Professional Documents

Culture Documents

Level 2.1 Module 6

Level 2.1 Module 6

Uploaded by

muhammad saleemCopyright:

Available Formats

You might also like

- Introductory Chemistry A Foundation 9Th Edition Steven S Zumdahl Full ChapterDocument51 pagesIntroductory Chemistry A Foundation 9Th Edition Steven S Zumdahl Full Chaptercathy.johnson159100% (7)

- En590 10PPM Commercial InvoiceDocument4 pagesEn590 10PPM Commercial InvoiceAdnan IsmailNo ratings yet

- Chemistry - Periodic Table - Advanced PDFDocument2 pagesChemistry - Periodic Table - Advanced PDFCA_Ken86% (7)

- Rankine Cycle ReportDocument12 pagesRankine Cycle Reportyunusis100% (1)

- Classics meet Jazz: 10 jazz fantasies on classical themes for flute and pianoFrom EverandClassics meet Jazz: 10 jazz fantasies on classical themes for flute and pianoRating: 3.5 out of 5 stars3.5/5 (14)

- Astronomia Full ScoreDocument106 pagesAstronomia Full Score于念一No ratings yet

- C 4 TTVC 4 C 4678Document1 pageC 4 TTVC 4 C 4678Silviu Ionescu LupeanuNo ratings yet

- 220kV HK Single Line DiagramDocument1 page220kV HK Single Line DiagramNguyễn Văn HuyNo ratings yet

- En OGC Catalogue MaxsealDocument32 pagesEn OGC Catalogue MaxsealHai Pham VanNo ratings yet

- XLP Pre L13 WL13P40Document2 pagesXLP Pre L13 WL13P40Aria NickbakhtNo ratings yet

- Material Compatability Chart - Galvanic Reaction - From E2-External-Moisture-3rd-Edition-Amendment-10Document2 pagesMaterial Compatability Chart - Galvanic Reaction - From E2-External-Moisture-3rd-Edition-Amendment-10BTNo ratings yet

- DPS-139AP+A+Philips+Q552 2E+LADocument4 pagesDPS-139AP+A+Philips+Q552 2E+LAYoshNo ratings yet

- Periodic TableCheap Charts Frank Schaffer Publications - BarCharts QuickStudyDocument2 pagesPeriodic TableCheap Charts Frank Schaffer Publications - BarCharts QuickStudyMatheus Eduardo100% (1)

- Tmpe2 Ev Er20Document1 pageTmpe2 Ev Er20Marko BradvicaNo ratings yet

- Susta Nable: Roof Floor Plan KeyplanDocument1 pageSusta Nable: Roof Floor Plan Keyplanvananht599No ratings yet

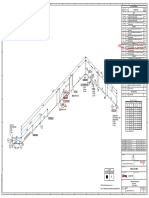

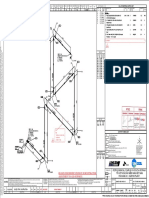

- Tal Wsa PNG Iso 1CS106901 - 02 - A01 - 00Document1 pageTal Wsa PNG Iso 1CS106901 - 02 - A01 - 00landeopauloNo ratings yet

- Window - Schedule DraughtingDocument1 pageWindow - Schedule Draughtingpanashekadangobt2201No ratings yet

- Tabla Periódica de Los Elementos QuímicosDocument2 pagesTabla Periódica de Los Elementos QuímicosGael Josue Vega100% (1)

- NS2 XG02 P1LBG 110001 - Auxiliary Steam System - P&IDDocument1 pageNS2 XG02 P1LBG 110001 - Auxiliary Steam System - P&IDdangnoexvietnamNo ratings yet

- Trimoterm Technical Specification SRDocument4 pagesTrimoterm Technical Specification SRМ ПNo ratings yet

- R2 - TYPICAL SLAB LVL (3rd, 4th, 5th, 7th & 8th Floor Slab LVL.) - HOTEL HYATT PLACE - Bharuch - 27.12.19-ModelDocument1 pageR2 - TYPICAL SLAB LVL (3rd, 4th, 5th, 7th & 8th Floor Slab LVL.) - HOTEL HYATT PLACE - Bharuch - 27.12.19-ModelNachiketa MithaiwalaNo ratings yet

- MIP17D48-C-3200-55Z-004. Rev.BDocument1 pageMIP17D48-C-3200-55Z-004. Rev.BHernan VasquezNo ratings yet

- 1731 DR 500-T5 PDFDocument1 page1731 DR 500-T5 PDFfanta calcioNo ratings yet

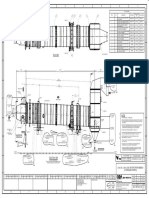

- Feed End: Do Not Scale If in Doubt AskDocument1 pageFeed End: Do Not Scale If in Doubt AskHugo BeltranNo ratings yet

