Professional Documents

Culture Documents

Atrium

Atrium

Uploaded by

Mehdi BeygCopyright:

Available Formats

You might also like

- Hvac Systems Design Handbook Fifth EditionDocument99 pagesHvac Systems Design Handbook Fifth Editionkambiado100% (1)

- Tagalog-English Construction TermsDocument3 pagesTagalog-English Construction TermsManet PalevinoNo ratings yet

- Wolter Jetfan Broschuere English 2017 PDFDocument15 pagesWolter Jetfan Broschuere English 2017 PDFViệt Đặng XuânNo ratings yet

- Smoke Management in Office BuildingsDocument7 pagesSmoke Management in Office BuildingsAbcoNo ratings yet

- CFD - ACUD CodeDocument6 pagesCFD - ACUD CodeDharmeswar SahNo ratings yet

- 10-Mechanical Extract System-Car Park VentilationDocument18 pages10-Mechanical Extract System-Car Park VentilationAli Ruhsen Cete100% (1)

- VENCO Articles Jet Fan System in Closed Car ParksDocument9 pagesVENCO Articles Jet Fan System in Closed Car ParksRuben AugustoNo ratings yet

- Car Park and Basement VentilationDocument20 pagesCar Park and Basement VentilationSaviour UdoNo ratings yet

- Acmv Technical ReportDocument10 pagesAcmv Technical Reportarun kurlanNo ratings yet

- Rebooting HVAC Systems For Post Pandemic RevivalDocument1 pageRebooting HVAC Systems For Post Pandemic RevivalEclatNo ratings yet

- UAE FC-2018 - CFD RequirementsDocument4 pagesUAE FC-2018 - CFD RequirementsYonish SisoNo ratings yet

- Ijb - Ijc II - Cat052.e0.Ed1Document10 pagesIjb - Ijc II - Cat052.e0.Ed1Vaibhav GuptaNo ratings yet

- ME Laws WK 8Document58 pagesME Laws WK 8Charle CandelarioNo ratings yet

- Operating Room Ventilation: Metalaire Periflow System Overview & Technical DiscussionDocument3 pagesOperating Room Ventilation: Metalaire Periflow System Overview & Technical DiscussionJorge FuentesNo ratings yet

- C03. FläktWoods - Car Park Ventilation - Ducted or Jet Thrust FanDocument7 pagesC03. FläktWoods - Car Park Ventilation - Ducted or Jet Thrust FanCzarSASNo ratings yet

- Compressed Air in Pharmaceutical ApplicationsDocument3 pagesCompressed Air in Pharmaceutical ApplicationsDamien MarleyNo ratings yet

- Duct Smoke DetectorfsDocument1 pageDuct Smoke DetectorfsAhmed AdelNo ratings yet

- Jet-Fan-Systems 2017-02 en E1749Document34 pagesJet-Fan-Systems 2017-02 en E1749MOHAN L BUJJINo ratings yet

- Guide To Stairwell AOVsDocument12 pagesGuide To Stairwell AOVsGrant MastersonNo ratings yet

- Group 3 ME LawsDocument105 pagesGroup 3 ME LawsGrande Jam AeraNo ratings yet

- Atrium Smoke Management System DesignDocument4 pagesAtrium Smoke Management System DesignCzarSASNo ratings yet

- GA90-500 GR110-200 Brochure PDFDocument22 pagesGA90-500 GR110-200 Brochure PDFmageedNo ratings yet

- Jet Fans Systems PDFDocument34 pagesJet Fans Systems PDFThinagaran ManiamNo ratings yet

- Induction Beams: Engineered Comfort For Today's BuildingsDocument10 pagesInduction Beams: Engineered Comfort For Today's Buildingsbuilder011No ratings yet

- Fiba Guide To Basketball Facilities - Air DistributionDocument2 pagesFiba Guide To Basketball Facilities - Air DistributionMustafa Onur SarıkayaNo ratings yet

- Technical Standard: (Signed Original On File) Sheet OFDocument7 pagesTechnical Standard: (Signed Original On File) Sheet OFd r hardyNo ratings yet

- Sfpe Smoke CH50Document82 pagesSfpe Smoke CH50ahmed selimNo ratings yet

- IA Compressor PKG - OptimizedDocument7 pagesIA Compressor PKG - OptimizedJetul PatelNo ratings yet

- Mechanical Ventilation Systems Are Frequently Applied To Commercial BuildingsDocument9 pagesMechanical Ventilation Systems Are Frequently Applied To Commercial BuildingsIbn Shaffee IVNo ratings yet

- A Method of Damper Control For Corridor Ventilation and Smoke ExtractionDocument15 pagesA Method of Damper Control For Corridor Ventilation and Smoke ExtractionrasheedillikkalNo ratings yet

