Professional Documents

Culture Documents

23-26 Textiles FFYApril-14

23-26 Textiles FFYApril-14

Uploaded by

jeya mohanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

23-26 Textiles FFYApril-14

23-26 Textiles FFYApril-14

Uploaded by

jeya mohanCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/291148269

THE TEXTILE INDUSTRY IN INDIA Looking For reforms

Article · April 2014

CITATION READS

1 6,670

1 author:

Swetha Thiruchanuru

Sri Sathya Sai Institute of Higher Learning

11 PUBLICATIONS 6 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

spiritual management: management lessons from epics View project

textile industry View project

All content following this page was uploaded by Swetha Thiruchanuru on 19 January 2016.

The user has requested enhancement of the downloaded file.

Market Survey

By: SWETHA THIRUCHANURU

DR K. VENUGOPAL RAO

THE TEXTILE INDUSTRY IN INDIA

Looking FOR REFORMs

The Indian textile industry is considered amongst one of the leading textile industries in the

world. It is divided into three segments, namely, cotton, synthetic and other textiles such as

jute, wool and silk. Apart from providing the basic necessities in the life of Indian people, it

plays a significant role in the country’s economic growth.

E

ither directly or in-

directly, it has been

estimated that one of

every six households

in the country depends

on the Indian textile industry for its

livelihood. The strong roots of pro-

duction of cotton yarns and ample

skilled and unskilled workers and

good export potential are the major

characteristics of the Indian textile

industry. This is a traditional, rich

and well-established industry, enjoy-

ing considerable demand in the do-

mestic as well as global markets.

Role of the

ers of cotton yarn in the world and try used to import massive quanti-

textile industry

there are good resources of fibres. ties of cotton in the range of 0.8 to

in Indian economy The country has a wide range of cot- 0.9 million bales per annum.

Indian textile industry contributes ton fibre and has a rapidly develop- However, after government

about 14 per cent to industrial produc- ing synthetic fibre industry. launched special schemes such as

tion, 4 per cent to the country’s gross The increase in the production of intensive cotton production pro-

domestic product (GDP) and 17 per cotton yarn from past two decades is grammes through successive five-

cent to its export earnings. Further, as follows: year plans, cotton production re-

it is a source of direct employment for Cotton production in India. ceived the necessary growth through

over 35 million people, which makes it The production of cotton yarn in- increase in area and sowing of hy-

the second largest provider of employ- creased from 3.43 million bales in brid varieties around mid 70s.

ment after agriculture. 1950-51 to 11.614 million bales in Since then, the country has be-

India has the advantage of abun- 2012-13. The growth rate increased come self-sufficient in cotton pro-

dant resources of raw materials. by about 10 per cent per annum. duction, barring a few years in the

The Indian textile industry has the Over the years, country has achieved late 90s and early 2000s when large

strength of a strong cotton produc- significant quantitative increase in quantities of cotton had to be im-

tion. It is one of the largest produc- cotton production. Till 1970s, coun- ported due to lower crop production

www.ffymag.com April 2014 • FACTS FOR YOU 23

Market Survey

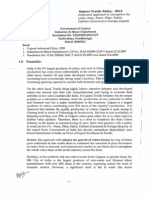

Table I cotton production per global rates.

hectare in the near Allocation for TUF was raised

Production and Yield of Cotton future. from ` 5.35 billion in 2006-07 to `

as per Area

Apart from meet- 9.11 billion in 2007-08. Handlooms

Year Area Production Yield ing the increased cot- are now covered under the TUF

(million (million bales (kilograms ton consumption by scheme. This scheme continues with

hectares) of 170 kg) per hectare)

domestic textile in- an investment target of ` 1510 bil-

1950-51 5.882 3.43 99 dustry, country may lion in the 12th plan (2012-17).

1960-61 7.61 6.012 134 have sufficient sur- Excise Duty Scheme. The ex-

1970-71 7.605 5.664 127 plus cotton to meet cise duty of yarn has increased from

1980-81 7.823 7.8 169 the requirements of four per cent to five per cent. The

1990-91 7.439 11.7 267 importing countries. mandatory excise duty of ten per

cent imposed on branded readymade

2000-01 8.576 14 278

Export garments would not only have seri-

2001-02 8.73 15.8 308

ous adverse impact to these highly

2002-03 7.667 13.6 302 scenario

labour-intensive segments but

2003-04 7.63 17.9 399 There was a sig- would also have significant opera-

2004-05 8.786 24.3 470 nificant growth in the tional problems for implementation.

