Professional Documents

Culture Documents

Case Study Group-7

Case Study Group-7

Uploaded by

sailolla30Copyright:

Available Formats

You might also like

- Jenny Craig SubstitutesDocument6 pagesJenny Craig SubstitutesLaurie Thomas60% (5)

- Blood in The ChocolateDocument55 pagesBlood in The ChocolateKandra100% (5)

- Botanical Grouping Guide-Courtesy of The Shakespeare DistilleryDocument3 pagesBotanical Grouping Guide-Courtesy of The Shakespeare DistillerysorentowNo ratings yet

- REAL BABY FOOD: Easy All-Natural Recipes For Your Baby and Toddler by Jenna HelwigDocument8 pagesREAL BABY FOOD: Easy All-Natural Recipes For Your Baby and Toddler by Jenna HelwigHoughton Mifflin Harcourt Cookbooks50% (2)

- Machine Recipe GuideDocument2 pagesMachine Recipe Guidehaque110% (1)

- Assignment A Research Report On Maggi Ban CaseDocument27 pagesAssignment A Research Report On Maggi Ban CaseFahad ul AminNo ratings yet

- Starting A Kakanin BusinessDocument10 pagesStarting A Kakanin BusinessRaven Parreño100% (1)

- Great Grasslands Grains Inc GGG Manufactures and Sells A WideDocument2 pagesGreat Grasslands Grains Inc GGG Manufactures and Sells A WideCharlotteNo ratings yet

- 5 1CPDocument1 page5 1CPsatarupaNo ratings yet

- Thesis On Banana ChipsDocument7 pagesThesis On Banana Chipsaprildavislittlerock100% (2)

- An Analysis On The Marketing Strategies OF Maggi: Presented By-Vaibhav Agarwal ROLL-44Document27 pagesAn Analysis On The Marketing Strategies OF Maggi: Presented By-Vaibhav Agarwal ROLL-44Vaibhav AgarwalNo ratings yet

- Easy Vegan Protein Bars - Minimalist Baker RecipesDocument2 pagesEasy Vegan Protein Bars - Minimalist Baker RecipesGLBNo ratings yet

- ALLERGY Food Challenge Prep LetterDocument4 pagesALLERGY Food Challenge Prep LetterCarla García TorresNo ratings yet

- Homemade Oatmeal Cookie Granola Recipe Easy To Make! - Fitness BlenderDocument9 pagesHomemade Oatmeal Cookie Granola Recipe Easy To Make! - Fitness BlenderMadalina GHEORGHENo ratings yet

- MaggieDocument45 pagesMaggieRitikaNo ratings yet

- Marketing Mix of MaggieDocument62 pagesMarketing Mix of MaggieAdnan KhanNo ratings yet

- Report On The Market Retention Strategies of Maggi in NagpurDocument50 pagesReport On The Market Retention Strategies of Maggi in NagpurHarmeet Kaur LambaNo ratings yet

- Product Plan BSBA-2A GROUP 1 - GrabAPatty PDFDocument12 pagesProduct Plan BSBA-2A GROUP 1 - GrabAPatty PDFQueen Paula Rañada GuangcoNo ratings yet

- Watch TV Live: The Importance of BananasDocument26 pagesWatch TV Live: The Importance of Bananasmaricon penalbaNo ratings yet

- Marketing Mix of MaggiDocument4 pagesMarketing Mix of MaggiAnwar khanNo ratings yet

- Tips For At-Home Yogurt Making: How To Make Yogurt RecipesDocument3 pagesTips For At-Home Yogurt Making: How To Make Yogurt RecipesAgnes P. SugaNo ratings yet

- Mango Jam ThesisDocument7 pagesMango Jam Thesisafjrqokne50% (2)

- Maggi Brand AuditDocument13 pagesMaggi Brand AuditNiranjan DasNo ratings yet

- Malunggay Bread ThesisDocument5 pagesMalunggay Bread ThesisMonique Carr100% (2)

- Meeting Your My Plate Goals On A BudgetDocument44 pagesMeeting Your My Plate Goals On A BudgetOWNEditorNo ratings yet

- August 2014 1406900366 22Document3 pagesAugust 2014 1406900366 22MukeshNo ratings yet

- Veggie Oatmeal Cookies 1Document41 pagesVeggie Oatmeal Cookies 1Wilhanne Del Rosario100% (1)

- OutlineDocument7 pagesOutlineJinky Nablo0% (1)

