Professional Documents

Culture Documents

WORLD-BEAM QS18E Clear Object Detection: Quick Start Guide

WORLD-BEAM QS18E Clear Object Detection: Quick Start Guide

Uploaded by

Débora Dos SanttosOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WORLD-BEAM QS18E Clear Object Detection: Quick Start Guide

WORLD-BEAM QS18E Clear Object Detection: Quick Start Guide

Uploaded by

Débora Dos SanttosCopyright:

Available Formats

WORLD-BEAM QS18E Clear Object Detection

Quick Start Guide

Expert™ Coaxial Polarized Retroreflective Sensor for Clear Object Detection

This guide is designed to help you set up and install the QS18 Clear Object Detection. For complete information on programming,

performance, troubleshooting, dimensions, and accessories, please refer to the Instruction Manual at www.bannerengineering.com.

Search for p/n 194469 to view the Instruction Manual. Use of this document assumes familiarity with pertinent industry standards and

practices.

WARNING: Not To Be Used for Personnel Protection

Never use this device as a sensing device for personnel protection. Doing so could lead to serious injury or death.

This device does not include the self-checking redundant circuitry necessary to allow its use in personnel safety

applications. A sensor failure or malfunction can cause either an energized or de-energized sensor output

condition.

Overview

The Banner QS18 sensor is a high performance clear object detection sensor.

Amber LED The polarized coaxial optical design ensures reliable detection of transparent,

(Output Indicator) translucent, and opaque targets at any distance between the sensor and the

reflector. Low contrast sensing applications include PET bottles, glass

Green LED containers, and shrink wrap. The sensor can also be used to detect optical

(Power Indicator) surfaces such as: LCD panels with built in polarizing films, solar panels, and

Push Button

semiconductor wafers.

Indicators (Two LEDs: One Green, One Amber)

Sensor Condition (Run Mode) Green LED Amber LED

Output OFF ON OFF

Output ON ON ON

Notification — Sensor needs to be reconfigured for Flashing at 5 Hz ON/OFF

reliable detection

Notification — Push button has been locked out Flashes 4 times and ON/OFF

returns to solid on

Models

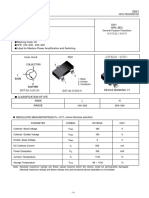

Models Mode Range Output Connector 1

QS18EN6XLPC NPN

COAXIAL

0 to 1.3 m (0 to 4.2 ft) on BRT-40X19A

P 0 to 2.0 m (0 to 6.5 ft) on BRT-51X51BM 2 m cable (6.5 ft)

QS18EP6XLPC PNP

POLAR RETRO 0 to 3.0 m (0 to 9.8 ft) on BRT-92X92C

CLEAR OBJECT

1 The standard 2 m (6.5 ft) cable models are listed.

• To order the 9 m (30 ft) cable models, add the suffix "W/30" to the cabled model number (for example QS18EN6XLPC W/30)

• To order the 4 pin Euro M12 integral connector, add the suffix "Q8" (for example QS18EN6LPCQ8)

• To order the 4 pin Euro M12 150 mm (6 inch) cable, add the suffix "Q5" (for example QS18EN6LPCQ5)

• To order a 4 pin Pico M8 integral connector, add the suffix "Q7" (for example QS18EN6LPCQ7)

• To order a 4 pin Pico M8 150 mm (6 inch) cable, add the suffix "Q" (for example QS18EN6XLPCQ)

Original Document 27 February 2017

195502 Rev. B

195502

WORLD-BEAM QS18E Clear Object Detection

Installing and Mounting the Sensor for Low Contrast Applications

Reliable transparent object detection depends on the sensor always detecting the object as "dark state" and the reflector as the "light

state". Using a recommended reflector, and proper orientation of the sensor to the reflector, is key to good clear object detection.

Optimize the reliable detection of transparent and clear objects by applying the following steps when mounting the sensor and selecting

a retroreflective target.

1. If a bracket is needed, mount the sensor onto the bracket.

2. Mount the sensor (or the sensor and the bracket) to the equipment at the desired location. Do not tighten at this time.

