Professional Documents

Culture Documents

Tyres and Wheels

Tyres and Wheels

Uploaded by

Kamal Jit DhimanCopyright:

Available Formats

You might also like

- DGR3 Field TestDocument8 pagesDGR3 Field TestKamal Jit DhimanNo ratings yet

- ITTAC Section 1Document18 pagesITTAC Section 1dharan51167% (3)

- Suggested Vendors ListDocument137 pagesSuggested Vendors Listrajiv kumar100% (1)

- Cr3213-4-03 Blind Rivet Spec: Additional InformationDocument2 pagesCr3213-4-03 Blind Rivet Spec: Additional InformationKamal Jit DhimanNo ratings yet

- ICA-172-28-00001 (Fuel Qty Indication)Document63 pagesICA-172-28-00001 (Fuel Qty Indication)Kamal Jit Dhiman100% (1)

- Cherry MS RivetsDocument17 pagesCherry MS RivetsKamal Jit Dhiman100% (1)

- Toyota Tacoma 2012 - Tvip V5 Part Number: PT398-35121: PreparationDocument22 pagesToyota Tacoma 2012 - Tvip V5 Part Number: PT398-35121: PreparationTomas OrozcoNo ratings yet

- Nitrogen: A Security Blanket For The Chemical Industry: Fluids and Solids HandlingDocument6 pagesNitrogen: A Security Blanket For The Chemical Industry: Fluids and Solids HandlingSubramanian RavichandranNo ratings yet

- Toy Crane ManualDocument12 pagesToy Crane Manuallahsivlahsiv684100% (1)

- Editor in chief,+EJERS 2224+correctedDocument12 pagesEditor in chief,+EJERS 2224+correctedtini taziekNo ratings yet

- Design Analysis of A Portable Manual Tyre Changer: European Journal of Engineering Research and Science November 2020Document13 pagesDesign Analysis of A Portable Manual Tyre Changer: European Journal of Engineering Research and Science November 2020Sakman SulaemanNo ratings yet

- TPCS Airless Tyres Report VARSHADocument27 pagesTPCS Airless Tyres Report VARSHASumit PatilNo ratings yet

- Institute Name Annamalai Univers India Ranking 2017 ID IR17-ENGG-2-1-33 Discipline EngineeringDocument8 pagesInstitute Name Annamalai Univers India Ranking 2017 ID IR17-ENGG-2-1-33 Discipline EngineeringNisha NishaNo ratings yet

- Report On Airless TyreDocument27 pagesReport On Airless TyreshivamNo ratings yet

- Rep14 04 PDFDocument45 pagesRep14 04 PDFVishnu RNo ratings yet

- Startup Idea Generation: Dr.S.Dinesh KumarDocument21 pagesStartup Idea Generation: Dr.S.Dinesh KumarSHAHULNo ratings yet

- DoR Guidelines For Flexible PavementDocument37 pagesDoR Guidelines For Flexible PavementkesharinareshNo ratings yet

- Giti - TBR - Catalog 2022Document52 pagesGiti - TBR - Catalog 2022Frank Rodriguez MiranoNo ratings yet

- CH 06 RowColumnAdjustmentsDocument29 pagesCH 06 RowColumnAdjustmentsGeorge KariukiNo ratings yet

- Highest Paid RankingsDocument1 pageHighest Paid RankingsPraveen ThakurNo ratings yet

- Big Achievements Happen When We Build On Each Other'S Ideas: 3/28/2020 DR FZS, Ched, Amu, India 1Document13 pagesBig Achievements Happen When We Build On Each Other'S Ideas: 3/28/2020 DR FZS, Ched, Amu, India 1Insha Zameer RazviNo ratings yet

- Off The Road Tyre Manual - Everything You Want To Know Abt OTH - Goodyear PDFDocument127 pagesOff The Road Tyre Manual - Everything You Want To Know Abt OTH - Goodyear PDFGaurav SharmaNo ratings yet

- Goodyear OTR Databook 3Document170 pagesGoodyear OTR Databook 3Raburgess1No ratings yet

- List of Facilitators For TrademarksDocument19 pagesList of Facilitators For Trademarkssaranya pugazhenthiNo ratings yet

- The 2016 Premium Tyre Range: For Cars, Suv/4X4S and VansDocument21 pagesThe 2016 Premium Tyre Range: For Cars, Suv/4X4S and VanswillupowersNo ratings yet

- Cement ContaminationDocument15 pagesCement ContaminationGaurav HazarikaNo ratings yet

- Afforestation Project SRPF Group 5 7 ReportDocument11 pagesAfforestation Project SRPF Group 5 7 Reportmistryvraj90No ratings yet

- Maintenance Manual - enDocument54 pagesMaintenance Manual - enSIDI MOHAMMED BENDELLANo ratings yet

- Sr. No. Product Laboratory DRDO Contact Industry Detailed Address Industry Contact PersonDocument3 pagesSr. No. Product Laboratory DRDO Contact Industry Detailed Address Industry Contact PersonamandeepNo ratings yet

- Utilization of Rubber Waste in Construction of Flexible PavementDocument8 pagesUtilization of Rubber Waste in Construction of Flexible Pavementathirah mfNo ratings yet

- Memo On Toll Category-1Document2 pagesMemo On Toll Category-1NV TechnologyNo ratings yet

- Basis Information of TyreDocument32 pagesBasis Information of TyreKARTHICKRAJ KANDASAMY100% (2)

- Segunda Tesis OpenDocument43 pagesSegunda Tesis OpenSandro FernandezNo ratings yet

- AAPA National Asphalt Specification Australian Asphalt PavementDocument48 pagesAAPA National Asphalt Specification Australian Asphalt Pavementeza marizkaNo ratings yet

- Technical Bulletin 2009-09 Choosing Correct Grease For EquiDocument4 pagesTechnical Bulletin 2009-09 Choosing Correct Grease For EquiNeelam P GogoiNo ratings yet

- Draft EIA - CompressedDocument381 pagesDraft EIA - Compressedshinchan007516No ratings yet

- Study of Partial Replacement of Coarse Aggregate in Concrete by Different Proportions of Un-Treated Waste Tyre RubberDocument9 pagesStudy of Partial Replacement of Coarse Aggregate in Concrete by Different Proportions of Un-Treated Waste Tyre RubberIJRASETPublicationsNo ratings yet

- Allopathic Loan 2019Document9 pagesAllopathic Loan 2019Main Sanatani HunNo ratings yet

- Airtra & Atma Consult On Epr - Tyre and Rubber RecyclingDocument1 pageAirtra & Atma Consult On Epr - Tyre and Rubber RecyclingleonardNo ratings yet

- PFD FileDocument235 pagesPFD FileabubakarabdulgafNo ratings yet

- 2018 AniketDocument60 pages2018 Aniketaniket chakiNo ratings yet

- JK Mysore Intership ReportDocument41 pagesJK Mysore Intership ReportSumanth Gowda100% (1)

- A Study of Cost Effective Hardness Rubber Compound For Bicycle TiresDocument23 pagesA Study of Cost Effective Hardness Rubber Compound For Bicycle TiresPrabath TharukaNo ratings yet