- Maggi Business PlanDocument10 pagesMaggi Business Plantanima_106607No ratings yet

- Final PresentationDocument23 pagesFinal Presentationjuldemar capillanNo ratings yet

- Formula Adjustment: (Nutramigen or Nutramigen With Enflora LGG)Document4 pagesFormula Adjustment: (Nutramigen or Nutramigen With Enflora LGG)Richard BakerNo ratings yet

- FEASIBILITYDocument10 pagesFEASIBILITYMarvelous Julia StamariaNo ratings yet

- Nutritional Benefits of AvocadosDocument2 pagesNutritional Benefits of AvocadosIndra SetiawanNo ratings yet

- Easy Dog Treat Recipes with 5 Ingredients or LessFrom EverandEasy Dog Treat Recipes with 5 Ingredients or LessRating: 5 out of 5 stars5/5 (1)

- Chapter 1Document23 pagesChapter 1Alessandra Abrau100% (1)

- Demand Analysis of MaggiDocument9 pagesDemand Analysis of MaggiGauravOberoi33% (3)

- Pasteurised Milk/suitable Infant Formula: at Each of The Following Steps Cookie, Muffin, Pancake, Cheese and YoghurtDocument2 pagesPasteurised Milk/suitable Infant Formula: at Each of The Following Steps Cookie, Muffin, Pancake, Cheese and YoghurtLuciana VieiraNo ratings yet

- 5lbs Shoppinglist UKDocument2 pages5lbs Shoppinglist UKdanielmarinicaNo ratings yet

- Taro Chips ResearchDocument16 pagesTaro Chips Researchjessy bitangaNo ratings yet

- Business PlanDocument4 pagesBusiness PlanPortia Guinto Gubantes Mandragora100% (2)

- Baby Corn ThesisDocument8 pagesBaby Corn Thesisybkpdsgig100% (1)

- Homemade Yogurt: IngredientsDocument1 pageHomemade Yogurt: IngredientsMoomNo ratings yet

- Free Sample Meal PlanDocument16 pagesFree Sample Meal PlanjacobNo ratings yet

- Research and Methodology of Maggi: Shreeraj HariharanDocument31 pagesResearch and Methodology of Maggi: Shreeraj HariharanShreeraj HariharanNo ratings yet

- Name: Shital Gosavi Roll No: 09 Sub: Economic (Demand Analysis)Document11 pagesName: Shital Gosavi Roll No: 09 Sub: Economic (Demand Analysis)Varshitha ReddyNo ratings yet

- Nutriliving Min Compressed 1 CompressedDocument19 pagesNutriliving Min Compressed 1 CompressedJaco NagelNo ratings yet

- Research Methodology On MaggiDocument28 pagesResearch Methodology On MaggiStella PaulNo ratings yet

- Advance E-BookDocument12 pagesAdvance E-BookvhvdqmhcvvNo ratings yet

- Groceries On A Budget (11 Pages)Document11 pagesGroceries On A Budget (11 Pages)Geraldyne100% (1)

- MAGGIEDocument23 pagesMAGGIEMuskan BohraNo ratings yet

- FeasibDocument4 pagesFeasibJna MarieNo ratings yet

- ENGWORKfinals BUSINESS PLANDocument15 pagesENGWORKfinals BUSINESS PLANOcubillo Froilan D.No ratings yet

- Yogurt Peanut Butter Banana Dog Treats RecipeDocument1 pageYogurt Peanut Butter Banana Dog Treats RecipeadrianagponsNo ratings yet

- Fungifun For Simple Minds (Psilosophy - Info)Document30 pagesFungifun For Simple Minds (Psilosophy - Info)GALA PORONo ratings yet

- Snacks Healthy Banana Blueberry MuffinsDocument1 pageSnacks Healthy Banana Blueberry MuffinsRax LlurNo ratings yet

- Your DT InvestigationDocument3 pagesYour DT InvestigationBie SchovalevskyNo ratings yet

- Group-6-Research - PDF 20240228 230838 0000Document8 pagesGroup-6-Research - PDF 20240228 230838 0000JOANNE ROANNE FELICIANONo ratings yet

- Topic "Research Methodology" ON " A Study On Nestle Product Maggi"Document33 pagesTopic "Research Methodology" ON " A Study On Nestle Product Maggi"Sunita Nishad0% (1)

- Squash Papaya ChipsDocument74 pagesSquash Papaya Chipsjanine barilla100% (2)

