Professional Documents

Culture Documents

Principle of Gating Riser

Principle of Gating Riser

Uploaded by

dhruvmistry3000 ratings0% found this document useful (0 votes)

11 views23 pagesThe document discusses principles of gating systems and risers used in metal casting. It describes the components of a gating system including pouring cups, sprues, runners, gates, and risers. It explains that the gating system should fill the mold cavity completely and introduce metal with low velocity to prevent erosion and gas pickup. Gate types like top, bottom, and parting line gates are described along with their advantages and disadvantages. Riser functions like compensating for shrinkage and allowing gas escape are summarized. Open and blind riser types are also outlined.

Original Description:

Original Title

5. Principle of Gating Riser

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses principles of gating systems and risers used in metal casting. It describes the components of a gating system including pouring cups, sprues, runners, gates, and risers. It explains that the gating system should fill the mold cavity completely and introduce metal with low velocity to prevent erosion and gas pickup. Gate types like top, bottom, and parting line gates are described along with their advantages and disadvantages. Riser functions like compensating for shrinkage and allowing gas escape are summarized. Open and blind riser types are also outlined.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

11 views23 pagesPrinciple of Gating Riser

Principle of Gating Riser

Uploaded by

dhruvmistry300The document discusses principles of gating systems and risers used in metal casting. It describes the components of a gating system including pouring cups, sprues, runners, gates, and risers. It explains that the gating system should fill the mold cavity completely and introduce metal with low velocity to prevent erosion and gas pickup. Gate types like top, bottom, and parting line gates are described along with their advantages and disadvantages. Riser functions like compensating for shrinkage and allowing gas escape are summarized. Open and blind riser types are also outlined.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 23

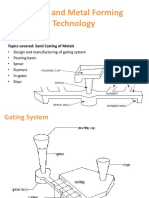

Principles of Gating System

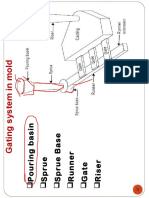

• The term gating

system refers to all

passageways

through which the

molten metal

passes to enter the

mold cavity.

• The gating system

is composed of

– Pouring cups

and basins

– Sprue

– Runner

– Gates

– Risers. Prof. J. V. Patel, UVPCE, Kherva 2

Principles of Gating System

• Since the way in which liquid

metal enters the mold has a

decided influence upon the quality

and soundness of a casting, the

different passages for the molten

metal are carefully designed and

produced.

• A gating system should avoid

sudden or right angle changes in

direction.

• Sudden change in direction causes

mold erosion, turbulence and gas

pick-up.

• If possible the gating system

should form a part of theProf.

pattern

J. V. Patel, UVPCE, Kherva 3

Requirements, Purposes or Functions of The Gating

System

A Gating system should,

– fill the mold cavity completely before freezing;

– introduce the liquid metal into the mold cavity with low velocity

and little turbulence, so that mold erosion, metal oxidation and

gas pickup is prevented;

– incorporate traps for the separation of non metallic inclusions

which are either introduced with the molten metal or are

dislodged in the gating system;

– regulate the rate at which liquid metal enters into the mold;

– be practicable and economical to make and;

– consume least metal. In other words, the metal solidified in

sprue, runner, gates and risers should be minimum because

gates, risers etc., are removed from the final casting; the gating

system should provideProf.

for the maximum yield.

J. V. Patel, UVPCE, Kherva 4

Characteristics

Gates

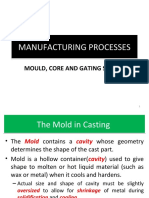

• A gate is a channel which connects runner with the mold cavity and

through which molten metal flows to fill the mold cavity.

• A gate should feed liquid metal to the casting at a rate consistent

with the rate of solidification.

• The size of the gate depends upon the rate of solidification.

• A small gate is used for a casting which solidifies slowly and vice-

versa.

• More than one gates may be used to feed a fast freezing casting.

• A gate should not have sharp edges as they (i.e., edges) may break

during pouring and (sand pieces) thus be carried with the molten

metal into the mold cavity..

• Moreover, sharp edges may cause localized delay in freezing, thus

resulting in the formation of voids and inclusions in the cast objects.

• A gate may be built as a part of the pattern or it may be cut in the

Prof. J. V. Patel, UVPCE, Kherva 5

mold with the help of a gate cutter.

