Professional Documents

Culture Documents

VCB Maint Checklist

VCB Maint Checklist

Uploaded by

Ashish Mahapatra0 ratings0% found this document useful (0 votes)

923 views3 pagesThe document provides checklists for maintenance of various electrical equipment:

1) It lists 27 steps for checking an Air Circuit Breaker (ACB), including cleaning, inspecting contacts and mechanisms, checking insulation resistance, and performing tests.

2) It describes 15 checks for a Vacuum Circuit Breaker (VCB), such as cleaning, inspecting contacts and mechanisms, checking insulation resistance, and replacing faulty parts.

3) It outlines 15 maintenance procedures for an Oil Circuit Breaker (OCB) that are similar to those for the VCB.

4) It lists 18 checks for an LT Panel including cleaning, inspecting bus bars, contacts, mechanisms and insulation resistance.

Original Description:

VCB maintenance

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides checklists for maintenance of various electrical equipment:

1) It lists 27 steps for checking an Air Circuit Breaker (ACB), including cleaning, inspecting contacts and mechanisms, checking insulation resistance, and performing tests.

2) It describes 15 checks for a Vacuum Circuit Breaker (VCB), such as cleaning, inspecting contacts and mechanisms, checking insulation resistance, and replacing faulty parts.

3) It outlines 15 maintenance procedures for an Oil Circuit Breaker (OCB) that are similar to those for the VCB.

4) It lists 18 checks for an LT Panel including cleaning, inspecting bus bars, contacts, mechanisms and insulation resistance.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

0 ratings0% found this document useful (0 votes)

923 views3 pagesVCB Maint Checklist

VCB Maint Checklist

Uploaded by

Ashish MahapatraThe document provides checklists for maintenance of various electrical equipment:

1) It lists 27 steps for checking an Air Circuit Breaker (ACB), including cleaning, inspecting contacts and mechanisms, checking insulation resistance, and performing tests.

2) It describes 15 checks for a Vacuum Circuit Breaker (VCB), such as cleaning, inspecting contacts and mechanisms, checking insulation resistance, and replacing faulty parts.

3) It outlines 15 maintenance procedures for an Oil Circuit Breaker (OCB) that are similar to those for the VCB.

4) It lists 18 checks for an LT Panel including cleaning, inspecting bus bars, contacts, mechanisms and insulation resistance.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

You are on page 1of 3

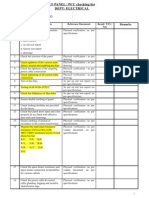

Check list ACB, VCB, OCB, LT PANEL

Air Circuit Breaker (ACB):

Panel 11 KV VCB type

1 Cleaning of breaker with CRC-226

Removal of old Grease and re-greasing the same with

2 recommended grease

Check condition of arcing contact and gap between fixed and

3 moving arcing contracts shall be checked.

Check condition of arcing contact and gap between fixed and

4 moving arcing contracts shall be checked.

Checking the reset mechanism, tripping of breaker through push

5 button.

Checking the reset mechanism, tripping of breaker through push

6 button.

7 Checking tripping of ACB through protection release.

8 Checking presence and proper tightening of hardware.

9 Checking presence of all cir clips.

Checking condition and alignment of jaw contract with cradle

10 terminals

11 Checking condition of ACB wiring and replace if required.

12 Checking and adjusting gap between hylam sheet and side plate.

13 Checking proper closing of all poles together.

14 Checking working of anti pumping device in case of EDO ACB.

15 Checking alignment of SIC and its operation.

16 Checking scrapping earth alignment.

17 Checking condition of arc chutes.

18 Checking U/V release pickup and drop off.

19 Checking ACB tripping through Shunt release.

20 Checking motor operation in case of EDO ACB.

21 Checking closing coil operation in case of EDO ACB.

22 Checking continuity and proper changeover of aux contract block.

23 Checking IR between phases – phase (ACB Closed condition).

24 Checking IR between phases – earth (ACB closed Condition).

25 Checking IR between phases – earth (ACB in open condition).

26 Setting of release as per the load.

After the inspection, the ACB shall be checked for proper

27 termination by mv drop Test

Vacuum Circuit Breaker (VCB):