- RecipesDocument13 pagesRecipesapi-538885097No ratings yet

- Maggi Research MethodologyDocument8 pagesMaggi Research MethodologyRohanNarkarNo ratings yet

- Only Sevens: Only Sevens Don't Stop, Let's Do ItDocument1 pageOnly Sevens: Only Sevens Don't Stop, Let's Do ItJuan CostaNo ratings yet

- Master Feeding Schedule 5 ML Program: All Measurements Are Per GallonDocument1 pageMaster Feeding Schedule 5 ML Program: All Measurements Are Per GallonChris TuckerNo ratings yet

- Case Study Group-6Document2 pagesCase Study Group-6sailolla30No ratings yet

- Job Satisfaction Survey GovtDocument1 pageJob Satisfaction Survey Govtsailolla30No ratings yet

- Polavaram Project: A Study On Rehabilitation and Resettlement Package and The Plight of AdivasisDocument20 pagesPolavaram Project: A Study On Rehabilitation and Resettlement Package and The Plight of Adivasissailolla30No ratings yet

- 100 Kilowatt-Hour Battery PackDocument1 page100 Kilowatt-Hour Battery Packsailolla30No ratings yet

- Ministry of Home Affair Ar 2017-18 For WebDocument334 pagesMinistry of Home Affair Ar 2017-18 For Websailolla30No ratings yet

- Adhoc Faculty Notification 2606Document3 pagesAdhoc Faculty Notification 2606sailolla30No ratings yet

- Kaola Saomplar Ki) Plabqata: Sai Eca Pi ससरकक Stotsa Aaof Ema Di.Ema Esa Maona Plaamt Eiryaa Stosana Ka^ManaDocument49 pagesKaola Saomplar Ki) Plabqata: Sai Eca Pi ससरकक Stotsa Aaof Ema Di.Ema Esa Maona Plaamt Eiryaa Stosana Ka^Manasailolla30No ratings yet

- Home Automation by Android Application Based Remote ControlDocument2 pagesHome Automation by Android Application Based Remote Controlsailolla30No ratings yet

- Vizag Steel Answer Key - TechDocument45 pagesVizag Steel Answer Key - Techsailolla30No ratings yet

- Decs Ece DeceDocument58 pagesDecs Ece Decesailolla30No ratings yet

- Mems Based Robot: The Hand Mechanical MovementDocument4 pagesMems Based Robot: The Hand Mechanical Movementsailolla30No ratings yet

- Tourism-Means To Sustainable Inclusive GrowthDocument2 pagesTourism-Means To Sustainable Inclusive Growthsailolla30No ratings yet

- NOCET 2013.doc - 100777Document3 pagesNOCET 2013.doc - 100777sailolla30No ratings yet

- What To Write in AnswerDocument1 pageWhat To Write in Answersailolla30No ratings yet

- Ham & Potato Hash With Baked Beans & Healthy Fried' Eggs: MethodDocument1 pageHam & Potato Hash With Baked Beans & Healthy Fried' Eggs: MethodBobNo ratings yet

- FriesDocument1 pageFriesXarbie RebadomiaNo ratings yet

- Prebeginner 2 - Module 1Document28 pagesPrebeginner 2 - Module 1Julia PiscoNo ratings yet

- Diet Chart For High Triglyceride Patient, High Triglycerides Diet Chart - Lybrate.Document5 pagesDiet Chart For High Triglyceride Patient, High Triglycerides Diet Chart - Lybrate.Sukalyan MukharjeeNo ratings yet

- Language Focus: More Beautiful ThanDocument5 pagesLanguage Focus: More Beautiful ThanGuSD PeloteroNo ratings yet

- Air Fryer Cook Times ChartDocument1 pageAir Fryer Cook Times Chartalberto hungNo ratings yet

- Baking Tools and Equipment and Their Uses: Cake Pans - Comes in Different Sizes and Shapes and May Be Round SquareDocument7 pagesBaking Tools and Equipment and Their Uses: Cake Pans - Comes in Different Sizes and Shapes and May Be Round SquareBrenNan ChannelNo ratings yet

- Tingkatan 5 English Week 1-4Document11 pagesTingkatan 5 English Week 1-4Ruban RubanNo ratings yet

- Day 8 ActivityDocument7 pagesDay 8 ActivityMark Anthony LibecoNo ratings yet

- Green Smoothie Recipe 1Document5 pagesGreen Smoothie Recipe 1Susyary SNo ratings yet

