Professional Documents

Culture Documents

GTO StationaryChuck

GTO StationaryChuck

Uploaded by

weslley.luzOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GTO StationaryChuck

GTO StationaryChuck

Uploaded by

weslley.luzCopyright:

Available Formats

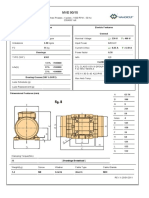

GTO Stationary chuck

■ For standard collets

■ Manual actuated

Application/customer benefits

• Highest clamping forces and stiffness for best machining quality

• Maximum economy due to quick change of collets and fast mounting

• High flexibility due to the use of standard collets

• Ideal for 5-axis machining due to the compact design

• Sensitive adjustment of the clamping force

Technical features

• Manual actuated by fast clamping function (clamping wrench SW 12)

• Repeatability ≤ 0.01 mm

• Pull-down effect

• Workpiece stop optional

• Horizontal or vertical mounting

• Threads for mounting a front stop

Standard equipment

Stationary chuck with clamping wrench

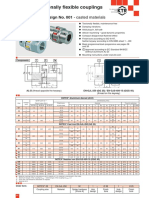

ØD

ØD1

K

T

H

h

T1

G

L C H7

Ø A

d

G1

(4x90°, 10 depth)

TK

A

L

Subject to technical changes.

Order review

Clamp.

Max. Weight

Type Id.-No. A L B H ØD ØD1 Ød h K G G1 T T1 TK ØC range

[kN] [kg]

[mm]

GTO 42 462500 100 130 130 100 100 81 11 53 5.5 M8 M5 87 7 90 12 80 4 - 42 7.9

GTO 65 462501 120 150 150 100 120 101.2 11 53 6 M10 M5 86 6 110 16 105 4 - 65 9.6

GTO 100 462502 170 200 200 110 165 146 13 60 4 M12 M5 95 10 155 20 150 40 - 100 17.5

D1 = Diameter of the collet (unclamped)

Max. kN = Maximum total clamping force

Pneumatic actuated version on request.

184 SMW-AUTOBLOK

You might also like

- 14 Pretty Pearl Jewelry Patterns For Every Occasion Free Ebook PDFDocument35 pages14 Pretty Pearl Jewelry Patterns For Every Occasion Free Ebook PDFDanijel Savic100% (2)

- 4E845 Machining The AR 15 Lower Reciever Forging PDFDocument62 pages4E845 Machining The AR 15 Lower Reciever Forging PDFpalaciosro100% (2)

- Craft Passion - Rhino - Crochet PatternDocument19 pagesCraft Passion - Rhino - Crochet PatternOanh Nguyễn Thị Phương100% (4)

- Machines For Producing Saws Blades: BS35 BS45 BS75Document7 pagesMachines For Producing Saws Blades: BS35 BS45 BS75Humberto MenaldoNo ratings yet

- Bolting Cat. Inside Spreads - InddDocument8 pagesBolting Cat. Inside Spreads - InddTaimoorNo ratings yet

- ProductOverview 2023 EN-38Document1 pageProductOverview 2023 EN-38Ismail AliNo ratings yet

- 09 Electric Tool UpdateDocument30 pages09 Electric Tool UpdateAji KaNo ratings yet

- cp1210 SpecsDocument2 pagescp1210 Specsyoucef alimNo ratings yet

- Rotex: Torsionally Flexible CouplingsDocument1 pageRotex: Torsionally Flexible CouplingsL.kolekarNo ratings yet

- Bucket Elevator EC 102-01-01Document2 pagesBucket Elevator EC 102-01-01Mehdi EDNo ratings yet

- KR - MV IDU - 4series - R410A - 5060Hz - Global - MFL55028426 - 0CVP0-05B - Jul.2016 PDFDocument474 pagesKR - MV IDU - 4series - R410A - 5060Hz - Global - MFL55028426 - 0CVP0-05B - Jul.2016 PDFEmmanuel MartínezNo ratings yet

- CELDA LCD-100K DatasheetDocument2 pagesCELDA LCD-100K DatasheetJOSENo ratings yet

- Multi V IV Indoor PDFDocument526 pagesMulti V IV Indoor PDFDavid AlbortNo ratings yet

- Axial Piston Fixed Motor A10FM Axial Piston Plug-In Motor A10FE Series 52Document38 pagesAxial Piston Fixed Motor A10FM Axial Piston Plug-In Motor A10FE Series 52Orlando AriasNo ratings yet