3. Align the sensor's light spot to the middle of the retroreflector.

4. Mount the retroreflector perpendicular to the sensor optical axis (± 5°).

5. Tighten the screws to secure the sensor (or the sensor and the bracket) to the aligned position.

Mounting Considerations for Opaque Objects with Mirror Like Surfaces

To minimize the potential for reflections from mirror like objects affecting the sensor, it is best to side mount the sensor.

Wiring Diagrams

NPN Models PNP Models Key

1. Brown

2. White

1 + 1

+ 3. Blue

3 10-30V dc

10-30V dc

– 3

–

4. Black

4 4

Load Load

2 Remote 2 Remote

Programming Programming

(N.O.) (N.O.)

Sensor Configuration

Sensor configuration can be implemented with the push button or the remote program wire. Configuration options include two sensing

modes: LIGHT SET and DARK SET. For configuration using the push button see Figure 1 on page 2. For configuration using the remote

program wire, please refer to the Instruction Manual at http://www.bannerengineering.com. Search for p/n 194469 to view the

Instruction Manual.

Sensor User Interface Push Button

Push Hold is > 2 sec. and < 4 sec.

Button (configuration using push button) Click is > 40 ms and < 800 ms

Press and hold push button > 2 sec. Initiate LIGHT/DARK SET

Click 2X Basic Configuration (alternating flashing Green and Amber LEDs at 1Hz)

Click 1X Set output to Light Operate (flashing Green and Amber 1X followed by acceptance flash)

Click 2X Set output to Dark Operate (flashing Green and Amber 2X followed by acceptance flash) default

Click 3X Set offset to 8% offest (flashing Green and Amber 3X followed by acceptance flash)

Click 4X Set offset to 16% offest (flashing Green and Amber 4X followed by acceptance flash) default

Click 5X Set offset to 32% offest (flashing Green and Amber 5X followed by acceptance flash)

Click 3x Advanced Configuration (simultaneous flashing both Green and Amber LEDs at 1Hz)

Click 1X Unlock push buttons (flashing Green and Amber 1X followed by acceptance flash) default

Click 2X Lock push buttons (flashing Green and Amber 2X followed by acceptance flash)

Click 3X Enable Auto compensation (flashing Green and Amber 3X followed by acceptance flash)

Click 4X Disable Auto compensation (flashing Green and Amber 4X followed by acceptance flash) default

Click 5X Enable 30 ms Off Delay (flashing Green and Amber 5X followed by acceptance flash)

Click 6X Disable 30 ms Off Delay (flashing Green and Amber 6X followed by acceptance flash) default

Figure 1. Push Button Input Flowchart

2 www.bannerengineering.com - Tel: +1-763-544-3164 P/N 195502 Rev. B

WORLD-BEAM QS18E Clear Object Detection

Light Set

Use Light SET for low contrast applications. Use either the push button or remote Sensor position’s threshold is a

input wire procedure to configure the sensor. programmable % offset below

the presented condition

Example Applications For Offset Percentages

Output ON Output OFF

8% Recommended for very low contrast applications with stable environmental conditions.

16% Recommended for most clear object detection applications in typical machine industrial Darkest Condition Most Light

presented

environments.

32% Recommended for high contrast detections such as brown or green bottles, or opaque

objects. This setting tolerates environmental challenges such as vibrations and dust Figure 2. LIGHT SET sensing mode in dark operate

build-up.

Table 1: LIGHT SET Push Button Configuration

Setup Action Result

Clear the light path to Press and hold the push LIGHT SET Configuration Accepted

the reflector. button 2 to 4 seconds. Green LED Indicator: Flashes 3 times.

Green and Amber LED Indicators: Acceptance flash - both LEDs flash 5 times rapidly in

unison.

The sensor returns to Run mode with the new settings.

LIGHT SET Configuration Not Accepted

If there is not enough return signal, the sensor will perform in DARK SET indicated by the

green and amber LED indicators flashing in unison 2 times followed by the green and amber

LED indicators flashing rapidly in unison 5 times.

