCC-3-450-EXB1-7000-0: MV Cable Routing To Drups Area Connection OverallAnalin SabilaNo ratings yet

- 3406 and 3456C Generator Set With Electrical System EMCP3.1, 3.2 and 3.3Document4 pages3406 and 3456C Generator Set With Electrical System EMCP3.1, 3.2 and 3.3nobodymagdesignNo ratings yet

- 16-45236-C009 - 3 - Modulación Trepas 3° Al 6° - UNO-Layout1Document1 page16-45236-C009 - 3 - Modulación Trepas 3° Al 6° - UNO-Layout1Nelson ContrerasNo ratings yet

- ISO - IPA 300 Lps - Pontianak - 28 - 08 - 2023Document17 pagesISO - IPA 300 Lps - Pontianak - 28 - 08 - 2023Asep MustapaNo ratings yet

- MRS-DWG-DD-ST-01-SL-5004 - R0 - Detail - Steel Truss-3Document1 pageMRS-DWG-DD-ST-01-SL-5004 - R0 - Detail - Steel Truss-3arman gauNo ratings yet

- Duct PipeDocument8 pagesDuct PipeVermer FabregasNo ratings yet

- A-120 - BLVD - 1 - Roof Floor PlanDocument1 pageA-120 - BLVD - 1 - Roof Floor PlanRaghu supertechNo ratings yet

- 3 2 PDFDocument2 pages3 2 PDFhernando ramosNo ratings yet

- Ec1-01a Ground Floor Fdas LayoutDocument1 pageEc1-01a Ground Floor Fdas LayoutSEDFREY DELA CRUZNo ratings yet

- Direction Flow: SheetDocument1 pageDirection Flow: SheetTusarkanta BiswalNo ratings yet

- Akari PTC80897 Ta8690 Ta8445 Tda2006Document1 pageAkari PTC80897 Ta8690 Ta8445 Tda2006محمد عبد شهريNo ratings yet