Professional Documents

Culture Documents

Fork Lift Ramp Calculation

Fork Lift Ramp Calculation

Uploaded by

rabOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fork Lift Ramp Calculation

Fork Lift Ramp Calculation

Uploaded by

rabCopyright:

Available Formats

PAGE

DQ. NO: JOB NO: DATE:

DESIGNED BY: CHECKED BY:

REV NO: REV DATE:

DESCRIPTION :

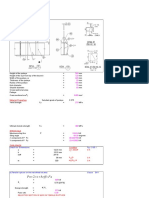

Fork Lift Ramp

A. Basic Assumptions:

Weight of Fork Lift = 1.5 Ton (Assume)

14.72 kN

3.306 kip

Capacity of Fork Lift= 4.5 Ton

44.15 kN

9.918 kip

Wheel Load = 1.5 Ton

14.72 kN

3.306 kip

Fy= 50 ksi (Hot Rolled IPE Section) Propertiies of IPE 300:

34.5 kN/cm2

Fy= 50 ksi (Steel Plate) tw= 7.1 mm

34.5 kN/cm2 0.280 in

Fy= 50 ksi (Cheq Plate) tf= 10.7 mm

34.5 kN/cm2 0.421 in

B. Required Plate Thikness (Acting as Flange for cut IPE 300)

P= 14.72 kN (Wheel load applied at the edge of the plate. The plate acting as flange of the cut IPE 300)

x1= 66.45 mm (Moment arm=(plate width-IPE web thk-twice weld size)/2)

6.645 cm (Plate width=150mm, weld size=5mm)

M= 97.78 kN-cm

tp= 1.46 cm (6*M/(Fb*B))^0.5

say 15 mm

0.591 in

B= 13.29 cm (B=2*x1,45 degree projection to point of maximum moment)

Fb= 20.7 kN/cm2 (0.6*Fy)

C. Required Cheq Plate Thkness

(Assume the plate is simply supported at plate edge. Distance between edges=725-150 which is 575mm)

(Max Moment occurs when a wheel is at the center)

P= 14.72 kN

L= 575 mm

57.5 cm

M= 105.8 kN-cm (P*L/8)

tp= 0.73 cm (6*M/(Fb*B))^0.5

say 8 mm

(B=2*x2,45 degree projection to point of maximum moment)

B= 57.5 cm (0.6*Fy)

Fb= 20.7 kN/cm2

PAGE

DQ. NO: JOB NO DATE:

DESIGNED BY: CHECKED BY:

REV NO: REV DATE:

DESCRIPTION :

Fork Lift Ramp

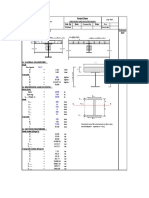

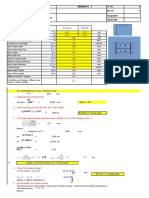

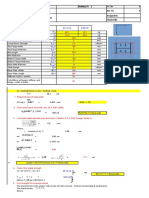

D. Check the adequacy of IPE 300

D.1 IPE 300 LOCAL WEB YIELDING

Rn/Ω= 34.85 kip (5k+N)*Fy*tw Eq J10-2 ,AISC 2005)

IPE 300 Web thkness is safe for local web yielding

Ω= 1.50

tw= 0.280 in IPE 300 web thkness

k= 0.748 in dist from outside face of outside plate to the web weld(Plate thk=15mm, weld=5mm)

N= 0.00 in Assume point application for wheel load

Fyw= 50.0 ksi

D.2. IPE 300 WEB CRIPPLING

Rn/Ω= 54.7 kip (0.8*tw^2*(1+3(N/d)(tw/tf)^1.5))(E*Fyw*tf/tw)^0.5 Eq J10-4 ,AISC 2005)

IPE 300 Web thkness is safe for web crippling

Ω= 2.00

N= 0.000 in Assume point application for wheel load

Fyw= 50 ksi

tf= 0.5906 in Plate thkness(Plate is acting as a flange for the cut portion of IPE300)

tw= 0.2795 in IPE 300 web thkness

E= 29000 ksi

d= 11.81 in depth of member

D.3. COMPRESSION BUCKLING OF IPE 300 WEB

Pfc= 3.306 kip Required Compressive force

Rn/Ω= 34.5 kip (24*tw^3*(E*Fyw)^0.5/h Eq J10-8 ,AISC 2005)

IPE 300 Web thkness is adequate to resist the Compressive force

Ω= 1.67

h= 10.969 in

tw= 0.2795 in

E= 29000 ksi

Fyw= 50.0 ksi

E. Size of Stiffener

ts= 8 mm (Assume)

0.315 in

The stiffener capacity will be checked with a full section as per Section J10.8 of ASCE 7-05.