Dark Set

Dark SET (maximum operating range) is the factory default setting and provides

maximum sensing range, ease of alignment, and reliable detection of opaque

objects. Dark Set provides a fixed threshold whenever the sensor is taught an

obstructed view. Fixed Threshold

Note: The sensor's light spot is made brighter for 60 seconds Output ON Output OFF

to assist in aligning the sensor to the reflector. This is

particularly useful for long range applications. Darkest

(no signal)

Most Light

(saturated

signal)

Figure 3. DARK SET sensing mode in dark operate

Table 2: DARK SET Push Button Configuration

Setup Action Result

Block the light path to Press and hold the push DARK SET Configuration Accepted

the reflector. button 2 to 4 seconds. Green and Amber LED Indicators: Flash 2 times.

Green and Amber LED Indicators: Acceptance flash - both LEDs flash 5 times rapidly in

unison.

The sensor returns to Run mode with the new settings.

DARK SET Configuration Not Accepted

If there is too much return signal, the sensor will perform in LIGHT SET indicated by the green

LED indicator flashing 3 times followed by the green and amber LED indicators flashing rapidly

in unison 5 times.

P/N 195502 Rev. B www.bannerengineering.com - Tel: +1-763-544-3164 3

WORLD-BEAM QS18E Clear Object Detection

Specifications

Supply Voltage Emitter LED

10 V to 30 V dc (10% maximum ripple) Visible red, 625 nm

Supply Current (Exclusive of Load Current) Indicators

< 25 mA at 15 V Two LEDs (1 green, 1 amber)

< 40 mA at 24 V Green solid: Indicates power applied and sensor ready

Repeatability Green flashing: Indicates sensor operating in marginal state, in need of

reconfiguration

100 µs Amber solid: Indicates output conducting

Supply Protection Circuitry Factory Default Settings

Protected against reverse polarity and transient voltages

Output Protection Circuitry Setting Factory Default

Protected against false pulse on power-up and continuous overload or short-

Sensing Mode Dark Set

circuit of output

Output Configuration Output Logic Dark Operate

Current sourcing (PNP) or current sinking (NPN), depending on model; Light- or

Offset Percent 16%

dark-operate selectable; Selectable 30 ms output OFF-delay

Rating: 100 mA max Push Button Unlocked

Off-state leakage current: < 50 µA at 30 V

ON-state saturation voltage: < 1.5 V at 10 mA; < 3 V 100 mA Auto Compensation Disabled

Output Response Time OFF Delay Disabled

Note: Momentary delay on power-up; output does not conduct during this

time

400 µs ON/OFF

Mounting Torque

Required Overcurrent Protection

Nose mount: 18 mm mounting nut, 20 lbf·in (2.3 N·m)

Side mount: Two M3 screws, 5 lbf·in (0.6 N·m)

WARNING: Electrical connections must be made

by qualified personnel in accordance with local Construction

and national electrical codes and regulations. ABS housing, PMMA window

Overcurrent protection is required to be provided by end product application Connections

per the supplied table. PVC-jacketed 4-conductor 2 m (6.5 ft) or 9 m (30 ft) unterminated cable, or 4-

Overcurrent protection may be provided with external fusing or via Current pin Euro-style or 4-pin Pico-style quick-disconnect (QD), either integral or 150

Limiting, Class 2 Power Supply. mm (6 in) pigtail, are available. QD cordsets are ordered separately.

Supply wiring leads < 24 AWG shall not be spliced. Operating Conditions

For additional product support, go to www.bannerengineering.com. Temperature: –40 °C to +70 °C (–40 °F to +158 °F)

Relative Humidity: 90% at +50 ºC (non-condensing)

Supply Wiring (AWG) Required Overcurrent Protection (Amps)

Environmental

20 5.0 IEC IP67

22 3.0 Application Notes

If the push button does not appear to be responsive, perform the push button

24 2.0 enable procedure

26 1.0 Certifications

28 0.8

30 0.5

Banner Engineering Corp. Limited Warranty

Banner Engineering Corp. warrants its products to be free from defects in material and workmanship for one year following the date of shipment. Banner Engineering Corp. will repair or

replace, free of charge, any product of its manufacture which, at the time it is returned to the factory, is found to have been defective during the warranty period. This warranty does not cover

damage or liability for misuse, abuse, or the improper application or installation of the Banner product.

THIS LIMITED WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES WHETHER EXPRESS OR IMPLIED (INCLUDING, WITHOUT LIMITATION, ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE), AND WHETHER ARISING UNDER COURSE OF PERFORMANCE, COURSE OF DEALING OR TRADE USAGE.

