Professional Documents

Culture Documents

Labor Productivity Kenyan Standard

Labor Productivity Kenyan Standard

Uploaded by

erickCopyright:

Available Formats

You might also like

- Construction Project ManagementDocument51 pagesConstruction Project Managementocduran4200486% (57)

- Paccar LeasingDocument11 pagesPaccar LeasingJennifer67% (3)

- Risk and Opportunities ProcedureDocument4 pagesRisk and Opportunities ProcedureRotimi Shitta-Bey100% (1)

- Role of Project Management Consultancy in Construction ProjectDocument5 pagesRole of Project Management Consultancy in Construction ProjectAbdelmuneimNo ratings yet

- Final Project Masnagment ReportDocument33 pagesFinal Project Masnagment ReportFawad IftikharNo ratings yet

- Job Order Costing - Del Rosario, Jameine SDocument42 pagesJob Order Costing - Del Rosario, Jameine SPatrick LanceNo ratings yet

- Pest Analysis of Pizza HutDocument7 pagesPest Analysis of Pizza HutRaj Gupta0% (1)

- Jacksonville Jaguars Media PlanDocument14 pagesJacksonville Jaguars Media PlanOakenshield1100% (1)

- Cve511 Civil EngineeringDocument9 pagesCve511 Civil EngineeringMoses KufreNo ratings yet

- Module 4Document25 pagesModule 4albatroos earlybirdNo ratings yet

- Construction Project ManagementDocument30 pagesConstruction Project ManagementLAL SANKAR100% (1)

- Homework Productivity RateDocument9 pagesHomework Productivity RateMel CoderesNo ratings yet

- A Review of Minimizing Delay in Construction IndusDocument10 pagesA Review of Minimizing Delay in Construction IndusRaja gopangNo ratings yet

- Contractors' Commitment To Early Completion of Projects: Research ArticleDocument6 pagesContractors' Commitment To Early Completion of Projects: Research ArticleRomie Ziatul FadlanNo ratings yet

- Developing Appropriate Labour Constants For Building Construction Processes in NigeriaDocument7 pagesDeveloping Appropriate Labour Constants For Building Construction Processes in NigeriaInternational Journal of Scientific Research in Science, Engineering and Technology ( IJSRSET )No ratings yet

- An Assessment of The Effect of Cost Control Techniques On Building Project Delivery in NigeriaDocument65 pagesAn Assessment of The Effect of Cost Control Techniques On Building Project Delivery in NigeriaLukman Olatunbosun (Elhadj Tunbosun)No ratings yet

- Construction Project Management: BY Saif Hasan 11510011 M. Arch. 1 YearDocument35 pagesConstruction Project Management: BY Saif Hasan 11510011 M. Arch. 1 YearKristine Delos ReyesNo ratings yet

- The Impact of Cost Control Techniques On Construction Projects DeliveryDocument71 pagesThe Impact of Cost Control Techniques On Construction Projects DeliveryNosa Isaac50% (2)

- Subject-Construction Engineering & ManagementDocument12 pagesSubject-Construction Engineering & ManagementAnil Chhotu JhaNo ratings yet

- Determine of Construction Contract PerioDocument72 pagesDetermine of Construction Contract PerioNewMuler AbuyeNo ratings yet

- Construction Project ManagementDocument51 pagesConstruction Project Managementocduran42004100% (5)

- All About Construction Labor PlanningDocument5 pagesAll About Construction Labor PlanningMohamedNo ratings yet

- Ce 413 General Introduction To The Construction IndustryDocument15 pagesCe 413 General Introduction To The Construction IndustryAdonis GenosaNo ratings yet

- Construction Contract MaagementDocument74 pagesConstruction Contract MaagementDevesh KumarNo ratings yet

- Tijani ProjectDocument23 pagesTijani Projecttemitopeabdulgafar8No ratings yet

- A Case For Acceleration Rather Than Extension of Time On Construction Projects in UgandaDocument4 pagesA Case For Acceleration Rather Than Extension of Time On Construction Projects in UgandaShahram FirouzbakhtNo ratings yet

- Introduction Module 1Document34 pagesIntroduction Module 1NinithaNo ratings yet

- Const MGMT IntroDocument15 pagesConst MGMT IntroAman PathaniaNo ratings yet

- 2 - Introduction To Const. Proj. Mgmt.Document52 pages2 - Introduction To Const. Proj. Mgmt.Jetty Cruz100% (3)

- Construction Engineering and ManagementDocument53 pagesConstruction Engineering and ManagementArnie Juliene AbogadoNo ratings yet

- An Innovative Time-Cost-Quality Tradeoff Modeling of Building ConstructionDocument18 pagesAn Innovative Time-Cost-Quality Tradeoff Modeling of Building ConstructionMorya developer0055No ratings yet

- PM Bba Bcon Vi Sem - 1Document32 pagesPM Bba Bcon Vi Sem - 1Anuj KharwalNo ratings yet

- Module 2 CMPMDocument9 pagesModule 2 CMPMKyle CasanguanNo ratings yet

- Lect. 2. Construction ManagementDocument26 pagesLect. 2. Construction Managementعلاوالدین شاکریNo ratings yet

- Construction Project ManagementDocument15 pagesConstruction Project ManagementPALKI GHAINo ratings yet

- Journal ManagementchallengesinconstructionDocument11 pagesJournal ManagementchallengesinconstructionRadika DikaNo ratings yet

- Systematic Project ManagementDocument7 pagesSystematic Project ManagementKarl Angelo CuellarNo ratings yet

- Document 2 DQWR 14032016Document7 pagesDocument 2 DQWR 14032016Moses KufreNo ratings yet

- "TOP 10" Key Issues Principles in Logistic and Supply Chain Management and Apply To A Real World SituationDocument11 pages"TOP 10" Key Issues Principles in Logistic and Supply Chain Management and Apply To A Real World SituationPovenesan Krishnan100% (1)

- A Critical Literature Review On Main CauDocument4 pagesA Critical Literature Review On Main CauKamil MohametNo ratings yet

- Effective Project Management - Essential Elements For Successful ProjectsDocument8 pagesEffective Project Management - Essential Elements For Successful Projectskatty_domínguez_8100% (3)

- Financial Mismanagement: A Leading Cause of Time and Cost Overrun in Mega Construction Projects in PakistanDocument4 pagesFinancial Mismanagement: A Leading Cause of Time and Cost Overrun in Mega Construction Projects in Pakistanscriptd_ozd3nNo ratings yet