- Low-Sodium Grocery List Low-Sodium Grocery List: Bread/Grains Condiments Bread/Grains CondimentsDocument1 pageLow-Sodium Grocery List Low-Sodium Grocery List: Bread/Grains Condiments Bread/Grains CondimentsRed ShadeNo ratings yet

- Week 8-9 - Food Styling and PhotographyDocument31 pagesWeek 8-9 - Food Styling and PhotographyKurt FranciscoNo ratings yet

- The Principles of Presenting, Serving and Storing 3Document9 pagesThe Principles of Presenting, Serving and Storing 3Michelle DoctorNo ratings yet

- Contoh Narrative Text Singkat Dan TerjemahannyaDocument7 pagesContoh Narrative Text Singkat Dan TerjemahannyaSantiago FernandoNo ratings yet

- Elllo Beg 25 - Akane Howard - Winter Vacation - Past TenseDocument1 pageElllo Beg 25 - Akane Howard - Winter Vacation - Past Tenseภัศรา แก้วบัวดีNo ratings yet

- Fondamenti Di Fisica Meccanica Onde Termodinamica 2015th Edition David Halliday Robert Resnick Full Chapter Download PDFDocument57 pagesFondamenti Di Fisica Meccanica Onde Termodinamica 2015th Edition David Halliday Robert Resnick Full Chapter Download PDFrauyacengi100% (2)

- Englsih Test Book 2Document19 pagesEnglsih Test Book 2arthur bueno lima bispoNo ratings yet

- Cakecentral MagazineDocument100 pagesCakecentral MagazineNorma Angelica Garcia83% (6)

- RecipeDocument1 pageRecipeAngélica Hernández ReyesNo ratings yet

- Dauerback GB PDFDocument24 pagesDauerback GB PDFSri. SiriNo ratings yet

- Floor Plan ScriptDocument4 pagesFloor Plan ScriptBelle Denniese FontelarNo ratings yet

- Model Essay 1: Bearing Mouth Water TemptedDocument10 pagesModel Essay 1: Bearing Mouth Water TemptedjaredNo ratings yet

- Tahun 5 Sesi 2023/2024: Ujian Akhir Sesi AkademikDocument15 pagesTahun 5 Sesi 2023/2024: Ujian Akhir Sesi Akademikdfvy658kvbNo ratings yet

- Creamy Keto Milk Chocolate Recipe - Sugar Free LondonerDocument2 pagesCreamy Keto Milk Chocolate Recipe - Sugar Free LondonerBella BossNo ratings yet

- Friendship Day GiftDocument12 pagesFriendship Day GiftvamsiNo ratings yet

- No Meat Athlete Cookbook Sample Recipes PDFDocument14 pagesNo Meat Athlete Cookbook Sample Recipes PDFPop DanNo ratings yet

- Final Haldi Ram ProjectDocument71 pagesFinal Haldi Ram ProjectNamrita BhadauriaNo ratings yet

Case Study Group-7

Case Study Group-7

Uploaded by

sailolla30Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Case Study Group-7

Case Study Group-7

Uploaded by

sailolla30Copyright:

Available Formats

CASE STUDY GROUP-7

Go Bananas!

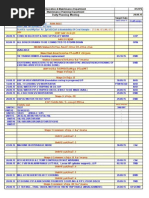

great grasslands grains, Inc. (GGG) manufactures and sells a wide variety of breakfast

cereals. GGG’s product development lab recently created a new cereal that consists of rice

flakes and banana-flavoured marshmallows. The company’s marketing research department

has tested the new cereal extensively and has found that consumers are enthusiastic about the

cereal when 16-ounce boxes contain at least 1.6 ounces and no more than 2.4 ounces of

the banana-flavoured marshmallows.

As GGG prepares to begin producing and selling 16-ounce boxes of the new cereal, which it

has named go Bananas!, management is concerned about the amount of banana flavoured

marshmallows. It wants to be careful not to include less than 1.6 ounces or more than 2.4

ounces of banana-flavoured marshmallows in each 16-ounce box of go Bananas!. Tina finkel,

VP of Production for GGG, has suggested that the company measure the weight of banana-

flavoured marshmallows in a random sample of 25 boxes of go Bananas! on a weekly basis.