1 Cleaning of Vacuum Circuit Breaker with CRC-226

Removal of old grease and re-greasing the same with

2 recommended grease

3 Check condition of SIC Contacts

4 Checking condition and alignment of jaw Contact

5 Checking and proper tightening of hardware

6 Checking proper closing of all poles together

7 Checking of breaker tripping through push button

8 Checking and adjusting gap between hylam sheet and side plate

9 Checking motor operation in case of EDO.

10 Checking of auxiliary contacts continuity proper change over

11 Checking presence of all circlips

12 Checking IR between phase – phase (VCB closed condition)

13 Checking IR between phase – earth (VCB closed condition)

14 Checking IR between phase – earth (VCB in Open condition)

15 Any faculty spare replace by new one, which will be charged extra.

Oil Circuit Breaker (OCB):

1 Cleaning of Oil Circuit Breaker with CRC-226

Removal of old grease and re-greasing the same with

2 recommended grease

3 Check condition of SIC Contacts

4 Checking condition and alignment of jaw Contact

5 Checking and proper tightening of hardware

6 Checking proper closing of all poles together

7 Checking of breaker tripping through push button

8 Checking and adjusting gap between hylam sheet and side plate

9 Checking motor operation in case of EDO.

10 Checking of auxiliary contacts continuity proper change over

11 Checking presence of all circlips

12 Checking IR between phase – phase (OCB closed condition)

13 Checking IR between phase – earth (OCB closed condition)

14 Checking IR between phase – earth (OCB in Open condition)

15 Any faculty spare replace by new one, which will be charged extra

LT Panel: We do following during regular maintenance of LT

Panel

1 Cleaning of Panel Breaker with CRC-226

2 Check condition of Bus bars

3 Checking condition and alignment of jaw Contact

4 Checking and proper tightening of hardwares

5 Checking of breaker tripping through push button

6 Checking motor operation in case of EDO.

7 Checking of auxiliary contacts continuity proper change overs

8 Checking presence of all circlips

9 Checking IR between phase – phase (ACB closed condition)

10 Checking IR between phase – earth (ACB closed condition)

11 Checking IR between phase – earth (ACB in Open condition)

12 Checking of Contactor NO NC Point

13 Checking of ad on block NO NC Point

14 Checking of Control Wiring

15 Checking of Thimble Tightness

16 Checking of MCCB

17 Checking o MCB

18 Any faculty spare replace by new one, which will be charged extra.

Control Wiring: We do following during regular maintenance of

Control Wiring

1 Checking of All Control Wiring

2 Checking of Contactor in NO/NC Point

3 Checking of Glass Relay in NO/NC Point

4 Checking of MCB Terminals

5 Checking of RCCB Terminals

6 Checking of Contactor Coil Resistance

7 Checking of auxiliary Contact

8 Checking of thimble of Terminals

9 Checking of indicator of Panel

10 Checking selectors switch in NO/NC Point

11 Checking of TNC Switch in NO/NC Point

12 Checking of Fuse Link Terminals

13 Checking of Timer Relay Terminals

14 Checking of Amp Meter Tightening at Terminals

15 Checking of voltage meter Tightening at Terminals

You might also like

- Panel Inspection Report FormatDocument5 pagesPanel Inspection Report Formatp mahesh goud100% (2)

- E021-Checklist LT PanelDocument1 pageE021-Checklist LT Panelaudiihussain67% (3)

- VFD Commissioning FormatDocument2 pagesVFD Commissioning FormatJun Lumayno100% (4)

- Transformer Check ListDocument2 pagesTransformer Check ListKanhiya Prasad80% (5)

- Earthpit Resistance Testing RecordsheetDocument1 pageEarthpit Resistance Testing RecordsheetawsomeNo ratings yet

- Rmu Visual Inspection ChecklistDocument1 pageRmu Visual Inspection ChecklistJoe_Average100% (3)

- Protocol-Motor Trial Run FormatDocument6 pagesProtocol-Motor Trial Run FormatAnuj Gautam0% (1)

