Professional Documents

Culture Documents

CAPMS Handout Color

CAPMS Handout Color

Uploaded by

Manish SoniOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CAPMS Handout Color

CAPMS Handout Color

Uploaded by

Manish SoniCopyright:

Available Formats

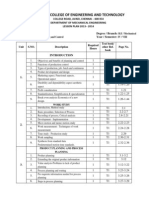

Mechanical Engineering Department, 03-09-2023

Engineering College, Ajmer

6ME4-02: Computer Integrated Manufacturing Systems

Tarun Kumar Aseri

Asst. Prof.

Mechanical Engineering

Engineering College, Ajmer

Barliya Circle, NH-8,

Ajmer-305025, India

Email: tarunaseri[at]ecajmer.ac.in

Syllabus

Introduction to computer aided PPC,

Introduction to computer aided inventory management,

Manufacturing resource planning (MRPII),

Computer process monitoring and

Shop floor control, computer process control.

Tarun Kumar Aseri Mechanical Department

6ME4-02: Computer Integrated

Manufacturing Systems 1

Mechanical Engineering Department, 03-09-2023

Engineering College, Ajmer

Learning Outcomes

Introduction to computer aided

production planning & Control (PPC)

Production Planning

Production Control

Limitation and Significance of PPC

Tarun Kumar Aseri Mechanical Department

PPC: Production Planning and Control

What is the Production Planning & Control?

Organizing and Planning of Manufacturing Processes

It ensures economic & maximum utilization of resources to achieve the

desired manufacturing results in terms of

QUALITY: QUANTITY: TIME: PLACE

Tarun Kumar Aseri Mechanical Department

6ME4-02: Computer Integrated

Manufacturing Systems 2

Mechanical Engineering Department, 03-09-2023

Engineering College, Ajmer

Objectives of PPC: To solve logistics problems

• To ensure quality output

• To ensure maximum utilization of all resources

• To maintain flexibility in manufacturing operations

• To maintain optimum level of inventory

• To increase overall efficiency

Tarun Kumar Aseri Mechanical Department

Traditional

Production

Planning and

Control

Tarun Kumar Aseri Mechanical Department

6ME4-02: Computer Integrated

Manufacturing Systems 3

Mechanical Engineering Department, 03-09-2023

Engineering College, Ajmer

Traditional Production, Planning and Control: Functions

Production Process

Forecasting Estimating

planning planning

Machine

Master Requirements

Purchasing loading and

scheduling planning

scheduling

Shipping and

Quality

Dispatching Expediting inventory

control

control

Tarun Kumar Aseri Mechanical Department

Traditional Production, Planning and Control: Functions

• Forecasting

• Projecting or Predicting the future sales activity of the firm’s product

• According to time horizon based estimates

• Long-term forecasting (≥ 5 years) involves future plant construction and

equipment acquisition

• Intermediate-term forecasting (≤ 2 years) used to plan for long-lead-time

material and component requirement

• Short-term forecasting (≤ 6 months) involves personnel hiring, purchasing,

production scheduling.

Tarun Kumar Aseri Mechanical Department

6ME4-02: Computer Integrated

Manufacturing Systems 4

Mechanical Engineering Department, 03-09-2023

Engineering College, Ajmer

Traditional Production, Planning and Control: Functions

• Production planning

• Also called as ‘Aggregate Production Planning’ as its function is to precedes

the detailed master production schedule

• Establish general production levels for product groups over the next year

• It based on the sales forecast and is used to

• Raise or lower inventories,

• Stabilize production over the planning horizon

• Allow for the launching of new product into the company’s product line

Tarun Kumar Aseri Mechanical Department

Traditional Production, Planning and Control: Functions

• Process planning

• It involves determining the sequence of manufacturing operations required to

produce a certain product and/or its components

• Carried out by manufacturing engineers as a very manual and clerical

procedure

• The Process plan documents is prepared by HAND, is also called a route sheet

• A listing of the operations and machine tools through which the part or product

must be routed

Tarun Kumar Aseri Mechanical Department

10

6ME4-02: Computer Integrated

Manufacturing Systems 5

Mechanical Engineering Department, 03-09-2023

Engineering College, Ajmer

Traditional Production, Planning and Control: Functions

• Estimating

• For predicting product prices and process cost

• Estimates the manufacturing lead times and production costs

• Manufacturing lead time: Total time required to process a work-part

• Production cost: Total of material cost + labor cost + applicable overhead cost

These estimates are based on: data contained in route sheet, purchasing files and

accounting records

Tarun Kumar Aseri Mechanical Department

11

Traditional Production, Planning and Control: Functions

• Master scheduling

• How many units (of particular product) are to be delivered and when

• Internalizes schedule of raw material purchase, orders for components from

the outdoor vendors and production schedules for parts made in house.