- Prai MembersDocument14 pagesPrai Membersraj RajputNo ratings yet

- Riya GuptaDocument32 pagesRiya Guptaanshulh35No ratings yet

- Method Statement-Earthing ImprovementDocument12 pagesMethod Statement-Earthing ImprovementShubham PatelNo ratings yet

- Utilization of Scrap Tyre Rubber in The Form of Aggregates As Partial Exchange With Existing AggregatesDocument8 pagesUtilization of Scrap Tyre Rubber in The Form of Aggregates As Partial Exchange With Existing AggregatesEditor IJTSRDNo ratings yet

- Full Casting Crown RestorationsDocument10 pagesFull Casting Crown RestorationsAhmed TalalNo ratings yet

- Araveti Santosh Kumar Gupta PDFDocument5 pagesAraveti Santosh Kumar Gupta PDFMukesh & Associates D3No ratings yet

- Effect of Addition of Waste Tyre Crumb Rubber On WDocument6 pagesEffect of Addition of Waste Tyre Crumb Rubber On Wveenau 1No ratings yet

- 2021 MTD100Document17 pages2021 MTD100jazz pastaNo ratings yet

- Tyre RetreadingpptDocument15 pagesTyre Retreadingpptshiva_ssk17100% (1)

- Reddy PDFDocument18 pagesReddy PDF20wj1a0339No ratings yet

- Ne W Jayam Resume3Document5 pagesNe W Jayam Resume3jayamsubramaniam.s100% (2)

- Guide For Design and Proportioning of Concrete Mixtures For PavementsDocument7 pagesGuide For Design and Proportioning of Concrete Mixtures For PavementsMuddasir RehmanNo ratings yet

- Non Pneumatic TyreDocument17 pagesNon Pneumatic Tyrereghurahul88No ratings yet

- Internship Report: TM Rubber (PVT.) LTDDocument6 pagesInternship Report: TM Rubber (PVT.) LTDsaudNo ratings yet

- CE 442 Material and Pavement Design: Chapter I: IntroductionDocument20 pagesCE 442 Material and Pavement Design: Chapter I: IntroductionMohammad DawaghrehNo ratings yet

- Otr GoodyearDocument170 pagesOtr GoodyearSaiful AhmadNo ratings yet

- Compact Tractor Brochure - D-117 (02-07)Document27 pagesCompact Tractor Brochure - D-117 (02-07)Vicente AlvioNo ratings yet

- K-Series Tire Guide AEXQ0403Document24 pagesK-Series Tire Guide AEXQ0403Jairo PalaciosNo ratings yet

- Banded Vs Bonded Space Maintainers: Finding Better Way OutDocument9 pagesBanded Vs Bonded Space Maintainers: Finding Better Way OutYashwanth SreedharaNo ratings yet

- Irjet V8i4192Document7 pagesIrjet V8i4192G Sai TejaNo ratings yet

- Internship Report For Compounding Department at General Tyre & Rubber Company of PakistanDocument22 pagesInternship Report For Compounding Department at General Tyre & Rubber Company of PakistanZeeshan Zahid0% (1)

- SB 639 Rocker Arm InspectionDocument3 pagesSB 639 Rocker Arm InspectionKamal Jit DhimanNo ratings yet

- 5 ClutchDocument31 pages5 ClutchKamal Jit DhimanNo ratings yet

- Service Bulletin1018Document6 pagesService Bulletin1018Kamal Jit DhimanNo ratings yet

- SI 1575 New Conecting Rod BushingDocument2 pagesSI 1575 New Conecting Rod BushingKamal Jit DhimanNo ratings yet

- Cherry Lock Blind Rivets CA-1005 PDFDocument38 pagesCherry Lock Blind Rivets CA-1005 PDFKamal Jit DhimanNo ratings yet

- SB 639 Rocker Arm InspectionDocument3 pagesSB 639 Rocker Arm InspectionKamal Jit DhimanNo ratings yet

- Tute Sheet 2 - Axial - Shear - Bearing StressDocument2 pagesTute Sheet 2 - Axial - Shear - Bearing StressKamal Jit DhimanNo ratings yet

- Tutorial 1 FM PDFDocument2 pagesTutorial 1 FM PDFKamal Jit DhimanNo ratings yet

- Tute 1-Revision of Normal Streses and Strains PDFDocument2 pagesTute 1-Revision of Normal Streses and Strains PDFKamal Jit DhimanNo ratings yet

- Thapar Institute of Engineering and Technology Patiala Optimization Methods (UMA-034)Document2 pagesThapar Institute of Engineering and Technology Patiala Optimization Methods (UMA-034)Kamal Jit DhimanNo ratings yet

- Population NotesDocument6 pagesPopulation NotesKamal Jit DhimanNo ratings yet

- Tutorial 3 FMDocument1 pageTutorial 3 FMKamal Jit DhimanNo ratings yet

- IntroductionDocument10 pagesIntroductionKamal Jit DhimanNo ratings yet

- Tutorial 2 FMDocument1 pageTutorial 2 FMKamal Jit DhimanNo ratings yet

- Tutorial 3 FMDocument1 pageTutorial 3 FMKamal Jit DhimanNo ratings yet

- SB 439aDocument6 pagesSB 439aKamal Jit DhimanNo ratings yet

- Water Pollution - UEN002+NumericalsDocument57 pagesWater Pollution - UEN002+NumericalsKamal Jit DhimanNo ratings yet

- The Introduction: Science: Why Is There A Need To Act?Document23 pagesThe Introduction: Science: Why Is There A Need To Act?Kamal Jit DhimanNo ratings yet

- Electrical Engineering (UEE001) : Dr. S. K. AggarwalDocument33 pagesElectrical Engineering (UEE001) : Dr. S. K. AggarwalKamal Jit DhimanNo ratings yet

- WWW - Milspec.parts/rivets/ms20600ad4w2 Description: Blind RivetDocument1 pageWWW - Milspec.parts/rivets/ms20600ad4w2 Description: Blind RivetKamal Jit DhimanNo ratings yet

- Biodegradable Polymers: By:Tushardhiman 1 0 1 9 0 8 1 13 C6Document7 pagesBiodegradable Polymers: By:Tushardhiman 1 0 1 9 0 8 1 13 C6Kamal Jit DhimanNo ratings yet

- MSA Aricraft Carburetor Service Manual Models MA3A, MA3PA, MA3SPA, MA4SPADocument19 pagesMSA Aricraft Carburetor Service Manual Models MA3A, MA3PA, MA3SPA, MA4SPAKamal Jit DhimanNo ratings yet

- RouterTable Bob PlansDocument24 pagesRouterTable Bob Plansiacob_gilberto6473100% (2)

- Pottery: Global Action Programme On Education For All Youth ProjectDocument28 pagesPottery: Global Action Programme On Education For All Youth ProjectJoao DuarteNo ratings yet

- York VRF CatalogDocument52 pagesYork VRF CatalogVijay Kumar100% (2)

- Eos System Data Sheet Eos M 290 enDocument4 pagesEos System Data Sheet Eos M 290 enMagdalena TylichováNo ratings yet

- PMD55 Catalogue EngDocument40 pagesPMD55 Catalogue EngTayachew BerhanNo ratings yet