2005-06 8.677 24.1 472 industry from 2010-11 Since most inputs for these seg-

2006-07 9.144 28 521 to 2011-12. Exports in ments would be coming through op-

2007-08 9.414 30.7 554 readymade garments tional excise duty regime, there will

2008-09 9.406 29 524 stand first and succeed- be very little duty credit to be uti-

2009-10 10.31 30.5 503 ing industries are cot- lised for payment of excise duty.

ton textiles, manmade Foreign Direct Investment

2010-11 11.142 339 517

and woollen fabrics. (FDI) Policy. One hundred per cent

2011-12 12.178 35.3 493

There are quit a FDI is allowed in the textile sector

2012-13 11.614 33.4 489 few companies play- under the automatic route. FDI in

Source: Ministry of Textiles and Cotton Advisory Board ing a key role in the sectors to the extent permitted under

industry and the ma- automatic route does not require any

and increasing cotton requirements jor companies are as mentioned in prior approval either by the govern-

of the domestic textile industry. Table III. ment of India or Reserve Bank of India

The Technology Mission on Cot- (RBI). The investors are only required

ton had been launched by the gov- Government initiatives to notify the regional office concerned

ernment of India in February 2000 of RBI within 30 days of receipt of in-

and support

for development of high yielding ward remittance. Ministry of Textiles

varieties, appropriate transfer of Government of India has initi- has set up an FDI cell to attract FDI in

technology, better farm manage- ated many schemes for textile indus- the textile sector in the country. The

ment practices and increased area try, such as: FDI cell has objectives such as: provide

under cultivation of BT cotton hy- The Technology Upgradation assistance and advisory support, assist

brids. These developments have re- Fund Scheme. Technology is the foreign companies in finding out joint

sulted into a really good turnaround key aspect to being competitive in the venture partners, sort out operational

in cotton production in the country global scenario. Owing to this reason, problems, maintenance and monitor-

from 2006-07. The yield per hectare, the government of India established ing of data pertaining to domestic and

which was stagnant at about 300kg the Technology Upgradation Fund international trade.

per hectare for more than 10 years, Scheme (TUFS) on April 1, 1999 to India’s share in global exports is

increased substantially and reached enable firms to access low-interest about four per cent. The export shares

a level of 554kg per hectare in the loans for technology upgradation. of the countries such as Korea, Tai-

cotton season of 2007-08. Under this scheme, the govern- wan, Mexico and Turkey are ahead

The fundamental changes that ment reimburses five per cent of and far better than India. Lack of

are taking place in the realm of cotton the interest rates charged by the upgradation of technology and manu-

cultivation in the country have the banks and financial institutions, facturing quality of products are the

potential to take the current produc- thereby ensuring credit availability main reasons for India lagging behind

tivity level near to the world average for upgradation of the technology at as compared to other countries.

24 FACTS FOR YOU • April 2014 www.ffymag.com

Market Survey

SWOT analysis Table II

Strengths. Production and Yield of Cotton in Various States of India

1. Abundant raw material avail- State 2010-11 2011-12

ability Area Production Yield Area Production Yield

2. Availability of low-cost man-

Punjab 0.53 1.6 513 0.56 1.7 516

power

Haryana 0.492 1.4 484 0.605 1.6 450

3. Growing economy and poten-

tial in domestic as well as interna- Rajasthan 0.335 0.9 457 0.53 1.5 481

tional market North total 1.357 3.9 489 1.695 4.8 481

Weaknesses. Gujarat 2.633 10.3 665 3.023 11.5 647

1. Lack of technological develop- Maharashtra 3.932 8.2 355 4.095 8.5 353

ment. India is one of the largest pro- Madhya Pradesh 0.6.5 1.7 445 0.706 1.8 433