• It includes schedule periods: dates, weeks or months

All events must be timed and coordinated such that it allow delivery of final

product accordingly master schedule

Tarun Kumar Aseri Mechanical Department

12

6ME4-02: Computer Integrated

Manufacturing Systems 6

Mechanical Engineering Department, 03-09-2023

Engineering College, Ajmer

Traditional Production, Planning and Control: Functions

• Requirement planning

• Based on master schedule

• Also termed as MATERIAL REQUIREMENT PLANNING (MRP)

• Planning include:

• Raw material

• Component needed to manufacture product

• Tools, jigs, fixture and machinery

Tarun Kumar Aseri Mechanical Department

13

Traditional Production, Planning and Control: Functions

• Machine loading and scheduling

• Allocation and schedule of jobs to machines/work-centers

• Each machine and work center: queue of job waiting to processed

• Several factors make machine loading and scheduling complex:

1. No. of individual parts/orders to be scheduled

2. Each product has its own individual process routing to be followed

3. No. of machines/work-centers are limited and have fixed features, capability so

as to perform certain operations only

Tarun Kumar Aseri Mechanical Department

14

6ME4-02: Computer Integrated

Manufacturing Systems 7

Mechanical Engineering Department, 03-09-2023

Engineering College, Ajmer

Traditional Production, Planning and Control: Functions

• Dispatching

• It concerned with issuing the individual orders to the machine operators.

• Involves giving out orders, tickets, route sheets, part drawing and job

instruction.

• Expediting

• Comparing the actual progress of the order against the production schedule

• If order fall behind schedule → the expeditor → Corrective action

Rearranging of order(s) of machine(s), hand moving of the job or decision as per

consultation with workshop and/or management personnel

Tarun Kumar Aseri Mechanical Department

15

Traditional Production, Planning and Control: Functions

• Quality control

• Responsible for assuring the quality of the product meets the standards

specified by designer

• Multiple times inspection of material or product (being manufactured) at

various level such as procurement as well as manufacturing

• Shipping and inventory control

• Shipping to the customer or stocking the item in inventory

• Control of Inventory: sales, production and maintain enough level of

inventories of raw material, components work-in-process.

Tarun Kumar Aseri Mechanical Department

16

6ME4-02: Computer Integrated

Manufacturing Systems 8

Mechanical Engineering Department, 03-09-2023

Engineering College, Ajmer

Tarun Kumar Aseri Mechanical Department

17

Problems with

Traditional PPC

• Plant capacity problem

• Suboptimal production schedule

• Long manufacturing lead times

• Inefficient inventory control

• Low work center utilization

• Process planning not followed

• Errors in engineering and manufacturing

records

• Quality problems

18

6ME4-02: Computer Integrated

Manufacturing Systems 9

Mechanical Engineering Department, 03-09-2023

Engineering College, Ajmer

1. Plant capacity problem

• Production fall behind schedule due to a lack of

labor and equipment.

• Results in excessive overtime, delays in meeting

delivery schedule, customer complaints,

backordering, so on and so forth

Problems with

Traditional 2. Suboptimal production schedule

PPC • The wrong jobs are schedules because of a lack of

clear order priorities, insufficient scheduling rules

and the ever-changing status of job in the shop.

• As a consequence, production runs are

interrupted by jobs whose priorities have

suddenly increased, machine set-up are increased

and jobs that are on scheduled fall behind

Tarun Kumar Aseri Mechanical Department

19

Problems with Traditional PPC cont…

3. Long manufacturing lead times 4. Inefficient inventory control

• It is an attempt to compensate for • Due to above mentioned all three

problem 1 and 2 (as mention in last problems, total inventories are too high

slide), production planner allow extra for raw materials, work-in-progress and

time produce an order. finished products.