- Lecture 1Document47 pagesLecture 1Shady DokhanNo ratings yet

- Al-Fadhli 2020 IOP Conf. Ser. Mater. Sci. Eng. 737 012040Document12 pagesAl-Fadhli 2020 IOP Conf. Ser. Mater. Sci. Eng. 737 012040عبدالسلام البرهوNo ratings yet

- Labour, Material and Equipment Management/ UtilizationDocument12 pagesLabour, Material and Equipment Management/ Utilizationpgrover1100% (1)

- FMEA, ConstructabilityDocument26 pagesFMEA, ConstructabilityRaymon PrakashNo ratings yet

- Project Management UNIT 1 OkDocument9 pagesProject Management UNIT 1 OkMohd AqdasNo ratings yet

- IJERA ContractorsPerformanceforConstructionProjectDocument8 pagesIJERA ContractorsPerformanceforConstructionProjectazilaadros86No ratings yet

- Variation - Variation OrderDocument5 pagesVariation - Variation OrderEren ArslanNo ratings yet

- Introduction To CMPDocument2 pagesIntroduction To CMPLester BiñasNo ratings yet

- Group1 Ass#2Document6 pagesGroup1 Ass#2Maritchelle AnduyanNo ratings yet

- The Influence of Client Brief and Change Order in Construction ProjectDocument7 pagesThe Influence of Client Brief and Change Order in Construction ProjectZahid EmuNo ratings yet

- Meseret Seifu 3234/06: Construction Manegment Assignment - IDocument15 pagesMeseret Seifu 3234/06: Construction Manegment Assignment - IMamaru Nibret DesyalewNo ratings yet

- Project Management Project SampleDocument87 pagesProject Management Project Samplemouli0067% (3)

- Research ArticleDocument14 pagesResearch Articlegtariku403No ratings yet

- Ep Unit 3Document6 pagesEp Unit 3Asif AliNo ratings yet

- Life Cycle of Civil Engineering ProjectsDocument28 pagesLife Cycle of Civil Engineering ProjectsMarvin Bryant MedinaNo ratings yet

- Rashid 2, 2018Document6 pagesRashid 2, 2018Cheng Ling YongNo ratings yet

- Assignment On Project Management: MBA - II Section - ADocument20 pagesAssignment On Project Management: MBA - II Section - Adilip_maniyaNo ratings yet

- Assessment of The Factors Contributing To Cost and Time Overrun in Building Construction Project: A Case Study of MauritaniaDocument16 pagesAssessment of The Factors Contributing To Cost and Time Overrun in Building Construction Project: A Case Study of MauritaniaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- CE-306: Construction ManagementDocument58 pagesCE-306: Construction ManagementusamaNo ratings yet

- Chris ProjectDocument35 pagesChris Projectashllybenks4492No ratings yet

- Effects of Construction Projects Schedule Overruns: A Case of The Gauteng Province, South AfricaDocument6 pagesEffects of Construction Projects Schedule Overruns: A Case of The Gauteng Province, South AfricaRizki SuryoNo ratings yet

- Construction Supervision Qc + Hse Management in Practice: Quality Control, Ohs, and Environmental Performance Reference GuideFrom EverandConstruction Supervision Qc + Hse Management in Practice: Quality Control, Ohs, and Environmental Performance Reference GuideRating: 5 out of 5 stars5/5 (2)

- Antony Mat. ScheduleDocument12 pagesAntony Mat. ScheduleerickNo ratings yet

- Mrs. Mitschele Mat. ScheduleDocument1 pageMrs. Mitschele Mat. ScheduleerickNo ratings yet

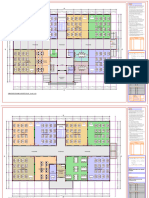

- Proposed Gentle Shepherd Classrooms BlockDocument9 pagesProposed Gentle Shepherd Classrooms BlockerickNo ratings yet

- Builders WorksDocument7 pagesBuilders WorkserickNo ratings yet

- Briefings - LiatDocument2 pagesBriefings - Liatapi-252471713No ratings yet

- Marketing - Section ADocument15 pagesMarketing - Section AArchana NeppolianNo ratings yet

- Form16 PDFDocument2 pagesForm16 PDFyyyNo ratings yet

- SSC Model Test 01Document9 pagesSSC Model Test 01nikhilam.comNo ratings yet

- GreenwashingDocument22 pagesGreenwashingErfi AnugrahNo ratings yet

- Inverse Optimization - A New Perspective On The Black-Litterman ModelDocument15 pagesInverse Optimization - A New Perspective On The Black-Litterman ModelJulio José100% (1)

- Aca 2024 PlannerDocument1 pageAca 2024 Planneryfarhana2002No ratings yet

- Eastern Assurance and Surety Co. v. IACDocument2 pagesEastern Assurance and Surety Co. v. IACIldefonso HernaezNo ratings yet

- Bank Reconciliation SampleDocument11 pagesBank Reconciliation SampleShaira BaltazarNo ratings yet

- Private EquityDocument63 pagesPrivate EquitysimreenNo ratings yet

- Classification of Lands JurisprudenceDocument151 pagesClassification of Lands JurisprudenceKrstn QbdNo ratings yet

- IT - Notes Sir OvaisDocument54 pagesIT - Notes Sir OvaisTauqeer AhmedNo ratings yet

- Actual Costing With Parallel COGM in S4HAHA22 Fiori App 1704696331Document25 pagesActual Costing With Parallel COGM in S4HAHA22 Fiori App 1704696331s25590No ratings yet

- Professor P Rameshan: Trade: Challenges & Strategies. New Delhi: Excel BooksDocument5 pagesProfessor P Rameshan: Trade: Challenges & Strategies. New Delhi: Excel BooksRuchi PundhirNo ratings yet

- Basic Valuation Concept: M.M.M (SEM - II) 2011-2014. Subject: Financial Management Prof. Arun D. ChandaranaDocument20 pagesBasic Valuation Concept: M.M.M (SEM - II) 2011-2014. Subject: Financial Management Prof. Arun D. ChandaranaVenky PragadaNo ratings yet

- Consumer Intention in Buying at The SupermarketDocument66 pagesConsumer Intention in Buying at The SupermarketLYNH 14No ratings yet