- Tal Wsa PNG Iso 1CS106701 - 01 - A01 - 00Document1 pageTal Wsa PNG Iso 1CS106701 - 01 - A01 - 00landeopauloNo ratings yet

- 707 - 65111 - EDXRF Periodic Table With FiltersDocument2 pages707 - 65111 - EDXRF Periodic Table With FiltersAKM LABOR100% (1)

- FORM U-5 MANUFACTURERS DATA REPORT SUPPLEMENTARY SHEET SHELL-AND-TUBE HEAT EXCHANGERS Edit2017-2Document2 pagesFORM U-5 MANUFACTURERS DATA REPORT SUPPLEMENTARY SHEET SHELL-AND-TUBE HEAT EXCHANGERS Edit2017-2Ashish PatelNo ratings yet

- FORM U-5 MANUFACTURERS DATA REPORT SUPPLEMENTARY SHEET SHELL-AND-TUBE HEAT EXCHANGERS Edit2017Document2 pagesFORM U-5 MANUFACTURERS DATA REPORT SUPPLEMENTARY SHEET SHELL-AND-TUBE HEAT EXCHANGERS Edit2017Ashish PatelNo ratings yet

- LSA & FI FI ArrangementDocument1 pageLSA & FI FI ArrangementemadNo ratings yet

- Periodic Table of The Elements Jul-2010Document2 pagesPeriodic Table of The Elements Jul-2010Arix MedinakuNo ratings yet

- Eagle-Eye Shaped Headlamp Electric Sunroof Auto Retractable Led Side Mirror Led High Mount Stop LampDocument2 pagesEagle-Eye Shaped Headlamp Electric Sunroof Auto Retractable Led Side Mirror Led High Mount Stop Lamprifki wahyudiNo ratings yet

- Attach Label After Connection of Cables Attach Label After Connection of CablesDocument1 pageAttach Label After Connection of Cables Attach Label After Connection of CablesJongchan Jason MoonNo ratings yet

- Condominio Orion em Construção - Sommerschield 2Document15 pagesCondominio Orion em Construção - Sommerschield 2Wendy Cinthia Nobela InácioNo ratings yet

- Overview of The Steelmaking Process - PosterDocument1 pageOverview of The Steelmaking Process - PosterThúlio NascimentoNo ratings yet

- J3BGDF02BR010 01 05Document1 pageJ3BGDF02BR010 01 05Naheed AkhtarNo ratings yet

- Quality Control: Lap Joint DetailDocument2 pagesQuality Control: Lap Joint DetailariNo ratings yet

- J3BGDF02BR009 01 05Document1 pageJ3BGDF02BR009 01 05Naheed AkhtarNo ratings yet

- J3BGDF02BR011 01 01Document1 pageJ3BGDF02BR011 01 01saleem naheedNo ratings yet

- J3BGDF02BR009 01 01Document1 pageJ3BGDF02BR009 01 01saleem naheedNo ratings yet

- Sheet - 1 - Pile Cap-09-08-22-A1-Pile LayoutDocument1 pageSheet - 1 - Pile Cap-09-08-22-A1-Pile LayoutThrk TwrNo ratings yet

- Final Design (Ifc) : Emergency LightingDocument1 pageFinal Design (Ifc) : Emergency LightingIbrahim AlqunoonNo ratings yet

- 179SKN02 3G Gen 04020 02R00Document1 page179SKN02 3G Gen 04020 02R00罗国伦No ratings yet

- Chamber Detail Drill Site B-Reva-5Document1 pageChamber Detail Drill Site B-Reva-5ahmed saadNo ratings yet

- J3BGDF02BR025 01 06Document1 pageJ3BGDF02BR025 01 06Naheed AkhtarNo ratings yet

- 036909C 2cae18 Iso en 23251 01 0S3Document1 page036909C 2cae18 Iso en 23251 01 0S3NguyenCanhBaoNo ratings yet

- Quality Control: Lap Joint DetailDocument2 pagesQuality Control: Lap Joint DetailariNo ratings yet

- Ea 0020Document1 pageEa 0020fereetNo ratings yet

- Ec-201 1Document1 pageEc-201 1Arief PutraNo ratings yet

- Typical Longitudinal Section of BeamDocument1 pageTypical Longitudinal Section of Beammanh hung leNo ratings yet

- LBP A3 Example Office Case StudyDocument1 pageLBP A3 Example Office Case StudyOsvaldo ColinNo ratings yet

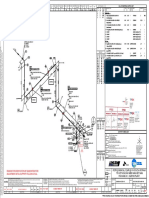

- Lax Imper One DPDocument1 pageLax Imper One DPKLAXATCNo ratings yet

- 3104 Bedroom-Standard-Isolation Rls PDFDocument1 page3104 Bedroom-Standard-Isolation Rls PDFVinay PallivalppilNo ratings yet

- C9 Marine Engine Electrical System: Right/Top ViewDocument2 pagesC9 Marine Engine Electrical System: Right/Top ViewTariqMaqsoodNo ratings yet