• The shop become overloaded, order • Stockout for an individual items that

priorities become confused and the needed for the production

result in excessively long manufacturing • High total inventory means high carrying

lead time. cost, while raw material stockout means

delays in meeting production schedules

Tarun Kumar Aseri Mechanical Department

20

6ME4-02: Computer Integrated

Manufacturing Systems 10

Mechanical Engineering Department, 03-09-2023

Engineering College, Ajmer

5. Low work center utilization

• This problem results in part from poor

scheduling (excessive product changeovers

and job interruptions) and from other

factors over which plant management has

limited control.

Problems with 6. Process planning not followed

Traditional • Regular planned routing is superseded by

an as hoc process sequence.

PPC cont… • It occurs, for instance, because of

bottlenecks at work centers in the planned

sequence and that results in longer setup,

improper tooling and less efficient

processes

Tarun Kumar Aseri Mechanical Department

21

Problems with Traditional PPC cont…

7. Errors in engineering and manufacturing records

• Bills of materials are not current, route sheet are not up to date with

respect to the latest engineering changes, inventory records are

inaccurate and production piece counts are incorrect.

8. Quality problems

• Quality defects are encountered in manufactured components and

assembly products, resulting in Rework or scrapped part and hence

delays in schedule

Tarun Kumar Aseri Mechanical Department

22

6ME4-02: Computer Integrated

Manufacturing Systems 11

Mechanical Engineering Department, 03-09-2023

Engineering College, Ajmer

Computer Aided/Integrated

Production Planning and Control

The Production Planning and Control not only concerns the problems of scheduling and

material management but also overlaps into the sciences of inventory control, operations

management, material handling, maintenance management, and information management.

8ME1A: Computer Integrated Manufacturing Systems 23

23

Production Planning & Control includes

Planning Dispatching

Loading

Production Routing Evaluation

Production Follow-up

and

planning control expediting

Scheduling Inspection

Tarun Kumar Aseri Mechanical Department

24

6ME4-02: Computer Integrated

Manufacturing Systems 12

Mechanical Engineering Department, 03-09-2023

Engineering College, Ajmer

Production Planning

Planning Routing Scheduling Loading

• What is the • Where it • When it • Who will

Task? needs to be needs to be perform the

carried out? carried out? task?

Tarun Kumar Aseri Mechanical Department

25

Planning

• It is the first element of production planning and

control.

• Planning means deciding in advance what is to be

done in future.

• An organizational set up is created to prepare plans

and policies.

• Various charts, manuals and production budgets are

also prepared.

• Planning provides a sound base for control.

• A separate department is set up for this work.

Tarun Kumar Aseri Mechanical Department

26

6ME4-02: Computer Integrated

Manufacturing Systems 13

Mechanical Engineering Department, 03-09-2023

Engineering College, Ajmer

Production Planning: Types

Aggregate production planning

• This involves the production output levels for major product lines produced by the firm.

• These plans must be coordinated among various functions in the firm, including product design,

production, marketing and sales

Master production planning

• The aggregate production plan must be converted into a master production schedule (MPS) which is a

specific plan of the quantities to be produced of individual models within each product line.

Material requirements planning (MRP)

• MRP is a planning technique, usually implemented by computer- that translates the MPS of end products

into a detailed schedule for the raw materials and parts used in those end products

Capacity planning

• Capacity planning is concerned with determining the labor and equipment resources needed to achieve the

master schedule.

Tarun Kumar Aseri Mechanical Department

27

Routing

• Routing is determining the exact path which will be

followed in production.

• It is the selection of the path from where each unit

have to pass before reaching the final stage.

• The stages from which goods are to pass are

decided in this process.

"Routing is the specification of the flow sequence of operations

and processes to be followed in producing a particular

manufacturing lot."( Alford & Beaty)

Tarun Kumar Aseri Mechanical Department

28

6ME4-02: Computer Integrated

Manufacturing Systems 14

Mechanical Engineering Department, 03-09-2023

Engineering College, Ajmer

Routine Procedure

• Deciding what part to be made or purchased

• Determining Materials required

• Determining Manufacturing Operations and Sequences

• Determining of Lot Sizes

• Determining of Scrap Factors

• Analysis of Cost of the Product

• Preparation of Production Control Forms

Tarun Kumar Aseri Mechanical Department

29

Scheduling

• Scheduling is the determining of time and date

when each operation is to be commenced or

completed.

