Professional Documents

Culture Documents

Office Space Interior B.O.Q. (Egypt)

Office Space Interior B.O.Q. (Egypt)

Uploaded by

Moustapha AlgoharyOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Office Space Interior B.O.Q. (Egypt)

Office Space Interior B.O.Q. (Egypt)

Uploaded by

Moustapha AlgoharyCopyright:

Available Formats

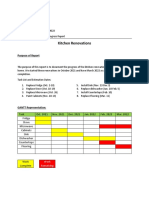

Bill of Quantities

Interior Works

Division Total

Description

(EGP)

SUMMARY

DIVISION 01 GENERAL REQUIREMENTS -

DIVISION 04 MASONRY

DIVISION 05 METALS

DIVISION 06 WOOD AND PLASTICS

DIVISION 07 THERMAL AND MOSITRUE PROTECTION

DIVISION 08 OPENINGS

DIVISION 09 FINISHES

DIVISION 10 SPECIALTIES

DIVISION 12 FURNISHINGS

DIVISION 21 FIRE SUPRESSION SYSTEM

DIVISION 22 PLUMBING WORKS

Sub-total -

Value Added Tax (VAT) on Contracting Services -

Total Construction Works

-

Inclusive of OH&P, Social Insurances and VAT

Summary page 1 / Project Code :

Item Description Qty Unit Rate (EGP) Total (EGP)

The Contractor

DIVISION is responsible

01 GENERAL for all co-ordination and data

REQUIREMENTS

collection from all suppliers , subcontractors, vendors and

manufacturers involved in the project regardless they are

A

assigned by him or by the client or by the landlord to ensure

delivering the best quality works and on a proper time as the

The contractor is to note that other contractors/suppliers

following

shall be given access to parts of the Works on

a particular date(s) notified to him in advance to

commence any works. The contractor is

understood to be aware that he will not have

the sole use of the site at all times and is

understood to have allowed for working with

other contractors/suppliers as per the instructions of the

Employer and/or his Consultants. The contractor

shall also allow for the protection of any

nuisance and/or obstruction to other contractors

engaged in or around the site 1 LS Included Included

The contractor shall coordinate all builder's work

drawings and working drawings, coordinate

subcontractors, other contractors assigned by the Employer

and any Statutory undertakings,

or others, works to ensure that each installation is

properly assembled and erected.

B The contractor is to provide all attendances,

general and special, on other contractors for the

duration of the works, this will include payment 1 LS Included Included

of electricity and water charges provided to other

contractors

C The Contractor is responsible to pay the cost

of water or electrical consumptions and

network pipes, during construction and fit out phase 1 LS Included Included

D The Contractor shall set out below and price

any other item which is necessary to complete

the works in accordance with the requirements of

specifications and other Contract Documents 1 LS Included Included

conditioned that the query is not listed or indicated

in the drawings (approval fom consultant & PM)

E Shop drawings, technical submittals, method

statement to be submitted to consultant for

approval before executing Works 1 LS Included Included

The Contractor to submit the as-built drawings from day one

F

of receiving the site cleared from any obstacles.

Also the contractor will submit again after execution of Works

1 LS Included Included

to be reviewed by consultant for approval.

And that for Civil , Arch and MEP.

G All installations shall be in conformity with the

latest regulations of local authorities and

international installation standards. These design

drawings/ documents shall be considered as

minimum requirements 1 LS Included Included

the contractor should make the soil borehole before starting

1 LS Included Included

any concrete works

Carried Forward -

01 General Requirements page 2 / Project Code :

Brought Forward -

The Contractor is responsible to coordinate all permits

from

civil defense , from authority govenrment and Mogama

1 LS Included Included

Elshriea

regardingbut the permits

permits, will be provided

the Consultant by client

responsible for provide all

documents

H The Contractor shall comply with the HSE policy

including but not limited

to permits for works, PPEs for all parts, training, etc. 1 LS Included Included

Equipment tests are limited to witness tests in Egypt. The

I Contractor must provide certificates of testing when applicable,

and warranties. Testing on site shall be required though. 1 LS Included Included

J Providing All needed training for operation. 1 LS Included Included

Providing All needed documentation ,warranty , certificates or

K

catalogues, etc.

1 LS Included Included

L Every item mentioned rate only , the contractor should submit

the full breakdown if requested.

DIVISION 1 GENERAL REQUIREMENTS (Cont'd)

Site facilities

A The Contractor is responsible to supply, install,

clean and maintain during the project duration

three separate closed rooms with dimensions

4x5 m all well painted; each room

two rooms should include AC suitable for the room

dimensions and all rooms should be secured by a door and

the three rooms should not be connected, for the

Employer team, the consultants team and the

samples . Each of the teams rooms should be furnished by

four desks, four employee chairs, six visitors chairs

and three lockers one of them should be safety

locker. The samples room shall be furnished by three

racks and the needed shelves

each room should be equipped by water cooler and coffee

machine and provide drinks during the project time. 1 LS Included Included

Photo copier separate for the consultant including all ink and

B paper supplies needed during the whole project duration, 1 LS Included Included

photo copier for all documents

C meeting room with a suitable

meeting table at least 20 seats to be attached

to the three offices and Aircooled 1 LS Included Included

E Allowance for mobilization through the entire project

life-cycle. 50% at first interim payment after

mobilization and the other 50% through five

equal installments afterwards 1 LS Included Included

The contractor should insure the internet connectivity on all

F

rooms via vodafone network only on his cost

1 LS Included Included

the contractor should make mock up , and submit all samples

if requested 1 LS Included Included

Carried Forward -

01 General Requirements page 3 / Project Code :

Brought Forward -

For items that have rate only or on provisional

sum

price, ,the contractor

and shouldshall

the Contractor provide a reasonable

submit a breakdown upon

request from the Employer and/or any of his Consultants

that might be subjected to revised price.

DIVISION 1 GENERAL REQUIREMENTS TO SUMMARY -

01 General Requirements page 4 / Project Code :

Item Description Qty Unit Rate (EGP) Total (EGP)

DIVISION 04 MASONRY

Scope of works of all items in accordance with the

preambles; and as detailed on drawings and

described in specifications. All rates shall include

for complying with the requirements therein

Internal Or External Walls

Supplying & constructing masonry block walls for

various spaces made of solid cement blocks or

perforated red blocks 250x120x60mm produced by

"Modern" "MISRCRETE", "TECHNO CRETE" or

similar including making openings for

windows & doors within new and existing walls with

the necessary lintels as per detailed drawings,

opening for necessary electro-mechanical works.

- fulfilling the hereinafter specifications: Connecting

the newbrick walls to the existing brick walls. Fixing

the brick wall to the building structure with

galvanized steel ties every 500 mm.Cement mortar

with minimum content of normal Portland

cement 300 kg/m3 with Providing R.C. Intermediate

tie Beams & lintels 120 or 250x300mm reinforced

with 3Ø12 top & bottom and stirrups Ø8/200mm.

The R.C. Beam shall be provided at 2200mm height.