- HM-V3Document2 pagesHM-V3meriem.rssfNo ratings yet

- SC+ Design Guidelines EnglishDocument27 pagesSC+ Design Guidelines EnglishMyron OikonomakisNo ratings yet

- FFU160HAX DatasheetDocument3 pagesFFU160HAX Datasheetracini454No ratings yet

- Products Water Treatment Chemicals I.boiler Chemicals WhenDocument7 pagesProducts Water Treatment Chemicals I.boiler Chemicals Whenemerald_27No ratings yet

- Fiber TechnologyDocument32 pagesFiber TechnologyPv KhoiNo ratings yet

- PIES CatalogueDocument48 pagesPIES Cataloguescooba84No ratings yet

- Chapter-1 Electric Heating and Welding: Electrical Power Utilization (10ee72)Document2 pagesChapter-1 Electric Heating and Welding: Electrical Power Utilization (10ee72)Akshay RajNo ratings yet

- List of Canned CycleDocument8 pagesList of Canned CycleMuthukumar KasinathanNo ratings yet

- Ftee 64 94 PDFDocument3 pagesFtee 64 94 PDFErvinBabicNo ratings yet

- Brentwood CT Getting Your Fill Article 2005 enDocument4 pagesBrentwood CT Getting Your Fill Article 2005 enAvicena AlbiruniNo ratings yet

- Automatic Control of Food Manufacturing ProcessesDocument5 pagesAutomatic Control of Food Manufacturing ProcesseskvnsaiNo ratings yet

- Technopro CatalogueDocument20 pagesTechnopro CatalogueAdnan KhanNo ratings yet

- Information Sheet 5.2-2 Waste Management Information Sheet 5.2-2 Waste Management Information Sheet 5.2-2 Waste ManagementDocument5 pagesInformation Sheet 5.2-2 Waste Management Information Sheet 5.2-2 Waste Management Information Sheet 5.2-2 Waste ManagementKaJong JaclaNo ratings yet

- Testing: Needle Valve SeriesDocument3 pagesTesting: Needle Valve SeriesToty DzNo ratings yet

- Section 067300 - Composite DeckingDocument4 pagesSection 067300 - Composite DeckingWENDING HUNo ratings yet

- Nxe Series Forklifts: Electric 2.0 To 3.5 Ton Capacity 4wheelDocument9 pagesNxe Series Forklifts: Electric 2.0 To 3.5 Ton Capacity 4wheelNguyen Quoc ChienNo ratings yet

- Baths PrecistermDocument2 pagesBaths Precistermabdul azizNo ratings yet

- C595 - 00 Blended CementDocument7 pagesC595 - 00 Blended CementLongLE100% (1)

- Field Trip Iwk Report 1Document12 pagesField Trip Iwk Report 1Musnira MusniraNo ratings yet

- Barton j8Document36 pagesBarton j8Ariz Joelee ArthaNo ratings yet

- Maintenance of TransformerDocument8 pagesMaintenance of TransformeranilsinghteslaNo ratings yet

- Main CatalogDocument151 pagesMain CatalogНикита МельниковNo ratings yet

Tyres and Wheels

Tyres and Wheels

Uploaded by

Kamal Jit DhimanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tyres and Wheels

Tyres and Wheels

Uploaded by

Kamal Jit DhimanCopyright:

Available Formats

10/22/20

Tyres

Dr. Devender Kumar

Assistant Professor

Mechanical Engineering Department

Thapar Institute of Engineering & Technology, Patiala, Punjab

Tyre requirements

1. To support the vehicle weight and distribute it over the road

surface.

2. To reduce power consumption by offering minimum rolling

resistance.

3. To contribute to the suspension of impact forces created by

road surface irregularities.

4. To provide sufficient traction, braking and steering forces on

road.

5. To safely operate the vehicle up to maximum designed speed of

vehicle.

6. To absorb road noise and vibration.

7. To perform as per the designed parameters over its life in

different drive conditions.

Dr. Devender Kumar,AP,MED,TIET,Patiala 2

Devender Kumar,AP,MED, Thapar U,Patiala 1

10/22/20

Types of Tyres

Based on material and construction type

• Tubed tyres

• Tubeless tyres

• Solid rubber tyres

• Run flat tyres

• Tuff-up tubed tyres

• Tweel- special air free tyres

Based on layout of internal construction

• Biased /cross ply tyres

• Radial tyres

Based on tread pattern

• Symmetric tyres

• Asymmetric tyres / directional tyres

• Weather specific tyresDr. Devender Kumar,AP,MED,TIET,Patiala 3

Radial Tyre

Biased Tyre

Dr. Devender Kumar,AP,MED,TIET,Patiala 4

Devender Kumar,AP,MED, Thapar U,Patiala 2

10/22/20

Run-flat Tyre

Solid Rubber Tyre

Dr. Devender Kumar,AP,MED,TIET,Patiala 5

Tweel Tyre

Dr. Devender Kumar,AP,MED,TIET,Patiala 6

Devender Kumar,AP,MED, Thapar U,Patiala 3

10/22/20

Technical terms

Dr. Devender Kumar,AP,MED,TIET,Patiala 7

Tyre Section

Dr. Devender Kumar,AP,MED,TIET,Patiala 8

Devender Kumar,AP,MED, Thapar U,Patiala 4

10/22/20

Construction Types

Cross-ply

Tyre

Construction

Dr. Devender Kumar,AP,MED,TIET,Patiala 9

Cross-ply

Tyre

Construction

Dr. Devender Kumar,AP,MED,TIET,Patiala 10

10

Devender Kumar,AP,MED, Thapar U,Patiala 5

10/22/20

Radial Tyres

Dr. Devender Kumar,AP,MED,TIET,Patiala 11

11

Radial-ply

Tyre

Construction

Dr. Devender Kumar,AP,MED,TIET,Patiala 12

12

Devender Kumar,AP,MED, Thapar U,Patiala 6

10/22/20

Ride Comfort

Cornering Behavior

Dr. Devender Kumar,AP,MED,TIET,Patiala 13

13

Contact Patch

Bias or Cross-Ply Tyres

Radial Tyres

Dr. Devender Kumar,AP,MED,TIET,Patiala 14

14

Devender Kumar,AP,MED, Thapar U,Patiala 7

10/22/20

Dr. Devender Kumar,AP,MED,TIET,Patiala 15

15

Advantages of Tubeless Tyres over Tubed Tyres

• Improved Road Contact

• Improved Safety

• Improved Ride Comfort

• Improved Cooling

• Improved wheel assembly balance

• Improved Braking

• Improved air retention after puncture

Dr. Devender Kumar,AP,MED,TIET,Patiala 16

16

Devender Kumar,AP,MED, Thapar U,Patiala 8

10/22/20

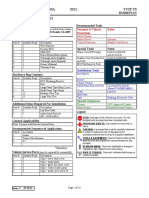

Tyre Specifications

Key Tyre Marking Description

Manufacturers or brand name, and commercial

A

name or identity.

Tyre size, construction and speed rating

designations. Tubelessdesignates a tyre which

requires no inner tube. See tyre sizes andspeed

B ratings below. DIN-type tyre marking also has the

load index encoded in it. These go from a load

index of 50 (190kg) up to an index of 169

(5800kg).