- Gate Valve - Metal SeatedDocument6 pagesGate Valve - Metal SeatedSathishkumar DhamodaranNo ratings yet

- KR - MV IDU - R410A - 5060Hz - Global - MFL61741606 - 0CVP0-09D (Apr.2016)Document457 pagesKR - MV IDU - R410A - 5060Hz - Global - MFL61741606 - 0CVP0-09D (Apr.2016)Victor Dynami PerkasaNo ratings yet

- Axial Piston Fixed Motor A10FM Axial Piston Plug-In Motor A10FE Series 52Document38 pagesAxial Piston Fixed Motor A10FM Axial Piston Plug-In Motor A10FE Series 52Ariel GamarraNo ratings yet

- NOLH NT ENG 50HzDocument54 pagesNOLH NT ENG 50Hzrudi 01No ratings yet

- 09 Electric Tool Catalog 10 PDFDocument26 pages09 Electric Tool Catalog 10 PDFIndonesian ThuglifeNo ratings yet

- Linear Drive CylindersDocument77 pagesLinear Drive Cylinderscleancamb1No ratings yet

- Technical Catalog HRA10VSO100DFR/31R: FeaturesDocument13 pagesTechnical Catalog HRA10VSO100DFR/31R: FeaturesMichail ArmitageNo ratings yet

- Direct Mount Temperature Switch: Model TSBDocument2 pagesDirect Mount Temperature Switch: Model TSBFabián AldanaNo ratings yet

- 53 Series Industrial Potentiometer 58 Series Industrial PotentiometerDocument1 page53 Series Industrial Potentiometer 58 Series Industrial PotentiometerTanvir AhmedNo ratings yet

- DMT280H редукторDocument2 pagesDMT280H редукторkamran mamedovNo ratings yet

- Pneumatic Actuators CatalogueDocument42 pagesPneumatic Actuators CataloguerserraNo ratings yet

- Tci StationaryDocument15 pagesTci Stationaryweslley.luzNo ratings yet

- NCS CatalogDocument27 pagesNCS Catalogminhdoan00No ratings yet

- T5009 T5009-6 Datasheet en 201408 C26I-E-01Document8 pagesT5009 T5009-6 Datasheet en 201408 C26I-E-01Leonardo RojasNo ratings yet

- Features:: Technical SpecificationsDocument2 pagesFeatures:: Technical SpecificationsreinpolyNo ratings yet

- Ferguson IM-pAC E-UKDocument2 pagesFerguson IM-pAC E-UKSuhas KODRENo ratings yet

- Mve90 15Document1 pageMve90 15Boulos NassarNo ratings yet

- FRD HB Range 2019 NewDocument17 pagesFRD HB Range 2019 Newrho myoung chullNo ratings yet

- Total Tube Length Reduced: Clamp CylinderDocument25 pagesTotal Tube Length Reduced: Clamp CylinderHoàng ThếNo ratings yet

- DTH Drill ToolsDocument24 pagesDTH Drill ToolsSophia GeNo ratings yet

- 1510 SKR Edition3 n0607Document2 pages1510 SKR Edition3 n0607AhmedRamadanNo ratings yet

- Ncommonness With The Usual Machine: Parts Name ZAXIS200 EX200 EX200 EX200 UH083 Engine AA-6BG1T A-6BG1T 6BD1TDocument23 pagesNcommonness With The Usual Machine: Parts Name ZAXIS200 EX200 EX200 EX200 UH083 Engine AA-6BG1T A-6BG1T 6BD1TMd Kasim KhanNo ratings yet

- 95 Standard Body Series Ignition Switches: Product DatasheetDocument1 page95 Standard Body Series Ignition Switches: Product Datasheetgowrav_hassanNo ratings yet

- Bowex Curved-Tooth Gear Couplings: Type As No. 004 and Spec.-I No. 005Document1 pageBowex Curved-Tooth Gear Couplings: Type As No. 004 and Spec.-I No. 005Mauricio Ariel H. OrellanaNo ratings yet

- Kobelt Tabla de EspecificacionesDocument43 pagesKobelt Tabla de EspecificacionesWilson CendalesNo ratings yet

- Clamp Cylinder: Total Tube Length ReducedDocument24 pagesClamp Cylinder: Total Tube Length ReducedYana SupriatnaNo ratings yet