This Warranty is exclusive and limited to repair or, at the discretion of Banner Engineering Corp., replacement. IN NO EVENT SHALL BANNER ENGINEERING CORP. BE LIABLE TO BUYER OR ANY

OTHER PERSON OR ENTITY FOR ANY EXTRA COSTS, EXPENSES, LOSSES, LOSS OF PROFITS, OR ANY INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES RESULTING FROM ANY PRODUCT

DEFECT OR FROM THE USE OR INABILITY TO USE THE PRODUCT, WHETHER ARISING IN CONTRACT OR WARRANTY, STATUTE, TORT, STRICT LIABILITY, NEGLIGENCE, OR OTHERWISE.

Banner Engineering Corp. reserves the right to change, modify or improve the design of the product without assuming any obligations or liabilities relating to any product previously

manufactured by Banner Engineering Corp. Any misuse, abuse, or improper application or installation of this product or use of the product for personal protection applications when the

product is identified as not intended for such purposes will void the product warranty. Any modifications to this product without prior express approval by Banner Engineering Corp will void the

product warranties. All specifications published in this document are subject to change; Banner reserves the right to modify product specifications or update documentation at any time.

Specifications and product information in English supersede that which is provided in any other language. For the most recent version of any documentation, refer to:

www.bannerengineering.com.

© Banner Engineering Corp. All rights reserved

You might also like

- Neve Technical Manual 5315-12-P Standard Broadcast ConsoleDocument164 pagesNeve Technical Manual 5315-12-P Standard Broadcast Consoletodd wilson100% (1)

- Toyota - Engine Immobiliser PDFDocument100 pagesToyota - Engine Immobiliser PDFTomas Ignacio Scagliotti94% (17)

- Kurzweil 250 Service ManualDocument230 pagesKurzweil 250 Service ManualaxmontiNo ratings yet

- Introduction To Electronics PDFDocument29 pagesIntroduction To Electronics PDFJake CabatinoNo ratings yet

- Q26 Series Sensors: B A C DDocument6 pagesQ26 Series Sensors: B A C DFernando BrasolinNo ratings yet

- WORLD-BEAM QS18 Expert With IO-Link: Quick Start GuideDocument4 pagesWORLD-BEAM QS18 Expert With IO-Link: Quick Start GuideDébora Dos SanttosNo ratings yet

- Banner Sensor ManualDocument8 pagesBanner Sensor ManualPumzile FaleniNo ratings yet

- Banner QL55 Luminescence SensorsDocument8 pagesBanner QL55 Luminescence SensorsMemik TylnNo ratings yet

- Q45U Ultrasonic Sensors With Analog Outputs (Short Range) : DatasheetDocument8 pagesQ45U Ultrasonic Sensors With Analog Outputs (Short Range) : DatasheetMohammad IsmailNo ratings yet

- World-Beam QS30ELVC Series: FeaturesDocument12 pagesWorld-Beam QS30ELVC Series: FeaturespopagrioNo ratings yet

- Q60AF SensorsDocument10 pagesQ60AF SensorsAlisonNo ratings yet

- ULP AN 26 Troubleshooting Checklist PDFDocument2 pagesULP AN 26 Troubleshooting Checklist PDFJhonson PadillaNo ratings yet

- Installation Instructions Series 9000 Lasersight Photoelectric SensorsDocument4 pagesInstallation Instructions Series 9000 Lasersight Photoelectric Sensorsy0o0o0No ratings yet

- A Full Line of Miniature Photoelectric Sensors Built For Performance and ValueDocument7 pagesA Full Line of Miniature Photoelectric Sensors Built For Performance and ValueFlorin MNo ratings yet

- Na2-N e CataDocument11 pagesNa2-N e Catatan tanNo ratings yet

- Description General Specifications: Photoswitch Photoelectric SensorsDocument8 pagesDescription General Specifications: Photoswitch Photoelectric Sensorsmekhman mekhtyNo ratings yet

- CF106 Data Sheet EN 2018-03Document4 pagesCF106 Data Sheet EN 2018-03AdeNo ratings yet