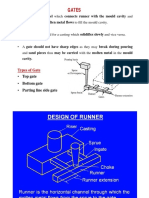

Types of Gates

• The major types of gates are,

1. Top Gate

2. Bottom gate

3. Parting line side gate

1. Top gate

• A top gate is sometimes also called

as Drop gate because the molten

metal just drops on the sand in the

bottom of the mold

• In top gate, a stream of liquid metal

impinges against the bottom of

mold cavity until a pool is formed

and this is kept in a state of

agitation until the mold is filled.

Prof. J. V. Patel, UVPCE, Kherva 6

Advantages of Top Gating

• Simplicity for moulding.

• Low consumption of additional metal.

• Generation of favourable temperature gradients to enable

directional solidification from the casting towards the gate which

serves as riser too.

Disadvantages of Top Gating

• The dropping liquid metal stream erodes the mold surface.

• Dropping metal does cutting action, lifts portions of the surface

and causes scab (Skin).

• Splashing of molten metal associated with the liquid metal stream

increase chances of oxidation.

• There is lot of turbulence and pick-up of air and other gases.

Prof. J. V. Patel, UVPCE, Kherva 7

2. Bottom Gate

• A bottom gate is made in

the drag portion of the

mold.

• In a bottom gate, liquid

metal fills rapidly the

bottom portion of the

mold cavity and rises

Simple bottom gate

steadily and gently up the

mold walls.

• Types of bottom gate are

– Simple bottom gate

– A horn gate

Prof. J. V. Patel, UVPCE, Kherva A horn gate 8

Advantages of Bottom Gating

• There is no scouring(Rubbing) and splashing in the bottom gate.

• As compared to top gate, a bottom gate involves little turbulence

and metal erosion.

• Bottom gate produces good casting surfaces.

Disadvantages of Bottom Gating

• In bottom gates, liquid metal enters the mold cavity at the bottom.

If freezing takes place at the bottom, it could choke off the metal

flow before the mold is full.

• A bottom gate creates an unfavorable temperature gradient and

makes it difficult to achieve directional solidification especially

when the bottom gate has a riser at the top of the casting.

• A bottom gate involves greater complexity of molding.

• The liquid metal cools as it rises the mold walls and results in cold

metal and cold mold near the (top) riser and hot metal and hot

mold near the gate. Prof. J. V. Patel, UVPCE, Kherva 9

3. Parting line side gate

• In parting line gates, the liquid metal enters the mold cavity from

the side of the mold (cavity) at the parting line separating cope and

drag at or the level of mold joint.

• Parting line gate can be made by the pattern itself or it can be cut

afterwards.

• As regards fluid flow, parting line gates stand in between top and

bottom gates.

• A parting line gate has sprue formed in the (sand of the) cope.

Where in figure

A. Pouring cup

B. Pouring basin

C. Spure or Down gate

D. Skin bob

E. Ingate

F. Choke

G. Mold cavity

H. Riser Prof. J. V. Patel, UVPCE, Kherva 10

• A recess is generally provided at the base of the sprue to avoid the

cutting of sand at this place.

Advantages of Parting Line Gating

• Parting line gates are simple to construct.

• Parting line gates are very fast to make.

• Parting line gates produce very satisfactory results when drag is not very

deep.

• Parting line gating makes best compromise between molding convenience

and the ideal gating arrangement.

Disadvantages of Parting Line Gating

• In case the parting line is not near the bottom of the mold cavity or the

drag portion is deep, some turbulence will occur as the liquid metal falls

into the mold cavity.

• Cascading (Spilling) of molten metal from a height in the mold cavity will

cause erosion or washing of the mold.

• Cascading in non-ferrous metals will promote air pickup by the liquid

metal and thus result in an inferior casting.

Prof. J. V. Patel, UVPCE, Kherva 11

Principles of Risering

Definition

• A riser or a feeder head

is a passage of sand

made in the cope

(mold) during ramming

the cope.

• The molten metal rises

in the feeder head after

the mold cavity is filled

up.

• This metal in the feeder

head (or riser)

compensates the

shrinkage as the casting

solidifies.

Prof. J. V. Patel, UVPCE, Kherva 12

Functions of Riser

• Metals and their alloys shrink as they cool and solidify. It creates a

partial vacuum within the casting. Partial vacuum leads to a

shrinkage void. This shrinkage void will grow and form shrinkage

cavity if extra liquid metal from outside the mold (cavity) is not

supplied.

• The primary function of the riser (attached with the mold) is to

feed metal to the solidifying casting so that shrinkage cavities are

get rid of.

• A riser permits the escape of air and mold gases as the mold cavity

is being filled with the molten metal.