ducers of cotton in the world. It is Central total 7.215 20.2 476 7.824 5.5 504

extremely important for the industry Andhra Pradesh 1.784 5.3 505 1.854 5.5 504

to adopt a technologically advanced

Karnataka 0.545 1 312 0.549 1.4 434

manufacturing process. But Indian

Tamil Nadu 0.122 0.5 697 0.121 0.5 702

textile industry is technologically

weak. For instance, Surat, Bhiwandi South total 2.451 6.8 472 2.524 7.4 498

and Sholapur are the renowned places Orissa 0.075 0.2 459 0.102 0.2 333

for fabric industries. Instead of replac- Others 0.045 0.2 756 0.046 0.2 739

ing new machinery, the outdated ones Total — 31.3 — — 34.4 —

are being used. China does not enter- Loose lint — 1.2 — — 1.2 —

tain the outdated ones and upgrades Grand total 11.142 32.5 496 12.191 35.6 496

and grabs the latest technology. While

**Area in million hectares; Production in million bales of 170 kg; Yield kg per hectare

the share of shuttleless looms in Chi- Source: Ministry of Textiles and Cotton Advisory Board

na is 23 per cent, in India traditional

handweave methods have been fol-

lowed usually and the shuttleless Opportunities. The following line between handloom and cotton

looms are only two per cent. are the opportunities: industry. Additionally, it is a wrong

2. Rigid government policies. 1. Large domestic and interna- perception of the government that

There are no proper reforms, which tional market potential these fabrics are only for traditional

is the major cause of industrial cri- 2. Retail industry and malls. The wear.

sis. Nineteen states in India culti- increase in the number of retail in- 2. Competition from other coun-

vate cotton but only a few states dustries and shopping malls can pro- tries—staggering performance of

such as Tamil Nadu, Maharashtra, vide huge opportunities. Further, the China. This sector has 18 per cent of

West Bengal, Odisha, Assam and An- market is gradually shifting towards share in China’s GDP. It depicts the

dra Pradesh undertake manufactur- branded readymade garments which magnificent status of China in the

ing of fabric. Even though there is can increase the opportunities further. sector. Cottage industries manufac-

a huge production of cotton but the Threats. ture fabrics in ample in this country.

yarn is unavailable. Yarn mills focus 1. Unstable price. There is a high It is appreciable that China has used

more on export than on the nation’s uncertainty and also unstable prices the local cotton for the purpose of

requirements. in the market. Owing to this, the us- country’s necessities. The exports

Further, there is no stability in age of cotton is not very high. Farm- take place only after meeting the

the prices of cotton that is used for ers resort to strike for getting mini- country’s requirement.

fabric manufacture. National Hand- mum support price in the market, Further, China’s motto is to gain

loom Development Corporation fails and yarn mills suffer if the price of high productivity by having less

to supply the yarn to looms at subsidy cotton increases. pressure on labour. Hence, they have

and it is the same in case of silk too. Government fails to meet the upgraded their technology, machines

Owing to the unstable prices in India, targets and is unable to resolve the and equipment.

traders import silk from China. India issues. India has huge cotton stocks 3. Threat for traditional market.

is rich in wool cultivation and is ex- but still industries are confined to a India is the second largest country

porting wool to other countries. few cities. In India, there is a divide in cultivating cotton and silk and

www.ffymag.com April 2014 • FACTS FOR YOU 25

Market Survey

this industry is pitiable. Though the

Table III

number of weaving machines were

Different Companies in the Indian Textile Industry increased but the industry failed to

Company Business areas sell its produce, and so the very less

Welspun India Ltd Home textiles, bathrobes and terry towels growth in exports has pushed the

sector into crisis.

Vardhman Group Yarn, fabric, sewing threads and acrylic fibre Approximately 30 schemes are

Alok Industries Ltd Home textiles, woven and knitted apparel, fabric garments and being implemented in the sector.

polyester yarn But there is no parity in fund dis-

Raymond Limited Worsted suiting, tailored clothing, denim, shirting, woollen outerwear tribution. Tirupur is one of the best

instances amongst many. It has

Arvind Mills Ltd Spinning, weaving, processing and garment production (denims,

been a role model and benchmark

shirting and khakis)

for India in terms of employer-la-

Bombay Dyeing & Bed linen, towels, furnishings, fabric for suits, shirts, dresses and bour team work and skilled work.