C Denotes type of car tyre construction.

M&S denotes a car tyre designed for mud and

D

snow. Reinforced marking only where applicable.

E Pressure marking requirement.

F ECE (not EEC) type approval mark and number.

North American Dept of Transport compliance

G

symbols and identification numbers.

H Country of manufacture.

Dr. Devender Kumar,AP,MED,TIET,Patiala 17

17

Typical tyre terminology.

Dr. Devender Kumar,AP,MED,TIET,Patiala 18

18

Devender Kumar,AP,MED, Thapar U,Patiala 9

10/22/20

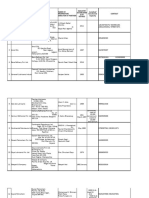

Tyre Dimensions and Markings

Dr. Devender Kumar,AP,MED,TIET,Patiala 19

19

Section Rim

Aspect ratio Radial Load index Speed rating

width diameter

Ultra high speed tyre size notations

149+

Section Aspect Rim Load Speed

mph Radial

width ratio diameter index rating

rated

Dr. Devender Kumar,AP,MED,TIET,Patiala 20

20

Devender Kumar,AP,MED, Thapar U,Patiala 10

10/22/20

The aspect ratio (profile) of a tyre

Dr. Devender Kumar,AP,MED,TIET,Patiala 21

21

Aspect Ratio decreased and

the Rim Diameter increased.

As per tyre designer’s “only 3% increment in circumference is permitted”

Dr. Devender Kumar,AP,MED,TIET,Patiala 22

22

Devender Kumar,AP,MED, Thapar U,Patiala 11

10/22/20

Aspect Ratio decreased and

the Rim Diameter increased.

Dr. Devender Kumar,AP,MED,TIET,Patiala 23

23

Effects of Aspect Ratio

• A higher aspect ratio provides a softer ride because they

will deflect more over irregular surfaces and under

heavy loads.

• However, lower aspect ratio tyres are normally used for

higher performance vehicles. They have a wider road

contact area (therefore better traction) and a faster

response. This results in less deflection under load,

causing a rougher ride to the vehicle.

Dr. Devender Kumar,AP,MED,TIET,Patiala 24

24

Devender Kumar,AP,MED, Thapar U,Patiala 12

10/22/20

Contact

Patch/ Tyre

Print of

different tyre

sizes

Dr. Devender Kumar,AP,MED,TIET,Patiala 25

25

Tyre size comparison and Compatibility

Dr. Devender Kumar,AP,MED,TIET,Patiala 26

26

Devender Kumar,AP,MED, Thapar U,Patiala 13

10/22/20

Table-1

Table-2

Dr. Devender Kumar,AP,MED,TIET,Patiala 27

27

Table-3

Dr. Devender Kumar,AP,MED,TIET,Patiala 28

28

Devender Kumar,AP,MED, Thapar U,Patiala 14

10/22/20

Influence of the Tyre on the Speedometer

The speedometer is designed to show slightly more than

actual, and under no circumstances less than, the actual

speed.

Actual speed (km /h) 30 60 120 180 240

Max displayed value (km/h) 37 70 136 202 268

3 mm tyre wear gives an advance of around 1%

Dr. Devender Kumar,AP,MED,TIET,Patiala 29

29

What Effect Does Tyre Size Have

on following

1. Speedometer Reading: Actual running speed is more than

displayed on speedometer if larger diameter (lead to increase

perimeter) tyres are used directly on same rims. As per definers

recommendation, only 3% increment in tyre perimeter is

acceptable. Surface velocity on the contact point of larger tyre is

more with same axle speed.

2. Odometer Reading: If tyre is larger than recommended that

odometer will show less reading than actually travelled. Larger

diameter tyre will cover the same distance in lesser number of

turns. e.g. if tyre is 10% larger and odometer reads 100 km then

actual distance travelled will be 110 km.

peri. 1m 10 turns

10 m

peri. 1.1m

9.09 turns

30

30

Devender Kumar,AP,MED, Thapar U,Patiala 15

10/22/20

Tyre rubber main composition

• 38% -Rubber: Natural/synthetic

• 16% -Reinforcements: Steel, rayon, nylon

• 30% -Compounds: Silica, carbon, chalk etc.

• 4% -Vulcanization: Sulphur, zinc oxide

• 2% -Miscellaneous

Bulk (40-60%) of tyre tread is composed of a variety of rubbers,

including natural rubber co-polymers, butadiene rubber, styrene

butadiene rubber (SBR), nitride rubber, isoprene rubber, neoprene

rubber and polysulphide rubber.

Source: Hildemann 1991; Rogge et al 1993; Kumata et al 1996 and 2000; Fishman and Turner 1999

Dr. Devender Kumar,AP,MED,TIET,Patiala 31

31

Under- and over-inflated tyre

Dr. Devender Kumar,AP,MED,TIET,Patiala 32

Source: https://www.bridgestonetire.com

32

Devender Kumar,AP,MED, Thapar U,Patiala 16

10/22/20

Symmetric Tyres

• Symmetric tyres have a same tread pattern on the inner

edge than the outer edge.

• Can be used to rotate on both directions.

• Tyres on front and rear axles can be interchanged on

either direction.

• General purpose tyre/all weather tyre.

Dr. Devender Kumar,AP,MED,TIET,Patiala 33

33

Symmetric Tyres

Dr. Devender Kumar,AP,MED,TIET,Patiala 34

34

Devender Kumar,AP,MED, Thapar U,Patiala 17

10/22/20

Asymmetric Tyres

• Asymmetric tyres have a different tread pattern on the

inner edge than the outer edge.

• The outer tread pattern is designed to improve

cornering on dry surfaces.

• The inner tread pattern is designed to improve traction

on wet surfaces.

• An asymmetric tyre must be mounted so the proper

edge faces the outside of the wheel.

• This type of tyre is generally marked with the word

outside to indicate which way it should be mounted on

the wheel. Dr. Devender Kumar,AP,MED,TIET,Patiala 35

35

Asymmetric Tyres

Dr. Devender Kumar,AP,MED,TIET,Patiala 36

36

Devender Kumar,AP,MED, Thapar U,Patiala 18

10/22/20

Asymmetric Tyres

Dr. Devender Kumar,AP,MED,TIET,Patiala 37

37

Directional Tyres

• Directional tyres are high-performance tyres designed to

rotate in a specific direction to minimize hydroplaning.

• Hydroplaning is a loss of control that occurs when layer

of water prevents the tyre tread from contacting the

road surface.

• Directional tyres have an arrow and the word rotation

molded onto their sidewalls.

• Care must be taken to mount directional tyres in the

proper location so they rotate in the desired direction.

Dr. Devender Kumar,AP,MED,TIET,Patiala 38

38

Devender Kumar,AP,MED, Thapar U,Patiala 19

10/22/20

Directional Tyres

Dr. Devender Kumar,AP,MED,TIET,Patiala 39

39

Dr. Devender Kumar,AP,MED,TIET,Patiala 40

40

Devender Kumar,AP,MED, Thapar U,Patiala 20

10/22/20

Run-Flat Tyres: Self Supporting Type

• Run-flat tyres have an extremely stiff sidewall construction so that

they are still usable with a loss of air pressure.

