Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

9 viewsMethanol Recovery Calculation 31-12-2023 R1

Methanol Recovery Calculation 31-12-2023 R1

Uploaded by

Preetpal SinghThis document summarizes the process and design parameters for recovering methanol and thionyl chloride from a reactor. It involves using hot water at 80°C in the reactor and a primary graphite condenser operating at 5°C to condense vapors. The maximum boil up rate is calculated to be 249kg/hr. It is recommended to use a plate heat exchanger instead of a shell and tube heat exchanger to reduce costs, with pumping flow rate of 36 m3/hr required due to methanol's properties.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Jacket Area CalculationDocument12 pagesJacket Area CalculationPraveen Prajapati100% (2)

- Storage Tank Heat Loss Calculation Rev - 0Document23 pagesStorage Tank Heat Loss Calculation Rev - 0fsijestNo ratings yet

- Heating Coil Sizing For Fuel Oil TankDocument2 pagesHeating Coil Sizing For Fuel Oil TankPouria Sabbagh100% (1)

- PRD Training Manual Rev.0 PDFDocument63 pagesPRD Training Manual Rev.0 PDFLEOG85100% (1)

- Heat Exchanger Specification SheetDocument1 pageHeat Exchanger Specification SheetRizal NajibNo ratings yet

- Standards.: General Fastener Standards BS OrderDocument33 pagesStandards.: General Fastener Standards BS OrderamdarvishvandNo ratings yet

- Methanol Recovery Calculation 31-12-2023Document1 pageMethanol Recovery Calculation 31-12-2023Preetpal SinghNo ratings yet

- Simulation An OptimizationDocument28 pagesSimulation An Optimizationalmoanna97100% (1)

- Heat Exchanger Sizing CalculatorDocument1 pageHeat Exchanger Sizing CalculatorandreicarbuneanuNo ratings yet

- Jacketed Vessel Heat Transfer (Half Pipe Coil) : MM Inch MM RPM MM M /HDocument30 pagesJacketed Vessel Heat Transfer (Half Pipe Coil) : MM Inch MM RPM MM M /Hmanoj75% (4)

- Design. Ref - Decuments: API 650, 11TH - ED M09Document9 pagesDesign. Ref - Decuments: API 650, 11TH - ED M09hgagNo ratings yet

- Final Energy Balance-Vizag DT 9-6-18Document14 pagesFinal Energy Balance-Vizag DT 9-6-18SUBHOMOYNo ratings yet

- HEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEDocument8 pagesHEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEhgagNo ratings yet

- HEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEDocument8 pagesHEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEhgagNo ratings yet

- HEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEDocument8 pagesHEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEhgagNo ratings yet

- HEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEDocument8 pagesHEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEhgagNo ratings yet

- HEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEDocument8 pagesHEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEhgagNo ratings yet

- HEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEDocument7 pagesHEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEhgagNo ratings yet

- HEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEDocument8 pagesHEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEhgagNo ratings yet

- HEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEDocument13 pagesHEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEhgagNo ratings yet

- HEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEDocument8 pagesHEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEhgagNo ratings yet

- HEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEDocument8 pagesHEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEhgagNo ratings yet

- Thermic Fluid Heater Data Sheet - Rev 0Document10 pagesThermic Fluid Heater Data Sheet - Rev 0Dhamotharan ChinnaduraiNo ratings yet

- Technological Institute of The PhilippinesDocument25 pagesTechnological Institute of The PhilippinesJohn Leonard FazNo ratings yet

- Chapter 9. Refrigeration and Liquefaction-StudentDocument28 pagesChapter 9. Refrigeration and Liquefaction-StudentFlorenceNo ratings yet

- Refrigeration and Air Conditionin1Document51 pagesRefrigeration and Air Conditionin1Jeremiah Angeles Bautista0% (1)

- Heat Exchanger Design - Part 2Document15 pagesHeat Exchanger Design - Part 2Siddhant SoymonNo ratings yet

- Heat Exchanger DesignDocument28 pagesHeat Exchanger DesignHussein AyoubNo ratings yet

- Thermodynamic Analysis of IC Engine: Air-Standard Cycle byDocument70 pagesThermodynamic Analysis of IC Engine: Air-Standard Cycle bySiraj MohammedNo ratings yet

- Fundamentals of Desalination ProcessesDocument6 pagesFundamentals of Desalination ProcessesElzubair EljaaliNo ratings yet

- The Three Steps of Thermodynamic Analysis of IC Engines AreDocument42 pagesThe Three Steps of Thermodynamic Analysis of IC Engines AreGODNo ratings yet