Complete works including supplying and casting

concrete Class (fcu 350kg/cm²) with min. content

of Normal Portland Cement 400kg/m3, rough

shuttering,supplying, placing, compacting of

concrete,dismantling of form work, curing and

testing,...etc. Strength not less than 100 kg/cm²

A Masonry Brick Walls 120mm Thick. 20 m²

B Masonry Brick Walls 250mm Thick or Higher 3 m3

Carried Forward -

04 Masonry page 5 / Project Code :

Brought Forward -

Additional items

Contractor to list here any additional items shown

on drawings or specifications; not priced elsewhere

in the bills of quantities and requires to complete

and handover the works; any quantities difference or

quantities adjustment to bill of quantities; separate

breakdown to be submitted

DIVISION 4 MASONRY TO SUMMARY -

04 Masonry page 6 / Project Code :

Item Description Qty Unit Rate (EGP) Total (EGP)

DIVISION 05 METALS

Scope of works of all items in accordance with the

preambles, and as detailed on drawings and

described in specifications. All rates shall include

for complying with the requirements therein

Decorative Metal Separator

Supplying and installing wall Brass separator, thickness 4

mm , width 2 cm , else .. with the approved groves or

configuration, stain finish with color as per the approved 14 m

sample. Samples & shop drawings must be submitted to Client

and Supervision for approval prior to commencing any works.

8 m²

Carried Forward

05 Metals page 7 / Project Code :

Brought Forward

Additional items

Contractor to list here any additional items shown

on drawings or specifications; not priced elsewhere

in the bills of quantities and requires to complete

and handover the works; any quantities difference or

quantities adjustment to bill of quantities; separate

breakdown to be submitted

DIVISION 12 FURNISHINGS TO SUMMARY -

05 Metals page 8 / Project Code :

Item Description Qty Unit Rate (EGP) Total (EGP)

DIVISION 06 WOOD AND PLASTICS

Scope of works of all items in accordance with the

preambles, and as detailed on drawings and

described in specifications. All rates shall include

for complying with the requirements therein

Rough carpentry

Pantry Units & Refreshment Point

kitchen furniture composed of :

upper AND/OR lower cabinets made of pressed wood

timber boards 18mm thick. Externally and internally

quality, color, texture and HPL or PolyLAC lipping.

A Complete work as shown on detail drawing, including

sub-structure works for hanging, smooth mechanism

for drawer units, hinges, locks, glossy (chrome color)

ST/ST drawer knobs and cupboard handles, etc.

Any local supplier but should to submit for approval before work

Include the oak veneer lextured laminate OR white

8 m²

laminate finish countertop with steel structure fixing

06 Wood and Plastics page 9 / Project Code :

Carried Forward

06 Wood and Plastics page 10 / Project Code :

Brought Forward

Additional items

Contractor to list here any additional items shown

on drawings or specifications; not priced elsewhere

in the bills of quantities and requires to complete

and handover the works; any quantities difference or

quantities adjustment to bill of quantities; separate

breakdown to be submitted

06 Wood and Plastics page 11 / Project Code :

DIVISION 12 FURNISHINGS TO SUMMARY -

06 Wood and Plastics page 12 / Project Code :

Item Description Qty Unit Rate (EGP) Total (EGP)

DIVISION 07 THERMAL AND MOSITRUE

PROTECTION

WATERPROOFING & MOISTURE PROTECTION

Supplying and applying of Flexible Waterproofing, by

two coats of Sika Latex and two coats of Sika Seal

107 manufactured by Sika or add two coats of

cementitious insulation for the flooring and walls

including felt layer , Primer layer, two plaster layers

and testing by the manufacturer approved installer

Waterproofing The manufacturer recommendation for

the application must be followed. The Works must be

done through the one of the certified applicator by

the manfacturer. Certificate of Guarantee must be

provided by the contractor , Should submit 10 years

warranty

7.1 For toilets , pantry Areas 33 m²

07 Thermal & Moisture page 13 / Project Code :

Carried Forward

07 Thermal & Moisture page 14 / Project Code :

Brought Forward

Additional items

Contractor to list here any additional items shown

on drawings or specifications; not priced elsewhere

in the bills of quantities and requires to complete

and handover the works; any quantities difference or

quantities adjustment to bill of quantities; separate

breakdown to be submitted

07 Thermal & Moisture page 15 / Project Code :

DIVISION 07 THERMAL & MOISTURE TO SUMMARY

07 Thermal & Moisture page 16 / Project Code :

Item Description Qty Unit Rate (EGP) Total (EGP)

DIVISION 8 OPENINGS

Scope of works of all items in accordance with the preambles;

and as detailed on drawings and described in specifications.

All rates shall include for complying with the requirements

therein

WOOD DOORS AND FRAMES

Supply and installation of wood doors and frames; The door

frame shall be of the partition width / wall width for thickness

up to 160mm and with 100mm width for higher thickness for

walls. Meeting Rooms doors shall provide a sound

transmission rate of not more that 40 dp. The door shall be

solid core flush made of hardwood frame, hardwood with

hardwood lipping and three-ply cross banded plywood with "A"

grade face cladding 6mm thickness for door leaf with a total

door leaf thickness of min. 50mm.

Plywood shall be cladded with Natural Oak veneer and lipping

and the price should include any decorative CNC graving and

heavy duty according to approved sample.Doors shall be

supplied complete with extruded timber frame, 4x heavy duty

ball bearing hinges produced by Lince, casa or similar, lock

with 3 keys -, All hardware is TESA brand or similar,door

stopper and door closer, two stainless steel pushing strips - as

per door type complete as shown on detail drawing. Data

sheets for ironmongery must be submitted for review and

approval prior of commencing the works. In addition the

Contractor shall submit detail drawings and a mock-up for

review and approval prior of starting the Works (the rate does

not include the access devices). For bathrooms doors , should

install louver

1 Door Type D1 for 1000 mm x 2100mm (refer to

Door description at door details DWG) 10 nr

2 Door Type D2 for 800 mm x 2100mm (refer to

Door description at door details DWG) 6 nr

3 Door Type D3 for 800 mm x 2100mm (refer to

Door description at door details DWG) 3 nr

4 Door Type D4 for 1100 mm x 2100mm (refer to

Door description at door details DWG) 1 nr

5 Door Type D5 for 1000 mm x 2100mm (refer to

Door description at door details DWG) 2 nr

6 Door Type D8 for 1000 mm x 2100mm (refer to

Door description at door details DWG) 1 nr

08 Openings page 17 / Project Code :

Carried Forward

08 Openings page 18 / Project Code :

Brought Forward

For Wooden Doors Accessories for all types from both

sides

For all selected models , should submit the selected

Models or similar function and prices

Included in each door

Included installing

Door Closer - Tesa CT500 included included

Door Hinges Tesa BISUL4543IS 114x102x3 included included

Door Lock Tesa 403050AI included included

Door Handle Tesa - Sena Aisi 304 included included

Door Cylinder - Tesa TD60 included included

Door Stopper- Half-dome door stopper Ø45 included included

For double leaf , door handle Tesa - 191 E included included

For toilets door , door lock push / pull , and kick plates included included

TEMPERED GLASS DOORS

Supplying and installing single tempered clear glass doorS

10m mm thick tempered clear glass with high quality ST/ST U

surrounding fixation accessories supplied by Dr Greish or

similer ..The rate shall include lower and upper ST/ST U-profile

for the doors, approved floor spring, 3 key brushed ST/ST

lock, satin finish ST/ST door handle.