- Chapter 9 BA 2001 Spring 2012Document3 pagesChapter 9 BA 2001 Spring 2012Jacqueline FritzNo ratings yet

- Form of Business OwnershipDocument12 pagesForm of Business OwnershipKennNo ratings yet

- Course File Printable PRMDocument25 pagesCourse File Printable PRMGurdil MehtaNo ratings yet

- Finance Training ManualDocument94 pagesFinance Training ManualSanju Dani100% (1)

- Applying Innovation Resistance Theory To Understand User Acceptance of Online Shopping PDFDocument6 pagesApplying Innovation Resistance Theory To Understand User Acceptance of Online Shopping PDFdicksonhtsNo ratings yet

- Session 08 Mm2 - Barco Case - OverDocument19 pagesSession 08 Mm2 - Barco Case - OverAshwin KumarNo ratings yet

- Modul Minggu Ke-2Document14 pagesModul Minggu Ke-2Sandi AdityaNo ratings yet

- Asia Lighterage & Shipping Vs CA - G.R. No. 147246. August 19, 2003Document6 pagesAsia Lighterage & Shipping Vs CA - G.R. No. 147246. August 19, 2003Ebbe DyNo ratings yet

- Day 1 Employee Quickstart Equinix Template v11Document13 pagesDay 1 Employee Quickstart Equinix Template v11Anonymous IFc0l5DLNo ratings yet

Labor Productivity Kenyan Standard

Labor Productivity Kenyan Standard

Uploaded by

erickOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Labor Productivity Kenyan Standard

Labor Productivity Kenyan Standard

Uploaded by

erickCopyright:

Available Formats

LABOUR PRODUCTIVITY IN THE KENYAN CONSTRUCTION INDUSTRY

Isabella Njeri Wachira, Lecturer

Department of Building Economics and Management, University of Nairobi,

Kenya

Abstract

Labour productivity is the measure of the efficiency with which a human being executes an

activity. This productivity is expressed as the units of output per hour e.g. cubic meters of concrete

per hour. In the Kenyan construction industry, labour is the most important factor influencing the

performance of the whole industry since the industry is basically labour intensive. Labour

productivity is the most important determinant of the contract period of projects and all the

consequent time related costs.

Customer satisfaction in the construction industry is measured by the ability of the construction

team to deliver the project within the stipulated time, cost and quality. The most important problem

in the Kenyan construction industry today is the inability of the construction team to deliver projects

within the stipulated time. This has eroded both customer satisfaction and confidence. This state

has among other causes been brought about by lack of labour productivity rates which lead to

inaccurate determination of activity duration’s and consequently, inadeuate estimation of contract

periods.

To correct this situation, we carried out a work measurement study with the aim of establishing

labour productivity of some basic trades. The results obtained are as follows: manual excavation

0.64cm/hr; walling 3.21sm/hr; steel fixing 22.84 lm/hr; formwork 3.72sm/hr concreting 1.57cm/hr;

plastering 3.77sm/hr; screeding 3.74sm/hr; painting 13.15sm/hr. Further analysis of the data

obtained in the work study indicated that the labour content of a project is an average of 19% of the

contract sum. It was also established the management factors, particularly in terms of availing

materials, adequacy of supervision and motivation of workers, are the most important factor

affecting labour productivity. These factors can be influenced positively by the training of

contractors in management skills like planning, scheduling and motivation of workers.

Keywords: Labour, productivity, work measurement, labour content

1. INTRODUCTION

The Kenyan construction industry is one of the most important sectors in the country's economy

whose level of activity is an indicator of the general economic performance of the country. It

contributes about 4% of the country's G.D.P and currently employs 79,000 persons [1] . In the last

five years, the construction industry has been on decline mainly because the government, who is the

sector's largest and most influential client, has reduced it's development expenditure drastically in line

with the prevailing economic climate particularly the structural adjustment program and reduction of

donor funds.

CIB W55 & W65 Joint Triennial Symposium

Customer Satisfaction : A focus for research & practice

Cape Town : 5-10 September 1999

Editors: Bowen, P. & Hindle, R.

Customer satisfaction in the construction industry can be measured by the ability of the construction

team to deliver the projects within time, cost and quality specified. The Kenyan construction industry

has been plagued by a variety of problems which have over time eroded customer satisfaction and

confidence to the extent that all participant in this industry are generally viewed as "crooks" who are

out to get the customer's money in return for shoddy work. One of the main problems in this industry

is the delivery of projects within the stipulated time. This phenomena has been studied by various

researchers inter alia Talukhaba, Mbatha and Wachira [2,3,4]. The researches have clearly shown that

poor time delivery is the most important problem in the industry where on-time delivery of

construction projects is an exception rather than a norm. Some of the projects investigated have time

delays of up to 1000% with the industry seemingly unable to remedy this sad situation which still

persists. Some of the problems identified as causing these time delays include; delay of payments,

poor/wrong contract time estimates, poor site management, delay in drawings, delay in decision

making, excessive variations, etc.

The contract period of a project is determined before the commencement of the work. It is

absolutely necessary that this contract period is assessed as accurately as possible if it is to be realistic

and achievable. A project's contract period is calculated via the following steps;

• first the project is divided into the various activities that are necessary for its

fulfilment,

• the duration necessary for each of these activities is then determined,

• the logic sequence of the activities is then established,

• the contract period is then determined by summing up the duration of all the

activities on the longest path or the critical path.

In the process of determining the contract period, it is important that the duration for each activity are

assessed accurately. In Kenya, the construction industry is mainly labour intensive and is likely to

remain so in the near future mainly because of the

Prohibitive costs of acquiring new machinery and equipment and the conservative nature of the

industry. Labour is the most important determinant of activity duration's.

Labour productivity rates are of paramount importance if activity duration's are to be determined

accurately. Local productivity rates are however not available since no work measurement study has

ever been undertaken and activity duration's are determined mainly by guesswork, hunch or feeling of

the tenderer, in accordance with the tenderer's perception of what is acceptable to the client or fixing

by the consultants with no regard to the contractor's ability to adhere to the same. This result in wrong

assessment of activity duration's and consequently wrong contract period estimation and is a major

contributor to time overruns. These time overruns have a variety of consequences to the construction

industry including;

• increase in the cost of the project as some costs are time related,

• denial of the client’s right to plan the use of the facilities under construction,

• loss of income for the client particularly when the facilities are for renting or

selling,

• loss of future development since the extra funds allocated to delayed project’s

entail forgoing of other projects,

• disillusionment of the client with the consultants & contractors [5].