• If the tyre leaks, you can drive the vehicle to a repair shop without

tyre and wheel damage.

Dr. Devender Kumar,AP,MED,TIET,Patiala 41

41

Run-Flat Tyres- Self Supporting Type

Dr. Devender Kumar,AP,MED,TIET,Patiala 42

Source: https://www.bridgestonetire.com

42

Devender Kumar,AP,MED, Thapar U,Patiala 21

10/22/20

Run-Flat Tyres: Support Ring Type

A cutaway of a run-flat tyre

with an insert for support

in case the tyre goes very

flat.

Dr. Devender Kumar,AP,MED,TIET,Patiala 43

43

Run-Flat Tyres - Support Ring Type

Dr. Devender Kumar,AP,MED,TIET,Patiala 44

Source: https://www.bridgestonetire.com

44

Devender Kumar,AP,MED, Thapar U,Patiala 22

10/22/20

Self-Sealing Tyres

• Some tyres are self-sealing (seal small punctures).

• These tyres have a coating of sealing compound applied

to their liners.

• If a nail punctures a self-sealing tyre, air pressure will

push the soft compound into the hole to stop air

leakage.

Dr. Devender Kumar,AP,MED,TIET,Patiala 45

45

Self-Sealing Tyres

A - Nail punctures the

tyre.

B - Nail is pulled out

C - Sealing compound

flows into the hole

to prevent air from

leaking out.

Dr. Devender Kumar,AP,MED,TIET,Patiala 46

46

Devender Kumar,AP,MED, Thapar U,Patiala 23

10/22/20

Winter Tyres are recommended

only for winters, which is

mandatory in some countries

Dr. Devender Kumar,AP,MED,TIET,Patiala 47

Source: https://www.bridgestonetire.com

47

Winter Tyres

Sipes

Dr. Devender Kumar,AP,MED,TIET,Patiala 48

48

Devender Kumar,AP,MED, Thapar U,Patiala 24

10/22/20

Winter Tyres

Holes for studds

Dr. Devender Kumar,AP,MED,TIET,Patiala 49

49

Dr. Devender Kumar,AP,MED,TIET,Patiala 50

50

Devender Kumar,AP,MED, Thapar U,Patiala 25

10/22/20

Dr. Devender Kumar,AP,MED,TIET,Patiala 51

51

Dr. Devender Kumar,AP,MED,TIET,Patiala 52

52

Devender Kumar,AP,MED, Thapar U,Patiala 26

10/22/20

Nitrogen Filled Tyres

• Ambient air is composed of:

– 1% Water Vapor + Other Gases – Escapes up to 250 times faster than

Nitrogen

– 21% Oxygen – Escapes 3-4 times faster than Nitrogen

– 78% Nitrogen – The largest molecule in air, dry, non-flammable.

• Due to large size, nitrogen molecules are the least permeable and

stay in tyre longer.

• A tyre filled with ‘Ambient Air’

can lose 1.5 psi (10.34kPa)

[approx 5% ] in less than a

month.

• When filled with nitrogen, it

can take up to six months to

lose 1.5 psi.

Dr. Devender Kumar,AP,MED,TIET,Patiala 53

53

Nitrogen Filled Tyres: Benefits

• Increased Fuel Efficiency – With reduced air leakage, correct tyre

pressure is maintained for longer time. This reduces rolling

resistance and improve fuel efficiency.

• Longer Tyre Life – Correct tyre pressure à Better contact patch à

less tyre wear.

• Increased Safety – Under-inflated tyres cause 90% of blowouts.

Nitrogen provides more reliable pressure & reduce chance of

blowout .

• Longer Rim Life – No Air à No water condensation à No Resting.

Pure Nitrogen is completely dry, hence eliminates condensation.

Dr. Devender Kumar,AP,MED,TIET,Patiala 54

54

Devender Kumar,AP,MED, Thapar U,Patiala 27

10/22/20

DOT Codes and the 6-year shelf life

DOT: Department of Transport (USA)

After yr 2000, the code was switched to a 4-digit

code

Example: 4 6 1 8 means the tyre was

manufactured in the 46th week of 2018.

Dr. Devender Kumar,AP,MED,TIET,Patiala 55

55

Porsche N-rated Tyres

Rating from N-0 to N-4

Dr. Devender Kumar,AP,MED,TIET,Patiala 56

56

Devender Kumar,AP,MED, Thapar U,Patiala 28

10/22/20

Tyre Wear (Squirm effect, Tyre Bite)

456 Chassis systems

the need to replace the tyres as they approach the Interchanging tyres

legal tread depth limit. Tyres should be subjected to At present, there are various recommendations

careful assessment during service periods and also regarding the interchanging of tyres, so tyre

on regular occasions by the driver to ensure that manufacturers’ guidance should be followed.

they deliver their optimum level of performance. Generally, cross-ply tyres should be interchanged

Worn tyres can dramatically alter the handling at frequent intervals if uniform tyre wear is to be

and braking performance of a vehicle so it is very achieved. Longitudinal changes (L/H front to L/H

important to ensure that they are in the best possible rear, etc.) and diagonal changes (R/H front to L/H rear

condition. Generally, the contact patch of a tyre on and spare to L/H front, etc.) are normally advised.

a regular vehicle is less than the size of a piece of Some manufacturers of radial-ply tyres recommend

A5 paper. For this reason, tyres are one of the most that the front tyres are not moved to the rear because

important areas of maintenance. of the different wear pattern of front and rear tyres.

Tyre pressures are also very important in ensuring

Legal requirements

that the tyre delivers its maximum level of traction

and grip. In many cases, the tyre pressures should be Legislation exists to prevent the use of a vehicle that

altered with different vehicle loads so it is important is fitted with defective tyres. The current regulations

to check the manufacturer’s recommended settings. specify the following tyre faults:

During routine inspection, tyres should be checked ! The use of unsuitable tyres

for the following defects: ! Under-inflation

! Break in the fabric in excess of 2.5 cm (1

Dr. Devender Kumar,AP,MED,TIET,Patiala 57in) or 10

! Inflation pressures per cent of the section width

! Wear and tread depth ! Lumps or bulges

57 ! Damage ! Exposure of cords

! Tread depth less than minimum. The law

Tread wear indication

requires a tread depth of at least 1.6 mm across

The tread of a modern tyre has a pattern that changes the central three-quarters of the breadth of

when the tread has worn down to a given limit. This tread around the entire circumference of the

safety feature allows an observer to determine the

Tread Wear indicate the fault in vehicle

tyre

danger limit quickly without having to use a tyre

tread depth gauge. A tyre with a puncture outside the central tread area

must be replaced according to British Standard (BS)

recommendations.

rapid wear at rapid wear at centre wear on one side feathered edge bald spot(s)

shoulders

under-inflation over-inflation excessive camber incorrect toe steering slackness

misalignment brake drum or disc

wear or distortion

worn dampers

unbalanced wheels

Figure 4.125 Abnormal tyre wear Dr. Devender Kumar,AP,MED,TIET,Patiala 58

58

Devender Kumar,AP,MED, Thapar U,Patiala 29

10/22/20

Heel-Tow Wear

Dr. Devender Kumar,AP,MED,TIET,Patiala 59

59

Side wall rubbing

Dr. Devender Kumar,AP,MED,TIET,Patiala 60

60

Devender Kumar,AP,MED, Thapar U,Patiala 30

10/22/20

Tyre Wear Indicator

Tread Depth Indicator

Tyres With Non Skid Depth (N.S.D.)

less than 0.8mm for two and three wheeler tyres

and 1.6 mm for other motor vehicles tyres are

unsafe to drive. Tyres worn beyond these limits are

not fit for use.