- SCHEMATIC All Models00109Document1 pageSCHEMATIC All Models00109Du TrầnNo ratings yet

- Stair Plan: Phase 2 Block 8 Lot 4 Avida Settings Nuvali Canlubang Calamba City LagunaDocument1 pageStair Plan: Phase 2 Block 8 Lot 4 Avida Settings Nuvali Canlubang Calamba City LagunaChristian ReyesNo ratings yet

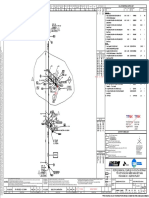

- 036909C 2bae07 Iso CBD 24521 01 0S1 CDocument1 page036909C 2bae07 Iso CBD 24521 01 0S1 CNguyenCanhBaoNo ratings yet

- 036909C 2bae05 Iso FW 57372 01 1S2Document2 pages036909C 2bae05 Iso FW 57372 01 1S2NguyenCanhBaoNo ratings yet

- 036909C 2cae05 Iso VT 27986 04 0S2Document1 page036909C 2cae05 Iso VT 27986 04 0S2NguyenCanhBaoNo ratings yet

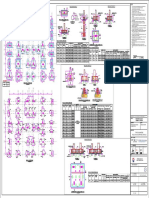

- Bill of Material Sketch ListDocument8 pagesBill of Material Sketch ListNguyenCanhBaoNo ratings yet

- 036909C 2CAE02 ISO HL 26118 01 0S1 Isometric Sketch Field Isometric Modifications Code 3Document3 pages036909C 2CAE02 ISO HL 26118 01 0S1 Isometric Sketch Field Isometric Modifications Code 3caochieuNo ratings yet

- P21020 Cit 0020 - 04Document1 pageP21020 Cit 0020 - 04Carlos David Hurtado MartinezNo ratings yet

- Instant Assessments for Data Tracking, Grade 1: Language ArtsFrom EverandInstant Assessments for Data Tracking, Grade 1: Language ArtsNo ratings yet

- Oil and The Falklands Malvinas Oil Companies Governments and IslandersDocument14 pagesOil and The Falklands Malvinas Oil Companies Governments and IslandersFrancisco Javier Rivera IbanezNo ratings yet

- Argumentative Essays TopicsDocument5 pagesArgumentative Essays Topicsbhhrxpaeg100% (2)

- Lift Cylinders PDFDocument14 pagesLift Cylinders PDFamineNo ratings yet

- Tewaycell-LFP12 8V60AhDocument2 pagesTewaycell-LFP12 8V60Aharbi jridiNo ratings yet

- Finalexam SolutionsDocument8 pagesFinalexam SolutionsJonah BallNo ratings yet

- Chemistry Module For Remidial ClassDocument52 pagesChemistry Module For Remidial ClassMuktaar HassenNo ratings yet

- B.5 Diesel Generator EngineDocument363 pagesB.5 Diesel Generator EngineedotambaNo ratings yet

- (FM CBMTEC) 240123#catalog For Air Compressors and Vacuum PlantsDocument6 pages(FM CBMTEC) 240123#catalog For Air Compressors and Vacuum PlantsslimaniNo ratings yet

- UHI 4 High Flow Insufflation Unit Flyer en 11020Document2 pagesUHI 4 High Flow Insufflation Unit Flyer en 11020APP SPPNo ratings yet

- Cooling Tower Thermodynamic Exp 5Document16 pagesCooling Tower Thermodynamic Exp 5hayder alaliNo ratings yet

- Physics 12.ODocument8 pagesPhysics 12.OavishnsamjainNo ratings yet

- Mercruiser Exhaust ManifoldsDocument30 pagesMercruiser Exhaust ManifoldsJSMarine Parts ChinaNo ratings yet

- EE-13 FaultsDocument11 pagesEE-13 FaultsNert IsturisNo ratings yet

- Further Product Details: Position Qty. Description SP 7-51Document10 pagesFurther Product Details: Position Qty. Description SP 7-51Bahtiar AntanaNo ratings yet

- Explosion Light & Fittings Brochure 2023Document23 pagesExplosion Light & Fittings Brochure 2023hashibpervez.shvenergybdNo ratings yet

- Tips To Save Energy in Cement Manufacturing Process - Infinity For Cement EquipmentDocument20 pagesTips To Save Energy in Cement Manufacturing Process - Infinity For Cement EquipmentsuritataNo ratings yet

- Invata SiwesDocument57 pagesInvata SiwesChiboy EmmanuelNo ratings yet

- Solar Energy Advantages and Disadvantages PDFDocument5 pagesSolar Energy Advantages and Disadvantages PDFabhijann12gNo ratings yet

- True False Not Given (Reading)Document5 pagesTrue False Not Given (Reading)Công Dương NguyễnNo ratings yet

- Template Label Print Telkomsel TRUST ProjectDocument7 pagesTemplate Label Print Telkomsel TRUST ProjectMedi ApriadiNo ratings yet