- A7CA89 Excel Template Shell and Tube Heat Exchanger Design P1and2 Us UnitsDocument5 pagesA7CA89 Excel Template Shell and Tube Heat Exchanger Design P1and2 Us UnitsMudabbir Shan AhmedNo ratings yet

- CH-01 30RBM360 Air Cooled Liquid Chiller Selection PDFDocument2 pagesCH-01 30RBM360 Air Cooled Liquid Chiller Selection PDFBilguun BurenjargalNo ratings yet

- Diseño IntercambiadorDocument9 pagesDiseño IntercambiadorMateo VanegasNo ratings yet

- #2. 열교환기 Design sheetDocument5 pages#2. 열교환기 Design sheet배광득0% (1)

- Thermal Design - 2 Effect Forward-Feed Evaporator Nama Aristya Kurniawan NIM 114 152 5005 Design BasisDocument4 pagesThermal Design - 2 Effect Forward-Feed Evaporator Nama Aristya Kurniawan NIM 114 152 5005 Design BasisAristya KurniawanNo ratings yet

- Pharma Engg. Heat Transfer AreaDocument4 pagesPharma Engg. Heat Transfer AreamanojNo ratings yet

- Tugas Perpindahan PanasDocument20 pagesTugas Perpindahan PanasLiyan Fajar GintaraNo ratings yet

- 20th Exam P4 ADocument13 pages20th Exam P4 AkaaisNo ratings yet

- Diseño de IntercambiadoresDocument20 pagesDiseño de IntercambiadoresMateo VanegasNo ratings yet

- Cryogenics For Particle AcceleratorsDocument78 pagesCryogenics For Particle AcceleratorsmahradNo ratings yet

- MGH HBDocument33 pagesMGH HBGauranka MoranNo ratings yet

- Heat Exchanger DesignDocument8 pagesHeat Exchanger Designkikokiko KarimNo ratings yet

- 30RBSR32 090RDocument1 page30RBSR32 090RmikhnaumenkoNo ratings yet

- PHE DesignDocument53 pagesPHE Designchgourishankar2000100% (1)

- Boil Up RateDocument1 pageBoil Up RateNitin KurupNo ratings yet

- Cement Kiln Pyro BalanceDocument40 pagesCement Kiln Pyro BalanceGanapathy SubramaniamNo ratings yet

- Storage Tank Heat Loss Calcs - Rev.1 31.12.2010Document18 pagesStorage Tank Heat Loss Calcs - Rev.1 31.12.2010shashi kant kumarNo ratings yet

- Heat Balance CalculationsDocument29 pagesHeat Balance CalculationsGuillermo Càceres100% (1)

- Thermodynamic Lab Experiment 8Document6 pagesThermodynamic Lab Experiment 8Ronaldo UlisiNo ratings yet

- ASP Cryogenics For Particle AcceleratorsDocument64 pagesASP Cryogenics For Particle AcceleratorsASHITA K BNo ratings yet

- Thermodynamic Analysis of IC Engine: Air-Standard CycleDocument62 pagesThermodynamic Analysis of IC Engine: Air-Standard CycleTesfa TemesgenNo ratings yet

- 76-Numericals On Heat exchanger-06-Nov-2019Material - I - 06-Nov-2019 - Heat - Exchanger PDFDocument39 pages76-Numericals On Heat exchanger-06-Nov-2019Material - I - 06-Nov-2019 - Heat - Exchanger PDFsiva yandraNo ratings yet

- Preliminary CalculationsDocument73 pagesPreliminary CalculationsFrancis TanNo ratings yet

- Shell and Tube Heat Exchanger Design: Fluid AllocationDocument6 pagesShell and Tube Heat Exchanger Design: Fluid AllocationLungeloNo ratings yet

- Pharma Engg. Heating & Cooling Time-CycleDocument2 pagesPharma Engg. Heating & Cooling Time-CyclepratikNo ratings yet

- Thermal Power Plant General OverviewDocument50 pagesThermal Power Plant General OverviewN3O LiveNo ratings yet

- Thermal Analysis of Shell and Tube Heat Exchanger Using Mat Lab and Floefd SoftwareDocument6 pagesThermal Analysis of Shell and Tube Heat Exchanger Using Mat Lab and Floefd SoftwaredinakaranpatelNo ratings yet

- A Modern Course in Statistical PhysicsFrom EverandA Modern Course in Statistical PhysicsRating: 3.5 out of 5 stars3.5/5 (2)

