Professional Documents

Culture Documents

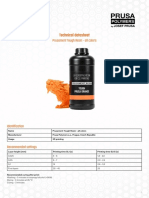

Prusament Techsheet PETG-1

Prusament Techsheet PETG-1

Uploaded by

renatoalpire1Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Prusament Techsheet PETG-1

Prusament Techsheet PETG-1

Uploaded by

renatoalpire1Copyright:

Available Formats

Version: 1.

0

Last update: 29-11-2018

TECHNICAL DATA SHEET

Prusament PE TG by Prusa Polymers

PETG is one of the most commonly used filaments. It is an excellent choice for printing mechanically

stressed parts. Compared to PLA, it is more heat resistant, more flexible and less brittle.

A P P L I C AT I O N S :

The typical use of PETG is printing functional and mechanical parts. Thanks to good layer adhesion it is

also suitable for waterproof prints.

N O T S U I TA B L E F O R :

Not suitable for tiny parts

P O S T- P R O C E S S I N G :

When post-processing PETG, it’s possible to use both dry and wet sanding.

I D E N T I F I CAT I O N :

Trade name Prusament PETG

Chemical name Copolyester

Usage FDM 3D printing

Diameter 1.75 ± 0.02 mm

Manufacturer Prusa Polymers, Prague, Czech Republic

RECOMMENDED PRINT SETTINGS:

Nozzle Temperature [°C] 250 ± 10

Heatbed Temperature [°C] 80 ± 10

Print Speed [mm/s] up to 200

T Y P I CA L M AT E R I A L P R O P E R T I E S :

Physical Properties Typical Value Method

Specific Gravity [g/cm3] 1.27 ISO 1183

Moisture Absorption 24 hours [%](1) 0.2 Prusa Polymers

Moisture Absorption 7 days [%](1) 0.3 Prusa Polymers

Moisture Absorption 4 weeks [%](1) 0.3 Prusa Polymers

Heat Deflection Temperature (0,45 MPa) [°C] 68 ISO 75

Tensile Yield Strength Filament [MPa] 46 ± 1 ISO 527

(1)

30 °C; humidity 30 %

M E C H A N I CA L P R O P E R T I E S O F P R I N T E D T E S T I N G S P E C I M E N S ( 2 ) :

Property / print direction Horizontal Vertical X,Y-Axis Vertical Z-Axis Method

Tensile Yield Strength [MPa] 47 ± 2 50 ± 1 30 ± 5 ISO 527-1

Tensile Modulus [GPa] 1.5 ± 0.1 1.5 ± 0.1 1.4 ± 0.1 ISO 527-1

Elongation at Yield Point [%] 5.1 ± 0.1 5.1 ± 0.1 2.5 ± 0.5 ISO 527-1

Impact Strength Charpy(3) [kJ/m2] NB(C)(4) NB(4) 5±1 ISO 179-1

(2)

Original Prusa i3 MK3 3D printer was used to make testing specimens. Slic3r Prusa Edition 1.40.0 was used to create

G-codes with following settings:Prusa PETG Filament; Print settings 0,20mm FAST (layers 0,2mm); solid layers Top:0

Bottom:0; Infill 100% Rectilinear, infill print speed 100mm/s; extrusion multiplier 1.07; extruder temperature 260°C all layers;

bed temperature 90°C all layers; other parameters set default

(3)

Charpy unnotched - Edgewise direction of blow according to ISO 179-1

(4)

NB (no break); C (complete break) in brackets second most frequent type of failure > 1/3

DISCLAIMER

The results presented in this data sheet are just for your information and comparison. Values are significantly dependent on print

settings, operators experiences and surrounding conditions. Everyone have to consider suitability and possible consequences of

printed parts usage. Prusa Polymers can not carry any responsibility for injures or any loss caused by using of Prusa Polymers material.