- Varistar Storm Trapper Secondary Class Mov Surge Arrester Catalog Ca235020enDocument8 pagesVaristar Storm Trapper Secondary Class Mov Surge Arrester Catalog Ca235020enrafeeqNo ratings yet

- Cruise Control (3RZ-FE)Document6 pagesCruise Control (3RZ-FE)Esteban LefontNo ratings yet

- Timing Chain ECNDocument21 pagesTiming Chain ECNalangarcia20244No ratings yet

- Chapter 6 Explosives and ExplosionsDocument9 pagesChapter 6 Explosives and ExplosionsCHRISTIAN PAHAYAHAY D.No ratings yet

- Linelazer 3000: 308685K Instructions - Parts ListDocument44 pagesLinelazer 3000: 308685K Instructions - Parts Listraj jangidNo ratings yet

- Risk Assessment and Risk Management Plan: Risk Description Rating Mitigation Measures ResponsibilityDocument4 pagesRisk Assessment and Risk Management Plan: Risk Description Rating Mitigation Measures Responsibilityم.عبدالرحيم سلمانNo ratings yet

- Uniform Technical Guidelines For Water Reticulation and PlumbingDocument211 pagesUniform Technical Guidelines For Water Reticulation and PlumbingFahmi YusoffNo ratings yet

- Carbon Market Year in Review 2020Document26 pagesCarbon Market Year in Review 2020Sayaka TsugaiNo ratings yet

Level 2.1 Module 6

Level 2.1 Module 6

Uploaded by

muhammad saleemOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Level 2.1 Module 6

Level 2.1 Module 6

Uploaded by

muhammad saleemCopyright:

Available Formats

8

(Perform Basic Welding Operations)

(Flames Produce different types of Oxy Acetylene Flames)

1

(Perform Oxy Acetylene Welding) 2

(Perform oxy-acetylene Flame Cutting Operations) 3

Perform Shielded Metal Arc Welding (SMAW) 4

(Perform Brazing Operation) 5

(Perform Post Welding Operations) 6

1 2 (General Fitter Basic)

1

(Produce different types of Oxy Acetylene Flames)

(flame)

(Neutral flame)

(Carburizing flame)

(Oxidizing flame)

(Technique) (heat)

(Oxy Acetylene welding)

(Technique) (heat)

(welding flame) (oxy acetylene)

(oxy acetylene)

3200

(oxy acetylene)

-

(Types of Flames in Gas Welding)

,

(Neutral flame) 1

(Carburizing flame) 2

(Oxidizing flame)

3

Oxy Acetylene

(Neutral Flame)

(Neutral) (chemically)

2 2 (General Fitter Basic)

Flame (acetylene gas)

(on)

) ( (neutral flame)

(Envelop)

(aluminum) (Cast iron) (stainless steel)

(neutral flame)

) 300 (3 000 6

( Carburizing flame)

(neutral flame)

(carburizing flame)

800 2 000 5

carbonize

( (zone)

)

" soft flame (iron oxide)

3 2 (General Fitter Basic)

(soft soldering) (Aluminum alloy) "(reducing flame)

(hard facing metals)

Oxidizing flame 3

(oxidizing flame)

(neutral flame) (oxidizing flame)

(applications)

(mechanical detriment)

(zinc compound) (bronze)

4 2 (General Fitter Basic)

2

(Perform Oxy Acetylene Welding)

(Advantages of Oxy Acetylene Welding)

(disadvantages of Oxy Acetylene Welding)

Tool & Equipments

(Gas Cylinders)

5 2 (General Fitter Basic)

(Regulator)

(Welding Torch)

1200

-

(oscillate)

(Types of Welding Joints)

(Butt Joint) 1

(Corner Joint) 2

"L"

(T-Joint) 3

"T"

(lap Joint) 4

6 2 (General Fitter Basic)

(Edge Joint ) 5

\

1

\ 2

3

4

5

/ 6

7

8

9

10

11

12

13

14

15

16

17

18

0 19

20

7 2 (General Fitter Basic)

1

) (Oxy Acetylene Welding

(Butt Joint) 1

(Lap Joint) 2

(Corner Joint) 3

(T- Joint) 4

(Edge Joint) 5

8 2 (General Fitter Basic)

3

(Perform Oxy Acetylene Flame Cutting Operations)

(Oxy Acetylene Flame Cutting)

" "

" "

molten slag

low alloy steel

) (50 2

economical

) (900 35

(Oxyfuel Cutting Advantages and Disadvantages)

Advantages

1

2

3

4

5

6

9 2 (General Fitter Basic)

Disadvantages

1

2

3

10 2 (General Fitter Basic)

1

2

preheating 3

kindling

4

narrow

" "

5

oxidizing

6

molten slag

7

11 2 (General Fitter Basic)