- Ambarish Tripathi CVDocument5 pagesAmbarish Tripathi CVPreetpal SinghNo ratings yet

- Matecconf Icome2019 01038Document6 pagesMatecconf Icome2019 01038Preetpal SinghNo ratings yet

- Methanol Recovery Calculation 31-12-2023Document1 pageMethanol Recovery Calculation 31-12-2023Preetpal SinghNo ratings yet

- Thesis P. JamzadDocument75 pagesThesis P. JamzadPreetpal SinghNo ratings yet

- Rajesh CV - 02.12.2023Document3 pagesRajesh CV - 02.12.2023Preetpal SinghNo ratings yet

- US2977197Document5 pagesUS2977197Preetpal SinghNo ratings yet

- Condensor Load CalculationDocument1 pageCondensor Load CalculationPreetpal SinghNo ratings yet

- Chemeo - 63 179 4 - Thionyl ChloridDocument3 pagesChemeo - 63 179 4 - Thionyl ChloridPreetpal SinghNo ratings yet

- Cause List 02.05.2023Document8 pagesCause List 02.05.2023Preetpal SinghNo ratings yet

- SEVA Plans-2020Document1 pageSEVA Plans-2020Preetpal SinghNo ratings yet

- Project Title: Company Name Project LeadDocument3 pagesProject Title: Company Name Project LeadPreetpal SinghNo ratings yet

- Level 3-Model 2Document1 pageLevel 3-Model 2Preetpal SinghNo ratings yet

- Rockinsul LRB PDFDocument1 pageRockinsul LRB PDFPreetpal SinghNo ratings yet

- 3800 PDFDocument202 pages3800 PDFRenny MataNo ratings yet

- CV ReinaldoZerpa+PEOPDocument2 pagesCV ReinaldoZerpa+PEOPReinaldo Zerpa PeñaNo ratings yet

- Mechanical Operations (CHE-205) (Makeup) (EngineeringDuniya - Com)Document3 pagesMechanical Operations (CHE-205) (Makeup) (EngineeringDuniya - Com)Cester Avila Ducusin100% (1)

- B737NG - 27 50 A3 01 PDFDocument1 pageB737NG - 27 50 A3 01 PDFMuhammed MudassirNo ratings yet

- Microtek Ups Sebz 1100Document6 pagesMicrotek Ups Sebz 1100alaa al dineNo ratings yet

- Transistor MCQDocument5 pagesTransistor MCQMark BelasaNo ratings yet

- Measurement Sheet: S.N. Description NO. L. B. D/H. Qtty. 1 TotalDocument19 pagesMeasurement Sheet: S.N. Description NO. L. B. D/H. Qtty. 1 Totaldan12345_007No ratings yet

- PDF - SYLLABUS B2.new PDFDocument4 pagesPDF - SYLLABUS B2.new PDFSaniya khanNo ratings yet

- The Sproutling Baby Monitor Keep Tabs On Your Newborn With This Smart Ankle BraceletDocument2 pagesThe Sproutling Baby Monitor Keep Tabs On Your Newborn With This Smart Ankle BraceletAllanStevenNo ratings yet

- L & T Catalogue 11Document3 pagesL & T Catalogue 11amulya00428No ratings yet

- Subtopic 6.5-6.7 FORM 4 KSSM 2020Document32 pagesSubtopic 6.5-6.7 FORM 4 KSSM 2020NurulNo ratings yet

- C 1173 Coupling StandardDocument4 pagesC 1173 Coupling StandardFernando GonçalvesNo ratings yet

- Failed Product: Kinetic BlazeDocument5 pagesFailed Product: Kinetic Blazeहुडदंग हास्य कवि सम्मलेनNo ratings yet

- Pajero Catalogue2Document13 pagesPajero Catalogue2almirb7100% (1)

- Poka Yoke & Mistake ProofingDocument26 pagesPoka Yoke & Mistake ProofingSarath Babu100% (1)

- Sae: An R Package For Small Area EstimationDocument18 pagesSae: An R Package For Small Area EstimationGregorio AlbánNo ratings yet

- Pile Length CalculationDocument3 pagesPile Length CalculationCivilax.comNo ratings yet

- CIV E 354 Geotechnical Engineering Ii: by Giovanni CascanteDocument11 pagesCIV E 354 Geotechnical Engineering Ii: by Giovanni CascanteVNo ratings yet

- Mte 3152 Electric Drives Mid TermDocument2 pagesMte 3152 Electric Drives Mid TermAjitash TrivediNo ratings yet

