Professional Documents

Culture Documents

2390 Crack Sealing

2390 Crack Sealing

Uploaded by

Francisco ParedesOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2390 Crack Sealing

2390 Crack Sealing

Uploaded by

Francisco ParedesCopyright:

Available Formats

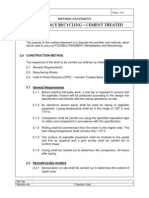

City of Regina

Standard Construction Specification SECTION 2390

CRACK SEALING

1.0 GENERAL

1.1 Scope

1.1.1 This section specifies requirements for products, equipment, procedures and

standards for routing the cracks and applying hot-poured rubberized asphalt

on the flexible pavement.

2.0 SEALANT AND EQUIPMENT

Use only those products in the Approved Products List, product ID:

o RP – 02: Crack Sealant

2.1 Crack Sealant

2.1.1 The crack sealant shall be a high-quality rubberized asphalt with proven

performance in Saskatchewan, Manitoba or Alberta. The product’s

performance must be field performance evaluated by independent public

agency and placed on the approved product list for that agency and meet -

rubber sealant which meets requirements of ASTM D6690 for type IV or

ASTM D6690 type IV modified which requires minimum Resilience at 25C

to be 30% and maximum flow at 60C to be 10 mm and passes required tests

according to ASTM D5329. The crack sealant supplier should be accredited

to the quality standard ISO 9001 and the environmental standard ISO

14001.The crack sealant should provide long life, healability, low service

temperature flexibility and high service temperature resistance to flow.

2.2 Equipment

2.2.1 Items used for crack sealing include but are not limited to the following:

.1 Traffic Accommodation (refer to Temporary Traffic Control Manual)

.2 Crack Router

.3 Vacuum Cleaner

.4 Hot Compressed-air Heat Lance (HAL) producing hot compressed air at 90

psi (620 kPa)

.5 Oil Jacketed Melting Kettles with Thermostatic Heat Controls,

Continuous Agitation, and Over-heating Safety Control

.6 Squeegee

.7 Blotter Coating

Revised: January 2017 Page 1 of 2

City of Regina

Standard Construction Specification SECTION 2390

CRACK SEALING

3.0 EXECUTION

3.1 Crack Preparation

3.1.1 Cracks and joints shall be cleaned using appropriate routing, sawing,

brushing, blowing, or other techniques to provide intact bonding faces which

are free of moisture, dust, or other contaminants.

3.2 Crack Routing and HAL Treatment

3.2.1 Cracks shall be widened using a router to form a sealant reservoir which is

20 mm wide and 20 mm deep. The routed cracks should then be cleaned by

Hot Air Lance to remove all dust and free all moisture and then sealed in

such a manner that the sealant is surface level upon cooling. All routed cracks

should be approved by the Engineer before sealing.

3.3 Crack Sealing

3.3.1 The sealant shall be applied using a melter-applicator unit. The melter-

applicator unit shall be a self-contained double boiler device. It must be

equipped with an on the electronic board heat-controlling device to permit

the attainment of a pre-determined temperature, then, maintain that

temperature as long as required. The unit shall also have a means to

vigorously and continuously agitate the sealant. The sealant shall be applied

to the pavement under pressure supplied by a positive displacement pump.

3.4 Blotter Coat

3.4.1 A blotter coat is required to prevent pick-up upon re-opening to traffic.

Coating materials should be approved by the Engineer. The cracks must be

sufficiently dry to permit bonding of the sealant. The contract shall ensure

traffic is not allowed on the newly sealed surface for one (1) hour from

completion of the crack sealing.

Revised: January 2017 Page 2 of 2

You might also like

- Method Statement For Rubber LiningDocument7 pagesMethod Statement For Rubber LiningJoseph PerezNo ratings yet

- Method Statement For Cold In-Place Recycling - CementDocument6 pagesMethod Statement For Cold In-Place Recycling - CementNordin Yunus100% (2)

- 039-Procedure Liquid Penetrant Testing PDFDocument13 pages039-Procedure Liquid Penetrant Testing PDFKöksal Patan100% (3)

- Marathon XHBDocument5 pagesMarathon XHBakbarNo ratings yet

- ASTRU - Vulcanising Cement, Cushion GumDocument7 pagesASTRU - Vulcanising Cement, Cushion GumBharat Chatrath50% (2)

- WP 11 Corrosion Protection Tape CoatingDocument3 pagesWP 11 Corrosion Protection Tape CoatingKarthikNo ratings yet