VERTICAL X,Y-AXIS VERTICAL Z-AXIS

HORIZONTAL

You might also like

- Module 5 Compressive and Flexural Strength of Wood NewDocument31 pagesModule 5 Compressive and Flexural Strength of Wood NewEUREKA JANAH MENDOZANo ratings yet

- BS en 12454-1998 Founding-Visual Examination of Surface Discontinuities-Steal Sand CastingsDocument8 pagesBS en 12454-1998 Founding-Visual Examination of Surface Discontinuities-Steal Sand Castingsadrianelc2No ratings yet

- Aspheric Lens Design PDFDocument1 pageAspheric Lens Design PDFJhon Cena100% (1)

- Asa Datasheet EngDocument3 pagesAsa Datasheet EngPDDELUCANo ratings yet

- Technical Data SheetDocument3 pagesTechnical Data Sheetrenaat.vanwayenbergeNo ratings yet

- Technical Data SheetDocument3 pagesTechnical Data Sheetrenaat.vanwayenbergeNo ratings yet

- Technical Data Sheet Prusament PcblendDocument3 pagesTechnical Data Sheet Prusament Pcblendrenaat.vanwayenbergeNo ratings yet

- Technical Data SheetDocument3 pagesTechnical Data SheetRobert AnderssonNo ratings yet

- Spec SheetDocument6 pagesSpec SheettristanNo ratings yet

- Raise3d Premium PETG TDS V3Document3 pagesRaise3d Premium PETG TDS V3Faris AlmarshadNo ratings yet

- Raise3D Premium ABS Technical Data Sheet: Physical PropertiesDocument3 pagesRaise3D Premium ABS Technical Data Sheet: Physical PropertiesdeepNo ratings yet

- PolyLite PETG TDS V5.3-20240309Document6 pagesPolyLite PETG TDS V5.3-20240309Freddy ArribasplataNo ratings yet

- PolyCast TDS V3Document2 pagesPolyCast TDS V3jerome.luganNo ratings yet

- TPU Filament Technical Data SheetDocument1 pageTPU Filament Technical Data SheetGanjar PramudiNo ratings yet

- PolyLite ABS TDS V5.3-20240324Document6 pagesPolyLite ABS TDS V5.3-20240324Edgar SotoNo ratings yet

- BL3 MarunDocument2 pagesBL3 Marunmohamad mostafaviNo ratings yet

- Ultimaker CPE+: Technical Data SheetDocument3 pagesUltimaker CPE+: Technical Data SheetFelipe TeixeiraNo ratings yet

- Domamid 6g30st1Document1 pageDomamid 6g30st1shahin_723No ratings yet

- Ultimaker PC: Technical Data SheetDocument3 pagesUltimaker PC: Technical Data SheetFelipe TeixeiraNo ratings yet

- Bambu Lab A1 3DDocument6 pagesBambu Lab A1 3DAngel Jacobo Figueroa ArriolaNo ratings yet

- Ultimaker Nylon: Technical Data SheetDocument3 pagesUltimaker Nylon: Technical Data SheetFelipe TeixeiraNo ratings yet

- Volumic FT en Pla UltraDocument2 pagesVolumic FT en Pla UltrakaleniaNo ratings yet

- Polymax PC Tds v4Document2 pagesPolymax PC Tds v4Hector GarciaNo ratings yet

- PolyFlex TPU90 TDS V5.1-20240212Document5 pagesPolyFlex TPU90 TDS V5.1-20240212Jonas SamsaNo ratings yet

- PolyCast TDS V5.2-20230912Document6 pagesPolyCast TDS V5.2-20230912GoNo ratings yet

- Econamid FL 6M20 - Pa6 M2oDocument1 pageEconamid FL 6M20 - Pa6 M2omuthuNo ratings yet

- Testing ReportDocument1 pageTesting ReportfaizNo ratings yet

- PolyMide CoPA TDS V5.2-20240223Document7 pagesPolyMide CoPA TDS V5.2-20240223Rakan El AtracheNo ratings yet

- PolyTerra-PLA TDS V5.3-20231113Document6 pagesPolyTerra-PLA TDS V5.3-20231113nerze0777No ratings yet

- Ultimaker PP: Technical Data SheetDocument3 pagesUltimaker PP: Technical Data SheetFelipe TeixeiraNo ratings yet

- DS DMH 400 PomDocument1 pageDS DMH 400 PomESTEFANY DE LOS SANTOSNo ratings yet

- DMH 400 Pom: Mechanical, Physical and Thermal PropertiesDocument1 pageDMH 400 Pom: Mechanical, Physical and Thermal PropertiesESTEFANY DE LOS SANTOSNo ratings yet

- Novatec Premium Ii: Technical Data SheetDocument1 pageNovatec Premium Ii: Technical Data SheetRuben PauwelsNo ratings yet