• The time and date of manufacturing each

component is fixed in such a way that assembling

for final product is not delayed in any way.

"The determination of the time that should be required

to perform each operation and also the time necessary

to perform the entire series, as routed, making

allowances for all factors concerned."(Kimball)

Tarun Kumar Aseri Mechanical Department

30

6ME4-02: Computer Integrated

Manufacturing Systems 15

Mechanical Engineering Department, 03-09-2023

Engineering College, Ajmer

Scheduling: Types

• Master Scheduling

• It is the breakup of production requirements.

• It is the start of scheduling.

• It is prepared by keeping in view the order or likely sales order in near future.

• Manufacturing Scheduling

• It is used where production process is continuous.

• The order of preference for manufacture is also mentioned in the schedule for

a systematic production planning.

• Detail Operation Scheduling

• It indicates the time required to perform each and every detailed operations of

a given process

Tarun Kumar Aseri Mechanical Department

31

Loading

• The execution of the scheduled

plan as per the route chalked

out.

• It includes the assignment of

the work to the operators at

their machines or work places.

• So Loading determines who

will do the work.

Tarun Kumar Aseri Mechanical Department

32

6ME4-02: Computer Integrated

Manufacturing Systems 16

Mechanical Engineering Department, 03-09-2023

Engineering College, Ajmer

Production Control: Scope

Control of material

Control of planning Control of tooling Control of materials Control of activities

handling

Control of Control of quantity Control of

Control of due dates

information & quality manufacturing capacity

Tarun Kumar Aseri Mechanical Department

33

Dispatching

• Dispatching refers to the

process of actually ordering

the work to be done.

• It involves putting the plan

into effect by issuing orders.

• It is concerned with starting

"Dispatches put production in effect by releasing and

the process and operation on

guiding manufacturing order in the sequence

the basis of route sheets and

previously determined by route sheets and

schedule charts.

schedules."(John A.Shubin)

Tarun Kumar Aseri Mechanical Department

34

6ME4-02: Computer Integrated

Manufacturing Systems 17

Mechanical Engineering Department, 03-09-2023

Engineering College, Ajmer

Dispatching Procedure

• Centralized Dispatching

• Under this, orders are directly issued to workmen and machines.

• It helps in exercising effective control.

• Decentralized Dispatching

• Under this procedure all work orders are issued to the foreman or dispatch

clerk of the department or section.

• It suffers from difficulties in achieving co-ordination among different

departments.

Tarun Kumar Aseri Mechanical Department

35

Follow Up and Expediting

• Progress may be assessed with the help of

routine reports or communication with

operating departments.

• The follow up procedure is used for

expediting and checking the progress.

"Follow up or expediting is that branch of production control

procedure which regulates the progress of materials and part through

the production process. "

Tarun Kumar Aseri Mechanical Department

36

6ME4-02: Computer Integrated

Manufacturing Systems 18

Mechanical Engineering Department, 03-09-2023

Engineering College, Ajmer

Inspection

• Inspection is the process of ensuring whether the

products manufactured are of requisite quality or

not.

• Inspection is undertaken both of products and

inputs.

• It is carried on at various levels of production

process so that pre-determined standards of quality

are achieved.

• Inspection ensures the maintenance of pre-

determined quality of products.

Tarun Kumar Aseri Mechanical Department

37

Evaluation: Corrective

Measures

• Adjusting the route

• Rescheduling of work

• Changing the workloads

• Repairs and Maintenance of machinery or equipment,

• Control over inventories

• Certain personnel decisions like training, transfer,

demotion etc.

• Alternate methods may be suggested to handle peak

loads.