- Basement Smoke VentilationDocument5 pagesBasement Smoke VentilationVarun MattooNo ratings yet

- Jet-Fan-Systems 2015-09 en E1591Document32 pagesJet-Fan-Systems 2015-09 en E1591a_salehiNo ratings yet

- Designing Car Park Ventilation SystemsDocument14 pagesDesigning Car Park Ventilation SystemsMohamed Mostafa Aamer100% (1)

- Tuttle and Bailey AdministrationDocument8 pagesTuttle and Bailey AdministrationElvis FariasNo ratings yet

- Part 2-Airconditioning-Ventilation-UserGuide - 1Document20 pagesPart 2-Airconditioning-Ventilation-UserGuide - 1Anonymous oUoJ4A8xNo ratings yet

- Sustainability PDFDocument24 pagesSustainability PDFEdmund YoongNo ratings yet

- Personal Ventilation: Emerging Technologies Emerging TechnologiesDocument6 pagesPersonal Ventilation: Emerging Technologies Emerging Technologiesscribd99190No ratings yet

- Zoned Smoke Control Applications: Using HVAC Systems To Limit SmokeDocument5 pagesZoned Smoke Control Applications: Using HVAC Systems To Limit SmokeNiong DavidNo ratings yet

- Build Tight RangeDocument8 pagesBuild Tight RangeMihai MunteanuNo ratings yet

- Enclosure Integrity Testing For Gas Suppressions - EnglishDocument4 pagesEnclosure Integrity Testing For Gas Suppressions - EnglishSalim Bakhsh100% (1)

- Appendix 1 Section 3 AS1668.2 2002Document5 pagesAppendix 1 Section 3 AS1668.2 2002bobNo ratings yet

- Dubai Green Building System: Version 2.0 - 2020Document40 pagesDubai Green Building System: Version 2.0 - 2020harikollam1981No ratings yet

- Impulse Ventilation An IntroductionDocument10 pagesImpulse Ventilation An IntroductionNupur Bhadra100% (1)

- Peace of Mind. Guaranteed.: Parking Garage / Car ParksDocument2 pagesPeace of Mind. Guaranteed.: Parking Garage / Car ParksPeroMentoroNo ratings yet

- Wolter Jetfan English 2014Document15 pagesWolter Jetfan English 2014jayanthahhy100% (1)

- Guidelines For Laboratory Design - 2013 - DiBerardinis - Appendix D Stack DesignDocument6 pagesGuidelines For Laboratory Design - 2013 - DiBerardinis - Appendix D Stack Designkeikhosravy.mNo ratings yet

- SolarDocument2 pagesSolarVineshNo ratings yet

- Pressurisation SystemDocument4 pagesPressurisation SystemEdmund YoongNo ratings yet

- YORK EconomizerPressurization AHUDocument8 pagesYORK EconomizerPressurization AHUAhmed TahaNo ratings yet

- Fire-2017-Corridor SmokeDocument1 pageFire-2017-Corridor Smokemhmdjdgmailcom100% (1)

- Compressed Air ApplicationsDocument4 pagesCompressed Air ApplicationsikrishnatNo ratings yet

- HVAC SystemDocument21 pagesHVAC Systemtinkusk24No ratings yet

- 9426 Air Traffic Services Planning ManualDocument16 pages9426 Air Traffic Services Planning Manualpaulo silvaNo ratings yet

- Numerical Simulation On Smoke Control of Impulse Ventilation in A Large Underground CarparkDocument5 pagesNumerical Simulation On Smoke Control of Impulse Ventilation in A Large Underground Carparkahmed ramadanNo ratings yet

- Air Conditioning of Wood and Paper Product Facilities PDFDocument4 pagesAir Conditioning of Wood and Paper Product Facilities PDFDaniel BolivarNo ratings yet

- A Breath of Fresh Air: Mine VentilationDocument6 pagesA Breath of Fresh Air: Mine VentilationMuhammad FarhadNo ratings yet

- Atrium Smoke ControlDocument8 pagesAtrium Smoke ControlSadeemNo ratings yet

- A330 Normal Law: Putting Fly-by-Wire Into PerspectiveFrom EverandA330 Normal Law: Putting Fly-by-Wire Into PerspectiveRating: 5 out of 5 stars5/5 (2)

- Temperature and Humidity Independent Control (THIC) of Air-conditioning SystemFrom EverandTemperature and Humidity Independent Control (THIC) of Air-conditioning SystemNo ratings yet

- Traditional House in AssamDocument7 pagesTraditional House in AssamM.Navyodai KanthNo ratings yet