ws= 70 mm (width of one stiffener approx. equal to (150-7.1)/2)

Lw= 177.5 mm (Lw=25*tw, as per Section J10.8 of ASCE 7-05)

(Lw=25*7.1=177.5mm)

A 2380 mm2 (Lw*tw+2*ws*ts)

23.8 cm2

Ix= 183.5 cm4

k= 0.75

L= 28 cm (from sketch)

r= 2.78 cm (I/A)^0.5

kL/r= 7.564

Fa= 20.32 kN/cm2 (Allowable compreesive stress)

Ps= 483.7 kN (Stiffener compressive capacity)

(The stiffener is designed as column based on Section J10.8 of ASCE 7-05)

Stiffener size of 8mm is adequate

You might also like

- Toyota Coralla 1996 Wiring Diagram OverallDocument34 pagesToyota Coralla 1996 Wiring Diagram Overallsixdust86% (139)

- Guide To Wireless Communications 4th Edition Olenewa Solutions ManualDocument13 pagesGuide To Wireless Communications 4th Edition Olenewa Solutions Manualsonemmanuelix83ua100% (26)

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- 16 ACI Acquirer Functional OverviewDocument64 pages16 ACI Acquirer Functional Overviewኣስፋ ሙሉNo ratings yet

- Section Properties: Design of Padeye As Per Aisc 360-2005Document5 pagesSection Properties: Design of Padeye As Per Aisc 360-2005Fadil WimalaNo ratings yet

- Pile Rebar DesignDocument4 pagesPile Rebar Designprakash100% (1)

- Reaction Kinetics and Reactor Design - John B ButtDocument1 pageReaction Kinetics and Reactor Design - John B ButtPutri Rahimi100% (1)

- Bagwa Army Taoist Magic - TYD Taoism Temple - Tin Yat DragonDocument8 pagesBagwa Army Taoist Magic - TYD Taoism Temple - Tin Yat DragonAlucardNo ratings yet

- Appendix - 4BDocument12 pagesAppendix - 4Bmoumita mukherjeeNo ratings yet

- 1 Input Data: Anchor Type and Size: Hsl-3 M12 or EquivalentDocument4 pages1 Input Data: Anchor Type and Size: Hsl-3 M12 or EquivalentNp PwNo ratings yet

- Foundation Design - 5110-P-001ABC - Rev 0Document11 pagesFoundation Design - 5110-P-001ABC - Rev 0Yatendra TyagiNo ratings yet

- Ring Design - Force CalculationDocument60 pagesRing Design - Force CalculationGomathi ananthNo ratings yet

- Pinned Base Plate-ECPLUS Design-ExampleDocument4 pagesPinned Base Plate-ECPLUS Design-ExampleNivarNo ratings yet

- Calculation Sheet: NPCC N/A Member Design - Aisc (Compact) VBDocument12 pagesCalculation Sheet: NPCC N/A Member Design - Aisc (Compact) VBinnovativekarthi0% (1)

- Beam Design UlsDocument5 pagesBeam Design UlsTodor Ivanov YankovNo ratings yet

- Design Base Plate For I Beam - Bottom BracketDocument1 pageDesign Base Plate For I Beam - Bottom BracketCon CanNo ratings yet

- Beam Splice Design: 1 Input Data: 1.1 Section and Section PropertiesDocument13 pagesBeam Splice Design: 1 Input Data: 1.1 Section and Section PropertiesVenkatesha Hebbar100% (1)

- Composite BeamDocument3 pagesComposite BeamMOHAMEDNo ratings yet

- 10 Design of End AnchorageDocument2 pages10 Design of End AnchorageSulabh GuptaNo ratings yet

- Your Company Logo: Page No. Project Subject Designed by Checked by Date 3/1/2015Document1 pageYour Company Logo: Page No. Project Subject Designed by Checked by Date 3/1/2015AamirShabbirNo ratings yet

- Pile E2 On WallDocument4 pagesPile E2 On WallSiew Kok HongNo ratings yet

- Bolt Design and Embedment Length CheckDocument6 pagesBolt Design and Embedment Length CheckHarish M PNo ratings yet

- R0.base Plate - (Top) )Document4 pagesR0.base Plate - (Top) )Srishti Project Consultants0% (1)

- Moment ConnectionDocument5 pagesMoment ConnectionALPHYL BALASABASNo ratings yet

- Beam Design of Reinforced ConcreteDocument2 pagesBeam Design of Reinforced ConcreteAmanda SmithNo ratings yet

- Bearing DesignDocument5 pagesBearing DesignVenkat RaoNo ratings yet

- Doubly Reinforced BeamDocument19 pagesDoubly Reinforced BeamLavender HoneyNo ratings yet

