Professional Documents

Culture Documents

RS-232 Frequently Asked Questions by Texas Instruments - Slla544

RS-232 Frequently Asked Questions by Texas Instruments - Slla544

Uploaded by

8403c36589584aCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RS-232 Frequently Asked Questions by Texas Instruments - Slla544

RS-232 Frequently Asked Questions by Texas Instruments - Slla544

Uploaded by

8403c36589584aCopyright:

Available Formats

www.ti.

com Table of Contents

Application Report

RS-232 Frequently Asked Questions

ABSTRACT

RS-232 has been existing for several decades. Although this single-ended interface is common, many questions

and problems do arise during the design and applications. This article collects some most frequently asked

questions to help the user understand this popular interface standard. The basics about how to set up the

interface are given in this article. The application tips help provide a successful implementation in the system.

Table of Contents

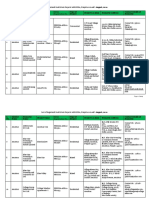

1 Introduction.............................................................................................................................................................................2

1.1 What is the valid signal level of RS-232?...........................................................................................................................2

1.2 What is the charge pump for in RS-232 transceivers? How does it work? ....................................................................... 2

1.3 How to select right capacitor for the charge pumps?......................................................................................................... 2

1.4 How to estimate the power dissipation of RS-232?........................................................................................................... 3

1.5 How to set up the handshaking of the RS-232 communication?....................................................................................... 3

1.6 How to configure the unused pins of RS-232 transceivers?.............................................................................................. 4

1.7 What is the slew rate and how is it related to the data rate?..............................................................................................4

2 Summary................................................................................................................................................................................. 4

Trademarks

All trademarks are the property of their respective owners.

SLLA544 – JANUARY 2021 RS-232 Frequently Asked Questions 1

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Introduction www.ti.com

1 Introduction

1.1 What is the valid signal level of RS-232?

Before deploying RS-232, you need to know what the valid signal is in the interface. Knowing the legit signal

level usually is that first step to implement or debug the communication.

Valid RS-232 signals are either in the range of +3 V to +15 V or the range −3 V to −15 V with respect to the

common ground (Figure 1-1). To be more specific, the driver output is Logic 0 when the voltage is between +5 V

and +15 V and is Logic 1 when the voltage is between -5 V to -15 V.

Received signal voltage level is that Logic 0 works on the received signal voltages up to +3 V to +15 V and Logic

1 works with voltages up to -3 V to -15 V.

Logic 0

15 V 15 V

5V

3V

Driver side 0V 0V Receiver side

-3 V

-5 V

-15 V -15V

Logic 1

Figure 1-1. RS-232 signal level

1.2 What is the charge pump for in RS-232 transceivers? How does it work?

In modern RS-232 transceivers, only one supply is needed to generate the valid RS-232 signaling. To generate

the voltage level higher than the supply, it is common that charge pumps are employed in RS-232 ICs. The detail

of the charge pump operation can be found in this article.

The basic idea is to use a clock signal to control switches alternatively. In the first clock cycle, the voltage up to

the supply is stored on a capacitor. This charge is transferred to the second capacitor with one end being

connected to the supply in the next cycle. By keeping transferring the energy from the supply to the capacitors,

2x voltage of the supply is generated on the capacitors.

1.3 How to select right capacitor for the charge pumps?

The charge pump needs to work with external flying capacitor and storage capacitor to generate the required

voltage from the supply. Please refer to the blog mentioned previously for the impact of different capacitor

values. Since the charge pump can double the supply voltage theoretically, it is recommended that the external

capacitors have at least 10V working voltage. Higher voltage rating could provide some margin for the voltage

variation in the applications.

2 RS-232 Frequently Asked Questions SLLA544 – JANUARY 2021

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

www.ti.com Introduction

1.4 How to estimate the power dissipation of RS-232?

To have enough budgets in the power design of the system, it is normally required to estimate the power

dissipation of the transceiver during the normal operation. However it is rare to find the active power

consumption on the RS-232 transceiver’s data sheet. The reason behind and estimate can be found in this

article.

To put it simply, since the power consumption is not linear, it is hard to quantize the value in various applications.