Manufacturing Company Ltd saris in cotton Similar spirit can be observed in

Garden Silk Mills Ltd Dyed and printed fabric Panipat fabric industry too at Har-

Aditya Birla Nuvo Ltd Madura Garments Lifestyle Retail Company Ltd yana. Unfortunately, the Andhra

(diversified conglomerate) Jaya Shree Textiles-Domestic linen and worsted yarn Pradesh units are unable to follow

Indian rayon- viscose filament yarn their examples.

Necessary actions. Excellent

ITC Lifestyle Lifestyle market

schemes and policies are already in

Reliance Industries Ltd Fabric and formal menswear existence but have failed in imple-

mentation. These is a dire need for

seventh largest country in the pro- Table IV vision, skill development, employ-

duction of wool all over the world. ment targets, welfare and market-

Global Textile Industry ing.

On the contrary, cotton industry has

and its Market Share of

only four per cent share in nation’s Subsidies. The present subsi-

Major Countries

GDP. This depicts the status of the dies and amenities provided by the

sector in India. Country Market share government have failed to catch the

4. Absence of reforms. Most of (per cent) industrialists’ attention. Indeed,

the cotton produced in India is be- Korea 22 textile industries can generate more

ing exported. Merely 19 per cent of Taiwan 21 employment than IT and pharma.

the cotton is meeting the nation’s China 18 But the government has failed in

requirements. Turkey 9 setting the standards.

Delays in disbursement of funds

Mexico 9

Status in Andhra Pradesh are causing slackness in the indus-

Pakistan 6

try. The government should also

India 4

In Tamil Nadu, technology focus on avoiding delay in disburse-

upgradation is comparatively better Others 11 ment of funds under Technology

than in Andhra Pradesh. Hence, the Source: GDP share of respective country websites Upgradation Fund Scheme.

productivity level is high. Further, Promotional activities. The

inspired by China’s technology, In- try. For instance, fabric industry sector requires promotional pro-

dia introduced technology upgrada- started three decades ago in Tiru- grammes, finance support, employ-

tion fund by spending ` 170 billion. pur at Tamil Nadu. It faced many ment generation programmes, mod-

Still it fails to meet the expectations. impediments, difficulties and crises ernisation of technology, subsidies,

Textile industry generates em- but it overcame all the barriers. At raw material supply, design and

ployment next only to agriculture. It present, it is exporting ` 150 billion technology assistance, and training

is such a crucial sector for employ- worth of fabrics to various places. and skill upgradation.

ment, but the laxity in the policy im- On the contrary, Andhra

plementation is adding to the woes Pradesh pioneered this industry at Swetha Thiruchanuru is a UGC-senior

of the sector. Sirisilla earlier than Tamil Nadu. research fellow while Dr K. Venugopal

Rao is a professor at Sri Krishnadevar-

The regional disparities have a But Andhra Pradesh has been fac- aya Institute of Management (SKIM),

bad affect on India’s cotton indus- ing crisis and the current status of Anantapur, Andhra Pradesh

26 FACTS FOR YOU • April 2014 www.ffymag.com

View publication stats

You might also like

- Pharma Companies IndiaDocument15 pagesPharma Companies Indiaganesh kondikire100% (1)

- Libro InglésDocument67 pagesLibro InglésAmanda Laynez Bermúdez100% (1)

- Operation Management in Textile IndustryDocument83 pagesOperation Management in Textile IndustryRishi Khanna57% (14)

- The Textile Industry in India Looking For Reforms: April 2014Document5 pagesThe Textile Industry in India Looking For Reforms: April 2014vinaymeenaNo ratings yet

- Neeru ProjectDocument232 pagesNeeru ProjectNeeraj Kumar RaviNo ratings yet

- Annual Report Textile IndustryDocument258 pagesAnnual Report Textile IndustryHitesh DemlaNo ratings yet

- Elite Fabs Deva - MsDocument51 pagesElite Fabs Deva - MsDevaragulNo ratings yet

- Textiles AnnualReport2018 2019 (English) PDFDocument263 pagesTextiles AnnualReport2018 2019 (English) PDFPallavi IngaleNo ratings yet

- Textile Ministry of IndiaDocument290 pagesTextile Ministry of IndiaSrujan KumarNo ratings yet