2

) (Oxy Acetylene Flame Cutting

12 2 (General Fitter Basic)

4

(Perform Shielded Metal Arc Welding (SMAW)

Consumables WPS

WPS

2F,2G 1F,1G

(Safety Preaction for Drilling)

1

2

3

4

5

6

7

(SMAW Process) SMAW

(SMAW)Shielded Metal Arc Welding

Coated Electrode

13 2 (General Fitter Basic)

6000C5000 C(9000 F) SMAW

Steel Stainless, Low Alloy

SMAW Steel

(Advantages of SMAW) SMAW

Equipment -1

-2

(Flux) (Granular) -3

-4

Alloys -5

SMAW

-6

(Disadvantages of SMAW) SMAW

Fume SMAW -1

inclusion Slag -2

-3

(Equipment) SMAW

(Equipment) SMAW

(Power Source)

(Electrode Holder)

(Welding Cables)

Earth Clamp

(Welding Both)

(Burner Plier)

Personal Protective Equiment (PPE's)

14 2 (General Fitter Basic)

(SMAW Power Sources) SMAW

-1

-2

-3

(Welding Transformer)

Static

(Alternating Current)

(Welding Rectifier)

DC AC

Polarity (Reverse) (Straight)

(Welding Generator)

D óC A óC

15 2 (General Fitter Basic)

(Electrode Holder)

(Conduct)

(Amp)

(Earth Clamp)

Workpiece Workpiece

(Welding Booth)

(Lighting)

(Cutting Tools)

(Gas Cutter) 1

Acetylene Low Alloy Steel

16 2 (General Fitter Basic)

(Shearing Tools/Machines) / 2

(Shearing)

(Hand Grinder) 3

(Angle Grinder)

(Bench Tools)

(Wire Brush)

17 2 (General Fitter Basic)

1

2

(Single V Butt Joint) / W óP óS 4

5

6

-7

SMAW

DC AC

(Flow)

"A"

"V"

(Resistance)

ohm

AC

(Fix) AC

DC

(Polarity)

D/C

18 2 (General Fitter Basic)

(Stright Polarity)

DC

(Reverse Polarity)

DC

SMAW

SMAW

1

2

(Work angle = 90 and Travel Angle = 70-80 )

3

3mm2 4

5

6

7

8

9

10

11

12

19 2 (General Fitter Basic)

1

(Make T-Joint in Flat by using SMAW process)

-9 -8 -7

-6 -5 -4 -3 -2 -1

-13-12 -11 -10

-1

-2

-3

(1F) -4

-5

8070 -6

1F -7

-8

-1

-2

-3

-4

-5

-6

20 2 (General Fitter Basic)

2

(Make Butt-Joint in Flat by using SMAW process)

-10 -9 -8 -7

-6 -5 -4 -3 -2

-1

-11

-1

-2

-3

(2F) -4

-5

-6

(2F) SMAW -7

-8

-1

-2

-3

-4

-5

-6

21 2 (General Fitter Basic)

5

Perform Brazing Operations

joints

flux

Oxidation

brazing

technique

melting agent

(Important Terminologies)

Base Metal

Filler Metal

unwanted oxidation : Flux

: Joint

: Brazing Temperature

:

Capillary Action

:

Oxidation

1

Base Metal

Filler Metal

unwanted metal oxidation Flux

22 2 (General Fitter Basic)

2

oxidation)

3

position joint

4

) Filler Metal (

5

) Filler Metal (

6

material ) Filler Metal (

7

23 2 (General Fitter Basic)

6

(Perform Post welding Operations)

(Dressing)

(Dressing)

(Polishing)

(Pickling)

(Post-Inspection)

Post welding Operations

Post welding Operations

(Dressing)

(Grinding)

(Polishing)

(Pickling)

(Post-Inspection)

24 2 (General Fitter Basic)

25 2 (General Fitter Basic)

1

2

3

4

5700

5

6

7

8

9

10

11

12

5700

13

14

15

16

26 2 (General Fitter Basic)

17

18

19

20

21

(filler metals)

22

23

1500 1100

24

oxidation

27 2 (General Fitter Basic)

1

)

2

3

4

300

5000 1000

5

6

7

8

9

10

11

28 2 (General Fitter Basic)

12

13

14

15

16

17

18

19

20

29 2 (General Fitter Basic)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

30 2 (General Fitter Basic)

You might also like

- Introductory Chemistry A Foundation 9Th Edition Steven S Zumdahl Full ChapterDocument51 pagesIntroductory Chemistry A Foundation 9Th Edition Steven S Zumdahl Full Chaptercathy.johnson159100% (7)

- En590 10PPM Commercial InvoiceDocument4 pagesEn590 10PPM Commercial InvoiceAdnan IsmailNo ratings yet

- Chemistry - Periodic Table - Advanced PDFDocument2 pagesChemistry - Periodic Table - Advanced PDFCA_Ken86% (7)