Tarun Kumar Aseri Mechanical Department

38

6ME4-02: Computer Integrated

Manufacturing Systems 19

Mechanical Engineering Department, 03-09-2023

Engineering College, Ajmer

LIMITATIONS OF PPC

• Assumption based

• Rigidity

• Difficult for small firms

• Costly

• Dependence on external factors

• Team work is a must

• Demands high level of co-ordination & efficiency

Tarun Kumar Aseri Mechanical Department

39

SIGNIFICANCE

• Structured & Planned Process

• Increased Production

• Seamless Plant Activity

• Better Co-ordination

• Optimal Resource Utilization

• Cost Control

• Rationalization of production

Activities

Tarun Kumar Aseri Mechanical Department

40

6ME4-02: Computer Integrated

Manufacturing Systems 20

Mechanical Engineering Department, 03-09-2023

Engineering College, Ajmer

Traditional vs Computer Aided PPC

Tarun Kumar Aseri Mechanical Department

41

Traditional vs Computer Aided PPC

Tarun Kumar Aseri Mechanical Department

42

6ME4-02: Computer Integrated

Manufacturing Systems 21

Mechanical Engineering Department, 03-09-2023

Engineering College, Ajmer

Summary

Traditional PPC and problems associated with it

PPC: To solve logistics problems to ensures economic &

maximum utilization of resources to achieve the desired

manufacturing results in terms of quality, quantity, time and place

Production Planning: Planning, Scheduling, Routing and Loading

Production Control: Dispatching, Follow-up and expediting,

Inspection, Evaluation (corrective measures)

Tarun Kumar Aseri Mechanical Department 43

43

Thank you for

your kind

attention

8ME1A: Computer Integrated Manufacturing Systems 44

44

6ME4-02: Computer Integrated

Manufacturing Systems 22

Mechanical Engineering Department, 03-09-2023

Engineering College, Ajmer

Syllabus

Introduction to computer aided PPC,

Introduction to computer aided inventory management,

Manufacturing resource planning (MRPII),

Computer process monitoring and

Shop floor control, computer process control.

Tarun Kumar Aseri Mechanical Department

45

6ME4-02: Computer Integrated

Manufacturing Systems 23

You might also like

- Solucionario Faires PDFDocument641 pagesSolucionario Faires PDFjuan13579100% (8)

- Capp 1Document24 pagesCapp 1Manish SoniNo ratings yet

- Pe 402 Automation in Manufacturing Module-IDocument87 pagesPe 402 Automation in Manufacturing Module-ISOUMYARUP CHOUDHURYNo ratings yet

- 0 Computer Aided Manufacturing CAMDocument14 pages0 Computer Aided Manufacturing CAMqwerty99No ratings yet

- E-Note 5467 Content Document 20231008095735AMDocument51 pagesE-Note 5467 Content Document 20231008095735AMGaurav TripathiNo ratings yet

- Computer Integrated ManufacturingDocument108 pagesComputer Integrated ManufacturingMuthuselvi SNo ratings yet

- Computerized Maintenance Management System (CMMS)Document31 pagesComputerized Maintenance Management System (CMMS)Jawad Ahmad Bin KhanNo ratings yet

- Backup of MTECH-2SEM-REG-OCT.2013Document1 pageBackup of MTECH-2SEM-REG-OCT.2013sudhakar kNo ratings yet

- Ie ApplicationDocument12 pagesIe Applicationrahmanshanto623No ratings yet

- Sharma SurajDocument2 pagesSharma SurajLata SurajNo ratings yet

- Lecture 3 Process PlanningDocument35 pagesLecture 3 Process Planningविशाल पुडासैनीNo ratings yet

- CAQCDocument10 pagesCAQCManish SoniNo ratings yet

- 17ME62 - DR - Sathish Kumar K MDocument284 pages17ME62 - DR - Sathish Kumar K MNJoyNo ratings yet

- Scope of Diploma in Mechanical EngineeringDocument160 pagesScope of Diploma in Mechanical Engineeringmohd_irfansalarNo ratings yet

- Student Copy CIM MSE 813Document58 pagesStudent Copy CIM MSE 813azharzebNo ratings yet

- Resumes / CV'SDocument4 pagesResumes / CV'SYoganandan PanchatcharamNo ratings yet

- PPCE - 8793 - Unit I - Introduction To Process PlanningDocument36 pagesPPCE - 8793 - Unit I - Introduction To Process PlanningJEEVA SNo ratings yet