- PRECASTDocument109 pagesPRECASTMike AlarNo ratings yet

- 27,30 - The Saudi Building Code (SBC) - PDF - 87-87Document1 page27,30 - The Saudi Building Code (SBC) - PDF - 87-87heshamNo ratings yet

- Leslie Simmons Hodgson Architect BiographyDocument32 pagesLeslie Simmons Hodgson Architect BiographyStanBirdNo ratings yet

- A-30, Sector-40 RevisedDocument8 pagesA-30, Sector-40 Revisedsunil kalwaniyaNo ratings yet

- Milan Cathedral - WikipediaDocument56 pagesMilan Cathedral - WikipediaTimyNo ratings yet

- 2) Apron & Drain For BEPS-23 School (60'x30'), Hlaing Thar Yar TownshipDocument2 pages2) Apron & Drain For BEPS-23 School (60'x30'), Hlaing Thar Yar TownshipShoon Lai AungNo ratings yet

- Trim Components: Steel Building & Residential Metal RoofingDocument32 pagesTrim Components: Steel Building & Residential Metal Roofingcaprater1No ratings yet

- Plumbing Max Fajardo PDFDocument175 pagesPlumbing Max Fajardo PDFJoe Luis BalaiboNo ratings yet

- Q1) Explain The Origin and Characteristics of Baroque Architecture With Examples of Roman Baroque ChurchesDocument7 pagesQ1) Explain The Origin and Characteristics of Baroque Architecture With Examples of Roman Baroque ChurchesAishwaryaNo ratings yet

- Terry Adams Construction/ HVAC ResumeDocument3 pagesTerry Adams Construction/ HVAC ResumeTerry AdamsNo ratings yet

- MMBC - 6: Topic - Acp Cladding Presented by - Manish.J SandhyaDocument25 pagesMMBC - 6: Topic - Acp Cladding Presented by - Manish.J SandhyaSneha DineshNo ratings yet

- Pressurized Stair CaseDocument8 pagesPressurized Stair CaseDesigner ForeverNo ratings yet

- Baroque Church PhilippinesDocument7 pagesBaroque Church PhilippinesMark Jefferson BorromeoNo ratings yet

- Cell / Model Name Description DateDocument9 pagesCell / Model Name Description DateSami AjNo ratings yet

- Antique Furniture StylesDocument3 pagesAntique Furniture StylesFreshhome VnNo ratings yet

- 9.1 - Rising Power of Rome PDFDocument17 pages9.1 - Rising Power of Rome PDFClaire NicerNo ratings yet

- Firewise Landscaping ChecklistDocument2 pagesFirewise Landscaping ChecklistSteven SchafersmanNo ratings yet

- Commercial Construction ScheduleDocument2 pagesCommercial Construction Schedulefinus marcalNo ratings yet

- Aa PresentationDocument12 pagesAa PresentationBinh Nguyen Tran QuocNo ratings yet

- Ceiling Plan: Notes All Ceiling Levels Mentioned Are From FFLDocument1 pageCeiling Plan: Notes All Ceiling Levels Mentioned Are From FFLsteauandreiNo ratings yet

- Ecoply Bracing - EP1 Specification (Apr-09)Document1 pageEcoply Bracing - EP1 Specification (Apr-09)郭骥No ratings yet

- The Prison of Unearthly Nightmares 04Document10 pagesThe Prison of Unearthly Nightmares 04krakcNo ratings yet

- Warehouse (30m. L X 15m. W X 4.5m.H) 03.08.2022-Layout1Document1 pageWarehouse (30m. L X 15m. W X 4.5m.H) 03.08.2022-Layout1Rigor Louise M. LegadaNo ratings yet

- Brochure AmbaramDocument13 pagesBrochure AmbaramAman GoyalNo ratings yet

- LEED For Operations and Maintenance Reference Guide Introduction PDFDocument20 pagesLEED For Operations and Maintenance Reference Guide Introduction PDFcevc1987_No ratings yet

- Labour Output Constants Masonry Concrete PDFDocument10 pagesLabour Output Constants Masonry Concrete PDFAwdhesh KumarNo ratings yet

- BVN 1984Document135 pagesBVN 1984shivaniNo ratings yet

- En (1063)Document1 pageEn (1063)reacharunkNo ratings yet

Atrium

Atrium

Uploaded by

Mehdi BeygCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Atrium

Atrium

Uploaded by

Mehdi BeygCopyright:

Available Formats

Chapter 13—Life Safety Systems 157

exhausted to the atmosphere. Supply air to the floor or floors above and below the fire zone can

be operated with 100% outdoor air to again pressurize the floor, effectively keeping the smoke-

laden air within the fire floor while it is exhausted to atmosphere.