- Festo Sensor Brochure EN135218 202206Document20 pagesFesto Sensor Brochure EN135218 202206Ricardo RojasNo ratings yet

- Robotics Sensors Kit: Starting WithDocument7 pagesRobotics Sensors Kit: Starting WithfsdfNo ratings yet

- Series Series: Enables Space Saving and Quick Installation!Document10 pagesSeries Series: Enables Space Saving and Quick Installation!Sitaram TilekarNo ratings yet

- R58E Series Expert Registration Mark Sensors: DatasheetDocument11 pagesR58E Series Expert Registration Mark Sensors: DatasheetVikaas JainNo ratings yet

- Harfaina ssc1 - MergedDocument11 pagesHarfaina ssc1 - MergedHarafaina Zubaira Farzana 4PA19CS021No ratings yet

- Assignment: Course Code Microcontroller Computer Peripherals and Interfacing LabDocument17 pagesAssignment: Course Code Microcontroller Computer Peripherals and Interfacing LabAll OneNo ratings yet

- Swing Gate Manual: DR - TD.6657MDocument9 pagesSwing Gate Manual: DR - TD.6657MAntonio FaidzNo ratings yet

- Installation Instructions 45LMS Laser Measurement Sensor: Important: Save These Instructions For Future UseDocument4 pagesInstallation Instructions 45LMS Laser Measurement Sensor: Important: Save These Instructions For Future UseDiauoliver RendersNo ratings yet

- Q4X Stainless Steel Analog Laser Sensor: Quick Start GuideDocument11 pagesQ4X Stainless Steel Analog Laser Sensor: Quick Start Guidepracmci automatizacion3No ratings yet

- Banner, LX Series Part-Sensing Light ScreenDocument4 pagesBanner, LX Series Part-Sensing Light Screenalejandro garciaNo ratings yet

- Series 6000: Description General SpecificationsDocument14 pagesSeries 6000: Description General SpecificationsGustavo AriasNo ratings yet

- 04 Item 225 (Salwico UV Flame Detector NS-AUV) Incl 221 andDocument3 pages04 Item 225 (Salwico UV Flame Detector NS-AUV) Incl 221 andAlexDorNo ratings yet

- Up3000 ManDocument21 pagesUp3000 Manandres buguenoNo ratings yet

- Stack Project Report On Smoke Detector Ilovepdf CompressedDocument36 pagesStack Project Report On Smoke Detector Ilovepdf Compressedtuyishiclaude18No ratings yet

- Surecross Wireless Q45 Sensor - Opposed: DatasheetDocument4 pagesSurecross Wireless Q45 Sensor - Opposed: DatasheetrdsrajNo ratings yet

- Picoscopevehiclediagnostics 1 PDFDocument16 pagesPicoscopevehiclediagnostics 1 PDFrunolevariNo ratings yet

- SLO Series Slot Sensor: DatasheetDocument4 pagesSLO Series Slot Sensor: DatasheetCrhistofi RochaNo ratings yet

- MAN - UV - Det UV560.rev1.eDocument59 pagesMAN - UV - Det UV560.rev1.eJonathan StruveNo ratings yet

- ARDU-5351 Manual EnglishDocument11 pagesARDU-5351 Manual EnglishStevanus ColonneNo ratings yet

- Sensor Banner NovoDocument7 pagesSensor Banner NovoDiego SouzaNo ratings yet

- Minor ProjectDocument22 pagesMinor Project205.Vyshnavi GrandhiNo ratings yet

- U-GAGE QT50ULB Series Sensors With Analog Output: DatasheetDocument11 pagesU-GAGE QT50ULB Series Sensors With Analog Output: DatasheetjfcolunaNo ratings yet

- Q5X Laser Triangulation Sensor With Analog Outputs: Quick Start GuideDocument12 pagesQ5X Laser Triangulation Sensor With Analog Outputs: Quick Start GuideJose Luis Gutierrez MartinezNo ratings yet

- XZone T QSGDocument2 pagesXZone T QSGHENRY MONTEJONo ratings yet

- Small and Thin 2 G Accelerometer ADXL322: Features General DescriptionDocument16 pagesSmall and Thin 2 G Accelerometer ADXL322: Features General DescriptionPrateek AgrawalNo ratings yet