CIB W55 & W65 Joint Triennial Symposium

Customer Satisfaction : A focus for research & practice

Cape Town : 5-10 September 1999

Editors: Bowen, P. & Hindle, R.

All these consequences have combined to erode the satisfaction and confidence of the construction

industry client. In an effort to try and correct this situation it was found necessary to carry out a work

measurement study to establish productivity rates for some of the main trades in the construction

industry.

Labour productivity is the measure of the efficiency with which a human being executes an activity

[6]. This productivity is expressed as the units of output per hour e.g. cubic meters of concrete per

hour or square meters of plaster per hour which forms the basis for estimating the duration of any

activity on the construction site e.g. the duration of walling as an activity = square meters of walling

needed / square meters of walling achievable per hour.

2. Work Measurement

Work measurement is the application of techniques designed to establish the time for a qualified

worker to carry out a specific job at a defined level of performance [7]. The total work content of any

job may be divided into three classes i.e.

•

basic work content defined as the absolute minimum time in which an operation

can be theoretically completed

• unnecessary work caused by bad design, specification, bad operational methods,

bad weather and shortcomings of management and workers

• ineffective work defined as time when man and machine are idle due to

extraneous reasons like weather or material shortages, shortcomings of

management like delay in provision of drawings, and shortcomings of labour like

lateness, idleness [7].

The attempt to maximise productivity, which will lead to optimisation of activity duration and

consequently contract period, is focused on the reduction of work content to as near the basic as

possible and to eliminate ineffective work.

Work measurement is the technique we used to evaluate production output levels of worker in the

following trades;

• excavation

• walling

• concreting

• plastering

• screeding

• painting

The study was carried out on building projects where the tradesmen were observed as they worked.

The tradesmen observed are deemed to be qualified worker i.e. workers having the necessary physical

attributes, possessing the required intelligence and education, and having acquired skill and knowledge

to carry out the work to satisfactory standard of safety, quantity and quality. Data sheets were then

used to record the number of workers, their level of skill, the activity that the workers were engaged in

during the time of observation and the time they took to complete the activity as recorded on a

stopwatch. Idle time were also recorded and their causes noted e.g. lunch break, lack of materials or

lack of instructions. The rates of working i.e. the speed and effectiveness with which the work is

being done - 100 being the desirable rate at which a man should consistently work - were also

observed and recorded. The time of observation ranged from two hours to whole working day (8 - 12

hours) depending on the activity e.g. for concreting which is usually piecework whole day

CIB W55 & W65 Joint Triennial Symposium

Customer Satisfaction : A focus for research & practice

Cape Town : 5-10 September 1999

Editors: Bowen, P. & Hindle, R.

observations were desirable in order to accurately assess the actual quantity of workdone. After the

period of observation the quantity of workdone was measured. Other aspects of the site were also

observed and recorded e.g. the weather conditions, availability of tools of trade, complexity of the

work, and workers wages.

The data sheets containing all the information were then used to calculate basic times. Basic time is

defined as the time for carrying out an element of work at standard rate and is calculated as;

Basic time = observed time x (observed rating/standard rating)

To this basic time a relaxation allowance is added to account for recovering from the varying degrees

of fatigue which will be experienced in different tasks under different conditions. Further, a

contingency allowance to cover the occasional random short lasting delays e.g. to receive instructions

in the working day is added. In construction this is normally taken as 5% [6]. The times obtained

are then abstracted and averaged in order to obtain a truly representative standard time. Standard time

is the total time in which a job should be done at standard performance and is calculated as;

Standard time = basic time + relaxation & other allowances

In order to get a truly representative time the average of a number of studies/observations is required.

In this study an average of forty observation were used for each trade.

3. Trades observed [5]

3.1. Excavation

This is manual excavation mainly in foundations. Unskilled workers are the main type of labour used

with a supervisor or Forman in charge to ensure that the labourers were excavating to the correct depth

and as set out. Tools used include spades, mattocks and hoes. The work involved the actual loosening

of soil and removal of the same from trenches using spades.

3.2. Walling

This involves the actual construction of the wall excluding the mixing of mortar. Skilled masons

assisted by labourers were the main type of labour. Tools include steel trowels, pans, ropes, levels,

measuring tapes and plumb balls.

3.3 Concreting

This is divided into three distinct activities;

3.3.1 Formwork

Timber and timber products e.g. plywood are the main material used and carpenters assisted by

labourers are the main type of labour employed. Tools used include hammers, chisels, measuring

tapes and saws.

3.3.2 Reinforcement

Materials used here include square twisted high tensile bars and mild steel bars. Steel fixers are the

main labour and the utilise tools like hacksaws and pieces of M.S. pipes for bending.

CIB W55 & W65 Joint Triennial Symposium

Customer Satisfaction : A focus for research & practice

Cape Town : 5-10 September 1999

Editors: Bowen, P. & Hindle, R.

3.3.3 Concreting

This involve the actual manufacture of the concrete mix i.e. mixing of aggregates, cement and water

mainly using a concrete mixer. Masons are the main skilled labour used assisted by gang of labourers

and machine operators. Equipment and tools used include concrete mixers, mechanical vibrators,

wheelbarrows, pans, trowels, levels and spades.

3.4. Plastering and Screeding

This involves the actual application of plaster or screed (mixture of sand, cement, and lime) to wall

and floors. The tradesmen here have there basic training as masons but have over time specialised in

these areas. Tools include trowels and levels.

3.5 Painting

This involves the decoration of various surfaces using paint. It is a highly specialised trade with

experienced painters usually working without the assistance of labourers. Tools include a variety of

brushes and sandpaper.

4. Summary of findings

Samples of the data obtained from observations is tabulated in the tables below (due to space

constraint it is not possible to present all the observations), clearly indicating the average labour

productivity output of the various trades. From the data collected it is clear that the Kenyan

construction worker spends an average of 91% of his time in active work and 9% is idle time. His

average working rate is 80 which is lower than the standard rate of 100. These figures are consistent

with the terms of employment in the industry where most workers are employed on piecework basis

and are allowed to leave before the official time (5 p.m.), once they have complete the allocated

work. The lower than standard rating is a reflecting of inadequacy of supervision of the workers and it

also shows that with increased supervision labour productivity can increase even without altering other

site conditions. This is further proved by the rating for concreting which averaged to 102 a

reflection of the intensity of supervision allotted to this trade due to the belief that it is the most

expensive trade (in terms of all-in-rate cost) and hence a need to keep a keen eye on it.