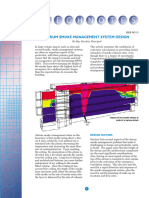

An example of how the unit on the fire floor could operate is shown in Figure 13.1.

The units on the one or two floors above and below the fire floor will operate as shown in

Figure 13.1. For these units (1) the outdoor air for smoke pressurization and the outdoor air for

normal operation of the unit will both open, (2) the return air damper and the smoke exhaust

riser damper will both close, and (3) the supply unit will operate with 100% outdoor air. To

ensure sufficient outdoor air, all of the other floor-by-floor units using the outdoor air riser

must be shut and the outdoor air riser must be sized to provide sufficient air to the number of

floors on which the supply units will operate with 100% outdoor air.

SMOKE MANAGEMENT IN ATRIUMS

An architectural feature of many buildings is the inclusion of an atrium to enhance the aes-

thetics of the building. The inclusion of an atrium presents special conditions of smoke

removal that are usually covered within the operative code for the jurisdiction within which the

building is located. Until recently, codes in the United States have mandated that a required

rate of smoke removal be provided for an atrium in terms of air changes per hour over the total

volume of the atrium and any open, connected areas. The latest research has determined that

this approach of air changes over a period of time is not an appropriate solution for a proper

smoke management design for an atrium. Accordingly, both the International Building Code

(ICC 2012) and NFPA 5000-2015, Building Construction and Safety Code, use a performance-

based design approach detailed in NFPA 92B-2000, Standard for Smoke Management Systems

in Malls, Atria, and Large Spaces, and as discussed in Handbook of Smoke Control Engineer-

ing (Klote et al. 2012).

Tall commercial buildings that contain an atrium must be provided with a smoke manage-

ment system that will obtain smoke movement control and removal. Generally, this is accom-

plished through the use of mechanical fans. Natural venting of these spaces is not normally a

viable alternative. Under the International Building Code and NFPA 5000-2015, the fans that

--```,``,,,`,,,,`,,,,,,`,,```,,,-`-`,,`,,`,`,,`---

Figure 13.1 Pressurized floors above and below the smoke zone.

Copyright American Society of Heating, Refrigerating and Air-Conditioning Engine

Provided by IHS under license with ASHRAE Licensee=Hong Kong Polytechnic University/9976803100

No reproduction or networking permitted without license from IHS Not for Resale, 10/03/2015 23:58:12 MDT

--```,``,,,`,,,,`,,,,,,`,,```,,,-`-`,,`,,`,`,,`--- 158 ASHRAE Design Guide for Tall, Supertall, and Megatall Building Systems

Figure 13.2 Floor-by-floor air-conditioning unit layout.

are installed in an atrium must function so as to contain the height of the accumulated smoke

layer in the upper portions of the atrium at a minimum of 10 ft (3 m) above the walking sur-

faces of the means of egress from the smoke zone. The exhaust fans will remove air from the

upper levels of the atrium. They will exhaust a sufficient quantity of air to keep the smoke

above the desired level from the largest calculated plume mass flow rate for alternative config-

urations possible. The means of determining the plume configuration will be based on the

design fire as defined in the building code. This, in turn, will permit the calculation of the fan

capacity that will obtain the goal of a 10 ft (3 m) smoke-clear area above the egress level. The

means of analyzing the plume configuration and exhaust fan capacity are detailed in NFPA

92B and in Handbook of Smoke Control Engineering.

The system must also be configured to provide a natural or mechanical supply of outdoor

air or air from spaces adjacent to the smoke zone to replace the air that is being exhausted.

The action of the designed system for the atrium is intended to maintain an environment

that will provide a means of egress for the occupants of the building while providing ongoing

conditions that will enable firefighting personnel to enter the space and both locate and control

the fire.

STAIRWELL PRESSURIZATION

Most building codes will require that the fire stairwells in a tall commercial building be

pressurized to keep them smoke free in the event of a fire in the building. The smoke-free

atmosphere is required for three reasons: (1) the stairs will be an area of refuge for building

occupants who are directed to leave a fire floor or floor in proximity to the fire floor, (2) the

stairs are an essential element in the escape route for the controlled evacuation of people from

the building, and (3) the stairs will be used by the firefighters as they attempt to control and

extinguish the fire.