- Rankine Cycle ReportDocument12 pagesRankine Cycle Reportyunusis100% (1)

- Classics meet Jazz: 10 jazz fantasies on classical themes for flute and pianoFrom EverandClassics meet Jazz: 10 jazz fantasies on classical themes for flute and pianoRating: 3.5 out of 5 stars3.5/5 (14)

- Astronomia Full ScoreDocument106 pagesAstronomia Full Score于念一No ratings yet

- C 4 TTVC 4 C 4678Document1 pageC 4 TTVC 4 C 4678Silviu Ionescu LupeanuNo ratings yet

- 220kV HK Single Line DiagramDocument1 page220kV HK Single Line DiagramNguyễn Văn HuyNo ratings yet

- En OGC Catalogue MaxsealDocument32 pagesEn OGC Catalogue MaxsealHai Pham VanNo ratings yet

- XLP Pre L13 WL13P40Document2 pagesXLP Pre L13 WL13P40Aria NickbakhtNo ratings yet

- Material Compatability Chart - Galvanic Reaction - From E2-External-Moisture-3rd-Edition-Amendment-10Document2 pagesMaterial Compatability Chart - Galvanic Reaction - From E2-External-Moisture-3rd-Edition-Amendment-10BTNo ratings yet

- DPS-139AP+A+Philips+Q552 2E+LADocument4 pagesDPS-139AP+A+Philips+Q552 2E+LAYoshNo ratings yet

- Periodic TableCheap Charts Frank Schaffer Publications - BarCharts QuickStudyDocument2 pagesPeriodic TableCheap Charts Frank Schaffer Publications - BarCharts QuickStudyMatheus Eduardo100% (1)

- Tmpe2 Ev Er20Document1 pageTmpe2 Ev Er20Marko BradvicaNo ratings yet

- Susta Nable: Roof Floor Plan KeyplanDocument1 pageSusta Nable: Roof Floor Plan Keyplanvananht599No ratings yet

- Tal Wsa PNG Iso 1CS106901 - 02 - A01 - 00Document1 pageTal Wsa PNG Iso 1CS106901 - 02 - A01 - 00landeopauloNo ratings yet

- Window - Schedule DraughtingDocument1 pageWindow - Schedule Draughtingpanashekadangobt2201No ratings yet

- Tabla Periódica de Los Elementos QuímicosDocument2 pagesTabla Periódica de Los Elementos QuímicosGael Josue Vega100% (1)

- NS2 XG02 P1LBG 110001 - Auxiliary Steam System - P&IDDocument1 pageNS2 XG02 P1LBG 110001 - Auxiliary Steam System - P&IDdangnoexvietnamNo ratings yet

- Trimoterm Technical Specification SRDocument4 pagesTrimoterm Technical Specification SRМ ПNo ratings yet

- R2 - TYPICAL SLAB LVL (3rd, 4th, 5th, 7th & 8th Floor Slab LVL.) - HOTEL HYATT PLACE - Bharuch - 27.12.19-ModelDocument1 pageR2 - TYPICAL SLAB LVL (3rd, 4th, 5th, 7th & 8th Floor Slab LVL.) - HOTEL HYATT PLACE - Bharuch - 27.12.19-ModelNachiketa MithaiwalaNo ratings yet

- MIP17D48-C-3200-55Z-004. Rev.BDocument1 pageMIP17D48-C-3200-55Z-004. Rev.BHernan VasquezNo ratings yet

- 1731 DR 500-T5 PDFDocument1 page1731 DR 500-T5 PDFfanta calcioNo ratings yet

- Feed End: Do Not Scale If in Doubt AskDocument1 pageFeed End: Do Not Scale If in Doubt AskHugo BeltranNo ratings yet

- Tal Wsa PNG Iso 1CS106701 - 01 - A01 - 00Document1 pageTal Wsa PNG Iso 1CS106701 - 01 - A01 - 00landeopauloNo ratings yet

- 707 - 65111 - EDXRF Periodic Table With FiltersDocument2 pages707 - 65111 - EDXRF Periodic Table With FiltersAKM LABOR100% (1)

- FORM U-5 MANUFACTURERS DATA REPORT SUPPLEMENTARY SHEET SHELL-AND-TUBE HEAT EXCHANGERS Edit2017-2Document2 pagesFORM U-5 MANUFACTURERS DATA REPORT SUPPLEMENTARY SHEET SHELL-AND-TUBE HEAT EXCHANGERS Edit2017-2Ashish PatelNo ratings yet

- FORM U-5 MANUFACTURERS DATA REPORT SUPPLEMENTARY SHEET SHELL-AND-TUBE HEAT EXCHANGERS Edit2017Document2 pagesFORM U-5 MANUFACTURERS DATA REPORT SUPPLEMENTARY SHEET SHELL-AND-TUBE HEAT EXCHANGERS Edit2017Ashish PatelNo ratings yet