- 1FG1106-1PD23-1AS1-Z D01+G23+G53+G99+K08 Datasheet enDocument3 pages1FG1106-1PD23-1AS1-Z D01+G23+G53+G99+K08 Datasheet enAung Naing OoNo ratings yet

- ZRD Rotary Valve Coperion Product Specification ZRD Rotary Valve (Heavy-Duty Premium)Document2 pagesZRD Rotary Valve Coperion Product Specification ZRD Rotary Valve (Heavy-Duty Premium)milivojNo ratings yet

- Pressure Washers C 100.7: The Light Entry-Level, High-Pressure Washer That Will Power Up Your Basic Outdoor CleaningDocument5 pagesPressure Washers C 100.7: The Light Entry-Level, High-Pressure Washer That Will Power Up Your Basic Outdoor CleaningyunanNo ratings yet

- Specification Equipment For StringingDocument36 pagesSpecification Equipment For StringingedwardoNo ratings yet

- BA GXX Gearbox Variante Automotive v1-0 enDocument60 pagesBA GXX Gearbox Variante Automotive v1-0 enBrentildaNo ratings yet

- GTB - Servo Positioning Rotary TableDocument2 pagesGTB - Servo Positioning Rotary Tabletony canNo ratings yet

- Liebherr Short Description Dmva Double MotorDocument4 pagesLiebherr Short Description Dmva Double MotornferreiNo ratings yet

- Picolo XL - en - 020107 - NEW PDFDocument4 pagesPicolo XL - en - 020107 - NEW PDFhepcomotionNo ratings yet

- EagleBurgmann - Cartex Dual Seals - ENDocument5 pagesEagleBurgmann - Cartex Dual Seals - ENSanket PanchalNo ratings yet

- 1FG1101-1RC26-2AW1-Z D03+K06 Datasheet enDocument2 pages1FG1101-1RC26-2AW1-Z D03+K06 Datasheet endlquirogaNo ratings yet

- Technical Brochure: Multi-Stage Centrifugal PumpDocument4 pagesTechnical Brochure: Multi-Stage Centrifugal PumpcurlyjockeyNo ratings yet

- Mve 500 - 3Document2 pagesMve 500 - 3Amol SarinNo ratings yet

- Soldadora Big Blue 400 Pro MILLERDocument8 pagesSoldadora Big Blue 400 Pro MILLERDemian CruzNo ratings yet

- Hh-411 Impact Type Hardness Testing Unit: Catalog No. E4299-810Document6 pagesHh-411 Impact Type Hardness Testing Unit: Catalog No. E4299-810D.T.No ratings yet

- Flexiroc T15 R: Surface Drill Rig For Quarrying and ConstructionDocument5 pagesFlexiroc T15 R: Surface Drill Rig For Quarrying and Constructionisalas314No ratings yet

- Cable To Ground Rod or Other Rounds: Mold FamilyDocument2 pagesCable To Ground Rod or Other Rounds: Mold FamilyCharlie MendozaNo ratings yet

- Motoniveladora Cat 140KDocument2 pagesMotoniveladora Cat 140KAdrian Andres Quilodran MirandaNo ratings yet

- Lineaarijohteiden RullatDocument1 pageLineaarijohteiden RullatAntti KoskiniemiNo ratings yet

- 2652 Dixi ENG May20Document8 pages2652 Dixi ENG May20Israel López LagosNo ratings yet

- Technical Catalog HRA6VM107HD1/63W: FeaturesDocument18 pagesTechnical Catalog HRA6VM107HD1/63W: FeaturesMichail ArmitageNo ratings yet

- Engineered Class Pulley BrochureDocument8 pagesEngineered Class Pulley BrochureLazzarus Az GunawanNo ratings yet

- SMC Air Cylinder PDFDocument121 pagesSMC Air Cylinder PDFRandy FajardoNo ratings yet

- MPZ Operating ManualDocument48 pagesMPZ Operating Manualweslley.luzNo ratings yet

- The FL Exible 5-Axis Vise: New GenerationDocument6 pagesThe FL Exible 5-Axis Vise: New Generationweslley.luzNo ratings yet

- Sintergrip StationaryDocument6 pagesSintergrip Stationaryweslley.luzNo ratings yet

- APS140-160 ZeroPoint ClampingSystemDocument8 pagesAPS140-160 ZeroPoint ClampingSystemweslley.luzNo ratings yet