The stair pressurization system must be capable of maintaining a pressure differential

between the stair and any floor that is sufficient to prohibit smoke-laden air from entering the

stairwell. The pressure differential will have a minimum and maximum value which, in the

case of the lower value, will be sufficient to keep the smoke from entering the stairwell and, in

Copyright American Society of Heating, Refrigerating and Air-Conditioning Engine

Provided by IHS under license with ASHRAE Licensee=Hong Kong Polytechnic University/9976803100

No reproduction or networking permitted without license from IHS Not for Resale, 10/03/2015 23:58:12 MDT

Chapter 13—Life Safety Systems 159

--```,``,,,`,,,,`,,,,,,`,,```,,,-`-`,,`,,`,`,,`---

Figure 13.3 A large modern atrium.

the case of the maximum value, will still allow the door to be opened by occupants trying to

enter the stair. The minimum value stated in the NFPA 101-2000, Life Safety Code, is 0.05 in.

of water (12.4 Pa) in a sprinklered building. For a door 7 ft tall by 3 ft wide (2.1 m tall by 0.9 m

wide), this would yield a pressure of 5.5 pounds (24 N) against the total surface of the door.

NFPA 101-2000 limits the force that will be required to set the door in motion in a new build-

ing to 30 lb (133 N), which, for the same 7 ft tall by 3 ft wide (2.1 m tall by 0.9 m wide) door,

would equate to a pressure of 0.27 in. of water (67.2 Pa). This maximum allowable value need

not be the basis of the design and frequently the maximum pressure will be between 0.05 and

0.15 in. of water (12.4 and 37.3 Pa). However, the minimum and the maximum pressure will be

established in the design specifications, and this range of pressure differentials will need to be

maintained in the stair pressurization system.

Copyright American Society of Heating, Refrigerating and Air-Conditioning Engine

Provided by IHS under license with ASHRAE Licensee=Hong Kong Polytechnic University/9976803100

No reproduction or networking permitted without license from IHS Not for Resale, 10/03/2015 23:58:12 MDT

160 ASHRAE Design Guide for Tall, Supertall, and Megatall Building Systems

Establishing this range of pressure is important as it is necessary to design any stairway

pressurization system to stay within this range with all doors closed or with a stipulated num-

ber of doors open. Alternative means of achieving these goals have resulted in a multiplicity of

configurations for stairwell pressurization systems, not all of which would be successful for the

tall commercial building.

For the tall commercial building, it is necessary to inject outdoor air into the stair at multi-

ple levels of the stair. There is not full agreement on the number of floors between the points of

injection, but three floors or less is probably a prudent recommendation.

The fans that bring the outdoor air into the stair will usually be located in mechanical

equipment rooms at more than one level in the building to limit the size of the vertical duct

attached to any fan installed to pressurize the stairs. Moreover, the air must be brought from a

location that will eliminate any possible contamination with smoke-laden air being expelled

from the building. Alternative means have been used to maintain the pressure in the stair

between the allowable minimum and maximum values. One successful means of maintaining

the pressure differential involves the installation of a series of barometric dampers, one on each

floor, to open when the maximum pressure is reached. The barometric dampers and the associ-

ated jumper duct will relieve excess air from the pressurized stair to the ceiling plenum adja-

cent to the stair. The jumper duct will require fire dampers that are necessary to retain the fire

rating of the exit stairs. The quantity of air being delivered by the fan under this arrangement

would be constant and would be determined by consideration of the number of floors served by

the fan, the tightness of the stair, and the maximum number of doors that can be opened at any

point of time.

An analysis with a network model can be used to evaluate if a pressurized elevator is capa-

ble of being successfully pressurized between the minimum and the maximum design pressure

differences. If analysis shows that successful pressurization is unlikely, the building can be

modified or an alternate system can be used. Some alternate systems include the following:

(1) stairwell compartmentation, (2) stairwell pressurization with fire floor exhaust, and (3)

stairwell ventilation. For more information about stairwell pressurization, see Chapter 15 of the

Handbook of Smoke Control Engineering (Klote et al. 2012).

ELEVATOR PRESSURIZATION

The elevator pressurization systems discussed in this section are intended to prevent

smoke from flowing from the fire floor through an elevator shaft and threatening life on other

floors. Usually, pressurized elevators are in buildings that have pressurized stairwells, and

buildings that have both usually need an engineering analysis done with network modeling.

Design of pressurized elevators is much more complicated than design of pressurized

stairwells, but there are a number of systems that can deal with this complexity. The reasons for

this complexity are as follows: (1) the building envelope is often not capable of effectively han-

dling the large airflow resulting from pressurization, and (2) open exterior doors on the ground

floor can cause high pressure differences across the elevator shaft at the ground floor. The basic

elevator pressurization system consists of only providing supply air the elevator shaft, but in

many situations the basic system cannot maintain successful pressurization.

An analysis with a network model can be used to evaluate if a pressurized elevator is capa-

ble of being successfully pressurized. If analysis shows that successful pressurization is

unlikely, the building can be modified or an alternate system can be used. Some alternate sys-

tems include the following:

• Exterior vent system

• Floor exhaust system

• Ground floor lobby system

Depending on local codes, an alternate system may need code approval. See Chapter 15 of

the Handbook of Smoke Control Engineering for more information about pressurized elevators.