- LSA & FI FI ArrangementDocument1 pageLSA & FI FI ArrangementemadNo ratings yet

- Periodic Table of The Elements Jul-2010Document2 pagesPeriodic Table of The Elements Jul-2010Arix MedinakuNo ratings yet

- Eagle-Eye Shaped Headlamp Electric Sunroof Auto Retractable Led Side Mirror Led High Mount Stop LampDocument2 pagesEagle-Eye Shaped Headlamp Electric Sunroof Auto Retractable Led Side Mirror Led High Mount Stop Lamprifki wahyudiNo ratings yet

- Attach Label After Connection of Cables Attach Label After Connection of CablesDocument1 pageAttach Label After Connection of Cables Attach Label After Connection of CablesJongchan Jason MoonNo ratings yet

- Condominio Orion em Construção - Sommerschield 2Document15 pagesCondominio Orion em Construção - Sommerschield 2Wendy Cinthia Nobela InácioNo ratings yet

- Overview of The Steelmaking Process - PosterDocument1 pageOverview of The Steelmaking Process - PosterThúlio NascimentoNo ratings yet

- J3BGDF02BR010 01 05Document1 pageJ3BGDF02BR010 01 05Naheed AkhtarNo ratings yet

- Quality Control: Lap Joint DetailDocument2 pagesQuality Control: Lap Joint DetailariNo ratings yet

- J3BGDF02BR009 01 05Document1 pageJ3BGDF02BR009 01 05Naheed AkhtarNo ratings yet

- J3BGDF02BR011 01 01Document1 pageJ3BGDF02BR011 01 01saleem naheedNo ratings yet

- J3BGDF02BR009 01 01Document1 pageJ3BGDF02BR009 01 01saleem naheedNo ratings yet

- Sheet - 1 - Pile Cap-09-08-22-A1-Pile LayoutDocument1 pageSheet - 1 - Pile Cap-09-08-22-A1-Pile LayoutThrk TwrNo ratings yet

- Final Design (Ifc) : Emergency LightingDocument1 pageFinal Design (Ifc) : Emergency LightingIbrahim AlqunoonNo ratings yet

- 179SKN02 3G Gen 04020 02R00Document1 page179SKN02 3G Gen 04020 02R00罗国伦No ratings yet

- Chamber Detail Drill Site B-Reva-5Document1 pageChamber Detail Drill Site B-Reva-5ahmed saadNo ratings yet

- J3BGDF02BR025 01 06Document1 pageJ3BGDF02BR025 01 06Naheed AkhtarNo ratings yet

- 036909C 2cae18 Iso en 23251 01 0S3Document1 page036909C 2cae18 Iso en 23251 01 0S3NguyenCanhBaoNo ratings yet

- Quality Control: Lap Joint DetailDocument2 pagesQuality Control: Lap Joint DetailariNo ratings yet

- Ea 0020Document1 pageEa 0020fereetNo ratings yet

- Ec-201 1Document1 pageEc-201 1Arief PutraNo ratings yet

- Typical Longitudinal Section of BeamDocument1 pageTypical Longitudinal Section of Beammanh hung leNo ratings yet

- LBP A3 Example Office Case StudyDocument1 pageLBP A3 Example Office Case StudyOsvaldo ColinNo ratings yet

- Lax Imper One DPDocument1 pageLax Imper One DPKLAXATCNo ratings yet

- 3104 Bedroom-Standard-Isolation Rls PDFDocument1 page3104 Bedroom-Standard-Isolation Rls PDFVinay PallivalppilNo ratings yet

- C9 Marine Engine Electrical System: Right/Top ViewDocument2 pagesC9 Marine Engine Electrical System: Right/Top ViewTariqMaqsoodNo ratings yet

- SCHEMATIC All Models00109Document1 pageSCHEMATIC All Models00109Du TrầnNo ratings yet

- Stair Plan: Phase 2 Block 8 Lot 4 Avida Settings Nuvali Canlubang Calamba City LagunaDocument1 pageStair Plan: Phase 2 Block 8 Lot 4 Avida Settings Nuvali Canlubang Calamba City LagunaChristian ReyesNo ratings yet

- 036909C 2bae07 Iso CBD 24521 01 0S1 CDocument1 page036909C 2bae07 Iso CBD 24521 01 0S1 CNguyenCanhBaoNo ratings yet

- 036909C 2bae05 Iso FW 57372 01 1S2Document2 pages036909C 2bae05 Iso FW 57372 01 1S2NguyenCanhBaoNo ratings yet

- 036909C 2cae05 Iso VT 27986 04 0S2Document1 page036909C 2cae05 Iso VT 27986 04 0S2NguyenCanhBaoNo ratings yet

- Bill of Material Sketch ListDocument8 pagesBill of Material Sketch ListNguyenCanhBaoNo ratings yet