- Finance Project - TextileDocument72 pagesFinance Project - TextilePooja Bindal100% (1)

- Cotton Fibre Quality ResearchDocument11 pagesCotton Fibre Quality ResearchprabhjotseehraNo ratings yet

- Century Enka Limited: BUY Industry: TextilesDocument5 pagesCentury Enka Limited: BUY Industry: TextilesChanduSaiHemanthNo ratings yet

- Spinning Project Profile FinalDocument23 pagesSpinning Project Profile FinalFaizan Motiwala67% (3)

- Research Report On Spinning Sector of Bangladesh-InitiationDocument24 pagesResearch Report On Spinning Sector of Bangladesh-InitiationjohnsumonNo ratings yet

- Govt Schemess Sep 2021Document6 pagesGovt Schemess Sep 2021DinakarNo ratings yet

- Indian Textile IndustryDocument7 pagesIndian Textile IndustrySuvan MahajanNo ratings yet

- Indian Ready Made Garments (Apparel) IndustryDocument17 pagesIndian Ready Made Garments (Apparel) IndustryGauravsNo ratings yet

- Statstics of Readynade Garments in Apparel IndustryDocument17 pagesStatstics of Readynade Garments in Apparel IndustryTanmay JagetiaNo ratings yet

- V. Indian Textile and Apparel Sector: An Analysis of Aspects Related To Domestic Supply and DemandDocument28 pagesV. Indian Textile and Apparel Sector: An Analysis of Aspects Related To Domestic Supply and DemandPRIYANKA H MEHTANo ratings yet

- Textile Industry'S Economic ContributionDocument58 pagesTextile Industry'S Economic ContributionRabya AlyNo ratings yet

- Cotton Yarn Project ProfileDocument20 pagesCotton Yarn Project ProfilesajidaliyiNo ratings yet

- Profile On Production of Jute BagsDocument20 pagesProfile On Production of Jute BagsM A Akad MasudNo ratings yet

- World: Cotton Yarn - Market Report. Analysis and Forecast To 2020Document7 pagesWorld: Cotton Yarn - Market Report. Analysis and Forecast To 2020IndexBox MarketingNo ratings yet

- Pakistan Textile Industry of Pakistan: Consulate General of Switzerland - KarachiDocument19 pagesPakistan Textile Industry of Pakistan: Consulate General of Switzerland - KarachiSadia KhawajaNo ratings yet

- A Project On The Spinning Industry of India: BY Deepak Luniya Roll No: 290Document45 pagesA Project On The Spinning Industry of India: BY Deepak Luniya Roll No: 290deepakluniyaNo ratings yet

- Quantitative and Qualitative Requirements of Cotton For IndustryDocument4 pagesQuantitative and Qualitative Requirements of Cotton For IndustrySabesh MuniaswamiNo ratings yet

- Structural Change, Technology and Employment in The Indian Textile Industry:1980-2010Document22 pagesStructural Change, Technology and Employment in The Indian Textile Industry:1980-2010Krishna KumarNo ratings yet

- Project Profile On Woven Fabric of Cotton Yarn: By: Team MembersDocument14 pagesProject Profile On Woven Fabric of Cotton Yarn: By: Team MemberssajidaliyiNo ratings yet

- Textile Business:: Fabric Science Assignment: Term 01Document32 pagesTextile Business:: Fabric Science Assignment: Term 01Shan AtrayNo ratings yet

- Gauze and BandageDocument26 pagesGauze and BandageRobel KefelewNo ratings yet

- Metal ZippersDocument25 pagesMetal ZippersEliasNo ratings yet

- Fazal Cloth1Document59 pagesFazal Cloth1FaiEz AmEen KhanNo ratings yet

- Project Profile On The Establishment of Commercial Starch Producing Plant Promoter: Dagnachew Kassahun Tel: 0918353443Document34 pagesProject Profile On The Establishment of Commercial Starch Producing Plant Promoter: Dagnachew Kassahun Tel: 0918353443Rass Getachew100% (1)

- Textiles Sector - Achievement ReportDocument12 pagesTextiles Sector - Achievement ReportAnkitaNo ratings yet

- Textile and GarmentsDocument10 pagesTextile and Garmentssameer7986No ratings yet