Dr. Devender Kumar,AP,MED,TIET,Patiala 61

http://atmaindia.org/tread-wear-indicator-twi/

61

Causes of Tyre Wear

• Incorrect Inflation

• Incorrect castor, camber

• Excessive braking, acceleration

• Out of balance wheels

• Misalignment

• Over-loading

• Wrong-loading

• Defective brakes

• Bleeding of air (when hot)

• Unequal tyres

• Incorrect rotation of tyres

• Careless driving

Dr. Devender Kumar,AP,MED,TIET,Patiala 62

62

Devender Kumar,AP,MED, Thapar U,Patiala 31

10/22/20

Wheel/Rim Geometry

Dr. Devender Kumar,AP,MED,TIET,Patiala 63

63

Disc Pressed Wheel

Source: www.depositphotos.com

Dr. Devender Kumar,AP,MED,TIET,Patiala 64

64

Devender Kumar,AP,MED, Thapar U,Patiala 32

10/22/20

Aluminum Alloy Wheels

Chrome

Finished

Chrome

Finish and

Painted

Diamond

Cut Painted

Aluminium

Surface

Finish

Dr. Devender Kumar,AP,MED,TIET,Patiala 65

Source: Engineering Clicks, DIY Trade, TSW Wheels, Manchester alloy wheel repair

65

Magnesium Alloy wheels

Advantages

• Very Light Weight

• High Strength

• Excellent Corrosion Resistance

Disadvantages

• High Cost

• Brittle

• Can catch fire if during accidents

Dr. Devender Kumar,AP,MED,TIET,Patiala 66

Source: www.baanvelgen.com/en/mr-magnesium-wheels-porsche-991-gt3-rs

66

Devender Kumar,AP,MED, Thapar U,Patiala 33

10/22/20

Carbon Fiber Composite Wheels

Advantages

• Extremely Light Weight

• High Strength

• Excellent Corrosion Resistance

Disadvantages

• Very High Cost

• Very Brittle

• Difficult to manufacture

Dr. Devender Kumar,AP,MED,TIET,Patiala 67

Source: www.autohauslancasterporsche.com

67

Wheel Offsets

Dr. Devender Kumar,AP,MED,TIET,Patiala 68

68

Devender Kumar,AP,MED, Thapar U,Patiala 34

10/22/20

Wheel Offsets

+ 0 -

Dr. Devender Kumar,AP,MED,TIET,Patiala 69

Source: www.discounttire.com

69

Multi-piece rims

2 piece

3 piece

Dr. Devender Kumar,AP,MED,TIET,Patiala 70

70

Devender Kumar,AP,MED, Thapar U,Patiala 35

10/22/20

Locking Ring Locking Rim

Source: www.mtfca.com Dr. Devender Kumar,AP,MED,TIET,Patiala 71

71

Three Piece Split Rim

Wheel Centre

Outer Rim

Inner Rim

Dr. Devender Kumar,AP,MED,TIET,Patiala 72

Source: www.carthrottle.com

72

Devender Kumar,AP,MED, Thapar U,Patiala 36

10/22/20

Rim Width

Clearance for Brake

Calipers

FRONT REAR

Offset

Back Spacing

CENTRE LINE

Front Spacing Dr. Devender Kumar,AP,MED,TIET,Patiala 73

73

Source: Asanti Wheels, Turbo Bricks Forum

Dr. Devender Kumar,AP,MED,TIET,Patiala 74

74

Devender Kumar,AP,MED, Thapar U,Patiala 37

10/22/20

Tubeless, Radial tyres with Alloy

wheels J give better safety, better

road grip, better fuel economy and

better rolling resistance.

You spend lot of money for better

rolling.

Someone needs your humanity for

rolling, to get life.

Dr. Devender Kumar,AP,MED,TIET,Patiala 75

75

Devender Kumar,AP,MED, Thapar U,Patiala 38

You might also like

- DGR3 Field TestDocument8 pagesDGR3 Field TestKamal Jit DhimanNo ratings yet

- ITTAC Section 1Document18 pagesITTAC Section 1dharan51167% (3)

- Suggested Vendors ListDocument137 pagesSuggested Vendors Listrajiv kumar100% (1)

- Cr3213-4-03 Blind Rivet Spec: Additional InformationDocument2 pagesCr3213-4-03 Blind Rivet Spec: Additional InformationKamal Jit DhimanNo ratings yet

- ICA-172-28-00001 (Fuel Qty Indication)Document63 pagesICA-172-28-00001 (Fuel Qty Indication)Kamal Jit Dhiman100% (1)

- Cherry MS RivetsDocument17 pagesCherry MS RivetsKamal Jit Dhiman100% (1)

- Toyota Tacoma 2012 - Tvip V5 Part Number: PT398-35121: PreparationDocument22 pagesToyota Tacoma 2012 - Tvip V5 Part Number: PT398-35121: PreparationTomas OrozcoNo ratings yet

- Nitrogen: A Security Blanket For The Chemical Industry: Fluids and Solids HandlingDocument6 pagesNitrogen: A Security Blanket For The Chemical Industry: Fluids and Solids HandlingSubramanian RavichandranNo ratings yet

- Toy Crane ManualDocument12 pagesToy Crane Manuallahsivlahsiv684100% (1)

- Editor in chief,+EJERS 2224+correctedDocument12 pagesEditor in chief,+EJERS 2224+correctedtini taziekNo ratings yet

- Design Analysis of A Portable Manual Tyre Changer: European Journal of Engineering Research and Science November 2020Document13 pagesDesign Analysis of A Portable Manual Tyre Changer: European Journal of Engineering Research and Science November 2020Sakman SulaemanNo ratings yet

- TPCS Airless Tyres Report VARSHADocument27 pagesTPCS Airless Tyres Report VARSHASumit PatilNo ratings yet

- Institute Name Annamalai Univers India Ranking 2017 ID IR17-ENGG-2-1-33 Discipline EngineeringDocument8 pagesInstitute Name Annamalai Univers India Ranking 2017 ID IR17-ENGG-2-1-33 Discipline EngineeringNisha NishaNo ratings yet

- Report On Airless TyreDocument27 pagesReport On Airless TyreshivamNo ratings yet

- Rep14 04 PDFDocument45 pagesRep14 04 PDFVishnu RNo ratings yet

- Startup Idea Generation: Dr.S.Dinesh KumarDocument21 pagesStartup Idea Generation: Dr.S.Dinesh KumarSHAHULNo ratings yet

- DoR Guidelines For Flexible PavementDocument37 pagesDoR Guidelines For Flexible PavementkesharinareshNo ratings yet

- Giti - TBR - Catalog 2022Document52 pagesGiti - TBR - Catalog 2022Frank Rodriguez MiranoNo ratings yet