--```,``,,,`,,,,`,,,,,,`,,```,,,-`-`,,`,,`,`,,`---

Copyright American Society of Heating, Refrigerating and Air-Conditioning Engine

Provided by IHS under license with ASHRAE Licensee=Hong Kong Polytechnic University/9976803100

No reproduction or networking permitted without license from IHS Not for Resale, 10/03/2015 23:58:12 MDT

You might also like

- Hvac Systems Design Handbook Fifth EditionDocument99 pagesHvac Systems Design Handbook Fifth Editionkambiado100% (1)

- Tagalog-English Construction TermsDocument3 pagesTagalog-English Construction TermsManet PalevinoNo ratings yet

- Wolter Jetfan Broschuere English 2017 PDFDocument15 pagesWolter Jetfan Broschuere English 2017 PDFViệt Đặng XuânNo ratings yet

- Smoke Management in Office BuildingsDocument7 pagesSmoke Management in Office BuildingsAbcoNo ratings yet

- CFD - ACUD CodeDocument6 pagesCFD - ACUD CodeDharmeswar SahNo ratings yet

- 10-Mechanical Extract System-Car Park VentilationDocument18 pages10-Mechanical Extract System-Car Park VentilationAli Ruhsen Cete100% (1)

- VENCO Articles Jet Fan System in Closed Car ParksDocument9 pagesVENCO Articles Jet Fan System in Closed Car ParksRuben AugustoNo ratings yet

- Car Park and Basement VentilationDocument20 pagesCar Park and Basement VentilationSaviour UdoNo ratings yet

- Acmv Technical ReportDocument10 pagesAcmv Technical Reportarun kurlanNo ratings yet

- Rebooting HVAC Systems For Post Pandemic RevivalDocument1 pageRebooting HVAC Systems For Post Pandemic RevivalEclatNo ratings yet

- UAE FC-2018 - CFD RequirementsDocument4 pagesUAE FC-2018 - CFD RequirementsYonish SisoNo ratings yet

- Ijb - Ijc II - Cat052.e0.Ed1Document10 pagesIjb - Ijc II - Cat052.e0.Ed1Vaibhav GuptaNo ratings yet

- ME Laws WK 8Document58 pagesME Laws WK 8Charle CandelarioNo ratings yet

- Operating Room Ventilation: Metalaire Periflow System Overview & Technical DiscussionDocument3 pagesOperating Room Ventilation: Metalaire Periflow System Overview & Technical DiscussionJorge FuentesNo ratings yet

- C03. FläktWoods - Car Park Ventilation - Ducted or Jet Thrust FanDocument7 pagesC03. FläktWoods - Car Park Ventilation - Ducted or Jet Thrust FanCzarSASNo ratings yet

- Compressed Air in Pharmaceutical ApplicationsDocument3 pagesCompressed Air in Pharmaceutical ApplicationsDamien MarleyNo ratings yet

- Duct Smoke DetectorfsDocument1 pageDuct Smoke DetectorfsAhmed AdelNo ratings yet

- Jet-Fan-Systems 2017-02 en E1749Document34 pagesJet-Fan-Systems 2017-02 en E1749MOHAN L BUJJINo ratings yet

- Guide To Stairwell AOVsDocument12 pagesGuide To Stairwell AOVsGrant MastersonNo ratings yet

- Group 3 ME LawsDocument105 pagesGroup 3 ME LawsGrande Jam AeraNo ratings yet

- Atrium Smoke Management System DesignDocument4 pagesAtrium Smoke Management System DesignCzarSASNo ratings yet

- GA90-500 GR110-200 Brochure PDFDocument22 pagesGA90-500 GR110-200 Brochure PDFmageedNo ratings yet

- Jet Fans Systems PDFDocument34 pagesJet Fans Systems PDFThinagaran ManiamNo ratings yet

- Induction Beams: Engineered Comfort For Today's BuildingsDocument10 pagesInduction Beams: Engineered Comfort For Today's Buildingsbuilder011No ratings yet

- Fiba Guide To Basketball Facilities - Air DistributionDocument2 pagesFiba Guide To Basketball Facilities - Air DistributionMustafa Onur SarıkayaNo ratings yet

- Technical Standard: (Signed Original On File) Sheet OFDocument7 pagesTechnical Standard: (Signed Original On File) Sheet OFd r hardyNo ratings yet

- Sfpe Smoke CH50Document82 pagesSfpe Smoke CH50ahmed selimNo ratings yet

- IA Compressor PKG - OptimizedDocument7 pagesIA Compressor PKG - OptimizedJetul PatelNo ratings yet