- Staircase DesignDocument2 pagesStaircase Designbalaji gmscNo ratings yet

- 5.design of Isolated FootingDocument4 pages5.design of Isolated FootingMadhubalaNo ratings yet

- Bolted Moment ConnectionDocument18 pagesBolted Moment ConnectionAlpha50% (2)

- Muk 38765 4Document6 pagesMuk 38765 4Suresh MahalingamNo ratings yet

- Ultimate Moment Capacity of Reinforced Concrete Section To EN 1992-2 - Clause 6.1Document5 pagesUltimate Moment Capacity of Reinforced Concrete Section To EN 1992-2 - Clause 6.1Randhir BharatNo ratings yet

- WEB - Welding DesignDocument2 pagesWEB - Welding DesignAdam MillerNo ratings yet

- Pad Footing - 2019.12.30 (APEC)Document5 pagesPad Footing - 2019.12.30 (APEC)Wai HonNo ratings yet

- EC - RC Pilecap - 4PGDocument2 pagesEC - RC Pilecap - 4PGJONHCENA13No ratings yet

- Base Plate & Anchor Bolt Design For Support Type 02B (Pipe 168.3) Loading DetailsDocument8 pagesBase Plate & Anchor Bolt Design For Support Type 02B (Pipe 168.3) Loading DetailsAsaru DeenNo ratings yet

- Calculation of Load Test Comp R6Document81 pagesCalculation of Load Test Comp R6faichan.p4113.gwNo ratings yet

- Flight: Spreadsheets To BS 8110Document4 pagesFlight: Spreadsheets To BS 8110Nezza AriffNo ratings yet

- AISC2005 Anchor Bolt5 Pin Connection NewDocument6 pagesAISC2005 Anchor Bolt5 Pin Connection NewThuyTranNo ratings yet

- AISC2005 Anchor Bolt5 Pin Connection NewDocument6 pagesAISC2005 Anchor Bolt5 Pin Connection NewThuyTranNo ratings yet

- MBBearing PlateDocument2 pagesMBBearing Platenongbig1No ratings yet

- Project Job Number EngineerDocument1 pageProject Job Number EngineerbenjipaulNo ratings yet

- PHC Calculation ASSHTO-LRDF 2007Document3 pagesPHC Calculation ASSHTO-LRDF 2007Nguyen D CongNo ratings yet

- PHC Calculation Asshto-Lrdf 2007Document3 pagesPHC Calculation Asshto-Lrdf 2007Nguyen D CongNo ratings yet

- Notes:: Supporting Beam Supported ColumnDocument2 pagesNotes:: Supporting Beam Supported Columnmassive85No ratings yet

- Design Doc. - Rt. WallDocument16 pagesDesign Doc. - Rt. WallAnindit MajumderNo ratings yet

- Check For Tension: TF TDF: MF m1 M MWDocument4 pagesCheck For Tension: TF TDF: MF m1 M MWkeerthivasan_mrvNo ratings yet

- Base Plate - MammutDocument8 pagesBase Plate - MammutAwais Hameed100% (1)

- 30m Anchor and Base Plate MonopoleDocument6 pages30m Anchor and Base Plate MonopoleEhtesham AliNo ratings yet

- Flight: Spreadsheets To BS 8110Document6 pagesFlight: Spreadsheets To BS 8110Kem RaiNo ratings yet

- Appendix - 4ADocument15 pagesAppendix - 4Amoumita mukherjeeNo ratings yet

- Design of Pile and Pile Cap BeamDocument4 pagesDesign of Pile and Pile Cap Beamshivendra kumarNo ratings yet

- Calculation of Bearing Plate Dimension:: Beam SectionDocument2 pagesCalculation of Bearing Plate Dimension:: Beam Sectionk.m.ariful islamNo ratings yet

- Baseplate-Kolom wf250Document79 pagesBaseplate-Kolom wf250Gary JonathanNo ratings yet

- Client: Reem General Contracting Est. Al Jubail, Dammam, Commercial Street Kingdom of Saudi Arabia Al KhobarDocument3 pagesClient: Reem General Contracting Est. Al Jubail, Dammam, Commercial Street Kingdom of Saudi Arabia Al KhobarUday UdmaleNo ratings yet

- End Plate Width & THK Calc Based On AngleDocument16 pagesEnd Plate Width & THK Calc Based On AnglebalaNo ratings yet

- 2010NSCP Square Ftg. Square Col BESADocument13 pages2010NSCP Square Ftg. Square Col BESAKuroshiro Yameda100% (1)

- AnchorageWithCircularBasePlate-DÍAZ CORNEJO ROBERTDocument3 pagesAnchorageWithCircularBasePlate-DÍAZ CORNEJO ROBERTRobert Díaz CornejoNo ratings yet