- 036909C 2CAE02 ISO HL 26118 01 0S1 Isometric Sketch Field Isometric Modifications Code 3Document3 pages036909C 2CAE02 ISO HL 26118 01 0S1 Isometric Sketch Field Isometric Modifications Code 3caochieuNo ratings yet

- P21020 Cit 0020 - 04Document1 pageP21020 Cit 0020 - 04Carlos David Hurtado MartinezNo ratings yet

- Instant Assessments for Data Tracking, Grade 1: Language ArtsFrom EverandInstant Assessments for Data Tracking, Grade 1: Language ArtsNo ratings yet

- Oil and The Falklands Malvinas Oil Companies Governments and IslandersDocument14 pagesOil and The Falklands Malvinas Oil Companies Governments and IslandersFrancisco Javier Rivera IbanezNo ratings yet

- Argumentative Essays TopicsDocument5 pagesArgumentative Essays Topicsbhhrxpaeg100% (2)

- Lift Cylinders PDFDocument14 pagesLift Cylinders PDFamineNo ratings yet

- Tewaycell-LFP12 8V60AhDocument2 pagesTewaycell-LFP12 8V60Aharbi jridiNo ratings yet

- Finalexam SolutionsDocument8 pagesFinalexam SolutionsJonah BallNo ratings yet

- Chemistry Module For Remidial ClassDocument52 pagesChemistry Module For Remidial ClassMuktaar HassenNo ratings yet

- B.5 Diesel Generator EngineDocument363 pagesB.5 Diesel Generator EngineedotambaNo ratings yet

- (FM CBMTEC) 240123#catalog For Air Compressors and Vacuum PlantsDocument6 pages(FM CBMTEC) 240123#catalog For Air Compressors and Vacuum PlantsslimaniNo ratings yet

- UHI 4 High Flow Insufflation Unit Flyer en 11020Document2 pagesUHI 4 High Flow Insufflation Unit Flyer en 11020APP SPPNo ratings yet

- Cooling Tower Thermodynamic Exp 5Document16 pagesCooling Tower Thermodynamic Exp 5hayder alaliNo ratings yet

- Physics 12.ODocument8 pagesPhysics 12.OavishnsamjainNo ratings yet

- Mercruiser Exhaust ManifoldsDocument30 pagesMercruiser Exhaust ManifoldsJSMarine Parts ChinaNo ratings yet

- EE-13 FaultsDocument11 pagesEE-13 FaultsNert IsturisNo ratings yet

- Further Product Details: Position Qty. Description SP 7-51Document10 pagesFurther Product Details: Position Qty. Description SP 7-51Bahtiar AntanaNo ratings yet

- Explosion Light & Fittings Brochure 2023Document23 pagesExplosion Light & Fittings Brochure 2023hashibpervez.shvenergybdNo ratings yet

- Tips To Save Energy in Cement Manufacturing Process - Infinity For Cement EquipmentDocument20 pagesTips To Save Energy in Cement Manufacturing Process - Infinity For Cement EquipmentsuritataNo ratings yet

- Invata SiwesDocument57 pagesInvata SiwesChiboy EmmanuelNo ratings yet

- Solar Energy Advantages and Disadvantages PDFDocument5 pagesSolar Energy Advantages and Disadvantages PDFabhijann12gNo ratings yet

- True False Not Given (Reading)Document5 pagesTrue False Not Given (Reading)Công Dương NguyễnNo ratings yet

- Template Label Print Telkomsel TRUST ProjectDocument7 pagesTemplate Label Print Telkomsel TRUST ProjectMedi ApriadiNo ratings yet

- Varistar Storm Trapper Secondary Class Mov Surge Arrester Catalog Ca235020enDocument8 pagesVaristar Storm Trapper Secondary Class Mov Surge Arrester Catalog Ca235020enrafeeqNo ratings yet

- Cruise Control (3RZ-FE)Document6 pagesCruise Control (3RZ-FE)Esteban LefontNo ratings yet

- Timing Chain ECNDocument21 pagesTiming Chain ECNalangarcia20244No ratings yet

- Chapter 6 Explosives and ExplosionsDocument9 pagesChapter 6 Explosives and ExplosionsCHRISTIAN PAHAYAHAY D.No ratings yet

- Linelazer 3000: 308685K Instructions - Parts ListDocument44 pagesLinelazer 3000: 308685K Instructions - Parts Listraj jangidNo ratings yet

- Risk Assessment and Risk Management Plan: Risk Description Rating Mitigation Measures ResponsibilityDocument4 pagesRisk Assessment and Risk Management Plan: Risk Description Rating Mitigation Measures Responsibilityم.عبدالرحيم سلمانNo ratings yet

- Uniform Technical Guidelines For Water Reticulation and PlumbingDocument211 pagesUniform Technical Guidelines For Water Reticulation and PlumbingFahmi YusoffNo ratings yet

- Carbon Market Year in Review 2020Document26 pagesCarbon Market Year in Review 2020Sayaka TsugaiNo ratings yet