- Textil Proposal13Document44 pagesTextil Proposal13mesfin eshete0% (1)

- Finance Project in Indian Cotton TextileDocument109 pagesFinance Project in Indian Cotton TextileRoyal ProjectsNo ratings yet

- Innovation and Technological Advancement in SpinningDocument9 pagesInnovation and Technological Advancement in SpinningSeveshNo ratings yet

- Cotton YarnDocument29 pagesCotton YarnThomas MNo ratings yet

- Chapter 1Document67 pagesChapter 1satseehraNo ratings yet

- Textile Industry - Colg Report - VardhmanDocument70 pagesTextile Industry - Colg Report - Vardhmanr_734100% (1)

- Pakistan Textiles Industry Challenges and SolutionsDocument12 pagesPakistan Textiles Industry Challenges and SolutionsMuqadas RehmanNo ratings yet

- A Crisis in Textile Industry in PakistanDocument21 pagesA Crisis in Textile Industry in Pakistanhashimali455100% (1)

- Bombay Dyeing Polyester Staple FiberDocument14 pagesBombay Dyeing Polyester Staple Fiberk_pareshNo ratings yet

- Textilies Sector Presentaion FICCIDocument15 pagesTextilies Sector Presentaion FICCIrjjain07No ratings yet

- Equity Research: Group AssignmentDocument16 pagesEquity Research: Group AssignmentMuskan BhartiaNo ratings yet

- 19 Laminated LeatherDocument19 pages19 Laminated LeatheryenealemNo ratings yet

- Gujarat Textile Policy 2012Document15 pagesGujarat Textile Policy 2012Michael KingNo ratings yet

- Umbargaon PowerloomDocument34 pagesUmbargaon PowerloomArchit SahareNo ratings yet

- Jute Industry Challanges & Opportunities in BangladeshDocument5 pagesJute Industry Challanges & Opportunities in Bangladeshsafkata_1No ratings yet

- Scenario of Textile Industry in BangladeshDocument23 pagesScenario of Textile Industry in BangladeshDewan Ajuad Hossain RifatNo ratings yet

- My SoreDocument38 pagesMy SoreRa Hu L MalladiNo ratings yet

- Textile Industry Risk Report DraftDocument35 pagesTextile Industry Risk Report Draftgujugu007No ratings yet

- Sustainable Innovations in Textile Chemical ProcessesFrom EverandSustainable Innovations in Textile Chemical ProcessesNo ratings yet

- Global Forest Sector Outlook 2050: Assessing Future Demand and Sources of Timber for a Sustainable EconomyFrom EverandGlobal Forest Sector Outlook 2050: Assessing Future Demand and Sources of Timber for a Sustainable EconomyNo ratings yet

- Reaching Zero with Renewables: Biojet FuelsFrom EverandReaching Zero with Renewables: Biojet FuelsNo ratings yet

- Harnessing the Fourth Industrial Revolution through Skills Development in High-Growth Industries in Central and West Asia—UzbekistanFrom EverandHarnessing the Fourth Industrial Revolution through Skills Development in High-Growth Industries in Central and West Asia—UzbekistanNo ratings yet

- Tales from the Development Frontier: How China and Other Countries Harness Light Manufacturing to Create Jobs and ProsperityFrom EverandTales from the Development Frontier: How China and Other Countries Harness Light Manufacturing to Create Jobs and ProsperityNo ratings yet

- Policies to Support the Development of Indonesia’s Manufacturing Sector during 2020–2024: A Joint ADB–BAPPENAS ReportFrom EverandPolicies to Support the Development of Indonesia’s Manufacturing Sector during 2020–2024: A Joint ADB–BAPPENAS ReportNo ratings yet

- Food Outlook: Biannual Report on Global Food Markets: June 2020From EverandFood Outlook: Biannual Report on Global Food Markets: June 2020No ratings yet

- Food Outlook: Biannual Report on Global Food Markets: June 2022From EverandFood Outlook: Biannual Report on Global Food Markets: June 2022No ratings yet

- - मुख्यमंत्री सीखो कमाओ योजनाDocument81 pages- मुख्यमंत्री सीखो कमाओ योजनाAmitNo ratings yet