Further observations indicate that the variations of labour productivity outputs in the industry are

mainly influenced by the management of the various sites. These management factors that affect the

efficiency of labour are:

• timely availability of materials and tools;

• supervision of the workers;

• motivation of workers.

These factors can be positively influenced by appropriate training of site management staff including

contractors, site managers, and foremen in management skills like planning and scheduling activities

and resources, co-ordination, supervision, control of projects, and motivation of workers. Motivation

of workers maybe simply paying them a fair wage for a honest days work and more humane terms of

employment as most workers in this industry perceive themselves as being exploited by their

employers. Wages in the industry vary widely and are mainly determined by availability of work in

specific geographical location, the speed at which the respective worker can carry out -an activity

and the workers ability to negotiate with the employer. Most workers are ignorant of the wage

guidelines issued by the Ministry of Labour and the casual nature of their terms of employment make

it impossible for them to join labour unions. There is therefore need for an education campaign among

CIB W55 & W65 Joint Triennial Symposium

Customer Satisfaction : A focus for research & practice

Cape Town : 5-10 September 1999

Editors: Bowen, P. & Hindle, R.

these construction workers to sensitise them on their right's and among employer's to show them the

benefits of fair wages and employment terms on site productivity and consequently contract duration

(proposal for the same is currently under consideration by JBC). Other factors affecting labour

productivity like weather, technology, size and complexity of project were found to be of secondary

importance. Clearly, there is a lot of potential for improvement of labour productivity in the Kenyan

construction industry and this should be exploited in the endeavour to efficiently utilise the scarce

resources available. New technologies that enhance labour productivity should be encouraged since

this industry is likely to remain labour intensive in the foreseeable future.

Table 9 shows the percentage labour content in the unit rates of the trades observed. Trades like

formwork and plastering have higher labour contents since they require more precision and time

which translates into higher labour costs. I believe that the average of 19% is applicable to all

construction trades and hence to the contract sum.

5. Conclusion

As the satisfaction of the construction industry customer becomes paramount and the resources

allocated to the industry continue to decline, survival of contracting firms in particular will hinge on

their ability to improve labour productivity in order to ensure timely delivery of construction projects.

The construction industry being labour intensive means that labour affects/influences the utilisation of

all the other resources allocated to the industry. Enhancement of efficiency must therefore be based on

labour productivity improvement.

As the construction industry endeavour to increase customer satisfaction and confidence by timely

delivery of construction project, standard labour productivity rates must be established so that they can

be used to estimate activity duration's and consequently realistic and achievable project duration's.

The study on which this paper is based is an attempt in that direction with productivity rates in

observed trades being as shown in tables 1-8 above.

Given that the Kenyan construction industry is similar to other construction industries in Africa, we

believe that these labour productivity rates are applicable to the whole region and particularly to

Eastern and Central Africa (similarity is in terms of technology and all-in-rates). They can therefore

be used in these regions for purposes of estimating activity duration's.

6. References

1. Ministry of Planning and National Development, Economic Survey 1998, Republic of Kenya,

Central Bereau of Statistics.

2. Mbatha C.M., Contract performance: A case of government projects in Kenya, (1986), M.A

thesis, University of Nairobi (unpublished).

3. Talukhaba A.A., Time and cost performance of construction project, (1989), M.A thesis,

University of Nairobi (unpublished).

4. Wachira I.N., Delays and cost overruns in public project in Kenya, (1992), M. Eng. thesis,

Concordia University (unpublished).

5. Wachira I.N., Work study in the Kenyan construction industry for JBC, (1997), Final report.

6. Nyagah J.M., An investigation into the causes of variations in labour productivity on the

construction sites, (1988), M.A thesis, University of Nairobi (unpublished).

7. Management Development Programme, Workstudy in the construction industry International

Labour Organisation, Geneva.

CIB W55 & W65 Joint Triennial Symposium

Customer Satisfaction : A focus for research & practice

Cape Town : 5-10 September 1999

Editors: Bowen, P. & Hindle, R.

Table 1. Excavation

Study Material (cm) Number of Operatives Rating Time in minutes Productivity

number excavated Skilled Unskilled Observed Idle Standard cm/hour

1 24,48 1 10 100 300 0 324,00 0,45

2 38,88 1 12 100 360 0 388,80 0,50

3 8,41 1 3 50 315 70 170,10 0,99

4 26,64 1 9 75 420 0 340,20 0,52

5 29,02 1 12 100 300 60 324,00 0,45

6 80,01 1 16 75 480 60 388,80 0,77

7 79,56 1 13 100 450 60 486,00 0,76

8 35,28 1 8 100 435 60 469,80 0,56

9 39,96 1 10 75 300 60 243,00 0,99

10 66,31 1 13 75 450 60 364,50 0,84

Average 0,64

Table 2. Walling

Study Area built Number of operatives Rating Time in minutes Productivity

number (sm) Skilled Unskilled Observed Idle Standard sm/hour

1 19,00 3 3 100 300 51 324,00 1,17

2 49,77 2 1 100 480 60 518,40 2,88

3 23,70 2 2 50 450 60 243,00 2,93

4 107,60 4 6 100 405 60 437,40 3,69

5 32,75 2 3 75 420 60 340,20 2,89

6 76,53 3 5 75 450 60 364,50 4,20

7 38,45 2 5 75 360 60 291,60 3,96

8 46,67 2 2 100 420 60 453,60 3,09

9 30,83 2 2 75 470 60 380,70 2,43

10 77,73 3 9 75 420 60 340,20 4,57

Average 3,21

Table 3. Reinforcement

Study Length Number of operatives Rating Time in minutes Productivity

number (lm) Skilled Unskilled Observed Idle Standard lm/hour

1 98,00 1 1 100 300 0 324,00 18,15

2 1131,60 6 7 110 355 45 421,74 26,83

3 1002,00 5 3 100 300 0 324,00 37,11

4 400,00 2 2 100 300 0 324,00 37,04

5 300,00 4 6 100 359 69 387,72 11,61

6 66,00 1 1 100 240 0 259,20 15,28

7 480,00 3 7 90 354 79 344,09 27,90

8 336,00 3 1 100 311 72 335,88 20,01

9 708,00 4 3 100 460 80 496,80 21,38

10 348,00 3 5 100 273 72 294,84 23,61

Average 22,84

CIB W55 & W65 Joint Triennial Symposium

Customer Satisfaction : A focus for research & practice

Cape Town : 5-10 September 1999

Editors: Bowen, P. & Hindle, R.