Each week, GGG can count the number of boxes out of the 25 boxes in the sample that

contain less than 1.6 ounces or more than 2.4 ounces of banana-flavoured marshmallows;

if the number of boxes that fail to meet the standard weight of banana-flavoured

marshmallows is too high, production will be shut down and inspected.

Ms. finkel and her staff have designed the production process so that only 8% of all

16-ounce boxes of go Bananas! fail to meet the standard weight of banana-flavoured

marshmallows.

After much debate, GGG management has decided to shut down production of

go Bananas! if at least five boxes in a weekly sample fail to meet the standard weight of

banana-flavoured marshmallows.

Prepare a managerial report that addresses the following issues.

1. Calculate the probability that a weekly sample will result in a shutdown of production if

the production process is working properly. Comment on GGG management’s policy for

deciding when to shut down production of go Bananas!.

2. GGG management wants to shut down production of go Bananas! no more than 1% of the

time when the production process is working properly. Suggest the appropriate number of

boxes in the weekly sample that must fail to meet the standard weight of banana-flavoured

marshmallows in order for production to be shut down if this goal is to be achieved.

3. Ms. finkel has suggested that if given sufficient resources, she could redesign the

production process to reduce the percentage of 16-ounce boxes of go Bananas! That fail to

meet the standard weight of banana-flavoured marshmallows when the process is working

properly. To what level must Ms. finkel reduce the percentage of 16-ounce boxes of go

Bananas! that fail to meet the standard weight of banana-flavoured marshmallows when the

process is working properly in order for her to reduce the probability at least five of the

sampled boxes fail to meet the standard to .01 or less?

You might also like

- Jenny Craig SubstitutesDocument6 pagesJenny Craig SubstitutesLaurie Thomas60% (5)

- Blood in The ChocolateDocument55 pagesBlood in The ChocolateKandra100% (5)

- Botanical Grouping Guide-Courtesy of The Shakespeare DistilleryDocument3 pagesBotanical Grouping Guide-Courtesy of The Shakespeare DistillerysorentowNo ratings yet

- REAL BABY FOOD: Easy All-Natural Recipes For Your Baby and Toddler by Jenna HelwigDocument8 pagesREAL BABY FOOD: Easy All-Natural Recipes For Your Baby and Toddler by Jenna HelwigHoughton Mifflin Harcourt Cookbooks50% (2)

- Machine Recipe GuideDocument2 pagesMachine Recipe Guidehaque110% (1)

- Assignment A Research Report On Maggi Ban CaseDocument27 pagesAssignment A Research Report On Maggi Ban CaseFahad ul AminNo ratings yet

- Starting A Kakanin BusinessDocument10 pagesStarting A Kakanin BusinessRaven Parreño100% (1)

- Great Grasslands Grains Inc GGG Manufactures and Sells A WideDocument2 pagesGreat Grasslands Grains Inc GGG Manufactures and Sells A WideCharlotteNo ratings yet

- 5 1CPDocument1 page5 1CPsatarupaNo ratings yet

- Thesis On Banana ChipsDocument7 pagesThesis On Banana Chipsaprildavislittlerock100% (2)

- An Analysis On The Marketing Strategies OF Maggi: Presented By-Vaibhav Agarwal ROLL-44Document27 pagesAn Analysis On The Marketing Strategies OF Maggi: Presented By-Vaibhav Agarwal ROLL-44Vaibhav AgarwalNo ratings yet

- Easy Vegan Protein Bars - Minimalist Baker RecipesDocument2 pagesEasy Vegan Protein Bars - Minimalist Baker RecipesGLBNo ratings yet

- ALLERGY Food Challenge Prep LetterDocument4 pagesALLERGY Food Challenge Prep LetterCarla García TorresNo ratings yet

- Homemade Oatmeal Cookie Granola Recipe Easy To Make! - Fitness BlenderDocument9 pagesHomemade Oatmeal Cookie Granola Recipe Easy To Make! - Fitness BlenderMadalina GHEORGHENo ratings yet

- MaggieDocument45 pagesMaggieRitikaNo ratings yet

- Marketing Mix of MaggieDocument62 pagesMarketing Mix of MaggieAdnan KhanNo ratings yet

- Report On The Market Retention Strategies of Maggi in NagpurDocument50 pagesReport On The Market Retention Strategies of Maggi in NagpurHarmeet Kaur LambaNo ratings yet