- CH 06 RowColumnAdjustmentsDocument29 pagesCH 06 RowColumnAdjustmentsGeorge KariukiNo ratings yet

- Highest Paid RankingsDocument1 pageHighest Paid RankingsPraveen ThakurNo ratings yet

- Big Achievements Happen When We Build On Each Other'S Ideas: 3/28/2020 DR FZS, Ched, Amu, India 1Document13 pagesBig Achievements Happen When We Build On Each Other'S Ideas: 3/28/2020 DR FZS, Ched, Amu, India 1Insha Zameer RazviNo ratings yet

- Off The Road Tyre Manual - Everything You Want To Know Abt OTH - Goodyear PDFDocument127 pagesOff The Road Tyre Manual - Everything You Want To Know Abt OTH - Goodyear PDFGaurav SharmaNo ratings yet

- Goodyear OTR Databook 3Document170 pagesGoodyear OTR Databook 3Raburgess1No ratings yet

- List of Facilitators For TrademarksDocument19 pagesList of Facilitators For Trademarkssaranya pugazhenthiNo ratings yet

- The 2016 Premium Tyre Range: For Cars, Suv/4X4S and VansDocument21 pagesThe 2016 Premium Tyre Range: For Cars, Suv/4X4S and VanswillupowersNo ratings yet

- Cement ContaminationDocument15 pagesCement ContaminationGaurav HazarikaNo ratings yet

- Afforestation Project SRPF Group 5 7 ReportDocument11 pagesAfforestation Project SRPF Group 5 7 Reportmistryvraj90No ratings yet

- Maintenance Manual - enDocument54 pagesMaintenance Manual - enSIDI MOHAMMED BENDELLANo ratings yet

- Sr. No. Product Laboratory DRDO Contact Industry Detailed Address Industry Contact PersonDocument3 pagesSr. No. Product Laboratory DRDO Contact Industry Detailed Address Industry Contact PersonamandeepNo ratings yet

- Utilization of Rubber Waste in Construction of Flexible PavementDocument8 pagesUtilization of Rubber Waste in Construction of Flexible Pavementathirah mfNo ratings yet

- Memo On Toll Category-1Document2 pagesMemo On Toll Category-1NV TechnologyNo ratings yet

- Basis Information of TyreDocument32 pagesBasis Information of TyreKARTHICKRAJ KANDASAMY100% (2)

- Segunda Tesis OpenDocument43 pagesSegunda Tesis OpenSandro FernandezNo ratings yet

- AAPA National Asphalt Specification Australian Asphalt PavementDocument48 pagesAAPA National Asphalt Specification Australian Asphalt Pavementeza marizkaNo ratings yet

- Technical Bulletin 2009-09 Choosing Correct Grease For EquiDocument4 pagesTechnical Bulletin 2009-09 Choosing Correct Grease For EquiNeelam P GogoiNo ratings yet

- Draft EIA - CompressedDocument381 pagesDraft EIA - Compressedshinchan007516No ratings yet

- Study of Partial Replacement of Coarse Aggregate in Concrete by Different Proportions of Un-Treated Waste Tyre RubberDocument9 pagesStudy of Partial Replacement of Coarse Aggregate in Concrete by Different Proportions of Un-Treated Waste Tyre RubberIJRASETPublicationsNo ratings yet

- Allopathic Loan 2019Document9 pagesAllopathic Loan 2019Main Sanatani HunNo ratings yet

- Airtra & Atma Consult On Epr - Tyre and Rubber RecyclingDocument1 pageAirtra & Atma Consult On Epr - Tyre and Rubber RecyclingleonardNo ratings yet

- PFD FileDocument235 pagesPFD FileabubakarabdulgafNo ratings yet

- 2018 AniketDocument60 pages2018 Aniketaniket chakiNo ratings yet

- JK Mysore Intership ReportDocument41 pagesJK Mysore Intership ReportSumanth Gowda100% (1)

- A Study of Cost Effective Hardness Rubber Compound For Bicycle TiresDocument23 pagesA Study of Cost Effective Hardness Rubber Compound For Bicycle TiresPrabath TharukaNo ratings yet

- Prai MembersDocument14 pagesPrai Membersraj RajputNo ratings yet

- Riya GuptaDocument32 pagesRiya Guptaanshulh35No ratings yet

- Method Statement-Earthing ImprovementDocument12 pagesMethod Statement-Earthing ImprovementShubham PatelNo ratings yet

- Utilization of Scrap Tyre Rubber in The Form of Aggregates As Partial Exchange With Existing AggregatesDocument8 pagesUtilization of Scrap Tyre Rubber in The Form of Aggregates As Partial Exchange With Existing AggregatesEditor IJTSRDNo ratings yet

- Full Casting Crown RestorationsDocument10 pagesFull Casting Crown RestorationsAhmed TalalNo ratings yet

- Araveti Santosh Kumar Gupta PDFDocument5 pagesAraveti Santosh Kumar Gupta PDFMukesh & Associates D3No ratings yet

- Effect of Addition of Waste Tyre Crumb Rubber On WDocument6 pagesEffect of Addition of Waste Tyre Crumb Rubber On Wveenau 1No ratings yet

- 2021 MTD100Document17 pages2021 MTD100jazz pastaNo ratings yet

- Tyre RetreadingpptDocument15 pagesTyre Retreadingpptshiva_ssk17100% (1)

- Reddy PDFDocument18 pagesReddy PDF20wj1a0339No ratings yet

- Ne W Jayam Resume3Document5 pagesNe W Jayam Resume3jayamsubramaniam.s100% (2)

- Guide For Design and Proportioning of Concrete Mixtures For PavementsDocument7 pagesGuide For Design and Proportioning of Concrete Mixtures For PavementsMuddasir RehmanNo ratings yet

- Non Pneumatic TyreDocument17 pagesNon Pneumatic Tyrereghurahul88No ratings yet

- Internship Report: TM Rubber (PVT.) LTDDocument6 pagesInternship Report: TM Rubber (PVT.) LTDsaudNo ratings yet

- CE 442 Material and Pavement Design: Chapter I: IntroductionDocument20 pagesCE 442 Material and Pavement Design: Chapter I: IntroductionMohammad DawaghrehNo ratings yet

- Otr GoodyearDocument170 pagesOtr GoodyearSaiful AhmadNo ratings yet

- Compact Tractor Brochure - D-117 (02-07)Document27 pagesCompact Tractor Brochure - D-117 (02-07)Vicente AlvioNo ratings yet

- K-Series Tire Guide AEXQ0403Document24 pagesK-Series Tire Guide AEXQ0403Jairo PalaciosNo ratings yet

- Banded Vs Bonded Space Maintainers: Finding Better Way OutDocument9 pagesBanded Vs Bonded Space Maintainers: Finding Better Way OutYashwanth SreedharaNo ratings yet

- Irjet V8i4192Document7 pagesIrjet V8i4192G Sai TejaNo ratings yet

- Internship Report For Compounding Department at General Tyre & Rubber Company of PakistanDocument22 pagesInternship Report For Compounding Department at General Tyre & Rubber Company of PakistanZeeshan Zahid0% (1)