- WP 11 Corrosion Protection Tape Coating123Document3 pagesWP 11 Corrosion Protection Tape Coating123KarthikNo ratings yet

- Norma ASTM Adhesivo TafDocument2 pagesNorma ASTM Adhesivo TafFabiola Arce SaraviaNo ratings yet

- Splash Zone Coating For Riser PipesDocument11 pagesSplash Zone Coating For Riser PipesĐiệnBiênNhâm100% (2)

- DC 781 Acetoxy SealantDocument3 pagesDC 781 Acetoxy SealantL.S.No ratings yet

- Technical Data Sheet: Silcoset 151 1 Part Adhesive SealantDocument2 pagesTechnical Data Sheet: Silcoset 151 1 Part Adhesive SealantArun VaideeswaranNo ratings yet

- Enviroline 2405 Application Guidelines: Protective Coatings Technical SupportDocument12 pagesEnviroline 2405 Application Guidelines: Protective Coatings Technical SupportskNo ratings yet

- Bituprime: Bituminous Roofing PrimerDocument2 pagesBituprime: Bituminous Roofing PrimerJalil TahirNo ratings yet

- SECTION 09980 Thin Film Polymer Floor Sealer Part 1 - General 1.01Document2 pagesSECTION 09980 Thin Film Polymer Floor Sealer Part 1 - General 1.01Eng CivilNo ratings yet

- Interzinc 22HSDocument4 pagesInterzinc 22HSTrịnh Minh KhoaNo ratings yet

- SPEC 2023-US01 - Introduction of Off-Site Anodic PretreatmentDocument9 pagesSPEC 2023-US01 - Introduction of Off-Site Anodic PretreatmentKathellyn OliveiraNo ratings yet

- Versathane Mastic Rapid Grade PDSDocument2 pagesVersathane Mastic Rapid Grade PDSjfairbairn69No ratings yet

- Pratt & Whitney Standard Practices Manual (PN 585005)Document22 pagesPratt & Whitney Standard Practices Manual (PN 585005)Paul FisherNo ratings yet

- For The Manufacture and Installation of Geonet: Uality Ontrol AnualDocument6 pagesFor The Manufacture and Installation of Geonet: Uality Ontrol AnualCESAR_OVIEDOFNo ratings yet

- Application of Emulsified Coal-Tar Pitch (Mineral Colloid Type)Document2 pagesApplication of Emulsified Coal-Tar Pitch (Mineral Colloid Type)Mohammad YaseenNo ratings yet

- Interchar 2090: Acrylic IntumescentDocument4 pagesInterchar 2090: Acrylic IntumescentEngTamerNo ratings yet

- Jotun Malathon TDSDocument5 pagesJotun Malathon TDSBiju_PottayilNo ratings yet

- Rapidcure: Waterproofing and Leak Arrest Product Group Rapidcure RCCDocument1 pageRapidcure: Waterproofing and Leak Arrest Product Group Rapidcure RCCHeramb TrifaleyNo ratings yet

- 22 13 18 - Drainage Waste and Vent Piping - PlasticDocument2 pages22 13 18 - Drainage Waste and Vent Piping - PlasticLangzkie NalipaNo ratings yet

- PH 464 - Open Gear Lubricant PDFDocument4 pagesPH 464 - Open Gear Lubricant PDFdfbdfbfdbfbNo ratings yet

- Spec Water Storage TanksDocument5 pagesSpec Water Storage TanksparthivNo ratings yet

- Tack CoatDocument11 pagesTack CoatRajib DasNo ratings yet

- Surface-Preparation-and-Painting Procedure - NISL - ENG-PRC-002Document4 pagesSurface-Preparation-and-Painting Procedure - NISL - ENG-PRC-002George OgbecheNo ratings yet

- Quickmast 341Document2 pagesQuickmast 341rakeshNo ratings yet

- Soft Natural Rubber Lining: Technical Data SheetDocument2 pagesSoft Natural Rubber Lining: Technical Data SheetSantosh JayasavalNo ratings yet

- Manhole-Bench Mix DesignDocument5 pagesManhole-Bench Mix DesignAhmadNo ratings yet

- Ceramic-Polymer 232 Spray Version - Ds - PDSDocument3 pagesCeramic-Polymer 232 Spray Version - Ds - PDSANIBALLOPEZVEGANo ratings yet

- Intertherm 972: Product DescriptionDocument4 pagesIntertherm 972: Product DescriptionRohit RathiNo ratings yet

- l2 Heat Shrink Sleeve DrawingDocument4 pagesl2 Heat Shrink Sleeve Drawingresp-ectNo ratings yet