The trick for a quick estimate is to convert the capacitive load into the equivalent resistance. Before the driver is

running out of juice, the power vs. load relation is pretty linear excluding the static power.

1.5 How to set up the handshaking of the RS-232 communication?

Handshaking is a way of flow control of the communication in many RS-232 applications, which can be

implemented in software or hardware. The main purpose of handshaking is to guarantee successful

communication by preventing receiver from overloading. Receivers will let the transmitter device to hold data

transmission if they are overloaded.

There are three types of handshaking: Software handshaking, Hardware handshaking and Both. Using RS-232

software handshaking can save the additional lines. One of the applications is sending data over telephone

lines. One RS-232 software protocol is called Xon/Xoff. The Xon/Xoff operates by sending the control characters

along the data line. Command Xon starts the transmission and Xoff stops it. For example, when an instrument

cannot accept more data from a computer, it could send a single Xoff character to the computer to let it stop

sending data. When the instrument is ready, it sends a Xon character to restart transmission. Xon is ASCII

character 17 and Xoff is ASCII character 19.

Hardware flow control (also called as RTS / CTS flow control) is superior compared to software flow control with

the cost of extra lines. In the diagram of 9 pin null modem communication (Figure 1-2), the RTS (Request To

Send) of the DTE (Data Terminal Equipment) is connected to the CTS (Clear To Send) of the DCE (Data Circuit-

terminating Equipment), same for the DTR (Data Terminal Ready) and the DSR (Data Set Ready). The DTE

initiates the transmission by setting the RTS in the ON state. When the DCE is ready, it puts the CTS on. Then

the DTE responds by placing the DTR line into the ON state, which stays on when the data is being transmitted.

Ground

1 5

DSR

6 9

DTR

2 RX 4

7 RTS CTS 8

3 TX TX 3

8 CTS RTS 7

4 RX 2

DTR

9 6

DSR

5 1

Ground

Figure 1-2. 9 Pin RS-232 handshaking connection

In some applications (for example, diagnostic purpose), the loopback function is requested to bypass the

hardware handshaking. The connection below (Figure 1-3) is an example of how to implement it. By connecting

CTS to RTS and DTR to DSR on the same side, the correct response is ensured.

SLLA544 – JANUARY 2021 RS-232 Frequently Asked Questions 3

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

Introduction www.ti.com

Ground

1 5

6 DSR 9

DTR

2 RX 4

7 RTS CTS 8

3 TX TX 3

8 CTS RTS 7

4 RX 2

DTR

9 DSR 6

5 1

Ground

Figure 1-3. 9 pin RS-232 loopback connection

1.6 How to configure the unused pins of RS-232 transceivers?

In many applications, all of the channels of the transceivers are not used. Let us use TRS3232 as an example,

which comes with two drivers and two receivers. If you only need to have one active channel in the system, you

need to know what to do with the unused channel. In TR3232, it is recommended to bias the transmitter input

(DIN) pins with pull up or pull down resistors. The receiver input (RIN) pins are internally integrated with 5-kΩ

resistors to ground per RS-232 standard. Therefore RIN, ROUT, DOUT can all left open.

1.7 What is the slew rate and how is it related to the data rate?

In RS-232 standard, the data rate is specified with the slew rate. Slew rate is defined as the change of an edge

represented by ΔV/Δt, while rise time only counts the time of a transition (10% to 90%, or 20% to 80%). RS-232

standard (TIA/EIA-232-F) limits the maximum slew to help reduce the likelihood of cross–talk between adjacent

signals. The history and technical discussion can be found in this application note.

For long cable or heavy load, the slew rate is limited by the device output current charging the capacitive load.

With short cable or light load, the on-chip slew rate control still makes sure the edge not too fast. For an

example, 200 kbps data rate signal has 5 µs unit bit time. The standard limits the transition time to be 4% of the

bit time, which is 0.2 µs in this case. With the maximum slew rate 30 V/µs, the output voltage is 30 x 0.2 = 6 V -

the minimum required voltage on the bus. We can tell this is the fastest data rate defined by the standard. If a

higher data rate is needed, the slew rate should be increased.