Table 4. Formwork

Study Area Number of operatives Rating Time in minutes Productivity

number (sm) Skilled Unskilled Observed Idle Standard lm/hour

1 39,44 2 4 100 405 60 437,40 2,71

2 21,84 1 2 75 315 0 255,15 5,14

3 16,48 1 1 75 330 60 267,30 3,70

4 68,40 3 3 100 315 60 340,20 4,02

5 22,40 1 3 100 360 57 388,80 3,46

6 111,25 2 4 115 434 70 539,03 6,19

7 33,25 2 2 90 240 0 233,28 4,28

8 216,00 4 6 80 540 41 466,56 6,94

9 20,88 1 2 110 429 79 509,65 2,46

10 20,88 1 5 100 360 0 388,80 3,22

Average 3,72

Table 5. Concreting

Study Concrete Number of operatives Rating Time in minutes Productivity

number (cm) Skilled Unskilled Observed Idle Standard cm/hour

1 36,20 4 25 105 489 65 554,53 0,98

2 65,36 4 30 110 512 148 608,26 1,61

3 36,02 4 27 120 244 49 316,22 1,71

4 67,50 4 27 100 360 0 388,80 2,60

5 80,40 4 39 75 390 0 315,90 3,82

6 10,44 1 6 75 420 60 340,20 1,84

7 17,03 2 11 100 360 0 388,80 1,31

8 55,50 6 30 125 261 40 352,35 1,58

9 45,69 4 21 100 352 118 380,16 1,80

10 54,60 3 12 125 375 29 506,25 2,16

Average 1,57

Table 6. Plastering

Study Concrete Number of operatives Rating Time in minutes Productivity

number (cm) Skilled Unskilled Observed Idle Standard cm/hour

1 24,02 2 1 75 320 75 259,20 2,78

2 21,24 2 0 50 310 65 167,40 3,81

3 17,28 2 3 110 139 12 165,13 3,14

4 9,24 1 1 120 103 49 133,49 4,15

5 13,05 1 1 100 330 0 356,40 2,20

6 23,40 2 2 75 258 42 208,98 3,36

7 10,00 1 1 50 252 0 136,08 4,41

8 45,16 2 5 75 450 60 364,50 3,72

9 46,61 4 4 90 195 0 189,54 3,69

10 10,70 1 1 75 280 20 226,80 2,83

Average 3,77

CIB W55 & W65 Joint Triennial Symposium

Customer Satisfaction : A focus for research & practice

Cape Town : 5-10 September 1999

Editors: Bowen, P. & Hindle, R.

Table 7. Screeding

Study Concrete Number of operatives Rating Time in minutes Productivity

number (cm) Skilled Unskilled Observed Idle Standard cm/hour

1 57,30 2 1 100 300 0 324,00 5,31

2 43,76 2 2 100 270 0 291,60 4,50

3 61,02 3 2 100 300 0 324,00 3,77

4 29,14 1 1 100 330 0 356,40 4,91

5 21,60 1 1 100 300 0 324,00 4,00

6 9,86 1 1 75 240 0 194,40 3,04

7 36,38 3 4 90 150 0 145,80 4,99

8 52,78 2 2 100 420 60 453,60 3,49

9 26,04 1 1 75 420 0 340,20 4,59

10 55,39 2 2 100 465 60 502,20 3,31

Average 3,74

Table 8. Painting

Study Area Number of operatives Rating Time in minutes Productivity

number (sm) Skilled Unskilled Observed Idle Standard sm/hour

1 49,68 1 0 100 150 0 162,00 18,40

2 54,00 1 1 75 320 70 259,20 12,50

3 24,00 1 1 75 200 0 162,00 8,89

4 69,80 1 0 100 270 0 291,60 14,36

5 99,00 1 0 130 300 0 421,20 14,10

6 70,04 1 0 75 300 60 243,00 17,29

7 47,30 1 1 100 240 0 259,20 10,95

8 90,31 2 0 95 228 12 233,93 11,58

9 71,40 2 0 75 285 0 230,85 9,28

10 105,28 1 0 100 345 60 372,60 16,95

Average 13,15

Table 9. Percentage labour content

Item Trade Unit Labour cost/ % labour Content

cm/sm/lm unit Kshs. per unit

1 Excavation 0,64 97,66 88,78

2 Walling 3,21 75,93 15,12

3 Reinforcement 22,84 6,93 18,93

4 Formwok 3,72 65,52 26,21

5 Concreting 1,57 374,20 10,52

6 Plastering 3,77 16,58 24,76

7 Screeding 3,74 16,71 19,96

8 Painting 13,15 9,98 17,22

Average (excluding excavation) 18,96

CIB W55 & W65 Joint Triennial Symposium

Customer Satisfaction : A focus for research & practice

Cape Town : 5-10 September 1999

Editors: Bowen, P. & Hindle, R.

You might also like

- Construction Project ManagementDocument51 pagesConstruction Project Managementocduran4200486% (57)

- Paccar LeasingDocument11 pagesPaccar LeasingJennifer67% (3)

- Risk and Opportunities ProcedureDocument4 pagesRisk and Opportunities ProcedureRotimi Shitta-Bey100% (1)

- Role of Project Management Consultancy in Construction ProjectDocument5 pagesRole of Project Management Consultancy in Construction ProjectAbdelmuneimNo ratings yet

- Final Project Masnagment ReportDocument33 pagesFinal Project Masnagment ReportFawad IftikharNo ratings yet

- Job Order Costing - Del Rosario, Jameine SDocument42 pagesJob Order Costing - Del Rosario, Jameine SPatrick LanceNo ratings yet

- Pest Analysis of Pizza HutDocument7 pagesPest Analysis of Pizza HutRaj Gupta0% (1)

- Jacksonville Jaguars Media PlanDocument14 pagesJacksonville Jaguars Media PlanOakenshield1100% (1)