- Composites: Action. According To This Principle, Better Combinations Are Fashioned by The Judicious Combination of TwoDocument1 pageComposites: Action. According To This Principle, Better Combinations Are Fashioned by The Judicious Combination of TwoRollysa MelaniasariNo ratings yet

- 1 3-WheatDocument9 pages1 3-WheatGohar AhmadNo ratings yet

- Development of PLA Hybrid Yarns For Biobased SelfDocument7 pagesDevelopment of PLA Hybrid Yarns For Biobased SelfTehseen MarwatNo ratings yet

- Passion Fruit Sector Document Version 1Document11 pagesPassion Fruit Sector Document Version 1Klara HarrisNo ratings yet

- Lesson 23 - Contract ManufacturingDocument15 pagesLesson 23 - Contract ManufacturingkannanNo ratings yet

- Group1 - SDRM End Term ProjectDocument22 pagesGroup1 - SDRM End Term ProjectYatin ChopraNo ratings yet

- JMBahemuka FoodSecurityInKenyaDocument19 pagesJMBahemuka FoodSecurityInKenyadan yaganNo ratings yet

- Investment in Date Palm Wood Waste Recycling Projects 2010Document4 pagesInvestment in Date Palm Wood Waste Recycling Projects 2010شركة الهلال للحج والعمرةNo ratings yet

- Chapter - 1: The Story of Village PalampurDocument6 pagesChapter - 1: The Story of Village Palampurrita sinhaNo ratings yet

- Tara Pharmacology PDF Medicalstudyzone - Com - CompressedDocument572 pagesTara Pharmacology PDF Medicalstudyzone - Com - Compressedunbridled.instinct.218No ratings yet

- Forest Society and ClononialismDocument4 pagesForest Society and Clononialism2No ratings yet

- Deterioration of AgricultureDocument3 pagesDeterioration of AgricultureMadhavan SeenivasanNo ratings yet

- Grade 9 Moving UpDocument70 pagesGrade 9 Moving UpMarian CoperNo ratings yet

- Story of Village PalampurDocument18 pagesStory of Village PalampurShaurya ManiktalaNo ratings yet

- List of Units in BawanaDocument65 pagesList of Units in BawanaPrasuk JainNo ratings yet

- Market Growth Business DirectoryDocument14 pagesMarket Growth Business DirectoryAman DubeyNo ratings yet

- Gateway and Apple: Two Different Journey Into Retailing: Aiub/Fba/Mba/ScmDocument1 pageGateway and Apple: Two Different Journey Into Retailing: Aiub/Fba/Mba/ScmShowkatNo ratings yet

- Aex 102 - Artificial Intelligence in AgricultureDocument14 pagesAex 102 - Artificial Intelligence in AgricultureBhuvanesh NagamaniNo ratings yet

- Infinitigroup: A Better WayDocument52 pagesInfinitigroup: A Better WayMartinus Bagus WicaksonoNo ratings yet

- Mysec Clo AugDocument4 pagesMysec Clo AugAsharam MaharanaNo ratings yet

- Price List - Service Packages & Plans Residential Services - Emerald Neopolis Karawang - 2021Document1 pagePrice List - Service Packages & Plans Residential Services - Emerald Neopolis Karawang - 2021Bernisela DamaraNo ratings yet

- Certificate Programme in Food:And Nutrition (CFN) Term-End Examination December, 2019Document8 pagesCertificate Programme in Food:And Nutrition (CFN) Term-End Examination December, 2019Rohit GhuseNo ratings yet

- Halal Standard (VHM)Document26 pagesHalal Standard (VHM)AHMAD MUSTA’AIN BIN AHMAD SUKERINo ratings yet

- New Yorker Electronics Adds 25 Manufacturers To Their Line CardDocument4 pagesNew Yorker Electronics Adds 25 Manufacturers To Their Line CardPR.comNo ratings yet

- Bank Invoice 0105 REVISEDDocument1 pageBank Invoice 0105 REVISEDFarah GoganNo ratings yet

- 01 1410 WallinDocument5 pages01 1410 WallinVictor HernandezNo ratings yet

- GPP Calendar of Activities 2022 23 SdoDocument5 pagesGPP Calendar of Activities 2022 23 SdoRomel GarciaNo ratings yet