- CappDocument24 pagesCappPRASHANTHNo ratings yet

- Accepted ManuscriptDocument21 pagesAccepted ManuscriptThịnh Nguyễn HữuNo ratings yet

- Atif Jabbar: BE (Electronics), ME (Mechatronics)Document2 pagesAtif Jabbar: BE (Electronics), ME (Mechatronics)atif jabbarNo ratings yet

- Lec 1 Introduction Slides 1 20 MergedDocument153 pagesLec 1 Introduction Slides 1 20 MergedNeeraj VarmaNo ratings yet

- By: M. Asjad Aamir (2016-ME-10) Umar Imtiaz (2016-ME-11) Naeemullah (2016-ME-12)Document20 pagesBy: M. Asjad Aamir (2016-ME-10) Umar Imtiaz (2016-ME-11) Naeemullah (2016-ME-12)MUHAMMAD ASJAD AAMIR AAMIR AMINNo ratings yet

- Optimization of Machining Time Using Feature Based Process PlanningDocument7 pagesOptimization of Machining Time Using Feature Based Process PlanningSuresh Rajagopal100% (1)

- Resume - Uday - Kumar - Mechanical Design EngineerDocument2 pagesResume - Uday - Kumar - Mechanical Design EngineerNikitaNo ratings yet

- CV Gayan Rantharu AttanayakeDocument4 pagesCV Gayan Rantharu AttanayakerantharuNo ratings yet

- Computer Integrated ManufacturingDocument61 pagesComputer Integrated ManufacturingjaisonNo ratings yet

- PDPP - Presentation.2.Four Plane Concept of Manufacturing - January.2021Document12 pagesPDPP - Presentation.2.Four Plane Concept of Manufacturing - January.2021Ashish Kumar100% (1)

- Industrial Engineering IntroductionDocument7 pagesIndustrial Engineering Introductiononline onlineNo ratings yet

- Akhil Maurya: An Enthusiastic & Energy-Driven Professional Pursuing Entry-Level Assignment As ProductionDocument2 pagesAkhil Maurya: An Enthusiastic & Energy-Driven Professional Pursuing Entry-Level Assignment As ProductionAkhil MauryaNo ratings yet

- Total Productive Maintenance Section 8: Uptime Strategies For Excellence in Maintenance ManagementDocument38 pagesTotal Productive Maintenance Section 8: Uptime Strategies For Excellence in Maintenance ManagementWadiin23No ratings yet

- Lec 10 MaintenanceDocument17 pagesLec 10 MaintenancemayaNo ratings yet

- Unit 2 Part 1Document17 pagesUnit 2 Part 1Abhishek KumarNo ratings yet

- Unit II: Production Planning and Control: Department of Mechanical Engineering, JSSATEN. 1Document42 pagesUnit II: Production Planning and Control: Department of Mechanical Engineering, JSSATEN. 1yash guotaNo ratings yet

- NPTEL Phase II - Mechanical Engineering - Industrial EngineeringDocument2 pagesNPTEL Phase II - Mechanical Engineering - Industrial EngineeringKaushalSinghNo ratings yet

- Senthilkumars CMM Programmer Kumars CMM ProgrammerDocument2 pagesSenthilkumars CMM Programmer Kumars CMM ProgrammerSenthil Kumar0% (1)

- Seminar Term Thesis Report FormatDocument13 pagesSeminar Term Thesis Report FormatchaitanyakolkataagarwalNo ratings yet

- Computer Aided Design and ManufacturingDocument161 pagesComputer Aided Design and Manufacturingsubra mani100% (5)

- Unit 1 Introduction CAD Lecture 2nd FEBDocument15 pagesUnit 1 Introduction CAD Lecture 2nd FEBdeepakmitrNo ratings yet

- MunendraSharma 13453974 - 05 06 - 1Document6 pagesMunendraSharma 13453974 - 05 06 - 1Mayur ShindeNo ratings yet

- Project Semester Report: Dy Auto India Pvt. LTDDocument55 pagesProject Semester Report: Dy Auto India Pvt. LTDAchint GuptaNo ratings yet