- Genesis 30uvDocument42 pagesGenesis 30uvCARLOSNo ratings yet

- B. Tech. II - Class Time Table - 2023-24 - OddDocument2 pagesB. Tech. II - Class Time Table - 2023-24 - OddYusuf GoriawalaNo ratings yet

- BNSG-9000 Firmware User's GuideDocument38 pagesBNSG-9000 Firmware User's GuideBalasundar Ramachandran100% (1)

- IZenBridge PMI ACP Program PDFDocument4 pagesIZenBridge PMI ACP Program PDFadetolahNo ratings yet

- Ultra Power Acb User ManualDocument138 pagesUltra Power Acb User ManualRaj KumarNo ratings yet

- Supplementary SpecificationDocument7 pagesSupplementary SpecificationFranklin PortilloNo ratings yet

- Arbore Cotit DesenDocument1 pageArbore Cotit DesenIonel Bogdan NeacșuNo ratings yet

- VRF Design Manual - SHRM Heat RecoveryDocument112 pagesVRF Design Manual - SHRM Heat RecoverySony CNo ratings yet

- Cruis'n Exotica (27in) Operations) (En)Document105 pagesCruis'n Exotica (27in) Operations) (En)bolopo2No ratings yet

- Datasheet Fike Interface Module 55-055Document2 pagesDatasheet Fike Interface Module 55-055roni kurniawanNo ratings yet

Methanol Recovery Calculation 31-12-2023 R1

Methanol Recovery Calculation 31-12-2023 R1

Uploaded by

Preetpal Singh0 ratings0% found this document useful (0 votes)

9 views1 pageThis document summarizes the process and design parameters for recovering methanol and thionyl chloride from a reactor. It involves using hot water at 80°C in the reactor and a primary graphite condenser operating at 5°C to condense vapors. The maximum boil up rate is calculated to be 249kg/hr. It is recommended to use a plate heat exchanger instead of a shell and tube heat exchanger to reduce costs, with pumping flow rate of 36 m3/hr required due to methanol's properties.

Original Description:

Calculation for recovery

Original Title

methanol recovery calculation 31-12-2023 R1

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document summarizes the process and design parameters for recovering methanol and thionyl chloride from a reactor. It involves using hot water at 80°C in the reactor and a primary graphite condenser operating at 5°C to condense vapors. The maximum boil up rate is calculated to be 249kg/hr. It is recommended to use a plate heat exchanger instead of a shell and tube heat exchanger to reduce costs, with pumping flow rate of 36 m3/hr required due to methanol's properties.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

9 views1 pageMethanol Recovery Calculation 31-12-2023 R1

Methanol Recovery Calculation 31-12-2023 R1

Uploaded by

Preetpal SinghThis document summarizes the process and design parameters for recovering methanol and thionyl chloride from a reactor. It involves using hot water at 80°C in the reactor and a primary graphite condenser operating at 5°C to condense vapors. The maximum boil up rate is calculated to be 249kg/hr. It is recommended to use a plate heat exchanger instead of a shell and tube heat exchanger to reduce costs, with pumping flow rate of 36 m3/hr required due to methanol's properties.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

Sr no Description of process

1 Recovery of ( Methanol + Thinoyl chloride ) is to be done in 08 KL GLR

2 Hot water of 80 degree celsius will be used in reactor jkt .

3 For vapor condensation , utility of +05 celsius will be in primary graphite condensor

4 Rxn mass is only 3441 Kg , Therefor for peak load calculation , volume occupancy factor is 0.5

5 During recovery mean reactor temperature is 40 celsius

Assumptions

1 Latent heat of pure methanol is used in rxn

Point to be checked

1 90 % recovery of rxn mass is to be done which may result in minimum temperature sensing & minimum stirring problem

Conclusion

1 Maximum boil up rate will be 249 Kg/hr

2 For thermic fluid , 01 KL reactor is not suitable

Recommendation

1 For thermic fluid , shell & tube heat exchanger of Heat transfer area 20 m2 should be used

2 For reduction in CAPEX , Plate heat exchanger can be used inplace of shell & tube heat exchanger.(Sizing should be done by vendor)