• A riser full of molten metal indicates that the mold cavity has

already been completely filled up with the same.

• A casting solidifying under the liquid metal pressure of the riser is

comparatively sound.

• Risers promote directional solidification.

Prof. J. V. Patel, UVPCE, Kherva 13

Risers

Types of Risers

1. Open Riser

2. Blind Riser

1. Open Riser

• The top of the open riser is open Open Riser

i.e., exposed to atmosphere.

• The liquid metal in the riser is fed to the solidifying casting under

force of gravity and atmospheric pressure till the top surface of the

riser solidifies and thereafter gravity is only the feeding force.

• An open riser is connected either at the top of cope, or on the

side at the parting line.

• An open riser is generallyProf.

cylindrical.

J. V. Patel, UVPCE, Kherva 14

Risers

Advantages of Open Riser

• An open riser is easy to mold as compared to a blind riser.

• An open riser is open to atmosphere, thus it ensures that unlike a

blind riser it will not draw metal from the casting as a result of

partial vacuum in the riser.

Limitations of Open Riser

• Open riser is not placed in the drag.

• Open riser is generally larger than a comparable blind riser.

• An open riser is more difficult to remove from the casting as

compared to blind riser.

Prof. J. V. Patel, UVPCE, Kherva 15

Risers

2. Blind Riser

• A blind riser is closed at its top; however, a vent or permeable core

at the top of the riser may be provided to have some exposure to

the atmosphere otherwise the vacuum created between the top of

the riser and the liquid metal level in the riser may not permit

proper feeding of liquid metal from riser to the casting. Gravity is

the only feeding force.

• A blind riser is connected, either at

the top of cope, or on the side of the

casting at the parting line or in the

drag.

• A blind riser is a rounded cavity and it

represents the minimum practical

ratio of surface area to volume and

thus associates a slow cooling rate

and is more efficient. Prof. J. V. Patel, UVPCE, Kherva

Blind Riser

16

Risers

Advantages of Blind Riser

• Blind risers can be placed at any position in the mold.

• A blind riser is smaller than a comparable open riser.

• A blind riser can be removed more easily from a casting.

• Blind risering promotes directional solidification better than the

open risering.

Limitations of Blind Riser

• It is difficult to mold a blind riser.

• A blind riser may draw liquid metal from the solidifying casting.

Prof. J. V. Patel, UVPCE, Kherva 17

Fettling & Cleaning of Castings

• Fettling is the name given to cover all those operations which help

giving the casting a good appearance after the same has been

shaken out of the sand mold.

• Fettling includes

1. Removal of cores from the casting.

2. Removal of adhering sand and oxide scale from the casting

surface (surface cleaning).

3. Removal of gates, risers, runners etc. from the casting.

4. Removal of fins, and other unwanted projections from the

castings.

Prof. J. V. Patel, UVPCE, Kherva 18

.

Fettling & Cleaning of Castings

1. Removal of Cores

• It may be difficult to remove dry sand and hardened cores in the

absence of suitable equipment.

• Hammering or vibrations imparted to cores does loosen and break

them up.

• Sand portions sticking inside the castings are removed by poking

action using a metal rod.

• Cores from larger castings may be removed effectively by

pneumatic rapping and hydro blasting.

.

Prof. J. V. Patel, UVPCE, Kherva 19

Fettling & Cleaning of Castings

2. Cleaning of Casting Surfaces

• The outside and inside surfaces of castings are cleaned of adhering

refractory (sand) particles and oxide scale and they (i.e., surfaces)

look smooth and pleasing.

• The extent of surface cleaning required depends upon the metal/

alloy of the casting and size of the casting.

• Steel castings (because of their high melting and pouring

temperatures and consequent burning of the sand in contact with

the molten metal) require considerable more cleaning than those of

iron and brass.

• Aluminium castings are virtually free from burned-on sand.

• Since heavy castings suffer more than light castings from the

burning-on of sand, their cleaning is more difficult.

• Sand may be removed from the surfaces of castings using hand

methods or mechanical equipment

Prof. J. V. Patel, UVPCE, Kherva 20

Fettling & Cleaning of Castings

3. Removal of gates and risers

• Numerous methods are available for removing feeding and gating

systems.

• The choice of a particular method depends upon the type of

metal/alloy,

— size of the casting,

— size of runners, gates and risers.