2 Summary

After knowing the signal voltage level, power dissipation estimate, and handshaking protocol, the user can set

the interface up for a successful communication scheme. Having answers to the application questions like

capacitor type, slew rate, and unused pins should help the user start on that path.

4 RS-232 Frequently Asked Questions SLLA544 – JANUARY 2021

Submit Document Feedback

Copyright © 2021 Texas Instruments Incorporated

IMPORTANT NOTICE AND DISCLAIMER

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING DATA SHEETS), DESIGN RESOURCES (INCLUDING REFERENCE

DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER RESOURCES “AS IS”

AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES, EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY

IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT OF THIRD

PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers designing with TI products. You are solely responsible for (1) selecting the appropriate

TI products for your application, (2) designing, validating and testing your application, and (3) ensuring your application meets applicable

standards, and any other safety, security, regulatory or other requirements.

These resources are subject to change without notice. TI grants you permission to use these resources only for development of an

application that uses the TI products described in the resource. Other reproduction and display of these resources is prohibited. No license

is granted to any other TI intellectual property right or to any third party intellectual property right. TI disclaims responsibility for, and you

will fully indemnify TI and its representatives against, any claims, damages, costs, losses, and liabilities arising out of your use of these

resources.

TI’s products are provided subject to TI’s Terms of Sale or other applicable terms available either on ti.com or provided in conjunction with

such TI products. TI’s provision of these resources does not expand or otherwise alter TI’s applicable warranties or warranty disclaimers for

TI products.

TI objects to and rejects any additional or different terms you may have proposed. IMPORTANT NOTICE

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2022, Texas Instruments Incorporated

You might also like

- The Art of Clean Up Life Made Neat and Tidy - Ursus WehrliDocument56 pagesThe Art of Clean Up Life Made Neat and Tidy - Ursus WehrliBritney MalcolmNo ratings yet

- Yokogawa Modbus Communication TrainingDocument37 pagesYokogawa Modbus Communication TrainingShiva Prasad M Pattar75% (4)

- Bernstein - Workplace-Democratization-Its-Internal-Dynamics (1976) PDFDocument140 pagesBernstein - Workplace-Democratization-Its-Internal-Dynamics (1976) PDFEndee Kristel Lim100% (1)

- General Chemical Safety Inspection ChecklistDocument3 pagesGeneral Chemical Safety Inspection ChecklistRizwan Khan100% (2)

- Sample Subcontractor AgreementDocument2 pagesSample Subcontractor Agreementisabellearnold100% (2)

- Manual de Variador de Velocidad WEG VECTORDocument32 pagesManual de Variador de Velocidad WEG VECTORSamuel Miranda PintoNo ratings yet

- Precision Voltage References: by Perry Miller, and Doug MooreDocument5 pagesPrecision Voltage References: by Perry Miller, and Doug MooreThomas SmithNo ratings yet

- LVS-800 Remote E01Document17 pagesLVS-800 Remote E01BAZAMOTOSNo ratings yet

- Interfaces: - High Data Rate, But ExpensiveDocument16 pagesInterfaces: - High Data Rate, But ExpensiveHARITHA JNo ratings yet

- 3-V To 5.5-V Multichannel RS-232 Line Driver and Receiver With 15-kV ESD ProtectionDocument28 pages3-V To 5.5-V Multichannel RS-232 Line Driver and Receiver With 15-kV ESD ProtectioncafosokNo ratings yet

- Hisense RS232 DocDocument16 pagesHisense RS232 DocrochaseletronicaNo ratings yet

- Slaa 343Document12 pagesSlaa 343ugmadhuNo ratings yet

- An 2Document7 pagesAn 2Carlos H. GojleviciusNo ratings yet

- FX MitsubishiDocument26 pagesFX MitsubishiPatty MayorgaNo ratings yet

- DME DMEIAU617 Pre-Recording1 v1Document38 pagesDME DMEIAU617 Pre-Recording1 v1Manisha PatelNo ratings yet