- Mumbai Univ SyllabusDocument18 pagesMumbai Univ SyllabusssaprodNo ratings yet

- Engineering SMU Jobdesk Rev0Document10 pagesEngineering SMU Jobdesk Rev0Hendra SamanthaNo ratings yet

- Oncept Hrough Ommission: Concept T Through C CommissionDocument8 pagesOncept Hrough Ommission: Concept T Through C CommissionalexanderbarajasNo ratings yet

- Productivity Improvement of Gear Housing by Reduction of Lead TimeDocument7 pagesProductivity Improvement of Gear Housing by Reduction of Lead Timegoutham ramNo ratings yet

- Chapter 1 - IntroductionDocument26 pagesChapter 1 - IntroductionDao Bao TinNo ratings yet

- Design Principles For Precision Engineering - OverviewDocument13 pagesDesign Principles For Precision Engineering - OverviewBrunoNo ratings yet

- 6ME3A Unit I IntroductiontoMechatronicsDocument17 pages6ME3A Unit I IntroductiontoMechatronicsMuhammmad FARAZNo ratings yet

- PPC Lesson PlanDocument2 pagesPPC Lesson PlanSathiya MoorthyNo ratings yet

- Unit I - (L 2)Document5 pagesUnit I - (L 2)Manish SoniNo ratings yet

- JBSMSE 2016 Celik Rennie AkinciDocument16 pagesJBSMSE 2016 Celik Rennie AkinciAnonymous PufNjgNo ratings yet

- Production Management: Master Production Schedule and Material Requirements PlanningDocument32 pagesProduction Management: Master Production Schedule and Material Requirements Planningrafael asssuncaoNo ratings yet

- Muhammad Umar Ibrahim: My ObjectivesDocument4 pagesMuhammad Umar Ibrahim: My Objectivesبصمة إبداع [Aseel khateeb]No ratings yet

- Computer Integrated Management: Advanced Manufacturing TechnologyDocument27 pagesComputer Integrated Management: Advanced Manufacturing TechnologyMuhammad Atif Qaim KhaniNo ratings yet

- Blue Geometric Robotics Engineering ResumeDocument2 pagesBlue Geometric Robotics Engineering ResumeIID SalemNo ratings yet

- Y. Vikas Singla: Project Management MaintenanceDocument3 pagesY. Vikas Singla: Project Management Maintenanceyv singlaNo ratings yet

- The Engine Testing Work-Flow Analysis Through Value Stream Mapping and SimulationDocument8 pagesThe Engine Testing Work-Flow Analysis Through Value Stream Mapping and SimulationTJPRC PublicationsNo ratings yet

- Discrete Event Simulation Based Approachfor Tracking Performanceof Segmental Productionat Precast YardDocument9 pagesDiscrete Event Simulation Based Approachfor Tracking Performanceof Segmental Productionat Precast Yardng28No ratings yet

- Iitk CAD PDFDocument174 pagesIitk CAD PDFRavi KumarNo ratings yet

- Basics & Design For Ultra Clean Vacuum - OverviewDocument16 pagesBasics & Design For Ultra Clean Vacuum - OverviewBojescu VaneaNo ratings yet

- CMMS Unleashed: Harnessing the Power of Technology for Efficient Maintenance Management: Cryotos CMMS, #1From EverandCMMS Unleashed: Harnessing the Power of Technology for Efficient Maintenance Management: Cryotos CMMS, #1Rating: 4 out of 5 stars4/5 (1)

- Unit I (L-8)Document12 pagesUnit I (L-8)Manish SoniNo ratings yet

- CAIM HandoutsDocument8 pagesCAIM HandoutsManish SoniNo ratings yet

- DocScanner Oct 18, 2022 08-59Document27 pagesDocScanner Oct 18, 2022 08-59Manish SoniNo ratings yet

- CIM NotesDocument21 pagesCIM NotesManish SoniNo ratings yet

- UNIT V TurbineDocument54 pagesUNIT V TurbineManish SoniNo ratings yet

- Reciprocating PumpDocument6 pagesReciprocating PumpManish SoniNo ratings yet

- Unit IV (Pump)Document32 pagesUnit IV (Pump)Manish SoniNo ratings yet

- Mechanics of FluidsDocument36 pagesMechanics of FluidsManish SoniNo ratings yet