• A few commonly used methods are given below:

1. Chipping hammers 5. Abrasive wheel slitting

2. Flogging (knocking off). 6. Machining.

3. Shearing. 7. Flame cutting.

4. Sawing

Prof. J. V. Patel, UVPCE, Kherva 21

Fettling & Cleaning of Castings

4. Removal of Fins And Other Unwanted Projections From Castings

• Castings are trimmed to remove fins, chaplets, wires, parting line

and the stumps of feeder heads and ingates. All these unwanted

projections are dressed flush with the surface.

• The methods employed to remove unwanted projections from the

castings are

– Chipping

– Sawing

– Flame cutting

– Flame gouging and flame scarfing.

– Grinding

– Abrasive belt machining

– Rotary tools cutting

– Trimming and sizing.

Prof. J. V. Patel, UVPCE, Kherva 22

You might also like

- Cathy O'Brien & Mark Philips - Trance Formation of America2Document224 pagesCathy O'Brien & Mark Philips - Trance Formation of America2bld200797% (35)

- Gating and Riser in CastingDocument12 pagesGating and Riser in CastingMadhava ShankarNo ratings yet

- 11 02 02 2023Document22 pages11 02 02 2023keshavkoolwalNo ratings yet

- Unit 2 Sand Moulding PART 2Document20 pagesUnit 2 Sand Moulding PART 2mahammad kamaluddeenNo ratings yet

- Casting2 (Gating System)Document99 pagesCasting2 (Gating System)monu61316No ratings yet

- Gating System For Casting2 - WT7 PDFDocument87 pagesGating System For Casting2 - WT7 PDFAzaad Maverick100% (1)

- Elements of Gating SystemDocument44 pagesElements of Gating SystemNemani RaghuNo ratings yet

- Sand Casting of Metals - Gating System For CastingDocument31 pagesSand Casting of Metals - Gating System For CastingAmruta Rane100% (1)

- Lec 3Document54 pagesLec 3May FadlNo ratings yet

- Gating&Risering SystemDocument44 pagesGating&Risering Systemmary100% (1)

- Design and Analysis of Gating SystemDocument25 pagesDesign and Analysis of Gating SystemChiranjeev SethiNo ratings yet

- Gating SystemDocument69 pagesGating SystemSaurabh ThakurNo ratings yet

- Gating System: The Passage That Leads The Molten Metal Into The Mould CavityDocument15 pagesGating System: The Passage That Leads The Molten Metal Into The Mould CavityjohnrabikNo ratings yet

- Lecture 6 Elements of Gating SystemDocument7 pagesLecture 6 Elements of Gating SystemNemani Raghu0% (1)

- Casting Lab 1Document20 pagesCasting Lab 1john johnsonNo ratings yet

- TY Lectures Gating Designe, Raisers ProblemsDocument134 pagesTY Lectures Gating Designe, Raisers ProblemsHrishikeshNo ratings yet

- 1.5 - GATING SYSTEM, RequirementsDocument38 pages1.5 - GATING SYSTEM, RequirementsRamu AmaraNo ratings yet

- Elements of Gating SystemDocument30 pagesElements of Gating Systemavutu_kunduru78% (9)

- Dr. Chaitanya Sharma Phd. Iit RoorkeeDocument33 pagesDr. Chaitanya Sharma Phd. Iit RoorkeeTrung Quoc Le100% (1)

- Manufacturing ProcessesDocument40 pagesManufacturing ProcessesFattihi EkhmalNo ratings yet

- 4Document24 pages4Sameer SonuNo ratings yet

- Lectute 7Document29 pagesLectute 7e22mecu0009No ratings yet

- Chapter 4 Gating SystemDocument54 pagesChapter 4 Gating Systemjoy fulNo ratings yet

- Gates: Through Which Molten Metal Flows To Fill The Mould CavityDocument36 pagesGates: Through Which Molten Metal Flows To Fill The Mould CavityAbinav DhinakarNo ratings yet

- Gatting SystemDocument7 pagesGatting SystemANIDHANo ratings yet

- Material Processing DefectsDocument52 pagesMaterial Processing DefectsAmeem TariqNo ratings yet

- Module 5 - Principles of Gating and RiseringDocument14 pagesModule 5 - Principles of Gating and RiseringGoutham ReddyNo ratings yet

- Gating Design V3Document31 pagesGating Design V3Chinh Thong TranNo ratings yet

- Experiment No. 6: Casting Is ADocument6 pagesExperiment No. 6: Casting Is AArun kumar rouniyarNo ratings yet