- 8400-A - External Painting & Protective CoatingsDocument19 pages8400-A - External Painting & Protective Coatingsamalhaj2013No ratings yet

- TotalEnergies EQUIVIS ZS 68Document2 pagesTotalEnergies EQUIVIS ZS 68Erik FloresNo ratings yet

- 3M Scotchkote 323Document6 pages3M Scotchkote 323tang weng waiNo ratings yet

- Rubber Lining ProcedureDocument9 pagesRubber Lining ProcedureIchsan RosidinNo ratings yet

- 13-Spec-Corrosion Protection System For Marine STRDocument3 pages13-Spec-Corrosion Protection System For Marine STRsunilbauchkarNo ratings yet

- Quickmast 341 - TDSDocument2 pagesQuickmast 341 - TDSMohamed AlhadidyNo ratings yet

- Marathon XHB - TDSDocument5 pagesMarathon XHB - TDSDamar WardhanaNo ratings yet

- Water Retention by Concrete Curing Materials: NOTE 2-A Commercial Wood Float EquippedDocument3 pagesWater Retention by Concrete Curing Materials: NOTE 2-A Commercial Wood Float EquippedEvert RiveraNo ratings yet

- Construction: Dow CorningDocument3 pagesConstruction: Dow Corningsamira bashirvandNo ratings yet

- Thermoplastic Road Marking Paint: Product Code: TTP 1 & TTP 2Document3 pagesThermoplastic Road Marking Paint: Product Code: TTP 1 & TTP 2Veera PandiNo ratings yet

- Astm D 4060Document3 pagesAstm D 4060Arab WeldersNo ratings yet

- Blasting ProcedureDocument3 pagesBlasting ProcedureFaiz ZainudinNo ratings yet

- E-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Interspeed - 6200 - Eng - Usa - A4 - 20210216Document4 pagesE-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Interspeed - 6200 - Eng - Usa - A4 - 20210216Zainal ArifinNo ratings yet

- ASRTU - Precured Tread RubberDocument7 pagesASRTU - Precured Tread RubberBharat ChatrathNo ratings yet

- 03 6000 - GroutingDocument4 pages03 6000 - GroutingAngelo Carlo MalabananNo ratings yet

- SECTION 02066 Road Work SpecDocument14 pagesSECTION 02066 Road Work Specahmed.atwanNo ratings yet

- Versathane Brush Grade PDSDocument2 pagesVersathane Brush Grade PDSjfairbairn69No ratings yet

- Thwi Tds (JK r2 0315) EnglishDocument2 pagesThwi Tds (JK r2 0315) EnglishMasood KhanNo ratings yet

- Application of Refined Coal Tar (Ready To Use, Commercial Grade)Document4 pagesApplication of Refined Coal Tar (Ready To Use, Commercial Grade)MohanadNo ratings yet

- A Guide For FLUOR & BASF Painting Specification of Typical Storage Tanks (Part 03 of 05)Document5 pagesA Guide For FLUOR & BASF Painting Specification of Typical Storage Tanks (Part 03 of 05)Adam Michael GreenNo ratings yet

- GRP General Procedure (EWS)Document16 pagesGRP General Procedure (EWS)Maged Ali Ragheb100% (1)

- Penguard Express MIO Technical Data SheetDocument5 pagesPenguard Express MIO Technical Data SheetGurdeep Sungh AroraNo ratings yet

- SPEC 2022-US02 Introduction of Off-Site Anodic PretreatmentDocument6 pagesSPEC 2022-US02 Introduction of Off-Site Anodic Pretreatmentyaser elmasryNo ratings yet

- 01 Mos STCJ - 10 Inch Diameter RTR Firewater Line Repair by Replacement of PipeDocument13 pages01 Mos STCJ - 10 Inch Diameter RTR Firewater Line Repair by Replacement of Pipetotoybibo1001No ratings yet

- Rubber Nanocomposites: Preparation, Properties, and ApplicationsFrom EverandRubber Nanocomposites: Preparation, Properties, and ApplicationsNo ratings yet

- An Assessment of Construction Professionals' Level of Compliance To Ethical Standards in The Nigerian Construction IndustryDocument20 pagesAn Assessment of Construction Professionals' Level of Compliance To Ethical Standards in The Nigerian Construction IndustryDavid MugaggaNo ratings yet

- Building Utilities 1 Lecture 1 PDFDocument3 pagesBuilding Utilities 1 Lecture 1 PDFSey Santmore57% (7)