- Product Plan BSBA-2A GROUP 1 - GrabAPatty PDFDocument12 pagesProduct Plan BSBA-2A GROUP 1 - GrabAPatty PDFQueen Paula Rañada GuangcoNo ratings yet

- Watch TV Live: The Importance of BananasDocument26 pagesWatch TV Live: The Importance of Bananasmaricon penalbaNo ratings yet

- Marketing Mix of MaggiDocument4 pagesMarketing Mix of MaggiAnwar khanNo ratings yet

- Tips For At-Home Yogurt Making: How To Make Yogurt RecipesDocument3 pagesTips For At-Home Yogurt Making: How To Make Yogurt RecipesAgnes P. SugaNo ratings yet

- Mango Jam ThesisDocument7 pagesMango Jam Thesisafjrqokne50% (2)

- Maggi Brand AuditDocument13 pagesMaggi Brand AuditNiranjan DasNo ratings yet

- Malunggay Bread ThesisDocument5 pagesMalunggay Bread ThesisMonique Carr100% (2)

- Meeting Your My Plate Goals On A BudgetDocument44 pagesMeeting Your My Plate Goals On A BudgetOWNEditorNo ratings yet

- August 2014 1406900366 22Document3 pagesAugust 2014 1406900366 22MukeshNo ratings yet

- Veggie Oatmeal Cookies 1Document41 pagesVeggie Oatmeal Cookies 1Wilhanne Del Rosario100% (1)

- OutlineDocument7 pagesOutlineJinky Nablo0% (1)

- Maggi Business PlanDocument10 pagesMaggi Business Plantanima_106607No ratings yet

- Final PresentationDocument23 pagesFinal Presentationjuldemar capillanNo ratings yet

- Formula Adjustment: (Nutramigen or Nutramigen With Enflora LGG)Document4 pagesFormula Adjustment: (Nutramigen or Nutramigen With Enflora LGG)Richard BakerNo ratings yet

- FEASIBILITYDocument10 pagesFEASIBILITYMarvelous Julia StamariaNo ratings yet

- Nutritional Benefits of AvocadosDocument2 pagesNutritional Benefits of AvocadosIndra SetiawanNo ratings yet

- Easy Dog Treat Recipes with 5 Ingredients or LessFrom EverandEasy Dog Treat Recipes with 5 Ingredients or LessRating: 5 out of 5 stars5/5 (1)

- Chapter 1Document23 pagesChapter 1Alessandra Abrau100% (1)

- Demand Analysis of MaggiDocument9 pagesDemand Analysis of MaggiGauravOberoi33% (3)

- Pasteurised Milk/suitable Infant Formula: at Each of The Following Steps Cookie, Muffin, Pancake, Cheese and YoghurtDocument2 pagesPasteurised Milk/suitable Infant Formula: at Each of The Following Steps Cookie, Muffin, Pancake, Cheese and YoghurtLuciana VieiraNo ratings yet

- 5lbs Shoppinglist UKDocument2 pages5lbs Shoppinglist UKdanielmarinicaNo ratings yet

- Taro Chips ResearchDocument16 pagesTaro Chips Researchjessy bitangaNo ratings yet

- Business PlanDocument4 pagesBusiness PlanPortia Guinto Gubantes Mandragora100% (2)

- Baby Corn ThesisDocument8 pagesBaby Corn Thesisybkpdsgig100% (1)

- Homemade Yogurt: IngredientsDocument1 pageHomemade Yogurt: IngredientsMoomNo ratings yet

- Free Sample Meal PlanDocument16 pagesFree Sample Meal PlanjacobNo ratings yet

- Research and Methodology of Maggi: Shreeraj HariharanDocument31 pagesResearch and Methodology of Maggi: Shreeraj HariharanShreeraj HariharanNo ratings yet

- Name: Shital Gosavi Roll No: 09 Sub: Economic (Demand Analysis)Document11 pagesName: Shital Gosavi Roll No: 09 Sub: Economic (Demand Analysis)Varshitha ReddyNo ratings yet

- Nutriliving Min Compressed 1 CompressedDocument19 pagesNutriliving Min Compressed 1 CompressedJaco NagelNo ratings yet

- Research Methodology On MaggiDocument28 pagesResearch Methodology On MaggiStella PaulNo ratings yet

- Advance E-BookDocument12 pagesAdvance E-BookvhvdqmhcvvNo ratings yet

- Groceries On A Budget (11 Pages)Document11 pagesGroceries On A Budget (11 Pages)Geraldyne100% (1)