- Course Code Microcontroller Computer Peripherals and Interfacing LabDocument17 pagesCourse Code Microcontroller Computer Peripherals and Interfacing LabAll OneNo ratings yet

- Presentation Smart StickDocument16 pagesPresentation Smart StickwhatseNo ratings yet

- Ex No 15 STUDY AND EXPERIMENT ON ULTRASONIC FLAW DETECTOR (MODEL Einstein - II TFT)Document10 pagesEx No 15 STUDY AND EXPERIMENT ON ULTRASONIC FLAW DETECTOR (MODEL Einstein - II TFT)Jagajith Sathis Chandran NairNo ratings yet

- QTR-L-1A Reflectance Sensor (2-Pack) : Functional DescriptionDocument3 pagesQTR-L-1A Reflectance Sensor (2-Pack) : Functional DescriptionEder BalamNo ratings yet

- How PIR Motion Sensor Works?Document9 pagesHow PIR Motion Sensor Works?Darwin VargasNo ratings yet

- Kidde KS-PS SmartOne Addressable Photoelectric Smoke Detector K-71-101Document4 pagesKidde KS-PS SmartOne Addressable Photoelectric Smoke Detector K-71-101Murali DaranNo ratings yet

- Sure Cross® Wireless Q45 Sensor - Button - LightDocument4 pagesSure Cross® Wireless Q45 Sensor - Button - LightAlisonNo ratings yet

- Cable Wire Tracer Tracker Kit Tone Probe MS6812Document10 pagesCable Wire Tracer Tracker Kit Tone Probe MS6812ristanintanNo ratings yet

- TPL 310d Localizador de Personas - TrappedDocument19 pagesTPL 310d Localizador de Personas - TrappedRodrigo CruzNo ratings yet

- EC103 User ManualDocument32 pagesEC103 User ManualMahandika Candra kiranaNo ratings yet

- Oscilloscope ST201C: An ISO 9001: 2000 CompanyDocument15 pagesOscilloscope ST201C: An ISO 9001: 2000 CompanyPramod MoryaNo ratings yet

- Installation Instructions Photoswitch Bulletin 42Ft Selfćteach Fiber OpticDocument4 pagesInstallation Instructions Photoswitch Bulletin 42Ft Selfćteach Fiber OpticFito RahNo ratings yet

- NF 8209 ManualDocument8 pagesNF 8209 ManualFAZRANIZA BINTI ABDULLAH (JTM-ADTECKEMAMAN)No ratings yet

- Banner QL50 Luminescence SensorsDocument8 pagesBanner QL50 Luminescence SensorsMemik TylnNo ratings yet

- Honeywell IS2535 Install GuideDocument2 pagesHoneywell IS2535 Install GuideAlarm Grid Home Security and Alarm MonitoringNo ratings yet

- Liq ProdData 71-T1056 ClarityIIDocument8 pagesLiq ProdData 71-T1056 ClarityIImohan.tijare.mtNo ratings yet

- Smoke Detector Instructions NittanDocument8 pagesSmoke Detector Instructions NittanTrefastoreNo ratings yet

- FinalDocument38 pagesFinalSree LakshmiNo ratings yet

- User Manual: Active Barrier SensorDocument11 pagesUser Manual: Active Barrier SensorROSEMARIO PORFIRIONo ratings yet

- Sesnsor Laser Bannner LTEPUQDocument12 pagesSesnsor Laser Bannner LTEPUQDiego VolponiNo ratings yet

- BannerDocument29 pagesBannerDébora Dos SanttosNo ratings yet

- IO-Link Data Reference Guide: QS18 Expert EmitterDocument3 pagesIO-Link Data Reference Guide: QS18 Expert EmitterDébora Dos SanttosNo ratings yet

- WORLD-BEAM QS18 Expert With IO-Link: Quick Start GuideDocument4 pagesWORLD-BEAM QS18 Expert With IO-Link: Quick Start GuideDébora Dos SanttosNo ratings yet

- World-Beam QS18 Expert Opposed-Mode With IO-Link: Quick Start GuideDocument6 pagesWorld-Beam QS18 Expert Opposed-Mode With IO-Link: Quick Start GuideDébora Dos SanttosNo ratings yet