3 Pumping flow rate required 36 m3/hr

Justification

1 Pumping flow rate is high because of low specific heat capacity & density of methanol as compared to water

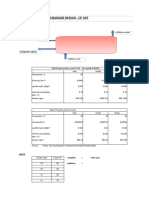

Recovery reactor 08 KL GLR

Sr no Description Units Remarks Note

1 Name of solvent Methanol

2 Latent heat of solvent 1175 KJ/kg

3 Maximum heat input 81 KW =(Overall HTC * HTA*Average approach*Volume factor) At 0.5 volume occupancy factor

4 Maximum boilup rate 249 Kg/hr =(Maximum heat input*3600/Latent heat of solvent) At 0.5 volume occupancy factor

Utility design for reactor condensor utility

Sr no Description Units Remarks Note

1 Inlet temperature 11 celsius T1

2 Outlet temperature 5 celsius T2

3 Inlet temperature of brine -15 celsius T3

4 Outlet temperture of brine -10 celsius T4

5 DELTA T1 21 celsius (T4-T1)

6 DELTA T2 20 celsius (T3-T2)

7 (DELTA T1)/DELTA T2) 1.05 celsius =(T4-T1)/(T3-T2)

8 LMTD 20.5 celsius =(DELTA T1-DELTAT2)/((LNDELTAT1/DELTAT2))

9 Overall HTC 250.0 W/M2k For Shell & tube heat exchanger

10 Heat load 97.6 KW =Maximum heat input *1.2 20 % safety factor is consider

11 Heat transfer area required 19.0 m2 =Heat load /(Overall HTC * LMTD)

Utility flow rate calculation

1 Specific heat capacity of methanol 2.5 KJ/KgK Cp

2 Temperature change across condensor 5 celsius ∆T

3 Density of methanol 792 Kg/m3 Density

4 Flow rate required 35.5 m3/hr =Heat load*3600/(Cp*Density*∆T)

Reactor condensor sizing for phase change only

Sr no Description Units Remarks

1 Vapour Inlet temperature 40 celsius T5

2 Vapour Outlet temperature 40 celsius T6

3 Inlet temperature of utility 5 celsius T7

4 Outlet temperture of utility 11 celsius T8

5 DELTA T3 29 celsius (T8-T5)

6 DELTA T4 35 celsius (T7-T6)

7 (DELTA T3)/DELTA T4) 0.83 celsius =(T8-T5)/(T7-T6)

8 LMTD 31.91 celsius =(DELTA T3-DELTAT4)/((LN(DELTAT3/DELTAT4))

9 Overall HTC 250 W/M2k For Graphite condensor

10 Heat load (At volume occupancy factor 0.5) 81 KW

11 Heat transfer area required(At volume occupancu factor 0.5) 10.20 m2 =Heat load /(Overall HTC * LMTD)

12 Heat transfer area required(At volume occupancu factor 1) 20.39 m2 =Heat load /(Overall HTC * LMTD)

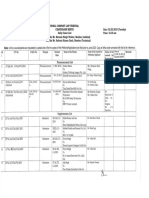

Shell Side Primary condensor Secondary condensor

Sr No MOC ID of equipment Capacity Volume Factor Heat transfer area Steam HWT CW CHW BRINE CW CHW CHW BRINE Boilup rate at different volume occupancy

1 GLR R-01 08 KL 0.5 20 104580 81340 58100 40670 26145 104580 81340 20916 16268 249

2 GLR R-01 08 KL 0.4 20 83664 65072 46480 32536 20916 83664 65072 16733 13014 199

3 GLR R-01 08 KL 0.3 20 62748 48804 34860 24402 15687 62748 48804 12550 9761 150

4 GLR R-01 08 KL 0.2 20 32536 100

5 GLR R-01 08 KL 0.1 20 16268 50

Total Load (W) 250992 195216 139440 97608 62748 250992 50198 50198 39043

Peak load 81340 0 81340 #REF!

Peak load with respective units 0 81 0 0 0 0 23 0 #REF!

Kg/hr KW TR TR TR TR TR TR TR

You might also like

- Jacket Area CalculationDocument12 pagesJacket Area CalculationPraveen Prajapati100% (2)

- Storage Tank Heat Loss Calculation Rev - 0Document23 pagesStorage Tank Heat Loss Calculation Rev - 0fsijestNo ratings yet

- Heating Coil Sizing For Fuel Oil TankDocument2 pagesHeating Coil Sizing For Fuel Oil TankPouria Sabbagh100% (1)

- PRD Training Manual Rev.0 PDFDocument63 pagesPRD Training Manual Rev.0 PDFLEOG85100% (1)

- Heat Exchanger Specification SheetDocument1 pageHeat Exchanger Specification SheetRizal NajibNo ratings yet

- Standards.: General Fastener Standards BS OrderDocument33 pagesStandards.: General Fastener Standards BS OrderamdarvishvandNo ratings yet