- Quick Turn SeriesDocument26 pagesQuick Turn Seriesweslley.luzNo ratings yet

- Mega Turn 500-600Document12 pagesMega Turn 500-600weslley.luzNo ratings yet

- The Art of Bending - Press Brake Tooling Solutions For Every Challenge - by Jeff Paulson - Marketing Manager - Wilson Tool InternationalDocument1 pageThe Art of Bending - Press Brake Tooling Solutions For Every Challenge - by Jeff Paulson - Marketing Manager - Wilson Tool InternationalSM TECH SRLNo ratings yet

- Tes SylineDocument40 pagesTes SylineBima SetiajiNo ratings yet

- 'Pigeon and Dove JackDocument6 pages'Pigeon and Dove Jackbuffylovez100% (1)

- Modern Manufacturing MethodsDocument3 pagesModern Manufacturing MethodsSree MurthyNo ratings yet

- DK Vanilla Pattern FinalDocument4 pagesDK Vanilla Pattern FinalJill KrahlingNo ratings yet

- Method Statement For Remmoal of Paint Using ChemicalDocument4 pagesMethod Statement For Remmoal of Paint Using ChemicalSumedhaSampathNo ratings yet

- Rose Ntal Sweater PatternDocument16 pagesRose Ntal Sweater PatternThanh Thảo NguyễnNo ratings yet

- BAB Witchy Gnome v1Document2 pagesBAB Witchy Gnome v1Jill KrahlingNo ratings yet

- Amigurumi GirDocument9 pagesAmigurumi GirJessica Carr100% (1)

- The Quality of MDF Workpieces Machined in CNC Milling Machine in Cutting Speeds, Feedrate, and Depth of CutDocument8 pagesThe Quality of MDF Workpieces Machined in CNC Milling Machine in Cutting Speeds, Feedrate, and Depth of CutMujib wahyu satriyoNo ratings yet

- Easter Gnome CROCHETGNOMEDocument9 pagesEaster Gnome CROCHETGNOMEEDINA POSTA100% (6)

- Autodesk® Inventor™ and Sheet Metal Manufacturing From Drawing To FabricationDocument15 pagesAutodesk® Inventor™ and Sheet Metal Manufacturing From Drawing To FabricationGraham MooreNo ratings yet

- Freeamigurumi Picpin Pro Christmas Bear Amigurumi Free Crochet PatternDocument10 pagesFreeamigurumi Picpin Pro Christmas Bear Amigurumi Free Crochet PatternSegundo Noriega100% (7)

- 9 Crochet DollDocument10 pages9 Crochet DollYvanna Ferreira100% (1)

- Arm Knit Cowl - Craft Cozy Checkerboard Afghan - Knit: InstructionsDocument1 pageArm Knit Cowl - Craft Cozy Checkerboard Afghan - Knit: InstructionsNicoleNo ratings yet

- Pferd - Limas Rotativas Cat. 202Document64 pagesPferd - Limas Rotativas Cat. 202MinatelNo ratings yet

- U3-01 - Rhino Pattern - ENDocument7 pagesU3-01 - Rhino Pattern - ENPamela Alejandra100% (4)

- Baby Blanket Crochet PatternDocument5 pagesBaby Blanket Crochet PatternsamNo ratings yet

- Price Quotation (Woven Shirt) : SL Description Consumption Uom Price ($) Price Unit Total PriceDocument3 pagesPrice Quotation (Woven Shirt) : SL Description Consumption Uom Price ($) Price Unit Total PriceTusshar AhmedNo ratings yet

- Hooded Scarf With EarsDocument4 pagesHooded Scarf With EarsIvanaBađura100% (1)

- Fabric Catalogue High Resolution Volume 2Document19 pagesFabric Catalogue High Resolution Volume 2Jawad RazaNo ratings yet

- Amigurumi Bunny PatternDocument26 pagesAmigurumi Bunny PatternCristina AmariuteiNo ratings yet

- ZZU 192 Workshop Practice IIDocument2 pagesZZU 192 Workshop Practice IISrikant PotluriNo ratings yet

- The Router Book A Complete Guide To The Router and Its Accesories - Pat WarnerThe Router BookDocument196 pagesThe Router Book A Complete Guide To The Router and Its Accesories - Pat WarnerThe Router Bookcrist87n100% (11)

- WVN0000314Document4 pagesWVN0000314Mobin AkhandNo ratings yet

- Princess Mitts From The Knitter's Book of Yarn by Clara ParkesDocument11 pagesPrincess Mitts From The Knitter's Book of Yarn by Clara ParkesCrafterNews9% (95)