- Base Plate Design by Is CodeDocument134 pagesBase Plate Design by Is CodeStructural Spreadsheets100% (1)

- TCC71 Stair Flight & Landing - SingleDocument7 pagesTCC71 Stair Flight & Landing - Singlehala_azhariNo ratings yet

- Ejma 2000Document7 pagesEjma 2000jhunkujha11No ratings yet

- Triangle Beam B1Document6 pagesTriangle Beam B1sallysel90No ratings yet

- Column Base PlateDocument4 pagesColumn Base PlateYHK3001No ratings yet

- Crackwidth Calculation Spreadsheet (Restricted Version)Document11 pagesCrackwidth Calculation Spreadsheet (Restricted Version)Nicholas ThompsonNo ratings yet

- Final DesignDocument62 pagesFinal DesignNishan GajurelNo ratings yet

- Vol5-Checklist EN PDFDocument3 pagesVol5-Checklist EN PDFsasha_saleNo ratings yet

- Mitsubishi Qm150dy-H DatasheetDocument5 pagesMitsubishi Qm150dy-H DatasheetcoronaqcNo ratings yet

- Prelim Exam - Attempt ReviewDocument15 pagesPrelim Exam - Attempt Reviewkoraijohnson7No ratings yet

- Solutions To Problem Set 6Document4 pagesSolutions To Problem Set 6eetahaNo ratings yet

- (Packt) Carl Cocchiaro - Selenium Framework Design in Data-Driven Testing (2018, Packt)Document447 pages(Packt) Carl Cocchiaro - Selenium Framework Design in Data-Driven Testing (2018, Packt)RPA Demo100% (1)

- CPA BEC Mock QuestionsDocument21 pagesCPA BEC Mock Questionsharish100% (1)

- Temenos Data Migration (TDM) ServicesDocument9 pagesTemenos Data Migration (TDM) Servicesthunder.ajay100% (2)

- Internal Alignment-Job EvaluationDocument27 pagesInternal Alignment-Job Evaluationmadgal212No ratings yet

- Publishers Package 2020Document4 pagesPublishers Package 2020orode franklynNo ratings yet

- Felcom250 500 Installation ManualDocument71 pagesFelcom250 500 Installation Manualguanglin siNo ratings yet

- Rumusan Laporan Panitia 2020Document42 pagesRumusan Laporan Panitia 2020Khairul Bariah KassimNo ratings yet

- Command Syntax Comparison & Contrast: Command/Function Ios/Ios-Xe Ios-Xr Nx-Os CommentsDocument4 pagesCommand Syntax Comparison & Contrast: Command/Function Ios/Ios-Xe Ios-Xr Nx-Os CommentsAhmed YahiaNo ratings yet

- Group 5 TechnopreneurshipDocument54 pagesGroup 5 TechnopreneurshipBrandy Juet EcleviaNo ratings yet

- Micro Project Report On: Airline Reservation SystemDocument17 pagesMicro Project Report On: Airline Reservation SystemAbhay Jadhav100% (1)

- Revised PMJJBY Enrolment Form - 30.5.2022-1Document2 pagesRevised PMJJBY Enrolment Form - 30.5.2022-1Sathish Varma KosuriNo ratings yet

- A Joint Optimization of Antenna Parameters in A Cellular Network Using Taguchi's MethodDocument5 pagesA Joint Optimization of Antenna Parameters in A Cellular Network Using Taguchi's MethodFelix J. Alvarez HerreraNo ratings yet

- Septic TankDocument1 pageSeptic TankUmesh SigdelNo ratings yet

- Manual Weintek Mt8051ipDocument2 pagesManual Weintek Mt8051ipYgor EuripedesNo ratings yet

- Exercise 6 PDFDocument2 pagesExercise 6 PDFviệt lêNo ratings yet

- ENGLISH TEST ON PROCEDURE TEXT (10 Items)Document2 pagesENGLISH TEST ON PROCEDURE TEXT (10 Items)ezevery7No ratings yet

- Bosch Ciss - Usb - Communication - ProtocolDocument19 pagesBosch Ciss - Usb - Communication - ProtocolDinhNo ratings yet

- Stress Report - Load CaseDocument26 pagesStress Report - Load Casesenthil muruganNo ratings yet

- Iso 17000Document57 pagesIso 17000Osama MohammedNo ratings yet

- Feasibility Study: Bangalore: Photovoltaic Glass For BuildingsDocument35 pagesFeasibility Study: Bangalore: Photovoltaic Glass For BuildingsPromtaC InnovationNo ratings yet

- HKB-2X Speaker Station: Linking People TogetherDocument3 pagesHKB-2X Speaker Station: Linking People TogetherJosé FélixNo ratings yet