- Methanol Recovery Calculation 31-12-2023Document1 pageMethanol Recovery Calculation 31-12-2023Preetpal SinghNo ratings yet

- Simulation An OptimizationDocument28 pagesSimulation An Optimizationalmoanna97100% (1)

- Heat Exchanger Sizing CalculatorDocument1 pageHeat Exchanger Sizing CalculatorandreicarbuneanuNo ratings yet

- Jacketed Vessel Heat Transfer (Half Pipe Coil) : MM Inch MM RPM MM M /HDocument30 pagesJacketed Vessel Heat Transfer (Half Pipe Coil) : MM Inch MM RPM MM M /Hmanoj75% (4)

- Design. Ref - Decuments: API 650, 11TH - ED M09Document9 pagesDesign. Ref - Decuments: API 650, 11TH - ED M09hgagNo ratings yet

- Final Energy Balance-Vizag DT 9-6-18Document14 pagesFinal Energy Balance-Vizag DT 9-6-18SUBHOMOYNo ratings yet

- HEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEDocument8 pagesHEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEhgagNo ratings yet

- HEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEDocument8 pagesHEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEhgagNo ratings yet

- HEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEDocument8 pagesHEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEhgagNo ratings yet

- HEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEDocument8 pagesHEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEhgagNo ratings yet

- HEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEDocument8 pagesHEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEhgagNo ratings yet

- HEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEDocument7 pagesHEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEhgagNo ratings yet

- HEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEDocument8 pagesHEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEhgagNo ratings yet

- HEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEDocument13 pagesHEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEhgagNo ratings yet

- HEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEDocument8 pagesHEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEhgagNo ratings yet

- HEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEDocument8 pagesHEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEhgagNo ratings yet

- Thermic Fluid Heater Data Sheet - Rev 0Document10 pagesThermic Fluid Heater Data Sheet - Rev 0Dhamotharan ChinnaduraiNo ratings yet

- Technological Institute of The PhilippinesDocument25 pagesTechnological Institute of The PhilippinesJohn Leonard FazNo ratings yet

- Chapter 9. Refrigeration and Liquefaction-StudentDocument28 pagesChapter 9. Refrigeration and Liquefaction-StudentFlorenceNo ratings yet

- Refrigeration and Air Conditionin1Document51 pagesRefrigeration and Air Conditionin1Jeremiah Angeles Bautista0% (1)

- Heat Exchanger Design - Part 2Document15 pagesHeat Exchanger Design - Part 2Siddhant SoymonNo ratings yet

- Heat Exchanger DesignDocument28 pagesHeat Exchanger DesignHussein AyoubNo ratings yet

- Thermodynamic Analysis of IC Engine: Air-Standard Cycle byDocument70 pagesThermodynamic Analysis of IC Engine: Air-Standard Cycle bySiraj MohammedNo ratings yet

- Fundamentals of Desalination ProcessesDocument6 pagesFundamentals of Desalination ProcessesElzubair EljaaliNo ratings yet

- The Three Steps of Thermodynamic Analysis of IC Engines AreDocument42 pagesThe Three Steps of Thermodynamic Analysis of IC Engines AreGODNo ratings yet

- A7CA89 Excel Template Shell and Tube Heat Exchanger Design P1and2 Us UnitsDocument5 pagesA7CA89 Excel Template Shell and Tube Heat Exchanger Design P1and2 Us UnitsMudabbir Shan AhmedNo ratings yet

- CH-01 30RBM360 Air Cooled Liquid Chiller Selection PDFDocument2 pagesCH-01 30RBM360 Air Cooled Liquid Chiller Selection PDFBilguun BurenjargalNo ratings yet

- Diseño IntercambiadorDocument9 pagesDiseño IntercambiadorMateo VanegasNo ratings yet

- #2. 열교환기 Design sheetDocument5 pages#2. 열교환기 Design sheet배광득0% (1)

- Thermal Design - 2 Effect Forward-Feed Evaporator Nama Aristya Kurniawan NIM 114 152 5005 Design BasisDocument4 pagesThermal Design - 2 Effect Forward-Feed Evaporator Nama Aristya Kurniawan NIM 114 152 5005 Design BasisAristya KurniawanNo ratings yet

- Pharma Engg. Heat Transfer AreaDocument4 pagesPharma Engg. Heat Transfer AreamanojNo ratings yet

- Tugas Perpindahan PanasDocument20 pagesTugas Perpindahan PanasLiyan Fajar GintaraNo ratings yet