- Overhauling of Electrical Motors: Novatex Limited SOP / E&I / 11Document4 pagesOverhauling of Electrical Motors: Novatex Limited SOP / E&I / 11OSAMA67% (3)

- CT Knee Point Voltage CalculationDocument2 pagesCT Knee Point Voltage CalculationPramod B.Wankhade90% (30)

- Aoh Checklist LT and HT MotorDocument8 pagesAoh Checklist LT and HT MotorElectrical Team100% (1)

- LT Panel SOP For Test ProcedureDocument5 pagesLT Panel SOP For Test ProcedureShrikanth Sola100% (2)

- LT Panel PDI SOPDocument4 pagesLT Panel PDI SOPShrikanth SolaNo ratings yet

- Transformer Daily Check ListDocument3 pagesTransformer Daily Check ListVatsavai Appala Narasimha Raju50% (8)

- ACB Maintenance ProcedureDocument1 pageACB Maintenance ProcedureMartono Abu HanifNo ratings yet

- NTPC Telangana: Standard ChecklistDocument3 pagesNTPC Telangana: Standard ChecklistVikrant Deshmukh100% (1)

- Check ListDocument6 pagesCheck ListSikandar Khan0% (2)

- Bom For Outdoor Type Panel & Indoor Type PanelDocument1 pageBom For Outdoor Type Panel & Indoor Type PanelHytech Pvt. Ltd.100% (1)

- Checklist For LT PanelDocument13 pagesChecklist For LT PanelSanket Jain80% (5)

- ELCB Testing ReportDocument1 pageELCB Testing ReportPradeep Yallanki100% (4)

- D.D. Builders Limited: Idax Consulting & Research PVT - LTDDocument8 pagesD.D. Builders Limited: Idax Consulting & Research PVT - LTDTARUNNo ratings yet

- VCB ServiceDocument1 pageVCB ServiceimranNo ratings yet

- Power Engineering - Check List ACB, VCB, OCB, LT PANELDocument7 pagesPower Engineering - Check List ACB, VCB, OCB, LT PANELAnonymous mNQq7oj100% (1)

- Procedure of Maintenance of 415V BUSDocument2 pagesProcedure of Maintenance of 415V BUSVatsavai Appala Narasimha Raju100% (1)

- VCB Maintenance ReportDocument8 pagesVCB Maintenance ReportSatya Barik100% (3)

- Maint - Check List - Oil Filled TransforsDocument2 pagesMaint - Check List - Oil Filled TransforsramNo ratings yet

- HT Panel ChecklistDocument1 pageHT Panel ChecklistMahfuza MansuraNo ratings yet

- LT Panel PDI SOPDocument4 pagesLT Panel PDI SOPShrikanth Sola100% (2)

- Masibus-8208 Manual PDFDocument36 pagesMasibus-8208 Manual PDFfaisal2106No ratings yet

- LT PANEL / PCC Checking List Dept: Electrical: Equipment Tag No: Incoming PCC Feeder No.: DateDocument3 pagesLT PANEL / PCC Checking List Dept: Electrical: Equipment Tag No: Incoming PCC Feeder No.: DateVelmurugan Chakkravarthy100% (4)

- Check List LT PanelDocument1 pageCheck List LT PanelAnil Patel100% (2)

- LCC Bus Coupler - Functional TestDocument7 pagesLCC Bus Coupler - Functional TestAmr ElkadyNo ratings yet

- C Power ACB ManualDocument9 pagesC Power ACB ManualanilerNo ratings yet

- HT Panel ChecklistDocument1 pageHT Panel Checklisttango member0% (1)

- Is 3043Document4 pagesIs 3043Jeya KannanNo ratings yet

- 11 KV VCB PanelDocument29 pages11 KV VCB PanelPrakash Rout100% (6)

- DG Set Abcd CheckDocument9 pagesDG Set Abcd CheckshirishNo ratings yet

- Transformer Daily Check ListDocument3 pagesTransformer Daily Check ListLokesh Kumar100% (1)

- CB Test ReportDocument2 pagesCB Test ReportLingga SuhadhaNo ratings yet

- Contact Resistance Test FormatDocument1 pageContact Resistance Test Formatrudra abhi100% (1)