- MAGGIEDocument23 pagesMAGGIEMuskan BohraNo ratings yet

- FeasibDocument4 pagesFeasibJna MarieNo ratings yet

- ENGWORKfinals BUSINESS PLANDocument15 pagesENGWORKfinals BUSINESS PLANOcubillo Froilan D.No ratings yet

- Yogurt Peanut Butter Banana Dog Treats RecipeDocument1 pageYogurt Peanut Butter Banana Dog Treats RecipeadrianagponsNo ratings yet

- Fungifun For Simple Minds (Psilosophy - Info)Document30 pagesFungifun For Simple Minds (Psilosophy - Info)GALA PORONo ratings yet

- Snacks Healthy Banana Blueberry MuffinsDocument1 pageSnacks Healthy Banana Blueberry MuffinsRax LlurNo ratings yet

- Your DT InvestigationDocument3 pagesYour DT InvestigationBie SchovalevskyNo ratings yet

- Group-6-Research - PDF 20240228 230838 0000Document8 pagesGroup-6-Research - PDF 20240228 230838 0000JOANNE ROANNE FELICIANONo ratings yet

- Topic "Research Methodology" ON " A Study On Nestle Product Maggi"Document33 pagesTopic "Research Methodology" ON " A Study On Nestle Product Maggi"Sunita Nishad0% (1)

- Squash Papaya ChipsDocument74 pagesSquash Papaya Chipsjanine barilla100% (2)

- RecipesDocument13 pagesRecipesapi-538885097No ratings yet

- Maggi Research MethodologyDocument8 pagesMaggi Research MethodologyRohanNarkarNo ratings yet

- Only Sevens: Only Sevens Don't Stop, Let's Do ItDocument1 pageOnly Sevens: Only Sevens Don't Stop, Let's Do ItJuan CostaNo ratings yet

- Master Feeding Schedule 5 ML Program: All Measurements Are Per GallonDocument1 pageMaster Feeding Schedule 5 ML Program: All Measurements Are Per GallonChris TuckerNo ratings yet

- Case Study Group-6Document2 pagesCase Study Group-6sailolla30No ratings yet

- Job Satisfaction Survey GovtDocument1 pageJob Satisfaction Survey Govtsailolla30No ratings yet

- Polavaram Project: A Study On Rehabilitation and Resettlement Package and The Plight of AdivasisDocument20 pagesPolavaram Project: A Study On Rehabilitation and Resettlement Package and The Plight of Adivasissailolla30No ratings yet

- 100 Kilowatt-Hour Battery PackDocument1 page100 Kilowatt-Hour Battery Packsailolla30No ratings yet

- Ministry of Home Affair Ar 2017-18 For WebDocument334 pagesMinistry of Home Affair Ar 2017-18 For Websailolla30No ratings yet

- Adhoc Faculty Notification 2606Document3 pagesAdhoc Faculty Notification 2606sailolla30No ratings yet

- Kaola Saomplar Ki) Plabqata: Sai Eca Pi ससरकक Stotsa Aaof Ema Di.Ema Esa Maona Plaamt Eiryaa Stosana Ka^ManaDocument49 pagesKaola Saomplar Ki) Plabqata: Sai Eca Pi ससरकक Stotsa Aaof Ema Di.Ema Esa Maona Plaamt Eiryaa Stosana Ka^Manasailolla30No ratings yet

- Home Automation by Android Application Based Remote ControlDocument2 pagesHome Automation by Android Application Based Remote Controlsailolla30No ratings yet

- Vizag Steel Answer Key - TechDocument45 pagesVizag Steel Answer Key - Techsailolla30No ratings yet

- Decs Ece DeceDocument58 pagesDecs Ece Decesailolla30No ratings yet

- Mems Based Robot: The Hand Mechanical MovementDocument4 pagesMems Based Robot: The Hand Mechanical Movementsailolla30No ratings yet

- Tourism-Means To Sustainable Inclusive GrowthDocument2 pagesTourism-Means To Sustainable Inclusive Growthsailolla30No ratings yet

- NOCET 2013.doc - 100777Document3 pagesNOCET 2013.doc - 100777sailolla30No ratings yet

- What To Write in AnswerDocument1 pageWhat To Write in Answersailolla30No ratings yet

- Ham & Potato Hash With Baked Beans & Healthy Fried' Eggs: MethodDocument1 pageHam & Potato Hash With Baked Beans & Healthy Fried' Eggs: MethodBobNo ratings yet