- Lecture 4Document10 pagesLecture 4Abdullah SubbirNo ratings yet

- MP-I-Lecture No. 12-13-14Document50 pagesMP-I-Lecture No. 12-13-14Osaid AhmadNo ratings yet

- Gating SystemDocument7 pagesGating SystemParth MaldhureNo ratings yet

- 1.0 Fundamentals of CastingDocument43 pages1.0 Fundamentals of CastingLoo Tong ShianNo ratings yet

- AnswersDocument30 pagesAnswersTanay NaikNo ratings yet

- Elements of Gating System:: A Gating System For Castings Can Be Broadly Divided IntoDocument16 pagesElements of Gating System:: A Gating System For Castings Can Be Broadly Divided IntoGomish Sharma100% (1)

- 15mec - 213 Manufacturing Technology-I: Subject: 15mec 213-Manufacturingtechnology-I Class: 4 Sem B.Tech-Mech A'Document40 pages15mec - 213 Manufacturing Technology-I: Subject: 15mec 213-Manufacturingtechnology-I Class: 4 Sem B.Tech-Mech A'subash naraharasettiNo ratings yet

- Metal CastingDocument6 pagesMetal CastingWesam abo HalimehNo ratings yet

- L7 Centrifugal CastingDocument23 pagesL7 Centrifugal CastingRahul DandugulaNo ratings yet

- Centrifugal CastingDocument18 pagesCentrifugal CastingArijit PatraNo ratings yet

- 5.0 Sand Moulding ProcessesDocument15 pages5.0 Sand Moulding ProcessesCatherine IjukaNo ratings yet

- Casting DefectsDocument57 pagesCasting DefectsFajar SiradzNo ratings yet

- Manufacturing Processes Ch.4 (10 and 11) CastingDocument143 pagesManufacturing Processes Ch.4 (10 and 11) Castingashoku24007No ratings yet

- Chapter 2 Metal Casting ProcessesDocument59 pagesChapter 2 Metal Casting Processesdagimawgchew777No ratings yet

- Mechanical Castings Ppt-2Document49 pagesMechanical Castings Ppt-2PubgArena 01No ratings yet

- Unit-3 - Special Moulding Processes PART-2Document25 pagesUnit-3 - Special Moulding Processes PART-2mahammad kamaluddeenNo ratings yet

- Metal CastingDocument40 pagesMetal CastingFahmi Sanji AlexanderNo ratings yet

- Casting TheoryDocument55 pagesCasting TheorygggNo ratings yet

- Lec 3b - Fluidity and SolidificationDocument49 pagesLec 3b - Fluidity and Solidificationnimdie jacksonNo ratings yet

- Manufacturing Processes (ME 361) Lecture-6: Instructor: Shantanu BhattacharyaDocument15 pagesManufacturing Processes (ME 361) Lecture-6: Instructor: Shantanu BhattacharyaSahil SundaNo ratings yet

- Casting 119 - EndDocument39 pagesCasting 119 - EndVarun AgrawalNo ratings yet

- 1-5-6 SprueDocument45 pages1-5-6 Sprueuday kiran thagirchiNo ratings yet

- Metal Casting ProcessesDocument61 pagesMetal Casting ProcessesBinyam HabtamuNo ratings yet

- Elements of Gating SystemDocument21 pagesElements of Gating SystemsudhirNo ratings yet

- 8 Die CastingDocument6 pages8 Die CastingAkshayNo ratings yet

- Casting DefectsDocument60 pagesCasting DefectsVaibhav AwacharNo ratings yet

- Steel Making Processes: Dr. Laraib Sarfraz KhanzadaDocument23 pagesSteel Making Processes: Dr. Laraib Sarfraz KhanzadaAsher AhmedNo ratings yet

- Exp1 CastingDocument7 pagesExp1 CastingMahmoud AlswaitiNo ratings yet

- Casting ProcessesDocument48 pagesCasting ProcessessumikannuNo ratings yet

- A Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesFrom EverandA Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesNo ratings yet

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkFrom EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkNo ratings yet

- Color Atlas Basic Technique for Metal Ceramics: An Introduction to Ceramic TechniqueFrom EverandColor Atlas Basic Technique for Metal Ceramics: An Introduction to Ceramic TechniqueNo ratings yet

- PolymersDocument27 pagesPolymersdhruvmistry300No ratings yet

- PatternsDocument46 pagesPatternsdhruvmistry300No ratings yet

- Moulding SandDocument10 pagesMoulding Sanddhruvmistry300No ratings yet

- Experiment 3Document4 pagesExperiment 3dhruvmistry300No ratings yet

- Experiment 4Document3 pagesExperiment 4dhruvmistry300No ratings yet

- Shore Protection Manual - Vol-II - US Army - 1984Document300 pagesShore Protection Manual - Vol-II - US Army - 1984hihappy2cuNo ratings yet