7 Door Type D7 for 900 mm x 2100mm (refer to

Door description at door details DWG) 45 nr

8 Door Type D9 for 3050 mm x 2100mm (refer to

Door description at door details DWG) 1 nr

For Hingd Glass Doors Accessories from both sides

Door Glass to Wall Hinges Tesa BISVP180IS

Door Top Glass to Wall Hinge: Tesa -

Door Top Glass to Wall Pivot: Tesa - PV1565V

Door Top Pivot: Tesa - PV3565V

Door Top Hinge: Tesa - BVS565V

Door Bottom Hinge: Tesa - BVI565V

Door Floor Spring: Tesa - PIC150

Door Handle Tesa - DTSRL600IS

LOCK DEVICES

9 Installation of door locks with cylinders for rquired rooms

Lock With Cylinder And Handles: Teas - CVETE5CMIS TBD nr

ACCESS DEVICES

10 Installation of access door devices for IT room and storage 2 nr

08 Openings page 19 / Project Code :

Carried Forward

Brought Forward

11 MASTER KEY

Supply and install a new Master Key for both

Existing & new Doors with all required dismantling

works, changing the cylinders for existing doors

,all accessories. ...etc. New System cylinders for

locks shall be with 8 digit coding system with high

durability, fire resistance, key related security and

attack resistance. New Keys can be ordered at

any time form the manufacturer without replacing

the delivered locks. The Contractor must submit SD,

data sheets and catalogues for the proposed

system along with the door schedule for review

and approval prior to starting any works.

A Per floor Master Key for the New & Existing

Service Doors including, IT,

Toilets and 3 nr

Additional items

Contractor to list here any additional items shown

on drawings or specifications; not priced elsewhere

in the bills of quantities and requires to complete

and handover the works; any quantities difference or

quantities adjustment to bill of quantities; separate

breakdown to be submitted

08 Openings page 20 / Project Code :

DIVISION 8 OPENINGS TO SUMMARY

08 Openings page 21 / Project Code :

Item Description Qty Unit Rate (EGP) Total (EGP)

DIVISION 9 FINISHES

Supplying and installing a cardboard cover to protect all internal

cladding works, doors etc. from day 3 till the preliminary handing

1

over. if any part of the cover is damaged, it must be restored

492 m²

immediately at the Contractor's cost.

Ditto as item above but with additional Gypsum Layer to cover all

2 existing finished floorings ,carpet and staircases till the final 1,004 m²

finishing stage before the PHO.

FLOOR FINISHES

Scope of works of all items in accordance with the

preambles; and as detailed on drawings and described in

specifications. All rates shall include for complying with the

requirements therein.

Floor finishes including surface preparation, painting fixings,

sand-cement backing mortar, adhesive and grout as shown

on drawings or according to site condition

Terrazzo (Mozaiko Tiles)

Floor self levelling compound at minimum thickness 3 mm

and the maximum 15 mm according to levels. Providing and

3 Supplying

applying aand installing

polymer terrazzocement

modified (mosaic) tilesfloor

base 300x300x30mm

levelling 790 m²

manufactured by hydraulic press. The tiles

compound as sikatransfloor or equivalent productshall be composed

on the of

two equal parts.

prepared surfaceTheofupper part shall

moasaico be made

tilesat a of an approved

minimum thickness

New cement

mixture flooring

of cement & marble chunks and the color shall be

of 3 mm after proper surface preparation and primed the

surface with Nitoprime 33 or equivalent product. Application

4 should be carried out as per manufacturer specification

EP01

a Light gray new cement flooring 351 m²

EP02

b Dark gray new cement flooring 44 m²

Tiling

Supply and Install Non-slip porcelain / ceramic floor tiles

flooring according to approved sample as shown on detail

drawing. The rate shall include all required design pattern,

corner protection with matching color, cutting, placing,

5

mortar,sand bed, joint spacers, filling the joints with

approved filling material i.e. grout produced by "SIKA" or

similar, ...etc. Type, color and samples must be submitted

for review and approval prior of starting the Works.

a CRM01

300 x 300mm local white ceramic tiles. 17 m²

b PRC01

600 x 600mm impoted porcelain tiles or local equivalent 32 m²

Carried Forward

09 Finishes page 22 / Project Code :

Brought Forward

Marble and Granite Tiles

Marble Tiles with thichncess not less than 2 cm shall be

installed using cement mortar on sand bed. The rate shall

include corner protection with matching color, cutting,

placing, mortar, filling the joints with approved filling material

i.e. grout produced by "SIKA" or similar, ...etc. Samples

must be submitted for review and approval prior of starting

6 the works and the item including the plaster works if

needed.The rate shall include supply the marble polishing

machine 8 levels , cutting, fixing the damaged area and

install new one to return to the origin case. filling the joints

with approved filling material. Samples of mockup polishig

must be submitted for review and approval prior of starting

the Works.

MB01

a Pietra gray polished 600 x 600mm flooring tiles 96 m²

MB02

b White clacatta polished and beveled edges marble tiles 15 m²

MB03

c Serpeggiante polished marble tiles 46 m²

GRN01

d Grary Al-Sherka polished 150 x 870mm granite flooring tiles 6 m²

GRN01

e Grary Al-Sherka polished 600 x 600mm granite flooring tiles 8 m²

Carpet Tiles:

CP-01

Delivery , Supply and install Carpet tiles causion back for

Flooring according to the approved colour 600x600 mm

carpet tiles to be installed on mozaiko or self leveling

concrete and the price should the selection include as the

following :

1. Manufacturing process : Tufting 1/10” looppile

2. Pile content: : 100% PP Stainsafe®

3. Total weight: Ca. 3.725 g/m²

4.Pile weight : Ca. 360 g/m²

7 5.Total height : Ca. 6.5 mm 401 m²

6.Pile height : Ca. 2,8 mm

7.Tuft density : Ca. 149.600/m²

8.Packaging : 5 m²

9.Antistatique : < 2 kV

10.Fire class : Cfl-s1(EN 13501-1)

11.Fastness to light : 5-6

12. Warranty : 10 years .

13. Origin : Europe

14. STC: 25db

Carried Forward

09 Finishes page 23 / Project Code :

Brought Forward

Floor Mat

8 Supply and install, Entrance mat recessed with aluminium 3 m²

frame

as per 2drawings

cm high and

and approved

thickness data

7 cmsheet

Entrance

. mat shall be

extruded aluminium profiles. Profile tread rails pitched at a

maximum 4 cm centers and connected by a continous vinyl

SKIRTING

9 Supplying and installing marble skirting, approved color.

Quantity measurement shall be based upon the net

executed works. All acc. to drawings and specs. Samples

a Pietra

must begray polishedfor Client and Supervision approval prior

submitted 8 m

b Serpeggiante polished 11 m

c Aluminum reveal 20 x 20mm 671 m

d White wood skirting 19 m

Brass threshold

BR-01

Supplying and installing Brass threshold thickness 4 mm ,

width 2 cm , else .. with the approved groves or

configuration, stain finish with color as per the approved

10 65 m

sample. Samples & shop drawings must be submitted to

Client and Supervision for approval prior to commencing

any works.