- Technical Information Bulletins Ajax # 010717Document28 pagesTechnical Information Bulletins Ajax # 010717harley florezNo ratings yet

- Smart Facades Buildings That Adapt To The Climate Through Their SkinDocument11 pagesSmart Facades Buildings That Adapt To The Climate Through Their SkinsergiiNo ratings yet

- Introduction To Prestressed Concrete Design PDFDocument43 pagesIntroduction To Prestressed Concrete Design PDFMarkVincentTulinaoNo ratings yet

- Sample For NangalisanDocument18 pagesSample For NangalisanNix GabrielNo ratings yet

- Gothic Renaissance Baroque, Industrial ArchitectureDocument57 pagesGothic Renaissance Baroque, Industrial ArchitectureJerzy ZuñigaNo ratings yet

- 2009 MAPA Install StructuralSupportsDocument7 pages2009 MAPA Install StructuralSupportslsaishankarNo ratings yet

- g+5 Building Pr1Document13 pagesg+5 Building Pr1aftabNo ratings yet

- Alloy CuCr1ZrDocument53 pagesAlloy CuCr1ZrPrashant PuriNo ratings yet

- Student Instructions: Select, Procure and Store Construction Materials For Low Rise ProjectsDocument18 pagesStudent Instructions: Select, Procure and Store Construction Materials For Low Rise ProjectsApoorv GargNo ratings yet

- CompanyListG LDocument198 pagesCompanyListG LMahasar SiddiquiNo ratings yet

- Cold FormingDocument25 pagesCold Formingpatel ketan100% (3)

- Senceive Case Study - Linton Bridge - 1Document1 pageSenceive Case Study - Linton Bridge - 1José Luis González HerreraNo ratings yet

- Designator Description of Assembly Unit Uraian Pekerjaan Unit QTY Material (IDR) Total Material (IDR) Service (IDR) Sub-DIV-Total (IDR) NODocument9 pagesDesignator Description of Assembly Unit Uraian Pekerjaan Unit QTY Material (IDR) Total Material (IDR) Service (IDR) Sub-DIV-Total (IDR) NOkhirana1780% (5)

- Material PropertiesDocument4 pagesMaterial Propertiesbratkp100% (1)

- 2019-9 Testing Anchors in Cracked MasonryDocument4 pages2019-9 Testing Anchors in Cracked MasonryEric WilkinsNo ratings yet

- Construction Material Management PDFDocument19 pagesConstruction Material Management PDFBala SubramaniamNo ratings yet

- Platipus Anchors - Sheet Pile Tieback Specifications and Submittal Package PDFDocument13 pagesPlatipus Anchors - Sheet Pile Tieback Specifications and Submittal Package PDFDIEGO TUNARROSANo ratings yet

- 8 Field Quality PlanDocument18 pages8 Field Quality Plangeorge_hem100% (1)

- Chapter 3 Shear ExamplesDocument30 pagesChapter 3 Shear ExamplesRefisa JiruNo ratings yet

- Cantilever Beam Design (Laterally Supported)Document1 pageCantilever Beam Design (Laterally Supported)Nikhil PoriyaNo ratings yet

- Assignment 2Document2 pagesAssignment 2johnmasefield50% (2)

- FMDS0200Document171 pagesFMDS0200Róger F. e SilvaNo ratings yet

- Corrosion Mapping by UT & PADocument24 pagesCorrosion Mapping by UT & PAInspection Engineer100% (2)

- Bambang Campus Bambang, Nueva VizcayaDocument6 pagesBambang Campus Bambang, Nueva VizcayaIvy Joy UbinaNo ratings yet

- Modeling Parameters For The Nonlinear Analysis of Reinforced Concrete Beams Under Cyclic LoadingDocument12 pagesModeling Parameters For The Nonlinear Analysis of Reinforced Concrete Beams Under Cyclic LoadingVladekNo ratings yet

- Partial Depth Repair of Concrete Pavements in Wisconsin: Report Number: WI 05 12Document31 pagesPartial Depth Repair of Concrete Pavements in Wisconsin: Report Number: WI 05 12Indra Ndara TruebluesNo ratings yet

- G6 - V - CE - Industrial Shed PDFDocument4 pagesG6 - V - CE - Industrial Shed PDFArbendra KumarNo ratings yet

- AGPT04E-22 Guide To Pavement Technology Part 4E Recycled MaterialsDocument94 pagesAGPT04E-22 Guide To Pavement Technology Part 4E Recycled MaterialsFábio LibórioNo ratings yet