- Manual ACS GeneralDocument8 pagesManual ACS GeneralEdwin GarciaNo ratings yet

- Max 3221Document26 pagesMax 3221Lervin CastilloNo ratings yet

- MAX3221 3-V To 5.5-V RS-232 Line Driver and Receiver With 15-kV ESD ProtectionDocument25 pagesMAX3221 3-V To 5.5-V RS-232 Line Driver and Receiver With 15-kV ESD Protectiony lNo ratings yet

- DEM LTRS Transmit / Receive Sequencer: DB-15 Connection With Additional ConnectionsDocument5 pagesDEM LTRS Transmit / Receive Sequencer: DB-15 Connection With Additional Connectionswa3yueNo ratings yet

- RS-232C:TELNET Protocol SpecificationsDocument54 pagesRS-232C:TELNET Protocol SpecificationsJVTO79No ratings yet

- EE-379 Embedded Systems and Applications: (Serial) BusesDocument40 pagesEE-379 Embedded Systems and Applications: (Serial) Busesss mNo ratings yet

- DP83822 Ieee802.3 COMPLIACEDocument21 pagesDP83822 Ieee802.3 COMPLIACENaveenNo ratings yet

- AN-979 The Practical Limits of RS-485: Application ReportDocument9 pagesAN-979 The Practical Limits of RS-485: Application ReportAkhilNo ratings yet

- RS 232 Specification StandardDocument9 pagesRS 232 Specification StandardTetsusaigaNo ratings yet

- LCM001-923 DatasheetDocument9 pagesLCM001-923 DatasheetRobert WangNo ratings yet

- DS276 Low Power Transceiver Chip: Features Pin AssignmentDocument11 pagesDS276 Low Power Transceiver Chip: Features Pin AssignmentJhónatan JuárezNo ratings yet

- TSM23C HardwareManual 920-0082BDocument28 pagesTSM23C HardwareManual 920-0082BJosue MuñozNo ratings yet

- Convertidor LBNP16301B-UserManualDocument16 pagesConvertidor LBNP16301B-UserManualJosé Ramón Rivera BarriosNo ratings yet

- Interfacing The ADS7881 To The TMS320C6713 DSP: Application ReportDocument14 pagesInterfacing The ADS7881 To The TMS320C6713 DSP: Application ReportSashikanth BethaNo ratings yet

- Max 3221 eDocument29 pagesMax 3221 evictorvpaiva07No ratings yet

- DS276 Low Power Transceiver Chip: Features Pin AssignmentDocument11 pagesDS276 Low Power Transceiver Chip: Features Pin AssignmentJairo PadronNo ratings yet

- Selecting and Using RS-232, RS-422, and RS-485 Serial Data StandardsDocument9 pagesSelecting and Using RS-232, RS-422, and RS-485 Serial Data StandardssoumyajitemdmNo ratings yet

- LM74610-Q1 Zero IQ Reverse Polarity Protection Smart Diode ControllerDocument31 pagesLM74610-Q1 Zero IQ Reverse Polarity Protection Smart Diode Controllereneas.baroneNo ratings yet

- DRV 8873Document58 pagesDRV 8873Sovi SoviNo ratings yet

- EDN Design Ideas 1998Document166 pagesEDN Design Ideas 1998chag1956100% (4)

- DRV8847 Dual H-Bridge Motor Driver: 1 Features 3 DescriptionDocument72 pagesDRV8847 Dual H-Bridge Motor Driver: 1 Features 3 DescriptionDaniel FernándezNo ratings yet

- Rs 232Document18 pagesRs 232vijay b100% (2)

- Opa365 Q11Document22 pagesOpa365 Q11Victor HernandezNo ratings yet

- Dsa 0016439Document4 pagesDsa 0016439Hector OsortoNo ratings yet

- What's The Difference Between The RS-232 and RS-485 Serial Interfaces?Document7 pagesWhat's The Difference Between The RS-232 and RS-485 Serial Interfaces?Pranjali patil100% (1)

- Swiftlink Commodore 64 RS232 Card ManualDocument4 pagesSwiftlink Commodore 64 RS232 Card ManualweirdocolectorNo ratings yet

- RS-422 and RS-485 Application Note: Balanced Line DriversDocument23 pagesRS-422 and RS-485 Application Note: Balanced Line DriversMarinel123No ratings yet