09 Finishes page 24 / Project Code :

Carried Forward

Brought Forward

CEILING

Ceiling finishes including surface preparation, painting,

fixings, metal suspension system as shown on drawings

Ceiling Works

Ceiling fixation specs

For the gypsum tiles; increase the fixation points using

additional approved Acmon bolt fixation diameter 6 mm,

with steel hanger rod diameter 6 mm, and after adding

galvanized steel T-sec bridge every 60 cm in the

longitudinal direction. Steel hanger rods must also be

repeated every 60 cm in the transversal direction and

connected with the lateral secondary steel beams of

the suspended false ceiling system.

- For the flat gypsum sheets; increase the number of steel

angle hangers of the suspension system to be maximum 90

cm in both directions, and accordingly add necessary

omega beams to satisfy this spacing limit. Each steel

hanger must be fixed in the RC slab using at least 2 steel

bolts 8 mm each, and screwed inside a plastic fisher 6 mm,

whereas the plastic fisher must be installed inside an air

cleaned hole drilled by using a Hilti drill inside the RC slab,

where Kimapoxy 165 or similar must be used to fix the

fisher and bolt.

- to assure that the supporting edge is at least 10 mm. It is

also preferable to use tiles with a weight limited to 1.00 kg.

- Check all the existing steel wire hangers to be galvanized

rod and scrow in (new c channel section )as attached pic

used for the suspended false ceiling and twist them properly

according to the technical and engineering standards

Suspended Gypsum Board

Supplying & erecting a complete system of suspended

ceiling made of plain gypsum fire code boards F(DF) 12mm

thick according to EN 520 standard - to be placed according

to the relevant reflected ceiling plan drawings and fixed to a

galvanized sub-structure. The sub-structure shall be

suspended by means of either anchor 6mm thickness

11 753 m²

bullets fix rapid hangers and wire with eyelet dia.4mm, or

slotted iron band or similar according to EN 14566 standard.

Technical data, samples, fixation and finishing accessories

and profiles according to EN 14195,14353 standards, &

mockups must be forwarded for approval and prior of

starting the works.

12 Ditto as item above, MOISTURE RESISTANT GYPSUM BOARD 55 m²

09 Finishes page 25 / Project Code :

Carried Forward

Brought Forward

Access Doors

Ditto as item above but for access doors.

13 Access Doors 450 x 450 mm - on wall 8 item

14 Access Doors 600 x 600mm - on ceiling 8 item

Painting

Supplying and applying approved high washable resistance,

sustainable, environmental friendly (green i.e. with low VOC

content to meet international environmental and

sustainability standards) flat matt emulsion paint

"Fenomastic Emulsion Silk" with approved color produced

by "Jotun" or similar to be applied for walls & ceiling, ...etc.

New Indoor Painting Works Technical data, Samples, Mock

up, ...etc. shall be submitted for review and 2.) Two coats of

15 Stucco The adopted painting system shall be as follows: 3.)

Two coats of Fenomastic Emulsion Silk 1.) One coat using

Fenomastic Primer and/or Penetrating Sealer for gypsum or

plaster surfaces Complete work incl. surface preparation

using approved putty to fill the cavities in the plastered

surface and also approved mastic putty to fill any visible hair

cracks and joints -whenever applicable, using masking tape

and protection for all existing / new installations. 660 m²

any pitting works shall include in this item

Complico paints for ceiling

Supply and apply COMPLICO paint with approved color for

ceiling , should approve MOS and material before application

16

according to the supervision instructions , including repair the

229 m²

existing plaster

09 Finishes page 26 / Project Code :

Carried Forward

Brought Forward

WALL FINISHES

Wall finishes including surface preparation,

painting, fixings, sand-cement backing mortar

adhesive and grout

Plaster

Treatment works and making good all plaster works to the

satisfaction of client and Supervision . End & corner

protection (Catnic or similar) Forming horizontal & vertical

guides 50mm wide and 15mm thick. min. at 1.5 mms

interval Applying of spatter dash coating 450 kg cement to 1

m3 sand before render coat is applied. Galvanized

expanded wire mesh produced by "METALX" or similar

150mm wide between structural elements & block works,

wall corners, to cover electrical conduits and between old

and new walls. Spraying with water and leave the surface till

dry. Cleaning of surfaces from dust, grease ..etc.

Scaffolding, tools, equipment, ..etc. Supplying and applying

an internal cement plaster layer on masonry brick walls,

window sills, R.C. walls, columns, lintels & ceiling with

average total thickness not less than 25mm. The rate of the

plaster works is to include:

Supplying & applying internal cement plaster in 2 coats for

walls, columns, side of beams, parapets, lintels, soffits &

17 200 m²

ceiling as indicated on detailed drawings and as directed by

Client and Supervision .

GLASS PARTITIONS

Supplying and installing Single Partition 10m mm thick

tempered clear glass with high quality ST/ST U surrounding

fixation accessories supplied by Dr Greish or is miler ..The

rate shall include a Dry Wall Partition the Glass to be

installed on top of the glass partition between the

suspended ceiling and the R.C. Slab with independent

fixation in the R.C. Slab for this part. (Price includes

submission of specialist manufacturer /supplier workshop

drawings and specifications). The Supplier must state that

the Glass Thickness Glass Partition 10mm thick. Complete

18

work as shown on detailed drawings including 10mm

tempered glass, proper and sound fixation to the floor,

walls, ceilings whenever required, using first class high

quality satin finish ST/ST fixation accessories, connectors,

lower and upper ST/ST U-profile for the doors, approved

floor spring, in case of raised floor installation R.C. Footing

or steel sections to support the Floor Spring, 3 key brushed

ST/ST lock, satin finish ST/ST door handle, providing sst/sst

protection for the latch for all doors adjacent to Dry Wall

Partitions, ..etc. and is sufficient for the panel height.

GL-01

a 10mm thick single clear tempered glass partition 284 m²

09 Finishes page 27 / Project Code :

Carried Forward

09 Finishes page 28 / Project Code :

Brought Forward

GL-02

b Sticker for tempered glass partition 160 m²

GL03 & GL04

Supplying and installing Back painted tempered Glass cladding

panel from Dr. Greiche thickness 6mm or similar approved with

c all fixation and finishing accessories. Price includes submission of 44 m²

specialist manufacturer/supplier shop drawings and Back Painted

Glass Cladding specifications

GL-05

d 20mm double clear tempered glass partition for meeting rooms 27 m²

BACK PAINTED GLASS PARTITIONS ,SEPARATORS ,

DOORS,

Supply and install a Compact 10 mm thick. white back tempered

glass partitions. Complete work including eight doors 750X2100

mm type D06, white color accessories, supports, angles, cloth

hanger with rubber stoppers, lock with sign, .....etc.). Contractor to

30 m²

submit samples / workshop drawings for review and approval

prior of commencing the

Gypsum partition

Supplying & erecting a complete system of partition made

of plain gypsum fire code boards F(DF) 16mm thick

according to EN 520 standard manufactured by "KNAUF" or

equivalent - to be placed according to the relevant plan

19 drawings and fixed to a galvanized sub-structure. Technical 674 m²

data, samples, fixation and finishing accessories and

profiles according to EN 14195,14353 standards, &

mockups must be forwarded for approval and prior of

starting the works.