- Q4X Stainless Steel Analog Laser Sensor: Instruction ManualDocument38 pagesQ4X Stainless Steel Analog Laser Sensor: Instruction ManualDébora Dos SanttosNo ratings yet

- Q4X Stainless Steel Laser Sensor With Dual Discrete Outputs and IO-LinkDocument51 pagesQ4X Stainless Steel Laser Sensor With Dual Discrete Outputs and IO-LinkDébora Dos SanttosNo ratings yet

- Memristor Project ReportDocument17 pagesMemristor Project ReportVarun MallyaNo ratings yet

- OpenScape 4000 V8 2Document12 pagesOpenScape 4000 V8 2Ehsan RohaniNo ratings yet

- Etap Transformer SizingDocument2 pagesEtap Transformer SizingJeffDeCastroNo ratings yet

- Medical Imaging Signals and SystemsDocument31 pagesMedical Imaging Signals and SystemssaraNo ratings yet

- Chapter 4 AzipullDocument101 pagesChapter 4 AzipullSergei KurpishNo ratings yet

- NW4000-60 VDR Authority Acces Manual V 2.1.5Document32 pagesNW4000-60 VDR Authority Acces Manual V 2.1.5Adi PrasetyoNo ratings yet

- Programmable ASIC Logic CellsDocument36 pagesProgrammable ASIC Logic CellsnandanNo ratings yet

- Instrumentation AmplifierDocument4 pagesInstrumentation Amplifierjassisc100% (1)

- AR2240C Datasheet: Quick SpecsDocument4 pagesAR2240C Datasheet: Quick SpecsHamza MalyonaNo ratings yet

- Wimax: Andrew Wireless SolutionsDocument1 pageWimax: Andrew Wireless SolutionsJura GirskiNo ratings yet

- Chap9 SampleDocument51 pagesChap9 SampleAbhishek MatNo ratings yet

- Occ 2e1Document5 pagesOcc 2e1Usman ShehbazNo ratings yet

- Absoluate Maxium RatingsDocument5 pagesAbsoluate Maxium RatingsRashidNo ratings yet

- DLD Question Bank: Unit 1Document4 pagesDLD Question Bank: Unit 1Mahadev ReddyNo ratings yet

- Katalog Kostek ETKA VWDocument22 pagesKatalog Kostek ETKA VWGregor KomNo ratings yet

- R Rep M.2014 1998 MSW eDocument69 pagesR Rep M.2014 1998 MSW eStephen PANNo ratings yet

- Sergio Franco Design With Operational Amplifiers and Analog Integrated Circuits Solution ManualDocument3 pagesSergio Franco Design With Operational Amplifiers and Analog Integrated Circuits Solution ManualWicked Alpha25% (4)

- LG 32LD350 - 32LD358 - 32LD359 LCD TV SMDocument44 pagesLG 32LD350 - 32LD358 - 32LD359 LCD TV SMantonysolencNo ratings yet

- Thyrotronic: Excellent Technology, Efficiency and QualityDocument8 pagesThyrotronic: Excellent Technology, Efficiency and QualityPetar TuskanNo ratings yet

- 1N5283 5314Document2 pages1N5283 5314Ex WueNo ratings yet

- 7604 Bts Operation DegradedDocument10 pages7604 Bts Operation DegradedSandeep Sanisetty100% (2)

- Tic 246Document5 pagesTic 246ewsewsewsNo ratings yet

- T2 - Precision PDFDocument4 pagesT2 - Precision PDFStephen BridgesNo ratings yet

- Arduino Ultrasonic Sensor (HC-SR04 or HY-SRF05)Document2 pagesArduino Ultrasonic Sensor (HC-SR04 or HY-SRF05)DesiantoNo ratings yet

- TTLDocument5 pagesTTLChaitanya Varma D100% (1)

- Om2000 - Out of Band Multiplexer Modulator - AmtDocument2 pagesOm2000 - Out of Band Multiplexer Modulator - AmtcandoxNo ratings yet

- Current Transformers (CT) Sensors - Interfacing With An ArduinoDocument5 pagesCurrent Transformers (CT) Sensors - Interfacing With An ArduinogeniunetNo ratings yet