- Cve511 Civil EngineeringDocument9 pagesCve511 Civil EngineeringMoses KufreNo ratings yet

- Module 4Document25 pagesModule 4albatroos earlybirdNo ratings yet

- Construction Project ManagementDocument30 pagesConstruction Project ManagementLAL SANKAR100% (1)

- Homework Productivity RateDocument9 pagesHomework Productivity RateMel CoderesNo ratings yet

- A Review of Minimizing Delay in Construction IndusDocument10 pagesA Review of Minimizing Delay in Construction IndusRaja gopangNo ratings yet

- Contractors' Commitment To Early Completion of Projects: Research ArticleDocument6 pagesContractors' Commitment To Early Completion of Projects: Research ArticleRomie Ziatul FadlanNo ratings yet

- Developing Appropriate Labour Constants For Building Construction Processes in NigeriaDocument7 pagesDeveloping Appropriate Labour Constants For Building Construction Processes in NigeriaInternational Journal of Scientific Research in Science, Engineering and Technology ( IJSRSET )No ratings yet

- An Assessment of The Effect of Cost Control Techniques On Building Project Delivery in NigeriaDocument65 pagesAn Assessment of The Effect of Cost Control Techniques On Building Project Delivery in NigeriaLukman Olatunbosun (Elhadj Tunbosun)No ratings yet

- Construction Project Management: BY Saif Hasan 11510011 M. Arch. 1 YearDocument35 pagesConstruction Project Management: BY Saif Hasan 11510011 M. Arch. 1 YearKristine Delos ReyesNo ratings yet

- The Impact of Cost Control Techniques On Construction Projects DeliveryDocument71 pagesThe Impact of Cost Control Techniques On Construction Projects DeliveryNosa Isaac50% (2)

- Subject-Construction Engineering & ManagementDocument12 pagesSubject-Construction Engineering & ManagementAnil Chhotu JhaNo ratings yet

- Determine of Construction Contract PerioDocument72 pagesDetermine of Construction Contract PerioNewMuler AbuyeNo ratings yet

- Construction Project ManagementDocument51 pagesConstruction Project Managementocduran42004100% (5)

- All About Construction Labor PlanningDocument5 pagesAll About Construction Labor PlanningMohamedNo ratings yet

- Ce 413 General Introduction To The Construction IndustryDocument15 pagesCe 413 General Introduction To The Construction IndustryAdonis GenosaNo ratings yet

- Construction Contract MaagementDocument74 pagesConstruction Contract MaagementDevesh KumarNo ratings yet

- Tijani ProjectDocument23 pagesTijani Projecttemitopeabdulgafar8No ratings yet

- A Case For Acceleration Rather Than Extension of Time On Construction Projects in UgandaDocument4 pagesA Case For Acceleration Rather Than Extension of Time On Construction Projects in UgandaShahram FirouzbakhtNo ratings yet

- Introduction Module 1Document34 pagesIntroduction Module 1NinithaNo ratings yet

- Const MGMT IntroDocument15 pagesConst MGMT IntroAman PathaniaNo ratings yet

- 2 - Introduction To Const. Proj. Mgmt.Document52 pages2 - Introduction To Const. Proj. Mgmt.Jetty Cruz100% (3)

- Construction Engineering and ManagementDocument53 pagesConstruction Engineering and ManagementArnie Juliene AbogadoNo ratings yet

- An Innovative Time-Cost-Quality Tradeoff Modeling of Building ConstructionDocument18 pagesAn Innovative Time-Cost-Quality Tradeoff Modeling of Building ConstructionMorya developer0055No ratings yet

- PM Bba Bcon Vi Sem - 1Document32 pagesPM Bba Bcon Vi Sem - 1Anuj KharwalNo ratings yet

- Module 2 CMPMDocument9 pagesModule 2 CMPMKyle CasanguanNo ratings yet

- Lect. 2. Construction ManagementDocument26 pagesLect. 2. Construction Managementعلاوالدین شاکریNo ratings yet

- Construction Project ManagementDocument15 pagesConstruction Project ManagementPALKI GHAINo ratings yet

- Journal ManagementchallengesinconstructionDocument11 pagesJournal ManagementchallengesinconstructionRadika DikaNo ratings yet

- Systematic Project ManagementDocument7 pagesSystematic Project ManagementKarl Angelo CuellarNo ratings yet

- Document 2 DQWR 14032016Document7 pagesDocument 2 DQWR 14032016Moses KufreNo ratings yet

- "TOP 10" Key Issues Principles in Logistic and Supply Chain Management and Apply To A Real World SituationDocument11 pages"TOP 10" Key Issues Principles in Logistic and Supply Chain Management and Apply To A Real World SituationPovenesan Krishnan100% (1)

- A Critical Literature Review On Main CauDocument4 pagesA Critical Literature Review On Main CauKamil MohametNo ratings yet

- Effective Project Management - Essential Elements For Successful ProjectsDocument8 pagesEffective Project Management - Essential Elements For Successful Projectskatty_domínguez_8100% (3)

- Financial Mismanagement: A Leading Cause of Time and Cost Overrun in Mega Construction Projects in PakistanDocument4 pagesFinancial Mismanagement: A Leading Cause of Time and Cost Overrun in Mega Construction Projects in Pakistanscriptd_ozd3nNo ratings yet

- Lecture 1Document47 pagesLecture 1Shady DokhanNo ratings yet

- Al-Fadhli 2020 IOP Conf. Ser. Mater. Sci. Eng. 737 012040Document12 pagesAl-Fadhli 2020 IOP Conf. Ser. Mater. Sci. Eng. 737 012040عبدالسلام البرهوNo ratings yet

- Labour, Material and Equipment Management/ UtilizationDocument12 pagesLabour, Material and Equipment Management/ Utilizationpgrover1100% (1)

- FMEA, ConstructabilityDocument26 pagesFMEA, ConstructabilityRaymon PrakashNo ratings yet

- Project Management UNIT 1 OkDocument9 pagesProject Management UNIT 1 OkMohd AqdasNo ratings yet

- IJERA ContractorsPerformanceforConstructionProjectDocument8 pagesIJERA ContractorsPerformanceforConstructionProjectazilaadros86No ratings yet

- Variation - Variation OrderDocument5 pagesVariation - Variation OrderEren ArslanNo ratings yet

- Introduction To CMPDocument2 pagesIntroduction To CMPLester BiñasNo ratings yet