Carried Forward

09 Finishes page 29 / Project Code :

Brought Forward

Cladding

Wood partition

Supply and install double side block board Partitions , to be

the total thickness 10 cm of 2 layers of 12 mm block

board . in the hereinafter specifications: Technical data,

samples, fixation and finishing accessories, & mock-ups

must be forwarded for approval and prior of starting the

works.

1.) Two wooden block layer , 12mm thick according to EN

520 standard each. Joints between boards shall be

completely concealed in order after being painted to visually

appear as a solid masonry wall.

2.) The framing and stiffeners shall be made of approved

galvanized metal sections with no exposed fastening

screws.

3.) The partitions should not expose any screws on panels

20 102 m²

or alum., but fixed to the floor and suspended ceiling

runners.

5) The scope of work includes providing approved finishing

and fixation accessories such as wall angles, corner, end,

edge beads and horizontal & vertical runner, approved anti

fungus mastic sealant for closing the joints with suspended

ceiling, alum/glass partitions, floors and walls, any required

and approved stiffener for fixing Alum., Glass Partition,

Frames of doors, smart boards whenever applicable ...etc.

structure and fixation accessories.

Carried Forward

09 Finishes page 30 / Project Code :

Brought Forward

Wood Cladding

Solid cladding

21 Supply and install wood cladding made of 18mm thick 61 m²

nlockboard veneered with Natural Oak veneer or PVC

laminate. The veneer shall be varnished and stained with

Decorative

the approvedwooden cladding

color. Rate - Wood

includes all theBaffles

required works, all

Supply and install made of Beech Pine solid wood buffles

fixed to 18mm MDF panel

lacquered finish stained with the approved color. Rate

includes all the required works, all the necessary sub

structure to support the cladding system on frames or brick

walls as shown on relevant drawings, protection paint for

22 any wooden substructure, the submission of

contractors/supplier shop drawing and Technical data

samples & mock-ups. (Price includes submission of

specialist manufacturer supplier shop drawings and

specifications)

a WD01

30 x 25 x 1200mm (height) with105mm spacing wood

11 m²

baffles with black laquered finish

WD02

30 x 25 x 900mm (height) with 70mm spacing wood baffles

b 8 m²

with black laquered finish

WD03

30 x 25 x 500mm (height) with 35mm spacing wood baffles

c 33 m²

with black laquered finish

WD04

30 x 25 x 1950mm (height) with 70mm spacing wood

d 32 m²

baffles with white laquered finish

WD05

30 x 40 1200mm (height) with 105mm spacing, vertical

34 nr

wood strips fixed to the floor, black lquered finish

Wooden Shelves

23 Supply & Install Per unit Wooden decorative shelf width 20 47 m

cm made of Beech Pine as details drawing and Render

shot , should approved sample &specs

HPL Cladding

Supply and install HPL sheet with seamless wood finish for

public toilets, fixed to wooden frame and 8mm thick plywood

24 board, all required accessories in accordance to the 10 m²

manufacturer's requirements.

09 Finishes page 31 / Project Code :

Carried Forward

Brought Forward

Supply and install HPL partitions with laminate metal look

finsih, fixed to wooden frame and 8mm thick plywood board,

25 all required accessories in accordance to the

manufacturer's requirements.

PRT01

Rectangualr shape partition with 2.25m² HPL cladding with

a 13 nr

middle embeded white board / TV unit (1.00 x 0.60m)

PRT02

"L" shape partition with 4.00m² HPL cladding with middle

b 5 nr

embeded white board &TV unit (1.00 x 0.60m)

PRT03

"V" shape partition with 4.00m² HPL cladding with middle

c 1 nr

embeded white board &TV unit (1.00 x 0.60m)

WALL CERAMIC

Supply and install 6mm. Thick.Ceramic wall tiles for spaces.

Color, pattern and size as shown on drawings. Tiles shall be

installed using cement mortar on masonry block walls. The

rate shall include corner protection with matching color,

cutting, placing, mortar, filling the joints with approved filling

material i.e. grout produced by "SIKA" or similar, ...etc.

Samples must be submitted for review and approval prior of

starting the Works .

26

a CRM02

100 x 200mm imported white ceramic tiles for coffe bar 15 m²

b CRM03

300 x 300mm imported white ceramic tiles for enclosed 81 m²

kitchen and storage

c PRC02

300 x 900mm imported white porcelain tiles for gents, laties

and handicap toilets. 96 m²

Acrylic fixed on Wall

LG-04

desk and table, made of 5mm thicknness sheets. Rate to

include ST/ST cap bolt Dia 6mm according to client and

Supervision instruction and approved sample.

27 LG-04 --> acrylic fixed logo 30 m

09 Finishes page 32 / Project Code :

Carried Forward

Brought Forward

SUN SCREEN ROLL BLINDS

Manual Sun Screen Roll Holder Supplying and installing

horizontal spring sun screen roller fabric blinds of various

widths as per actual site measurements. Blinds are made of

fire retardant fabric (fiber-glass) of approved quality and

color. The blind system is composed of and aluminum tube

to resist corrosion and abrasion of diameter approx. 45mm

pending on the supplier. Complete work incl. removable

spring unit, a compatible “Side glider” friction unit, all

28 206 m²

necessary FIRST CLASS fixation accessories, proper and

sound fixation above window lintel using FISHER and/or

HILTI frame anchors HRD-SRT 10x60/10, …etc. System to

include smooth pulling mechanism via a PVC chain that is

efficient enough to carry the fabric weight during operation.

Blinds can be sourced from "ALLAM" or similar. Data sheets

+ samples must be submitted for review & approval prior of

commencing the Works.

Vanity For Refreshment point

29 Supplying and installing pressed wood timber thickness 4

cm ,laminate finish, oak veneer texture for vanity top for

Refreshment point 6 m²

Supplying and installing pressed wood timber thickness 4

30 cm ,white laminate finish, for the counter top for corridor

kitchenette points. 7 m²

Acrlyic strips

Supplying and installing Acrlyic strips 4 mm thk. With

31 224 ml

suspension glossy finish including the lighting should

approved sample &specs

32 PLEXI LOGO

LG-01

a Supply and install Metal structure for PLEXI LIGHTING 13 m²

LETTERS with self lighting Logo

LG-02

b Supply and install PLEXI LIGHTING LETTERS with 16 m²

FLUORESCENT FIXED

LG-03

c Supply and install PLEXI LIGHTING LETTERS with brass fixed 20 m

backlit logo

LG-05

d Supply and install PLEXI LOGO with SELF LIGHTING FIXED 20 m²

PLEXI LOGO

LG-06

e Supply and install PLEXI LIGHTING LETTERS with 16 m²

FLUORESCENT FIXED

09 Finishes page 33 / Project Code :

Carried Forward

09 Finishes page 34 / Project Code :

Brought Forward

Marble and Granite Cladding

Marble and granite cladding with thichncess not less than 2

cm shall be installed using cement mortar on masonry block

walls. The rate shall include corner protection with matching

color, cutting, placing, mortar, filling the joints with approved

filling material i.e. grout produced by "SIKA" or

similar, ...etc. Samples must be submitted for review and

33 approval prior of starting the Works and the item including

the plaster works if needed.The rate shall include supply the

marble polishing machine 8 levels , cutting, fixing the

damaged area and install new one to return to the origin

case. filling the joints with approved filling material.