- Mechanical Ventilation Systems Are Frequently Applied To Commercial BuildingsDocument9 pagesMechanical Ventilation Systems Are Frequently Applied To Commercial BuildingsIbn Shaffee IVNo ratings yet

- A Method of Damper Control For Corridor Ventilation and Smoke ExtractionDocument15 pagesA Method of Damper Control For Corridor Ventilation and Smoke ExtractionrasheedillikkalNo ratings yet

- Basement Smoke VentilationDocument5 pagesBasement Smoke VentilationVarun MattooNo ratings yet

- Jet-Fan-Systems 2015-09 en E1591Document32 pagesJet-Fan-Systems 2015-09 en E1591a_salehiNo ratings yet

- Designing Car Park Ventilation SystemsDocument14 pagesDesigning Car Park Ventilation SystemsMohamed Mostafa Aamer100% (1)

- Tuttle and Bailey AdministrationDocument8 pagesTuttle and Bailey AdministrationElvis FariasNo ratings yet

- Part 2-Airconditioning-Ventilation-UserGuide - 1Document20 pagesPart 2-Airconditioning-Ventilation-UserGuide - 1Anonymous oUoJ4A8xNo ratings yet

- Sustainability PDFDocument24 pagesSustainability PDFEdmund YoongNo ratings yet

- Personal Ventilation: Emerging Technologies Emerging TechnologiesDocument6 pagesPersonal Ventilation: Emerging Technologies Emerging Technologiesscribd99190No ratings yet

- Zoned Smoke Control Applications: Using HVAC Systems To Limit SmokeDocument5 pagesZoned Smoke Control Applications: Using HVAC Systems To Limit SmokeNiong DavidNo ratings yet

- Build Tight RangeDocument8 pagesBuild Tight RangeMihai MunteanuNo ratings yet

- Enclosure Integrity Testing For Gas Suppressions - EnglishDocument4 pagesEnclosure Integrity Testing For Gas Suppressions - EnglishSalim Bakhsh100% (1)

- Appendix 1 Section 3 AS1668.2 2002Document5 pagesAppendix 1 Section 3 AS1668.2 2002bobNo ratings yet

- Dubai Green Building System: Version 2.0 - 2020Document40 pagesDubai Green Building System: Version 2.0 - 2020harikollam1981No ratings yet

- Impulse Ventilation An IntroductionDocument10 pagesImpulse Ventilation An IntroductionNupur Bhadra100% (1)

- Peace of Mind. Guaranteed.: Parking Garage / Car ParksDocument2 pagesPeace of Mind. Guaranteed.: Parking Garage / Car ParksPeroMentoroNo ratings yet

- Wolter Jetfan English 2014Document15 pagesWolter Jetfan English 2014jayanthahhy100% (1)

- Guidelines For Laboratory Design - 2013 - DiBerardinis - Appendix D Stack DesignDocument6 pagesGuidelines For Laboratory Design - 2013 - DiBerardinis - Appendix D Stack Designkeikhosravy.mNo ratings yet

- SolarDocument2 pagesSolarVineshNo ratings yet

- Pressurisation SystemDocument4 pagesPressurisation SystemEdmund YoongNo ratings yet

- YORK EconomizerPressurization AHUDocument8 pagesYORK EconomizerPressurization AHUAhmed TahaNo ratings yet

- Fire-2017-Corridor SmokeDocument1 pageFire-2017-Corridor Smokemhmdjdgmailcom100% (1)

- Compressed Air ApplicationsDocument4 pagesCompressed Air ApplicationsikrishnatNo ratings yet

- HVAC SystemDocument21 pagesHVAC Systemtinkusk24No ratings yet

- 9426 Air Traffic Services Planning ManualDocument16 pages9426 Air Traffic Services Planning Manualpaulo silvaNo ratings yet

- Numerical Simulation On Smoke Control of Impulse Ventilation in A Large Underground CarparkDocument5 pagesNumerical Simulation On Smoke Control of Impulse Ventilation in A Large Underground Carparkahmed ramadanNo ratings yet

- Air Conditioning of Wood and Paper Product Facilities PDFDocument4 pagesAir Conditioning of Wood and Paper Product Facilities PDFDaniel BolivarNo ratings yet

- A Breath of Fresh Air: Mine VentilationDocument6 pagesA Breath of Fresh Air: Mine VentilationMuhammad FarhadNo ratings yet

- Atrium Smoke ControlDocument8 pagesAtrium Smoke ControlSadeemNo ratings yet

- A330 Normal Law: Putting Fly-by-Wire Into PerspectiveFrom EverandA330 Normal Law: Putting Fly-by-Wire Into PerspectiveRating: 5 out of 5 stars5/5 (2)