- 20th Exam P4 ADocument13 pages20th Exam P4 AkaaisNo ratings yet

- Diseño de IntercambiadoresDocument20 pagesDiseño de IntercambiadoresMateo VanegasNo ratings yet

- Cryogenics For Particle AcceleratorsDocument78 pagesCryogenics For Particle AcceleratorsmahradNo ratings yet

- MGH HBDocument33 pagesMGH HBGauranka MoranNo ratings yet

- Heat Exchanger DesignDocument8 pagesHeat Exchanger Designkikokiko KarimNo ratings yet

- 30RBSR32 090RDocument1 page30RBSR32 090RmikhnaumenkoNo ratings yet

- PHE DesignDocument53 pagesPHE Designchgourishankar2000100% (1)

- Boil Up RateDocument1 pageBoil Up RateNitin KurupNo ratings yet

- Cement Kiln Pyro BalanceDocument40 pagesCement Kiln Pyro BalanceGanapathy SubramaniamNo ratings yet

- Storage Tank Heat Loss Calcs - Rev.1 31.12.2010Document18 pagesStorage Tank Heat Loss Calcs - Rev.1 31.12.2010shashi kant kumarNo ratings yet

- Heat Balance CalculationsDocument29 pagesHeat Balance CalculationsGuillermo Càceres100% (1)

- Thermodynamic Lab Experiment 8Document6 pagesThermodynamic Lab Experiment 8Ronaldo UlisiNo ratings yet

- ASP Cryogenics For Particle AcceleratorsDocument64 pagesASP Cryogenics For Particle AcceleratorsASHITA K BNo ratings yet

- Thermodynamic Analysis of IC Engine: Air-Standard CycleDocument62 pagesThermodynamic Analysis of IC Engine: Air-Standard CycleTesfa TemesgenNo ratings yet

- 76-Numericals On Heat exchanger-06-Nov-2019Material - I - 06-Nov-2019 - Heat - Exchanger PDFDocument39 pages76-Numericals On Heat exchanger-06-Nov-2019Material - I - 06-Nov-2019 - Heat - Exchanger PDFsiva yandraNo ratings yet

- Preliminary CalculationsDocument73 pagesPreliminary CalculationsFrancis TanNo ratings yet

- Shell and Tube Heat Exchanger Design: Fluid AllocationDocument6 pagesShell and Tube Heat Exchanger Design: Fluid AllocationLungeloNo ratings yet

- Pharma Engg. Heating & Cooling Time-CycleDocument2 pagesPharma Engg. Heating & Cooling Time-CyclepratikNo ratings yet

- Thermal Power Plant General OverviewDocument50 pagesThermal Power Plant General OverviewN3O LiveNo ratings yet

- Thermal Analysis of Shell and Tube Heat Exchanger Using Mat Lab and Floefd SoftwareDocument6 pagesThermal Analysis of Shell and Tube Heat Exchanger Using Mat Lab and Floefd SoftwaredinakaranpatelNo ratings yet

- A Modern Course in Statistical PhysicsFrom EverandA Modern Course in Statistical PhysicsRating: 3.5 out of 5 stars3.5/5 (2)

- Ambarish Tripathi CVDocument5 pagesAmbarish Tripathi CVPreetpal SinghNo ratings yet

- Matecconf Icome2019 01038Document6 pagesMatecconf Icome2019 01038Preetpal SinghNo ratings yet

- Methanol Recovery Calculation 31-12-2023Document1 pageMethanol Recovery Calculation 31-12-2023Preetpal SinghNo ratings yet

- Thesis P. JamzadDocument75 pagesThesis P. JamzadPreetpal SinghNo ratings yet

- Rajesh CV - 02.12.2023Document3 pagesRajesh CV - 02.12.2023Preetpal SinghNo ratings yet

- US2977197Document5 pagesUS2977197Preetpal SinghNo ratings yet

- Condensor Load CalculationDocument1 pageCondensor Load CalculationPreetpal SinghNo ratings yet

- Chemeo - 63 179 4 - Thionyl ChloridDocument3 pagesChemeo - 63 179 4 - Thionyl ChloridPreetpal SinghNo ratings yet

- Cause List 02.05.2023Document8 pagesCause List 02.05.2023Preetpal SinghNo ratings yet

- SEVA Plans-2020Document1 pageSEVA Plans-2020Preetpal SinghNo ratings yet

- Project Title: Company Name Project LeadDocument3 pagesProject Title: Company Name Project LeadPreetpal SinghNo ratings yet