Samples of mockup polishig must be submitted for review

and approval prior of starting the Works.

MB05

a PIETRA GRAY MARBLE CLADDING HONED 25 m²

GRN03

GRAY AL-SHERKA GRANITE 150 x 400mm CLADDING

b 6 m²

POLISHED

GRN04

c GRAY AL-SHERKA GRANITE CLADDING POLISHED 16 m²

GRN05

d DOUBLE BLACK GRANITE CLADDING POLISHED 7 m²

Additional items

Contractor to list here any additional items shown

on drawings or specifications; not priced elsewhere

in the bills of quantities and requires to complete

and handover the works; any quantities difference or

quantities adjustment to bill of quantities; separate

breakdown to be submitted

DIVISION 9 FINISHES TO SUMMARY

09 Finishes page 35 / Project Code :

Item Description Qty Unit Rate Total (EGP)

DIVISION 10 SPECIALITIES

Scope of works of all items in accordance with the

preambles; and as detailed on drawings and

described in specifications. All rates shall include

for complying with the requirements therein

TOILET ACCESSORIES

Supply and installation of the following toilet

accessories including trims, hardwares and

finishings

Ref. Type RH, Single Robe Hook (high Category)

1 AIKE or Alpine local similer , door mount 11 nr

Ref. Type TPH, Toilet Paper Holder (High Category)

2 AIKE or Alpine local similer , wall mount 11 nr

Ref. Type SD, Automatic sensor Soap Dispenser (high

3 Category)

AIKE or Alpine local similer , touchless , wall mount 7 nr

Ref. Type Fm², Clear glass mirror on aluminium frame

4 invisible , Height as drawings MR03 12 m²

Ref. Type Tissue holder

5 AIKE or Alpine local similer , touchless , wall mount 4 nr

6 kitchenette sink with mixer

Ref , Hans CICO CDUC 750

Ref , GROHE –eurosmart 36422000 2 nr

PROTECTION BOXES

Supplying and installing transparent acrylic

protection box for the thermostat with a three key

lock. Sample must be submitted for review prior to

7 Acrylic Protection Box commencing any works. 2 item

Steel / Glass Protection Box

Supplying and installing a red color steel / safety

glass protection box for the Fm²00 Manual release.

Sample must be submitted for review prior to

8 commencing any works. 2 item

Key Box

Supplying and installing key box. The box shall

house hangers for the keys with external lock with

three keys. Sample must be submitted for review

9 prior to commencing any works. 2 item

10 Specialities page 36 / Project Code :

Carried Forward

10 Specialities page 37 / Project Code :

Brought Forward

Supplying and installing PVC internal signs of various

INTERNAL

dimensions SIGNS

for Electrical Cupboard, HVAC Plant Rooms and

Hose Reels, Fire Station, Fire Extinguisher, ..etc. Complete

work including text engraving, color, chamfered edges, back

adhesive, vertical and horizontal alignment, …etc. Setting out

C shall be as directed

Commencing by owner. Samples must be submitted for

the Works. 62 nr

review & approval prior of Internal Signs for Elec, HVAC,

Signs for Toilets & Pantry

A Supplying and installing ST/ST signs on Toilets and Pantries 5 nr

doors wiht text " Push , exit , pull , etc" to be fixed through the

use of ST/ST

Additional screws flat head for wood door leaf and self-

items

adhesive back for steel door leaf. Samples must be submitted

Contractor to list here any additional items shown

on drawings or specifications; not priced elsewhere

in the bills of quantities and requires to complete

and handover the works; any quantities difference or

quantities adjustment to bill of quantities; separate

breakdown to be submitted

DIVISION 10 SPECIALTIES TO SUMMARY

10 Specialities page 38 / Project Code :

Item Description Qty Unit Rate Total (EGP)

DIVISION 12 FURNISHINGS

Scope of works of all items in accordance with the

preambles; and as detailed on drawings and

described in specifications. All rates shall include

for complying with the requirements therein

CURTAINS AND DRAPES

1 Supply and installation of the following draperies including

A accessories including trims,

Black out drapes,medium mounting

beige brackets,

color as hardware,

approved sample 37 m²

fittings, fastenings and installation by a single manufacturer

B Transparent drapes, white color as approved sample 37 m²

Carried Forward

12 Furnishings page 39 / Project Code :

Brought Forward

Additional items

Contractor to list here any additional items shown

on drawings or specifications; not priced elsewhere

in the bills of quantities and requires to complete

and handover the works; any quantities difference or

quantities adjustment to bill of quantities; separate

breakdown to be submitted

DIVISION 10 SPECIALTIES TO SUMMARY

12 Furnishings page 40 / Project Code :

Description Qty Unit Rate Total (EGP)

DIVISION 22 PLUMBING WORKS

Scope of works of all items in accordance with the

preambles, and as detailed on drawings and

described in specifications. All rates shall include

for complying with the requirements therein

For all selected models , should submit the selected

Models or similar function and prices

All fixtures items should include any valves or required

accessories and full connected with the new or existing system

PLUMBING

Sanitary fixtures, as per selection schedule including

necessary fittings, accessories, trims valves,

traps spouts and short lengths of water supply and

waste pipes

1 Ref. Type HS, Hand spray with flexible hose and

wall hook

Ideal --> | B0011 | Trigger Spray shower set 11 nr

2 Ref. Type LAV1, Under counter Lavatory as render shot

Ref.Duravit :D-Code furniture washbasin

Dura style 0372430000

Lavatory Mixer : GROHE – 32917KS0

Solenoid valve integrated in body

Electronic sensor full basin functions

Flexible hoses G3/8" for water supply system

connection

Lead and nickel free waterways (BLUE

technology)

Aerator laminar 4,7 l/min

Sensor cover for cleaning purposes

Easy fix system for installation

Product is only for use in high pressure systems

(min. 0,5 bar)

include any valves or required accessories 6 nr

3 Custom Spanish Black marble lavatory as render shot

Lavatory Mixer : GROHE – 32917KS0

Solenoid valve integrated in body

Electronic sensor full basin functions

Flexible hoses G3/8" for water supply system

connection

Lead and nickel free waterways (BLUE

technology)

Aerator laminar 4,7 l/min

Sensor cover for cleaning purposes

Easy fix system for installation

Product is only for use in high pressure systems

(min. 0,5 bar) 2 nr

22 Plumbing page 41 / Project Code :

Carried Forward

22 Plumbing page 42 / Project Code :

Brought Forward

4 ADA compliant Lavatory

Ref.Duravit :D-Code furniture washbasin

Dura style 231060

Siphon Cover: D-Code 085718

Lavatory Mixer : GROHE – 32917KS0

Solenoid valve integrated in body

Electronic sensor full basin functions

Flexible hoses G3/8" for water supply system

connection

Lead and nickel free waterways (BLUE

technology)