- Acdb - Function TestDocument4 pagesAcdb - Function TestDinesh Pitchaivel0% (1)

- Form Motor Solo Run Interlock FuncDocument1 pageForm Motor Solo Run Interlock FuncImam HanafiNo ratings yet

- QAP of HT Breaker Panel SchneiderDocument1 pageQAP of HT Breaker Panel Schneidermadhu_bedi12No ratings yet

- 1 AcdbDocument9 pages1 AcdbmaheshknmNo ratings yet

- Appendix-2 (POWER PANEL Test Report)Document2 pagesAppendix-2 (POWER PANEL Test Report)hafed baccoucheNo ratings yet

- C&S Pricelist 2022Document145 pagesC&S Pricelist 2022Jimmy Shah100% (1)

- Enclosed ATS: Enclosed Automatic Transfer SwitchDocument20 pagesEnclosed ATS: Enclosed Automatic Transfer SwitchPrasenjit Maity100% (1)

- Vd4 1vdu09001-Yn ManualDocument56 pagesVd4 1vdu09001-Yn ManualAndrew Sison100% (2)

- 2 Check List For 4.16KV VCBDocument6 pages2 Check List For 4.16KV VCBmatthew_70% (1)

- Dry Type Transformer Test Report: Page 1 of 2Document2 pagesDry Type Transformer Test Report: Page 1 of 2erwin5sambas5aryana100% (1)

- Prok DVs - ACCL - CatalougeDocument3 pagesProk DVs - ACCL - CatalougekapilNo ratings yet

- NEW MPCB Selection ChartDocument6 pagesNEW MPCB Selection ChartSamarendu Baul0% (1)

- Site Test Report: Under Ground Cables Precommissioning Test SheetDocument1 pageSite Test Report: Under Ground Cables Precommissioning Test SheetNaser Mahamid100% (1)

- Grid Station General Checking Checklist YittiDocument2 pagesGrid Station General Checking Checklist Yittianurag_jay12464100% (1)

- Old LT Panel 400 AmpDocument5 pagesOld LT Panel 400 AmpAbhinav TewariNo ratings yet

- Belt Watch PDFDocument5 pagesBelt Watch PDFkalaiNo ratings yet

- VCB PM PDFDocument15 pagesVCB PM PDFAccidental EngineerNo ratings yet

- Ring Main Unit Testing and Commissioning Method StatementDocument4 pagesRing Main Unit Testing and Commissioning Method StatementAleen Gamal Al-DinjiNo ratings yet

- Circuit Breaker MaintDocument4 pagesCircuit Breaker MaintSelvn SubramanianNo ratings yet

- Air Circuit Breaker-2Document9 pagesAir Circuit Breaker-2ssvasavaongcNo ratings yet

- Acb Scope of WorkDocument1 pageAcb Scope of WorkBrijesh SinghNo ratings yet

- ELECTDocument10 pagesELECTThirunavukkarasuThiruNo ratings yet

- Power Transformer Pre Commisioning ChecklistDocument26 pagesPower Transformer Pre Commisioning ChecklistRajesh TK100% (3)

- Havells STADxDocument20 pagesHavells STADxAshish MahapatraNo ratings yet

- Afcat Sample Question PaperDocument6 pagesAfcat Sample Question PaperAshish MahapatraNo ratings yet

- UPS QuotationsDocument6 pagesUPS QuotationsAshish MahapatraNo ratings yet

- GATE 2011 Mechanical Engineering Question PaperDocument14 pagesGATE 2011 Mechanical Engineering Question PaperAshish MahapatraNo ratings yet

- CIL Coal India MT Electrical Question Paper For Management Trainees ExamDocument7 pagesCIL Coal India MT Electrical Question Paper For Management Trainees ExamAshish Mahapatra100% (1)

- Coal India Limited CIL General Knowledge Question Paper Answers Model PaperDocument4 pagesCoal India Limited CIL General Knowledge Question Paper Answers Model PaperAshish Mahapatra77% (31)

- HX94 HumiditySens BrochureDocument2 pagesHX94 HumiditySens BrochureSani PoulouNo ratings yet