- RS 232 Repeater KFD2-FF-Ex2.RS232: FunctionDocument4 pagesRS 232 Repeater KFD2-FF-Ex2.RS232: FunctionEder AlexandreNo ratings yet

- MAX3221E 3-V To 5.5-V Single-Channel RS-232 Line Driver/Receiver With 15-kV IEC ESD ProtectionDocument26 pagesMAX3221E 3-V To 5.5-V Single-Channel RS-232 Line Driver/Receiver With 15-kV IEC ESD ProtectionThibaud RouilléNo ratings yet

- ProReact Digital Sensor Control Unit Installation Manual 2Document17 pagesProReact Digital Sensor Control Unit Installation Manual 2saoborjaNo ratings yet

- MBDocument19 pagesMBErman GÖGENNo ratings yet

- Snlu 036 ADocument29 pagesSnlu 036 AFaber Alexis Maldonado PembertyNo ratings yet

- RS232 422 485 I2c SpiDocument6 pagesRS232 422 485 I2c SpiShen JinWei100% (1)

- Features Applications: SLLS792 - JUNE 2007Document19 pagesFeatures Applications: SLLS792 - JUNE 2007Jose SoaresNo ratings yet

- NetController II - Feature BlastDocument6 pagesNetController II - Feature Blastjhon bayonaNo ratings yet

- TASCAM CD-400U/CD-400UDAB CONTROL I/O Terminals RS-232C TELNET Protocol SpecificationsDocument28 pagesTASCAM CD-400U/CD-400UDAB CONTROL I/O Terminals RS-232C TELNET Protocol SpecificationsChhim AnasNo ratings yet

- LoRaWAN (IOT L2S F1&F2)Document4 pagesLoRaWAN (IOT L2S F1&F2)Jossemar Bartolo OnayramNo ratings yet

- Data Type ID Troublshooting V4Document15 pagesData Type ID Troublshooting V4David J. MoranNo ratings yet

- Video - LTC 8786 Series RS-232 To Biphase ConverterDocument3 pagesVideo - LTC 8786 Series RS-232 To Biphase ConverterAabel CiexNo ratings yet

- Iomrmpxxxx00 GBDocument27 pagesIomrmpxxxx00 GBSuranNo ratings yet

- LM74700-Q1 Low I Reverse Battery Protection Ideal Diode ControllerDocument31 pagesLM74700-Q1 Low I Reverse Battery Protection Ideal Diode ControllermstrkoskiNo ratings yet

- ds90lv032a (1)Document26 pagesds90lv032a (1)sh msNo ratings yet

- Selecting and Using RS-232, RS-422, and RS-485 Serial Data StandardsDocument11 pagesSelecting and Using RS-232, RS-422, and RS-485 Serial Data StandardsIman AkbariNo ratings yet

- RS232Document26 pagesRS232Pratesh Kumar Reddy100% (3)

- Ads 131 A 02Document93 pagesAds 131 A 02dhanabal rNo ratings yet

- "MAX3221 3-V To 5.5-V RS-232 Line Driver and Receiver" Datasheet (Revision P)Document27 pages"MAX3221 3-V To 5.5-V RS-232 Line Driver and Receiver" Datasheet (Revision P)d4n13jNo ratings yet

- max3221-RS232 Driver ReceiverDocument25 pagesmax3221-RS232 Driver Receiverjustinvil1103No ratings yet

- WAN TECHNOLOGY FRAME-RELAY: An Expert's Handbook of Navigating Frame Relay NetworksFrom EverandWAN TECHNOLOGY FRAME-RELAY: An Expert's Handbook of Navigating Frame Relay NetworksNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- HA17524Document18 pagesHA175248403c36589584aNo ratings yet

- OPI1264Document4 pagesOPI12648403c36589584aNo ratings yet

- Ps22a74 eDocument11 pagesPs22a74 e8403c36589584aNo ratings yet

- 3S111Document1 page3S1118403c36589584aNo ratings yet

- Bitzer 4EC-6.2Y-40SDocument5 pagesBitzer 4EC-6.2Y-40S8403c36589584aNo ratings yet