Aerator laminar 4,7 l/min

Sensor cover for cleaning purposes

Easy fix system for installation

Product is only for use in high pressure systems

(min. 0,5 bar)

include any valves or required accessories 1 nr

5 Ref. Type WC1, Urinal water closet with flush Valve

Urinals : Ideal standard | Eurovit | S6120

with separator HPL 25*90 or Ideal standard separator

Flush button type : "GROHE" : 37 321 001 ( 230 V)

Flush tank : "GROHE" : 38 786 001 2 nr

include any valves or required accessories

6 Ref. Type WC2, Wall-mounted water closet with

flush valve (High Category) - P- Trap

Cabinet : Duravit G 3191 with douche

Seat cover : Duravit soft close compatible with closet

Flush tank (built in wall) : Grohy 38528001

plates flush button : Ref : GROHE , 38393SD1 ( 230V) 11 nr

include any valves or required accessories

Additional items

Contractor to list here any additional items shown

on drawings or specifications; not priced elsewhere

in the bills of quantities and requires to complete

and handover the works; any quantities difference or

quantities adjustment to bill of quantities; separate

breakdown to be submitted

22 Plumbing page 43 / Project Code :

DIVISION 22 PLUMBING TO SUMMARY

22 Plumbing page 44 / Project Code :

You might also like

- Villa - Interior B.O.Q. (Egypt)Document30 pagesVilla - Interior B.O.Q. (Egypt)Moustapha AlgoharyNo ratings yet

- OU Open University SM358 2013 Exam SolutionsDocument54 pagesOU Open University SM358 2013 Exam Solutionssam smith100% (3)

- Civil & Interior Works Boq - NXP SL - No Description Unit QTY A Civil Work 1.0 Block Work 100Mm THKDocument8 pagesCivil & Interior Works Boq - NXP SL - No Description Unit QTY A Civil Work 1.0 Block Work 100Mm THKShreya BhattacharyaNo ratings yet

- Construction Document Sheet Numbers and Sheet OrderDocument4 pagesConstruction Document Sheet Numbers and Sheet OrderAnnisa SyahraniNo ratings yet

- Base PlateDocument45 pagesBase PlateMuhammed Ali60% (5)

- Total Quality Management in TATA POWERDocument104 pagesTotal Quality Management in TATA POWERAnil Kumar SinghNo ratings yet

- GIA CatalogueDocument100 pagesGIA CatalogueJennifer Kelley100% (2)

- Airbus EtopsDocument99 pagesAirbus Etopskonser100% (2)

- BoqDocument14 pagesBoqTaranjot SinghNo ratings yet

- Abstract of Quantities of Interior Civil Work at First FloorDocument6 pagesAbstract of Quantities of Interior Civil Work at First FloorSantanu ShresthaNo ratings yet

- Using Excel Templates To Estimate Interior DesignDocument1 pageUsing Excel Templates To Estimate Interior DesignweworkinsNo ratings yet

- Using Excel Templates To Estimate Interior DesignDocument1 pageUsing Excel Templates To Estimate Interior DesignSakera Patel100% (1)

- Homeby - In: Quotation For Home Interiors Carpentry FinishDocument6 pagesHomeby - In: Quotation For Home Interiors Carpentry FinishBakiaraj100% (1)

- Interior Furnishing Work of New Circle Office in Bank'S Own Building at Plot No. 4, PSP, Saket Nagar, Near Aiims BhopalDocument37 pagesInterior Furnishing Work of New Circle Office in Bank'S Own Building at Plot No. 4, PSP, Saket Nagar, Near Aiims BhopalSAI ASSOCIATENo ratings yet

- Ocean Life: Interior Design and Execution Estimation Name of Customer:SiddappaDocument6 pagesOcean Life: Interior Design and Execution Estimation Name of Customer:Siddappaksquare constructionNo ratings yet

- Boq For Interior Furnishing Works at Chandni Chowk Branch: S.N. Item of Work Qty. Unit Rate Amount 1 FlooringDocument7 pagesBoq For Interior Furnishing Works at Chandni Chowk Branch: S.N. Item of Work Qty. Unit Rate Amount 1 FlooringBRGRNo ratings yet

- Progress ReportDocument3 pagesProgress Reportapi-592757050No ratings yet

- Estimate - Quatation For 1700Document5 pagesEstimate - Quatation For 1700QUAD CONSTRUCTIONNo ratings yet

- Boq For Interior WorksDocument1 pageBoq For Interior WorksAr. Libin K BabyNo ratings yet

- Compliance StatementDocument6 pagesCompliance StatementhinNo ratings yet

- Interior Doc Boq DharapuramDocument8 pagesInterior Doc Boq Dharapuramakshay salviNo ratings yet

- Proposal Quotation For Residential Interior Works in Gonibakary 01-01-2023Document2 pagesProposal Quotation For Residential Interior Works in Gonibakary 01-01-2023Sabekun NaharNo ratings yet

- QuotationDocument2 pagesQuotationdapliewNo ratings yet

- Interior Design Client Questionnaire For Initial Consultation 2020Document1 pageInterior Design Client Questionnaire For Initial Consultation 2020Alexandru IvanciuNo ratings yet

- Tender B - Architectural SpecficationsDocument188 pagesTender B - Architectural SpecficationsJe M'appelle NofreNo ratings yet

- Progress ReportDocument3 pagesProgress Reportapi-592929885No ratings yet

- Interior Work& Electric Work at Lab, at Bedf Modipurm ParticularsDocument9 pagesInterior Work& Electric Work at Lab, at Bedf Modipurm ParticularsSiam Hasan100% (1)

- Aluminum Frame 8: 132 SeaterDocument16 pagesAluminum Frame 8: 132 SeaterAbraham KramonyNo ratings yet

- 4 - Interiors BOQ MahimDocument13 pages4 - Interiors BOQ MahimdawitgggNo ratings yet

- Boq FurnishingDocument3 pagesBoq FurnishingDevanshu GurudeoNo ratings yet

- Schedule of QuantityDocument10 pagesSchedule of QuantityMuhammad SafdarNo ratings yet

- Bedauli BoqDocument15 pagesBedauli BoqFaquruddin AliNo ratings yet

- Furniture Work Price BidDocument4 pagesFurniture Work Price Bidshubham kumar0% (1)

- SL No Description Unit Quantity Remarks Total Amount Excluding Taxes - Rate (INR) Amount (INR)Document18 pagesSL No Description Unit Quantity Remarks Total Amount Excluding Taxes - Rate (INR) Amount (INR)Chaitanya IdateNo ratings yet

- Interior Design ContractDocument2 pagesInterior Design ContractmaheshNo ratings yet

- BOQ Restaurant: Urban OakDocument5 pagesBOQ Restaurant: Urban OakManohar RobertNo ratings yet

- Boq Iimu Modular Kitchen and WardrobeDocument4 pagesBoq Iimu Modular Kitchen and WardrobePrajeet HegadeNo ratings yet

- D) Furniture Supply & InstallationDocument14 pagesD) Furniture Supply & InstallationslinthruNo ratings yet

- Finishing BOQDocument3 pagesFinishing BOQHarpreet SinghNo ratings yet

- Pricebid Ramsagarpura IntDocument4 pagesPricebid Ramsagarpura Intمهدي المقدمNo ratings yet