- FriesDocument1 pageFriesXarbie RebadomiaNo ratings yet

- Prebeginner 2 - Module 1Document28 pagesPrebeginner 2 - Module 1Julia PiscoNo ratings yet

- Diet Chart For High Triglyceride Patient, High Triglycerides Diet Chart - Lybrate.Document5 pagesDiet Chart For High Triglyceride Patient, High Triglycerides Diet Chart - Lybrate.Sukalyan MukharjeeNo ratings yet

- Language Focus: More Beautiful ThanDocument5 pagesLanguage Focus: More Beautiful ThanGuSD PeloteroNo ratings yet

- Air Fryer Cook Times ChartDocument1 pageAir Fryer Cook Times Chartalberto hungNo ratings yet

- Baking Tools and Equipment and Their Uses: Cake Pans - Comes in Different Sizes and Shapes and May Be Round SquareDocument7 pagesBaking Tools and Equipment and Their Uses: Cake Pans - Comes in Different Sizes and Shapes and May Be Round SquareBrenNan ChannelNo ratings yet

- Tingkatan 5 English Week 1-4Document11 pagesTingkatan 5 English Week 1-4Ruban RubanNo ratings yet

- Day 8 ActivityDocument7 pagesDay 8 ActivityMark Anthony LibecoNo ratings yet

- Green Smoothie Recipe 1Document5 pagesGreen Smoothie Recipe 1Susyary SNo ratings yet

- Low-Sodium Grocery List Low-Sodium Grocery List: Bread/Grains Condiments Bread/Grains CondimentsDocument1 pageLow-Sodium Grocery List Low-Sodium Grocery List: Bread/Grains Condiments Bread/Grains CondimentsRed ShadeNo ratings yet

- Week 8-9 - Food Styling and PhotographyDocument31 pagesWeek 8-9 - Food Styling and PhotographyKurt FranciscoNo ratings yet

- The Principles of Presenting, Serving and Storing 3Document9 pagesThe Principles of Presenting, Serving and Storing 3Michelle DoctorNo ratings yet

- Contoh Narrative Text Singkat Dan TerjemahannyaDocument7 pagesContoh Narrative Text Singkat Dan TerjemahannyaSantiago FernandoNo ratings yet

- Elllo Beg 25 - Akane Howard - Winter Vacation - Past TenseDocument1 pageElllo Beg 25 - Akane Howard - Winter Vacation - Past Tenseภัศรา แก้วบัวดีNo ratings yet

- Fondamenti Di Fisica Meccanica Onde Termodinamica 2015th Edition David Halliday Robert Resnick Full Chapter Download PDFDocument57 pagesFondamenti Di Fisica Meccanica Onde Termodinamica 2015th Edition David Halliday Robert Resnick Full Chapter Download PDFrauyacengi100% (2)

- Englsih Test Book 2Document19 pagesEnglsih Test Book 2arthur bueno lima bispoNo ratings yet

- Cakecentral MagazineDocument100 pagesCakecentral MagazineNorma Angelica Garcia83% (6)

- RecipeDocument1 pageRecipeAngélica Hernández ReyesNo ratings yet

- Dauerback GB PDFDocument24 pagesDauerback GB PDFSri. SiriNo ratings yet

- Floor Plan ScriptDocument4 pagesFloor Plan ScriptBelle Denniese FontelarNo ratings yet

- Model Essay 1: Bearing Mouth Water TemptedDocument10 pagesModel Essay 1: Bearing Mouth Water TemptedjaredNo ratings yet

- Tahun 5 Sesi 2023/2024: Ujian Akhir Sesi AkademikDocument15 pagesTahun 5 Sesi 2023/2024: Ujian Akhir Sesi Akademikdfvy658kvbNo ratings yet

- Creamy Keto Milk Chocolate Recipe - Sugar Free LondonerDocument2 pagesCreamy Keto Milk Chocolate Recipe - Sugar Free LondonerBella BossNo ratings yet

- Friendship Day GiftDocument12 pagesFriendship Day GiftvamsiNo ratings yet

- No Meat Athlete Cookbook Sample Recipes PDFDocument14 pagesNo Meat Athlete Cookbook Sample Recipes PDFPop DanNo ratings yet

- Final Haldi Ram ProjectDocument71 pagesFinal Haldi Ram ProjectNamrita BhadauriaNo ratings yet