- PolyMax PLA TDS V4Document2 pagesPolyMax PLA TDS V4fNo ratings yet

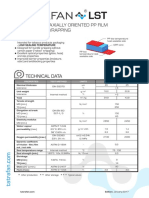

- Coextruded Biaxially Oriented PP Film For Tobacco Wrapping: Technical DataDocument2 pagesCoextruded Biaxially Oriented PP Film For Tobacco Wrapping: Technical DataJan GawełNo ratings yet

- Filament Specifications Unit ValueDocument4 pagesFilament Specifications Unit ValueRoberto Gonzalo PelazNo ratings yet

- KOPA® KN333G40SIBL: Properties Measurement Condition Test Method Unit Typical ValueDocument2 pagesKOPA® KN333G40SIBL: Properties Measurement Condition Test Method Unit Typical Valuehugo santiago chavez godoyNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data Sheetrenaat.vanwayenbergeNo ratings yet

- DMH 401 POM Black: Mechanical, Physical and Thermal PropertiesDocument1 pageDMH 401 POM Black: Mechanical, Physical and Thermal Propertiessetiadi pratondoNo ratings yet

- Pla Texture Wood ArceDocument4 pagesPla Texture Wood ArceRoberto Gonzalo PelazNo ratings yet

- Technical Data Sheet: Dimensions 1,75 MM 2,85 MMDocument1 pageTechnical Data Sheet: Dimensions 1,75 MM 2,85 MMgandroiidNo ratings yet

- Datasheet 1332408905 PDFDocument1 pageDatasheet 1332408905 PDFSheikh Tahsina Trading CorporationNo ratings yet

- Property Test Method Unit Typicalvalue : BL3 License Grade Code HF 4670 (THT)Document1 pageProperty Test Method Unit Typicalvalue : BL3 License Grade Code HF 4670 (THT)MohamadMostafaviNo ratings yet

- Technical Data Sheet PC: Filament SpecificationsDocument3 pagesTechnical Data Sheet PC: Filament SpecificationsVladimir SarmientoNo ratings yet

- Tasnee 1925ASDocument1 pageTasnee 1925ASpolymeianNo ratings yet

- Data Sheet EFPP 1007BLDocument1 pageData Sheet EFPP 1007BLMỹ Hạnh BùiNo ratings yet

- Glass Fiber Reinforced Polypropylene Composite Pipes: Safe and Practical For All Hot Water and Heating ApplicationsDocument2 pagesGlass Fiber Reinforced Polypropylene Composite Pipes: Safe and Practical For All Hot Water and Heating Applicationskhaled redaNo ratings yet

- TDS GLACE - enDocument1 pageTDS GLACE - enmr.mennensNo ratings yet

- 3d Systems Accura 25 Datasheet Usen 2018 07 11 Web - 0Document1 page3d Systems Accura 25 Datasheet Usen 2018 07 11 Web - 0Pankaj ShahNo ratings yet

- E PlaDocument1 pageE PlaYilmer SanchezNo ratings yet

- Addigy FPB 2684 000000 A - en - 86299607 22256723 22681304Document4 pagesAddigy FPB 2684 000000 A - en - 86299607 22256723 22681304propornhub42No ratings yet

- Yemchio Transparente PDFDocument1 pageYemchio Transparente PDFSantiago López AlarcónNo ratings yet

- Yemchio Transparente PDFDocument1 pageYemchio Transparente PDFSantiago López AlarcónNo ratings yet

- Mdpe MCH 3713Document4 pagesMdpe MCH 3713mohamad mostafaviNo ratings yet

- Saerfoam Range Mech Prop 2017 r04 EPDocument1 pageSaerfoam Range Mech Prop 2017 r04 EPchaunceyrollestonNo ratings yet

- PP TDSDocument2 pagesPP TDSsribachaNo ratings yet

- Polysonic Pla en v5.3 Tds 20240215Document7 pagesPolysonic Pla en v5.3 Tds 20240215commando.blacklightNo ratings yet

- ABSplus Data SheetDocument1 pageABSplus Data SheetuarkgolfNo ratings yet

- M58 M68 K Resin InstructionDocument3 pagesM58 M68 K Resin InstructionAllen HardingNo ratings yet

- Data Sheet Advanced-PP 1102 K: Properties Unit Test Method ValueDocument1 pageData Sheet Advanced-PP 1102 K: Properties Unit Test Method ValueErnesto Cheguavara100% (1)

- TDS - HZ 01CPR - V02 - enDocument2 pagesTDS - HZ 01CPR - V02 - enFakhreddine BousninaNo ratings yet