- Temperature and Humidity Independent Control (THIC) of Air-conditioning SystemFrom EverandTemperature and Humidity Independent Control (THIC) of Air-conditioning SystemNo ratings yet

- Traditional House in AssamDocument7 pagesTraditional House in AssamM.Navyodai KanthNo ratings yet

- PRECASTDocument109 pagesPRECASTMike AlarNo ratings yet

- 27,30 - The Saudi Building Code (SBC) - PDF - 87-87Document1 page27,30 - The Saudi Building Code (SBC) - PDF - 87-87heshamNo ratings yet

- Leslie Simmons Hodgson Architect BiographyDocument32 pagesLeslie Simmons Hodgson Architect BiographyStanBirdNo ratings yet

- A-30, Sector-40 RevisedDocument8 pagesA-30, Sector-40 Revisedsunil kalwaniyaNo ratings yet

- Milan Cathedral - WikipediaDocument56 pagesMilan Cathedral - WikipediaTimyNo ratings yet

- 2) Apron & Drain For BEPS-23 School (60'x30'), Hlaing Thar Yar TownshipDocument2 pages2) Apron & Drain For BEPS-23 School (60'x30'), Hlaing Thar Yar TownshipShoon Lai AungNo ratings yet

- Trim Components: Steel Building & Residential Metal RoofingDocument32 pagesTrim Components: Steel Building & Residential Metal Roofingcaprater1No ratings yet

- Plumbing Max Fajardo PDFDocument175 pagesPlumbing Max Fajardo PDFJoe Luis BalaiboNo ratings yet

- Q1) Explain The Origin and Characteristics of Baroque Architecture With Examples of Roman Baroque ChurchesDocument7 pagesQ1) Explain The Origin and Characteristics of Baroque Architecture With Examples of Roman Baroque ChurchesAishwaryaNo ratings yet

- Terry Adams Construction/ HVAC ResumeDocument3 pagesTerry Adams Construction/ HVAC ResumeTerry AdamsNo ratings yet

- MMBC - 6: Topic - Acp Cladding Presented by - Manish.J SandhyaDocument25 pagesMMBC - 6: Topic - Acp Cladding Presented by - Manish.J SandhyaSneha DineshNo ratings yet

- Pressurized Stair CaseDocument8 pagesPressurized Stair CaseDesigner ForeverNo ratings yet

- Baroque Church PhilippinesDocument7 pagesBaroque Church PhilippinesMark Jefferson BorromeoNo ratings yet

- Cell / Model Name Description DateDocument9 pagesCell / Model Name Description DateSami AjNo ratings yet

- Antique Furniture StylesDocument3 pagesAntique Furniture StylesFreshhome VnNo ratings yet

- 9.1 - Rising Power of Rome PDFDocument17 pages9.1 - Rising Power of Rome PDFClaire NicerNo ratings yet

- Firewise Landscaping ChecklistDocument2 pagesFirewise Landscaping ChecklistSteven SchafersmanNo ratings yet

- Commercial Construction ScheduleDocument2 pagesCommercial Construction Schedulefinus marcalNo ratings yet

- Aa PresentationDocument12 pagesAa PresentationBinh Nguyen Tran QuocNo ratings yet

- Ceiling Plan: Notes All Ceiling Levels Mentioned Are From FFLDocument1 pageCeiling Plan: Notes All Ceiling Levels Mentioned Are From FFLsteauandreiNo ratings yet

- Ecoply Bracing - EP1 Specification (Apr-09)Document1 pageEcoply Bracing - EP1 Specification (Apr-09)郭骥No ratings yet

- The Prison of Unearthly Nightmares 04Document10 pagesThe Prison of Unearthly Nightmares 04krakcNo ratings yet

- Warehouse (30m. L X 15m. W X 4.5m.H) 03.08.2022-Layout1Document1 pageWarehouse (30m. L X 15m. W X 4.5m.H) 03.08.2022-Layout1Rigor Louise M. LegadaNo ratings yet

- Brochure AmbaramDocument13 pagesBrochure AmbaramAman GoyalNo ratings yet

- LEED For Operations and Maintenance Reference Guide Introduction PDFDocument20 pagesLEED For Operations and Maintenance Reference Guide Introduction PDFcevc1987_No ratings yet

- Labour Output Constants Masonry Concrete PDFDocument10 pagesLabour Output Constants Masonry Concrete PDFAwdhesh KumarNo ratings yet

- BVN 1984Document135 pagesBVN 1984shivaniNo ratings yet

- En (1063)Document1 pageEn (1063)reacharunkNo ratings yet