- Passenger Boarding Bridges AdelteDocument8 pagesPassenger Boarding Bridges AdelteIsmail SayyedNo ratings yet

- NITTTR Bhopal Training Programme LetterDocument2 pagesNITTTR Bhopal Training Programme LetterRahul KumarNo ratings yet

- Texas VernacularDocument2 pagesTexas VernacularHeritageDesignStudioNo ratings yet

- Early Career ProgramDocument3 pagesEarly Career ProgramArmel HamidouNo ratings yet

- Motorsport Careers GuideDocument40 pagesMotorsport Careers GuideMarcos SoarNo ratings yet

- Cylinder Head GasketsDocument2 pagesCylinder Head GasketsAdi_DCE0% (1)

- PhysicsDocument18 pagesPhysicsduttasunanda730No ratings yet

- MaintenancemeetingDocument34 pagesMaintenancemeetingRemy AhmadNo ratings yet

- Pipe Stress Amp SupportDocument24 pagesPipe Stress Amp SupportShilpa GanganNo ratings yet

- A Step-by-Step Example To Find Concrete Column Capacity of Arbitrary Shape, According To ACI 318-11Document5 pagesA Step-by-Step Example To Find Concrete Column Capacity of Arbitrary Shape, According To ACI 318-11Fady Abdel AzizNo ratings yet

- Design Patterns: Strategy PatternDocument11 pagesDesign Patterns: Strategy PatternilijakljNo ratings yet

- Minimum Required InterferenceDocument4 pagesMinimum Required InterferenceParag NaikNo ratings yet

- Revflyer ICE-SEAM 2022 (19-4-2022)Document1 pageRevflyer ICE-SEAM 2022 (19-4-2022)Kevin Lieus FelixNo ratings yet

- An Overview On Future Electric Steering System: A Project ApproachDocument8 pagesAn Overview On Future Electric Steering System: A Project ApproachAnonymous kw8Yrp0R5rNo ratings yet

- 2017 18commencement ProgramDocument65 pages2017 18commencement Programsatish PNo ratings yet

- Raj System BrochureDocument28 pagesRaj System BrochureAnurag GuptaNo ratings yet

- ENVI136 Cheat Sheet 6Document5 pagesENVI136 Cheat Sheet 6Dim WitNo ratings yet

- PWS 2 3 PLUS EnglishDocument3 pagesPWS 2 3 PLUS EnglishMario PSNo ratings yet

- Project Delivery Method Comparison Guide: Description Advantages DisadvantagesDocument2 pagesProject Delivery Method Comparison Guide: Description Advantages DisadvantagesM Zubair AhmadNo ratings yet

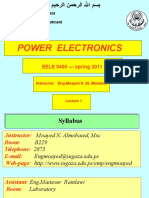

- Power Electronics: EELE 5450 - Spring 2011Document22 pagesPower Electronics: EELE 5450 - Spring 2011faisal140No ratings yet

- Drawing List GIDocument6 pagesDrawing List GIimhalidaNo ratings yet

- Mep AssumptionsDocument12 pagesMep Assumptionssachinsaklani23No ratings yet

- ACI 423.5R-99 Partially Prestressed ConcreteDocument37 pagesACI 423.5R-99 Partially Prestressed ConcreteingpulgarNo ratings yet

- Constructability Tools and Techniques in Use in The Nigerian Construction Industry PDFDocument19 pagesConstructability Tools and Techniques in Use in The Nigerian Construction Industry PDFsalim_0No ratings yet

- Wa0001Document29 pagesWa0001collins unankaNo ratings yet

- 16 X 7 Skimmer Pool - 310119Document16 pages16 X 7 Skimmer Pool - 310119D J Ben UzeeNo ratings yet

- Electronic Circuit ConstructionDocument5 pagesElectronic Circuit ConstructionMatovu HerbertNo ratings yet

- MQF Level 3: Diploma in Mechanical EngineeringDocument9 pagesMQF Level 3: Diploma in Mechanical EngineeringA SNo ratings yet

- Jungheinrich Epc Spare Parts List Et v4!37!506!10!2023 2Document43 pagesJungheinrich Epc Spare Parts List Et v4!37!506!10!2023 2josephdavis171001fspNo ratings yet