- Climatic-Chambers DS FDMDocument3 pagesClimatic-Chambers DS FDMconkhimocNo ratings yet

- Ccs Assignment 2Document7 pagesCcs Assignment 2VINIKSHA SHREE A CSE studentNo ratings yet

- Nitish-ResumeDocument1 pageNitish-Resumeshariq khanNo ratings yet

- Standards For Mobile Health-Related AppsDocument9 pagesStandards For Mobile Health-Related Appsharsono harsonoNo ratings yet

- Setting Product Strategy: Marketing Management, 13 EdDocument43 pagesSetting Product Strategy: Marketing Management, 13 EdEucharistia Yacoba NugrahaNo ratings yet

- Timeline of Indian History - Wikipedia, The Free EncyclopediaDocument24 pagesTimeline of Indian History - Wikipedia, The Free EncyclopediaPrabhu Charan TejaNo ratings yet

- English EssayDocument32 pagesEnglish Essayapi-3731661100% (3)

- Instruction of Installation The Operating Manual For The 220kv TransformerDocument12 pagesInstruction of Installation The Operating Manual For The 220kv TransformerArman PracoyoNo ratings yet

- 951 SignedDocument21 pages951 SignedDany GunawanNo ratings yet

- Dogmatism, Religion, and Psychological Type.Document16 pagesDogmatism, Religion, and Psychological Type.ciprilisticusNo ratings yet

- DivergentDocument3 pagesDivergentsasingNo ratings yet

- Organizational Behavior: Robbins & JudgeDocument18 pagesOrganizational Behavior: Robbins & JudgeYandex PrithuNo ratings yet

- 6 Speed Automatic Gearbox 09g EngDocument241 pages6 Speed Automatic Gearbox 09g EngGime PedrozaNo ratings yet

- Checklist - Turning Client To Lateral or Prone PositionDocument3 pagesChecklist - Turning Client To Lateral or Prone PositionNorhaina AminNo ratings yet

- Alkene and Alkyne - by Resonance PDFDocument45 pagesAlkene and Alkyne - by Resonance PDFPrasad Yarra100% (1)

- Excel Basics RoadmapDocument3 pagesExcel Basics RoadmapLalatenduNo ratings yet

- Weight and Mass SEDocument5 pagesWeight and Mass SEGabriel LouimaNo ratings yet

- MedCare Visions - International Sales BookDocument26 pagesMedCare Visions - International Sales BookZandoNo ratings yet

- Copper Tube HandbookDocument66 pagesCopper Tube HandbookRafael Leonardo GomezNo ratings yet

- Experimentalstudies On The Effects of Reduction in Gear Tooth Stiffness Lubricant Film Thicknessina Spur Geared SystemDocument13 pagesExperimentalstudies On The Effects of Reduction in Gear Tooth Stiffness Lubricant Film Thicknessina Spur Geared SystemBurak TuncerNo ratings yet

- MTP44001Document63 pagesMTP44001Dong-seob ParkNo ratings yet

- Metercat 6.1.1.0 Release NotesDocument7 pagesMetercat 6.1.1.0 Release NotesCarlos Guzman BonifacioNo ratings yet

- Assignment 5Document9 pagesAssignment 5wacih58121No ratings yet

- Patrol GR: GI MA EM LC EC FE CL MT Automatic Transmission AT TF PD FA RA BR ST RS BT HA EL IDXDocument2 pagesPatrol GR: GI MA EM LC EC FE CL MT Automatic Transmission AT TF PD FA RA BR ST RS BT HA EL IDXAttila SomorjaiNo ratings yet

- Crusader Communicator: "Safer at Home" Edition #5: Sheboygan Lutheran High SchoolDocument7 pagesCrusader Communicator: "Safer at Home" Edition #5: Sheboygan Lutheran High SchoolMatt ThielNo ratings yet

- Bas 98 Atex 2156 XDocument11 pagesBas 98 Atex 2156 XFelipe CamusNo ratings yet

- 10 Top Photography Composition RulesDocument6 pages10 Top Photography Composition Rulesaj4fall086050No ratings yet

- Certificate of Eligibility FinalDocument9 pagesCertificate of Eligibility Finalgena sanchez BernardinoNo ratings yet