- Nema Limit Switches - 9007TUB1Document3 pagesNema Limit Switches - 9007TUB1tonySuperman17No ratings yet

- Rationalization Energy Based On Automatic Street Lighting SystemDocument5 pagesRationalization Energy Based On Automatic Street Lighting Systemhamza mandlwiNo ratings yet

- Fluke Pm6304 ManualDocument160 pagesFluke Pm6304 ManualYung SangNo ratings yet

- Dimensions: NJ5-18GM-N-V1Document3 pagesDimensions: NJ5-18GM-N-V1giridharNo ratings yet

- Devicenet Armorblock™ Network Powered 16-Input Module: Installation InstructionsDocument16 pagesDevicenet Armorblock™ Network Powered 16-Input Module: Installation InstructionsJoel GallegosNo ratings yet

- DICA Question Bank Units - 1,2,3Document4 pagesDICA Question Bank Units - 1,2,3mkrNo ratings yet

- Modul 2 Power System Studies 1Document41 pagesModul 2 Power System Studies 1Anargya WidyatamaNo ratings yet

- AC Dual Inlet Forward Centrifugal Fans: LongwellDocument21 pagesAC Dual Inlet Forward Centrifugal Fans: LongwellYoussef HalloumNo ratings yet

- 120MWp Rotterdam Sun Shine Generation Phase 1B - 240314 - 171650Document28 pages120MWp Rotterdam Sun Shine Generation Phase 1B - 240314 - 171650MpiloNo ratings yet

- Versaflood Ii Wallighter: ApplicationsDocument2 pagesVersaflood Ii Wallighter: ApplicationsKarlos Antonio Salinas MoralesNo ratings yet

- Filter Design1Document66 pagesFilter Design1ec academicNo ratings yet

- XHST-10AB Programmable Timer ControllerDocument12 pagesXHST-10AB Programmable Timer ControllerJie ChenNo ratings yet

- 12kVDoubleTierPanel PDFDocument2 pages12kVDoubleTierPanel PDFLokman ToolibNo ratings yet

- Elx303 ExamDocument5 pagesElx303 ExamNadeesha BandaraNo ratings yet

- Pure Sine Wave Inverter ProjectDocument5 pagesPure Sine Wave Inverter ProjectZOOM TECH BANGLANo ratings yet

- Gpwii - Pii - 160FDocument2 pagesGpwii - Pii - 160FashokghtNo ratings yet

- 15 - L-9 (DK) (Pe) ( (Ee) Nptel)Document1 page15 - L-9 (DK) (Pe) ( (Ee) Nptel)GagneNo ratings yet

- B 01Document27 pagesB 01Kasi ChinnaNo ratings yet

- EEE 209 Presentation 3 (Circuits Cont)Document185 pagesEEE 209 Presentation 3 (Circuits Cont)Mert YılmazNo ratings yet

- NTC 220 - 50 Manual Rev00Document57 pagesNTC 220 - 50 Manual Rev00Xuân NHNo ratings yet

- BE1 87B Bus Differential RelayDocument75 pagesBE1 87B Bus Differential RelayAngie León100% (1)

- Altivar 12 Variable Frequency Drives VFD - ATV12HU15M3Document11 pagesAltivar 12 Variable Frequency Drives VFD - ATV12HU15M3Leví StrataNo ratings yet

- AN10496 Vacuum Cleaner With Philips P89LPC901Document32 pagesAN10496 Vacuum Cleaner With Philips P89LPC901zdravkorrNo ratings yet

- Caso Estudio Baker SKF - 2Document1 pageCaso Estudio Baker SKF - 2jhonatanNo ratings yet

- A Review On Frequency Selective Surfaces and Its ApplicationsDocument7 pagesA Review On Frequency Selective Surfaces and Its ApplicationsVijeta Diwan.21DR0213No ratings yet

- Catalog VIKODocument40 pagesCatalog VIKOshhoneNo ratings yet

- Infinitum Gen4 IoM 20230811Document10 pagesInfinitum Gen4 IoM 20230811jonaslomlomNo ratings yet