- Proposal For: Mandovra Construction CompanyDocument4 pagesProposal For: Mandovra Construction CompanyHimanhsu ParmarNo ratings yet

- 20190507-TS-Construction of Front Fence and Gate at GSIS Cauayan Branch OfficeDocument9 pages20190507-TS-Construction of Front Fence and Gate at GSIS Cauayan Branch OfficeJoella MaderaNo ratings yet

- Kishore 2BHK Modular BOQDocument5 pagesKishore 2BHK Modular BOQSharan SaiNo ratings yet

- Interior Design Estimate SampleDocument3 pagesInterior Design Estimate SampleAnurag MukhopadhyayNo ratings yet

- Contract PointsDocument2 pagesContract PointsPriyankNo ratings yet

- PWD Staff QTR Estimate (2) NFNDocument315 pagesPWD Staff QTR Estimate (2) NFNjitender pal vermaNo ratings yet

- Quote - R1, 20012021, Boq For BOH Area Interiors & Civil WorkDocument19 pagesQuote - R1, 20012021, Boq For BOH Area Interiors & Civil WorkShruti SinghNo ratings yet

- Your Home Interiors Quotation.: WWW - Aantrik.inDocument21 pagesYour Home Interiors Quotation.: WWW - Aantrik.inhiteshNo ratings yet

- Razole - Revised - 010922Document4 pagesRazole - Revised - 010922kuffainNo ratings yet

- All in RatesDocument7 pagesAll in Rateskian hongNo ratings yet

- Boq (9.3.2022)Document1 pageBoq (9.3.2022)dubai eyeNo ratings yet

- Percentage Boq: Total Amount Without Taxes in Total Amount in WordsDocument12 pagesPercentage Boq: Total Amount Without Taxes in Total Amount in WordsSHYAM RAJNo ratings yet

- Boq - MS Door - R00Document1 pageBoq - MS Door - R00Zeeshan AliNo ratings yet

- Boq Interior (English)Document15 pagesBoq Interior (English)Rio Gottes HolleNo ratings yet

- Designers & Consultancy: Dear SirDocument2 pagesDesigners & Consultancy: Dear SirAjin SNo ratings yet

- BOQ Assam Tender New OfficeDocument12 pagesBOQ Assam Tender New OfficeRashed100% (1)

- Washroom Washroom 1: GurugramDocument4 pagesWashroom Washroom 1: GurugramAr Aditya SagarNo ratings yet

- Green Wall BOQDocument1 pageGreen Wall BOQDiaszNo ratings yet

- Dubai Parks & Resorts: Legoland HotelDocument28 pagesDubai Parks & Resorts: Legoland HotelChikwado DicksonNo ratings yet

- Villa 60 Material ListDocument9 pagesVilla 60 Material Listk.o.m channel (kmeng)No ratings yet

- R-1 BOQ ElectricalDocument36 pagesR-1 BOQ ElectricalDivyansh GuptaNo ratings yet

- Construction of Primary Hospital ExcelDocument58 pagesConstruction of Primary Hospital ExcelDipesh BasnetNo ratings yet

- Megas Architectural Services Pvt. LTD.: Civil WorkDocument5 pagesMegas Architectural Services Pvt. LTD.: Civil WorkSarin100% (1)

- Bills of Quantities - PreliminariesDocument17 pagesBills of Quantities - PreliminariesKris Nauth100% (1)

- Interior Specifcation - Guide SampleDocument64 pagesInterior Specifcation - Guide Samplecharlize.mfsyNo ratings yet

- The Nepal Engineering Council ActDocument14 pagesThe Nepal Engineering Council ActRazn NhemaphukiNo ratings yet

- SDC 04comp-14-001 Item 6Document19 pagesSDC 04comp-14-001 Item 6Dave VegasNo ratings yet

- Syllabus DJT 50110Document3 pagesSyllabus DJT 50110Sharizal SanikNo ratings yet

- Cargills Annual Report 2013 PDFDocument100 pagesCargills Annual Report 2013 PDFArunallNo ratings yet

- The Adoption of The Principles of Equity Jurisprudence Into The ADocument12 pagesThe Adoption of The Principles of Equity Jurisprudence Into The AAjinkya PatilNo ratings yet

- Finale Manuscript1 3.1Document14 pagesFinale Manuscript1 3.1Emmanuel BaccarayNo ratings yet

- Parth Purandare SAP: 80101190556 1. Introduce YourselfDocument4 pagesParth Purandare SAP: 80101190556 1. Introduce YourselfParth Hemant PurandareNo ratings yet

- Designing and Managing Integrated Marketing ChannelDocument40 pagesDesigning and Managing Integrated Marketing ChannelindahNo ratings yet

- Uso Cursores Anidados PDFDocument7 pagesUso Cursores Anidados PDFIvan AlvaradoNo ratings yet

- 2 Classes and Objects2018-10-23 14 - 17 - 43Document71 pages2 Classes and Objects2018-10-23 14 - 17 - 43RiyaNo ratings yet

- CMD Message: Deepak Kumar Hota Chairman & Managing Director BemlDocument1 pageCMD Message: Deepak Kumar Hota Chairman & Managing Director BemlMadhurya KrishnaNo ratings yet

- CALP Glossary 2023 ENDocument41 pagesCALP Glossary 2023 ENHendra WijayaNo ratings yet

- Business Plan Group 5Document21 pagesBusiness Plan Group 5Tabaaa YtNo ratings yet

- Kolb QuestionnaireDocument8 pagesKolb Questionnaireaandgand7cattosNo ratings yet

- Legal Brief - MetahumansDocument3 pagesLegal Brief - MetahumansEver Alcazar50% (2)

- Vision, Mission, School Map and History of OLRADocument4 pagesVision, Mission, School Map and History of OLRAJowel Mercado RespicioNo ratings yet

- English - Grade VIII - My Lost Dollar - Chapter - 1Document4 pagesEnglish - Grade VIII - My Lost Dollar - Chapter - 1Vishvavenkat K SNo ratings yet

- NullDocument2 pagesNullapi-27552272No ratings yet

- International Emergency Nursing: Yong Eun Kwon, Miyoung Kim, Sujin ChoiDocument7 pagesInternational Emergency Nursing: Yong Eun Kwon, Miyoung Kim, Sujin ChoiAmrinder RandhawaNo ratings yet

- Chapter 2 Lost Spring With AnswersDocument15 pagesChapter 2 Lost Spring With AnswersSqop GamingNo ratings yet

- Set Up A Branch in The UK of Your Business in 90 DAYSDocument3 pagesSet Up A Branch in The UK of Your Business in 90 DAYSThe SmartMove2UkNo ratings yet

- MTE 220 Course - NotesDocument163 pagesMTE 220 Course - NotesqNo ratings yet

- Entrainment Losses in Barometric TowersDocument5 pagesEntrainment Losses in Barometric TowersGeorge Isaac McQuilesNo ratings yet

- Arca South Presentation 1Document17 pagesArca South Presentation 1api-264962879No ratings yet

- Passion Fruit Cashflow ProjectionDocument16 pagesPassion Fruit Cashflow ProjectionEphranceNo ratings yet