- Esguerra v. Trinidad, G.R. No. 169890, Mar. 12, 2007Document12 pagesEsguerra v. Trinidad, G.R. No. 169890, Mar. 12, 2007idko2wNo ratings yet

- Rosewood Hotels & Resorts: Customer Lifetime Value (CLTV) Analysis InputsDocument3 pagesRosewood Hotels & Resorts: Customer Lifetime Value (CLTV) Analysis InputsVishal GoyalNo ratings yet

- Annual Report DSSA 2018 PDFDocument320 pagesAnnual Report DSSA 2018 PDFSudarmadi DmaNo ratings yet

- Clinical Abstract FormDocument1 pageClinical Abstract Formsyringomyelia0% (1)

- Sri Guru Singh Sabha Patrika, 16 November 2022, Year 6 Issue 206Document8 pagesSri Guru Singh Sabha Patrika, 16 November 2022, Year 6 Issue 206Raj SinghNo ratings yet

- PDF Revised Agricultural CREDIT PDFDocument23 pagesPDF Revised Agricultural CREDIT PDFanand sahuNo ratings yet

- List of Registered ProjectsDocument214 pagesList of Registered ProjectsSunny SinghNo ratings yet

- E Commerce ReportDocument21 pagesE Commerce ReportMidul Khan100% (2)

- DeductionsDocument10 pagesDeductionsceline marasiganNo ratings yet

- Grade 12 Surah Nur 1 12Document24 pagesGrade 12 Surah Nur 1 12op.aspect.xNo ratings yet

- DirectoryDocument3 pagesDirectoryfem-femNo ratings yet

- Bank Failures in 2010Document14 pagesBank Failures in 2010Richarnellia-RichieRichBattiest-CollinsNo ratings yet

- The Parable of The TalentsDocument4 pagesThe Parable of The TalentsMaggie PedrozoNo ratings yet

- Reading Material - CompiledDocument172 pagesReading Material - CompiledArpit DhakaNo ratings yet

- CepiaDocument16 pagesCepiaEriq GardnerNo ratings yet

- Authors' Manuscript Submission GuidelinesDocument3 pagesAuthors' Manuscript Submission GuidelinesAnamika ChoudharyNo ratings yet

- Dokumen - Tips - Latihan Soal Sap Finance Lengkap Ada JawabanDocument6 pagesDokumen - Tips - Latihan Soal Sap Finance Lengkap Ada Jawabanurbae chaNo ratings yet

- ANSYS Polyflow in ANSYS Workbench Users GuideDocument60 pagesANSYS Polyflow in ANSYS Workbench Users GuideV CafNo ratings yet

- World Bank Report 2007Document197 pagesWorld Bank Report 2007GlennKesslerWPNo ratings yet

- Opw 2000 Series Installation ManualDocument16 pagesOpw 2000 Series Installation ManualrubenNo ratings yet

- People v. Duca, October 9, 2009, G.R. No. 171175Document7 pagesPeople v. Duca, October 9, 2009, G.R. No. 171175brahmsNo ratings yet

- Grade 12 NSC Accounting Preparatory 2017 Possible AnswersDocument19 pagesGrade 12 NSC Accounting Preparatory 2017 Possible AnswersTimothy NgwerumeNo ratings yet

- Types of Financial MarketsDocument3 pagesTypes of Financial Marketskate trishaNo ratings yet

- Acc 103 - Day 23 - SasDocument3 pagesAcc 103 - Day 23 - Sasfecamacho53No ratings yet

- The Indian Patent Act - 1970: Harnoor Singh (16) Ashmeet KaurDocument41 pagesThe Indian Patent Act - 1970: Harnoor Singh (16) Ashmeet KaurGagan KauraNo ratings yet

- Government of The Virgin Islands v. Warren P. Berry. Appeal of Warren Berry. Appeal of Guillermo Brignoni, 604 F.2d 221, 3rd Cir. (1979)Document16 pagesGovernment of The Virgin Islands v. Warren P. Berry. Appeal of Warren Berry. Appeal of Guillermo Brignoni, 604 F.2d 221, 3rd Cir. (1979)Scribd Government DocsNo ratings yet