- Level 3-Model 2Document1 pageLevel 3-Model 2Preetpal SinghNo ratings yet

- Rockinsul LRB PDFDocument1 pageRockinsul LRB PDFPreetpal SinghNo ratings yet

- 3800 PDFDocument202 pages3800 PDFRenny MataNo ratings yet

- CV ReinaldoZerpa+PEOPDocument2 pagesCV ReinaldoZerpa+PEOPReinaldo Zerpa PeñaNo ratings yet

- Mechanical Operations (CHE-205) (Makeup) (EngineeringDuniya - Com)Document3 pagesMechanical Operations (CHE-205) (Makeup) (EngineeringDuniya - Com)Cester Avila Ducusin100% (1)

- B737NG - 27 50 A3 01 PDFDocument1 pageB737NG - 27 50 A3 01 PDFMuhammed MudassirNo ratings yet

- Microtek Ups Sebz 1100Document6 pagesMicrotek Ups Sebz 1100alaa al dineNo ratings yet

- Transistor MCQDocument5 pagesTransistor MCQMark BelasaNo ratings yet

- Measurement Sheet: S.N. Description NO. L. B. D/H. Qtty. 1 TotalDocument19 pagesMeasurement Sheet: S.N. Description NO. L. B. D/H. Qtty. 1 Totaldan12345_007No ratings yet

- PDF - SYLLABUS B2.new PDFDocument4 pagesPDF - SYLLABUS B2.new PDFSaniya khanNo ratings yet

- The Sproutling Baby Monitor Keep Tabs On Your Newborn With This Smart Ankle BraceletDocument2 pagesThe Sproutling Baby Monitor Keep Tabs On Your Newborn With This Smart Ankle BraceletAllanStevenNo ratings yet

- L & T Catalogue 11Document3 pagesL & T Catalogue 11amulya00428No ratings yet

- Subtopic 6.5-6.7 FORM 4 KSSM 2020Document32 pagesSubtopic 6.5-6.7 FORM 4 KSSM 2020NurulNo ratings yet

- C 1173 Coupling StandardDocument4 pagesC 1173 Coupling StandardFernando GonçalvesNo ratings yet

- Failed Product: Kinetic BlazeDocument5 pagesFailed Product: Kinetic Blazeहुडदंग हास्य कवि सम्मलेनNo ratings yet

- Pajero Catalogue2Document13 pagesPajero Catalogue2almirb7100% (1)

- Poka Yoke & Mistake ProofingDocument26 pagesPoka Yoke & Mistake ProofingSarath Babu100% (1)

- Sae: An R Package For Small Area EstimationDocument18 pagesSae: An R Package For Small Area EstimationGregorio AlbánNo ratings yet

- Pile Length CalculationDocument3 pagesPile Length CalculationCivilax.comNo ratings yet

- CIV E 354 Geotechnical Engineering Ii: by Giovanni CascanteDocument11 pagesCIV E 354 Geotechnical Engineering Ii: by Giovanni CascanteVNo ratings yet

- Mte 3152 Electric Drives Mid TermDocument2 pagesMte 3152 Electric Drives Mid TermAjitash TrivediNo ratings yet

- Genesis 30uvDocument42 pagesGenesis 30uvCARLOSNo ratings yet

- B. Tech. II - Class Time Table - 2023-24 - OddDocument2 pagesB. Tech. II - Class Time Table - 2023-24 - OddYusuf GoriawalaNo ratings yet

- BNSG-9000 Firmware User's GuideDocument38 pagesBNSG-9000 Firmware User's GuideBalasundar Ramachandran100% (1)

- IZenBridge PMI ACP Program PDFDocument4 pagesIZenBridge PMI ACP Program PDFadetolahNo ratings yet

- Ultra Power Acb User ManualDocument138 pagesUltra Power Acb User ManualRaj KumarNo ratings yet

- Supplementary SpecificationDocument7 pagesSupplementary SpecificationFranklin PortilloNo ratings yet

- Arbore Cotit DesenDocument1 pageArbore Cotit DesenIonel Bogdan NeacșuNo ratings yet

- VRF Design Manual - SHRM Heat RecoveryDocument112 pagesVRF Design Manual - SHRM Heat RecoverySony CNo ratings yet

- Cruis'n Exotica (27in) Operations) (En)Document105 pagesCruis'n Exotica (27in) Operations) (En)bolopo2No ratings yet

- Datasheet Fike Interface Module 55-055Document2 pagesDatasheet Fike Interface Module 55-055roni kurniawanNo ratings yet