- Group1 Ass#2Document6 pagesGroup1 Ass#2Maritchelle AnduyanNo ratings yet

- The Influence of Client Brief and Change Order in Construction ProjectDocument7 pagesThe Influence of Client Brief and Change Order in Construction ProjectZahid EmuNo ratings yet

- Meseret Seifu 3234/06: Construction Manegment Assignment - IDocument15 pagesMeseret Seifu 3234/06: Construction Manegment Assignment - IMamaru Nibret DesyalewNo ratings yet

- Project Management Project SampleDocument87 pagesProject Management Project Samplemouli0067% (3)

- Research ArticleDocument14 pagesResearch Articlegtariku403No ratings yet

- Ep Unit 3Document6 pagesEp Unit 3Asif AliNo ratings yet

- Life Cycle of Civil Engineering ProjectsDocument28 pagesLife Cycle of Civil Engineering ProjectsMarvin Bryant MedinaNo ratings yet

- Rashid 2, 2018Document6 pagesRashid 2, 2018Cheng Ling YongNo ratings yet

- Assignment On Project Management: MBA - II Section - ADocument20 pagesAssignment On Project Management: MBA - II Section - Adilip_maniyaNo ratings yet

- Assessment of The Factors Contributing To Cost and Time Overrun in Building Construction Project: A Case Study of MauritaniaDocument16 pagesAssessment of The Factors Contributing To Cost and Time Overrun in Building Construction Project: A Case Study of MauritaniaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- CE-306: Construction ManagementDocument58 pagesCE-306: Construction ManagementusamaNo ratings yet

- Chris ProjectDocument35 pagesChris Projectashllybenks4492No ratings yet

- Effects of Construction Projects Schedule Overruns: A Case of The Gauteng Province, South AfricaDocument6 pagesEffects of Construction Projects Schedule Overruns: A Case of The Gauteng Province, South AfricaRizki SuryoNo ratings yet

- Construction Supervision Qc + Hse Management in Practice: Quality Control, Ohs, and Environmental Performance Reference GuideFrom EverandConstruction Supervision Qc + Hse Management in Practice: Quality Control, Ohs, and Environmental Performance Reference GuideRating: 5 out of 5 stars5/5 (2)

- Antony Mat. ScheduleDocument12 pagesAntony Mat. ScheduleerickNo ratings yet

- Mrs. Mitschele Mat. ScheduleDocument1 pageMrs. Mitschele Mat. ScheduleerickNo ratings yet

- Proposed Gentle Shepherd Classrooms BlockDocument9 pagesProposed Gentle Shepherd Classrooms BlockerickNo ratings yet

- Builders WorksDocument7 pagesBuilders WorkserickNo ratings yet

- Briefings - LiatDocument2 pagesBriefings - Liatapi-252471713No ratings yet

- Marketing - Section ADocument15 pagesMarketing - Section AArchana NeppolianNo ratings yet

- Form16 PDFDocument2 pagesForm16 PDFyyyNo ratings yet

- SSC Model Test 01Document9 pagesSSC Model Test 01nikhilam.comNo ratings yet

- GreenwashingDocument22 pagesGreenwashingErfi AnugrahNo ratings yet

- Inverse Optimization - A New Perspective On The Black-Litterman ModelDocument15 pagesInverse Optimization - A New Perspective On The Black-Litterman ModelJulio José100% (1)

- Aca 2024 PlannerDocument1 pageAca 2024 Planneryfarhana2002No ratings yet

- Eastern Assurance and Surety Co. v. IACDocument2 pagesEastern Assurance and Surety Co. v. IACIldefonso HernaezNo ratings yet

- Bank Reconciliation SampleDocument11 pagesBank Reconciliation SampleShaira BaltazarNo ratings yet

- Private EquityDocument63 pagesPrivate EquitysimreenNo ratings yet

- Classification of Lands JurisprudenceDocument151 pagesClassification of Lands JurisprudenceKrstn QbdNo ratings yet

- IT - Notes Sir OvaisDocument54 pagesIT - Notes Sir OvaisTauqeer AhmedNo ratings yet

- Actual Costing With Parallel COGM in S4HAHA22 Fiori App 1704696331Document25 pagesActual Costing With Parallel COGM in S4HAHA22 Fiori App 1704696331s25590No ratings yet

- Professor P Rameshan: Trade: Challenges & Strategies. New Delhi: Excel BooksDocument5 pagesProfessor P Rameshan: Trade: Challenges & Strategies. New Delhi: Excel BooksRuchi PundhirNo ratings yet

- Basic Valuation Concept: M.M.M (SEM - II) 2011-2014. Subject: Financial Management Prof. Arun D. ChandaranaDocument20 pagesBasic Valuation Concept: M.M.M (SEM - II) 2011-2014. Subject: Financial Management Prof. Arun D. ChandaranaVenky PragadaNo ratings yet

- Consumer Intention in Buying at The SupermarketDocument66 pagesConsumer Intention in Buying at The SupermarketLYNH 14No ratings yet

- Chapter 9 BA 2001 Spring 2012Document3 pagesChapter 9 BA 2001 Spring 2012Jacqueline FritzNo ratings yet

- Form of Business OwnershipDocument12 pagesForm of Business OwnershipKennNo ratings yet

- Course File Printable PRMDocument25 pagesCourse File Printable PRMGurdil MehtaNo ratings yet

- Finance Training ManualDocument94 pagesFinance Training ManualSanju Dani100% (1)

- Applying Innovation Resistance Theory To Understand User Acceptance of Online Shopping PDFDocument6 pagesApplying Innovation Resistance Theory To Understand User Acceptance of Online Shopping PDFdicksonhtsNo ratings yet

- Session 08 Mm2 - Barco Case - OverDocument19 pagesSession 08 Mm2 - Barco Case - OverAshwin KumarNo ratings yet

- Modul Minggu Ke-2Document14 pagesModul Minggu Ke-2Sandi AdityaNo ratings yet

- Asia Lighterage & Shipping Vs CA - G.R. No. 147246. August 19, 2003Document6 pagesAsia Lighterage & Shipping Vs CA - G.R. No. 147246. August 19, 2003Ebbe DyNo ratings yet

- Day 1 Employee Quickstart Equinix Template v11Document13 pagesDay 1 Employee Quickstart Equinix Template v11Anonymous IFc0l5DLNo ratings yet