- SB 639 Rocker Arm InspectionDocument3 pagesSB 639 Rocker Arm InspectionKamal Jit DhimanNo ratings yet

- 5 ClutchDocument31 pages5 ClutchKamal Jit DhimanNo ratings yet

- Service Bulletin1018Document6 pagesService Bulletin1018Kamal Jit DhimanNo ratings yet

- SI 1575 New Conecting Rod BushingDocument2 pagesSI 1575 New Conecting Rod BushingKamal Jit DhimanNo ratings yet

- Cherry Lock Blind Rivets CA-1005 PDFDocument38 pagesCherry Lock Blind Rivets CA-1005 PDFKamal Jit DhimanNo ratings yet

- SB 639 Rocker Arm InspectionDocument3 pagesSB 639 Rocker Arm InspectionKamal Jit DhimanNo ratings yet

- Tute Sheet 2 - Axial - Shear - Bearing StressDocument2 pagesTute Sheet 2 - Axial - Shear - Bearing StressKamal Jit DhimanNo ratings yet

- Tutorial 1 FM PDFDocument2 pagesTutorial 1 FM PDFKamal Jit DhimanNo ratings yet

- Tute 1-Revision of Normal Streses and Strains PDFDocument2 pagesTute 1-Revision of Normal Streses and Strains PDFKamal Jit DhimanNo ratings yet

- Thapar Institute of Engineering and Technology Patiala Optimization Methods (UMA-034)Document2 pagesThapar Institute of Engineering and Technology Patiala Optimization Methods (UMA-034)Kamal Jit DhimanNo ratings yet

- Population NotesDocument6 pagesPopulation NotesKamal Jit DhimanNo ratings yet

- Tutorial 3 FMDocument1 pageTutorial 3 FMKamal Jit DhimanNo ratings yet

- IntroductionDocument10 pagesIntroductionKamal Jit DhimanNo ratings yet

- Tutorial 2 FMDocument1 pageTutorial 2 FMKamal Jit DhimanNo ratings yet

- Tutorial 3 FMDocument1 pageTutorial 3 FMKamal Jit DhimanNo ratings yet

- SB 439aDocument6 pagesSB 439aKamal Jit DhimanNo ratings yet

- Water Pollution - UEN002+NumericalsDocument57 pagesWater Pollution - UEN002+NumericalsKamal Jit DhimanNo ratings yet

- The Introduction: Science: Why Is There A Need To Act?Document23 pagesThe Introduction: Science: Why Is There A Need To Act?Kamal Jit DhimanNo ratings yet

- Electrical Engineering (UEE001) : Dr. S. K. AggarwalDocument33 pagesElectrical Engineering (UEE001) : Dr. S. K. AggarwalKamal Jit DhimanNo ratings yet

- WWW - Milspec.parts/rivets/ms20600ad4w2 Description: Blind RivetDocument1 pageWWW - Milspec.parts/rivets/ms20600ad4w2 Description: Blind RivetKamal Jit DhimanNo ratings yet

- Biodegradable Polymers: By:Tushardhiman 1 0 1 9 0 8 1 13 C6Document7 pagesBiodegradable Polymers: By:Tushardhiman 1 0 1 9 0 8 1 13 C6Kamal Jit DhimanNo ratings yet

- MSA Aricraft Carburetor Service Manual Models MA3A, MA3PA, MA3SPA, MA4SPADocument19 pagesMSA Aricraft Carburetor Service Manual Models MA3A, MA3PA, MA3SPA, MA4SPAKamal Jit DhimanNo ratings yet

- RouterTable Bob PlansDocument24 pagesRouterTable Bob Plansiacob_gilberto6473100% (2)

- Pottery: Global Action Programme On Education For All Youth ProjectDocument28 pagesPottery: Global Action Programme On Education For All Youth ProjectJoao DuarteNo ratings yet

- York VRF CatalogDocument52 pagesYork VRF CatalogVijay Kumar100% (2)

- Eos System Data Sheet Eos M 290 enDocument4 pagesEos System Data Sheet Eos M 290 enMagdalena TylichováNo ratings yet

- PMD55 Catalogue EngDocument40 pagesPMD55 Catalogue EngTayachew BerhanNo ratings yet

- HM-V3Document2 pagesHM-V3meriem.rssfNo ratings yet

- SC+ Design Guidelines EnglishDocument27 pagesSC+ Design Guidelines EnglishMyron OikonomakisNo ratings yet

- FFU160HAX DatasheetDocument3 pagesFFU160HAX Datasheetracini454No ratings yet

- Products Water Treatment Chemicals I.boiler Chemicals WhenDocument7 pagesProducts Water Treatment Chemicals I.boiler Chemicals Whenemerald_27No ratings yet

- Fiber TechnologyDocument32 pagesFiber TechnologyPv KhoiNo ratings yet

- PIES CatalogueDocument48 pagesPIES Cataloguescooba84No ratings yet

- Chapter-1 Electric Heating and Welding: Electrical Power Utilization (10ee72)Document2 pagesChapter-1 Electric Heating and Welding: Electrical Power Utilization (10ee72)Akshay RajNo ratings yet

- List of Canned CycleDocument8 pagesList of Canned CycleMuthukumar KasinathanNo ratings yet

- Ftee 64 94 PDFDocument3 pagesFtee 64 94 PDFErvinBabicNo ratings yet

- Brentwood CT Getting Your Fill Article 2005 enDocument4 pagesBrentwood CT Getting Your Fill Article 2005 enAvicena AlbiruniNo ratings yet

- Automatic Control of Food Manufacturing ProcessesDocument5 pagesAutomatic Control of Food Manufacturing ProcesseskvnsaiNo ratings yet

- Technopro CatalogueDocument20 pagesTechnopro CatalogueAdnan KhanNo ratings yet

- Information Sheet 5.2-2 Waste Management Information Sheet 5.2-2 Waste Management Information Sheet 5.2-2 Waste ManagementDocument5 pagesInformation Sheet 5.2-2 Waste Management Information Sheet 5.2-2 Waste Management Information Sheet 5.2-2 Waste ManagementKaJong JaclaNo ratings yet

- Testing: Needle Valve SeriesDocument3 pagesTesting: Needle Valve SeriesToty DzNo ratings yet

- Section 067300 - Composite DeckingDocument4 pagesSection 067300 - Composite DeckingWENDING HUNo ratings yet

- Nxe Series Forklifts: Electric 2.0 To 3.5 Ton Capacity 4wheelDocument9 pagesNxe Series Forklifts: Electric 2.0 To 3.5 Ton Capacity 4wheelNguyen Quoc ChienNo ratings yet

- Baths PrecistermDocument2 pagesBaths Precistermabdul azizNo ratings yet

- C595 - 00 Blended CementDocument7 pagesC595 - 00 Blended CementLongLE100% (1)

- Field Trip Iwk Report 1Document12 pagesField Trip Iwk Report 1Musnira MusniraNo ratings yet

- Barton j8Document36 pagesBarton j8Ariz Joelee ArthaNo ratings yet

- Maintenance of TransformerDocument8 pagesMaintenance of TransformeranilsinghteslaNo ratings yet

- Main CatalogDocument151 pagesMain CatalogНикита МельниковNo ratings yet