Professional Documents

Culture Documents

Condensor Load Calculation

Condensor Load Calculation

Uploaded by

Preetpal SinghCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Condensor Load Calculation

Condensor Load Calculation

Uploaded by

Preetpal SinghCopyright:

Available Formats

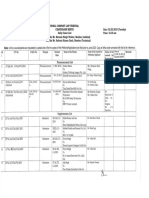

Condensor Load Calculation (TC Process)

Description UOM Remarks

Solvent Methanol + TC -

Total Solvent in reaction mass 3441 Kg 90% will be distilled out

Distillation time 20 hrs

Rate of distillation 172 Kg/hr

Latent Heat of solvent (MeOH+TC) 263 Kcal/Kg

Heat Load on condenser during recovery 45245 Kcal/hr

Utility temp In, Tinlet 5 ˚C

Utility temp out, Toutlet 10 ˚C 5 degc delta assumed

Solvent Vapor Temp In, Tinlet 40.0 ˚C

Solvent Vapor Temp Out, Toutlet 40.0 ˚C

ΔT1 30.0 ˚C

ΔT2 35.0 ˚C

LMTD 32.44 ˚C

Available Condenser Area, A 24 m2

Overall heat transfer coefficient, Ucondensor 150 2

Kcal/Hr (m ) ˚C

Heat Load by condenser 116769

Condensor adequate Adequate -

Secondary Utility Cooling

Description UOM

Reactor Capacity 1000 L

Solvent for secondary utility MeOH -

Quantity of solvent in reactor 800 L 80% filling assumed

Specific heat of Solvent 0.6 Kcal/Kg ˚C

Initial temperature 25 ˚C

Final temperature after cooling 5 ˚C

Total Heat Load 9600 Kcal

Mean temperature, T1 5 ˚C

Maximum temperature, T2 25 ˚C

Note: CHB temp and flow rate both are

CHB Inlet temperature, t1 -15 ˚C

required for effective cooling

CHB outlet temperature, t2 -10 ˚C

ΔT1 20 ˚C

ΔT2 35 ˚C

LMTD 26.8 ˚C

Overall heat transfer coefficient, UJacket 500.0 Kcal/Hr (m2) ˚C

Area of jacket 2.6 m2

Heat that can be transfer through the jacket 34953 Kcal/hr

Cooling Time, t 0.27 hrs

5.0 m3/hr

Pump flow Rate (m3/hr)

6.3 m3/hr 80% efficiency

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Ambarish Tripathi CVDocument5 pagesAmbarish Tripathi CVPreetpal SinghNo ratings yet

- Matecconf Icome2019 01038Document6 pagesMatecconf Icome2019 01038Preetpal SinghNo ratings yet

- Thesis P. JamzadDocument75 pagesThesis P. JamzadPreetpal SinghNo ratings yet

- Rajesh CV - 02.12.2023Document3 pagesRajesh CV - 02.12.2023Preetpal SinghNo ratings yet

- US2977197Document5 pagesUS2977197Preetpal SinghNo ratings yet

- Methanol Recovery Calculation 31-12-2023Document1 pageMethanol Recovery Calculation 31-12-2023Preetpal SinghNo ratings yet

- Cause List 02.05.2023Document8 pagesCause List 02.05.2023Preetpal SinghNo ratings yet

- Level 3-Model 2Document1 pageLevel 3-Model 2Preetpal SinghNo ratings yet

- Chemeo - 63 179 4 - Thionyl ChloridDocument3 pagesChemeo - 63 179 4 - Thionyl ChloridPreetpal SinghNo ratings yet

- Project Title: Company Name Project LeadDocument3 pagesProject Title: Company Name Project LeadPreetpal SinghNo ratings yet

- SEVA Plans-2020Document1 pageSEVA Plans-2020Preetpal SinghNo ratings yet

- Rockinsul LRB PDFDocument1 pageRockinsul LRB PDFPreetpal SinghNo ratings yet