- Tds Rev 3.0: Technical Data Sheet: Thermax™ Peek 3D Printing FilamentDocument1 pageTds Rev 3.0: Technical Data Sheet: Thermax™ Peek 3D Printing FilamentnhzaidiNo ratings yet

- Testing Application Standard No 114-95 PDFDocument58 pagesTesting Application Standard No 114-95 PDFÁngel Rodríguez IsassiNo ratings yet

- Mechanics of Materials Project Sem2!13!14Document2 pagesMechanics of Materials Project Sem2!13!14Tikar MengkuangNo ratings yet

- Hilti Hvu & HasDocument2 pagesHilti Hvu & HasSatyam Kumar MishraNo ratings yet

- Methods of Sampling Paints, Varnishes: Part 5 Mechanical Tests Section. 4 Print Free Test (Document2 pagesMethods of Sampling Paints, Varnishes: Part 5 Mechanical Tests Section. 4 Print Free Test (GopalMahantaNo ratings yet

- Cone Penetration of Lubricating Grease: Standard Test Methods ForDocument14 pagesCone Penetration of Lubricating Grease: Standard Test Methods ForRodrigo Briceño IbarraNo ratings yet

- BoQ-Beam Retrofitting Works LandTDocument2 pagesBoQ-Beam Retrofitting Works LandTAbhijit KarpeNo ratings yet

- Design of Composite Columns v3 - Ver1 (KJ) AMDDocument104 pagesDesign of Composite Columns v3 - Ver1 (KJ) AMDImran SaikatNo ratings yet

- Lesson 2. Properties of MaterialsDocument30 pagesLesson 2. Properties of MaterialsJustine James DuqueNo ratings yet

- Geotechnical Engineering Series - Slope StabilityDocument62 pagesGeotechnical Engineering Series - Slope StabilitykkkelvinNo ratings yet

- TDS Brilliant G180-A50Document3 pagesTDS Brilliant G180-A50Mohit100% (1)

- SikafloorMultiFlexPB-21-certificare OS13Document4 pagesSikafloorMultiFlexPB-21-certificare OS13George EnescuNo ratings yet

- Funny Problems in Intuitive Topology Ruhollah Tavakoli (200510,5p.)Document5 pagesFunny Problems in Intuitive Topology Ruhollah Tavakoli (200510,5p.)Anonymous 9CFSMtNo ratings yet

- Gubbi enISI Cube Mould Manufacturer - Cube Mould SuppliertDocument13 pagesGubbi enISI Cube Mould Manufacturer - Cube Mould SuppliertgubbientNo ratings yet

- HIT Rebar Fatigue enDocument7 pagesHIT Rebar Fatigue enWalter CastilloNo ratings yet

- Vigas Ipn, Ipe, Hea, Heb, Upn, Upl, Upe, UpamDocument10 pagesVigas Ipn, Ipe, Hea, Heb, Upn, Upl, Upe, UpamAndres SantamariaNo ratings yet

- Chapter 16: Composites: Issues To Address..Document27 pagesChapter 16: Composites: Issues To Address..Navish KotwalNo ratings yet

- 7430 - Sigmacover 630Document0 pages7430 - Sigmacover 630eraswastaNo ratings yet

- Mechanical Properties of Composite Laminated PlatesDocument12 pagesMechanical Properties of Composite Laminated PlatesMikyas BelayNo ratings yet

- 3RES08Document14 pages3RES08Shay WaxenNo ratings yet

- Earthquake Resistance BuildingDocument11 pagesEarthquake Resistance BuildingAnirudra Sharma100% (1)

- Flat Film Forming: Andrew Leithead Chris Barr Nick AntonakosDocument32 pagesFlat Film Forming: Andrew Leithead Chris Barr Nick AntonakosHOANGVUNL1988No ratings yet

- Surface Chemistry Resonance NoteDocument8 pagesSurface Chemistry Resonance Notehsuyab100% (5)

- Program 200522Document10 pagesProgram 200522melosNo ratings yet

- ALUPEX BrochureDocument5 pagesALUPEX BrochureTamas PapikNo ratings yet

- Ch1 Elasticity (1) UthmDocument34 pagesCh1 Elasticity (1) UthmNordiana IdrisNo ratings yet

- solidworks ขั้นพื้นฐานDocument74 pagessolidworks ขั้นพื้นฐานChonTicha'No ratings yet

- Foundation-Ch 7 PDFDocument19 pagesFoundation-Ch 7 PDFAlbanNo ratings yet