Professional Documents

Culture Documents

J-11 8010 Manual ACN-3-A

J-11 8010 Manual ACN-3-A

Uploaded by

chou youCopyright:

Available Formats

You might also like

- Cessna 525A B - 00B9E8-MAN-21-00-08Rev21Document92 pagesCessna 525A B - 00B9E8-MAN-21-00-08Rev21Csaba KohányNo ratings yet

- S-20/S-200 Series High Tension Magneto Service ManualDocument132 pagesS-20/S-200 Series High Tension Magneto Service ManualYoonjoon Huh67% (3)

- X42002.Continental Ign - MagnetoDocument140 pagesX42002.Continental Ign - Magnetoleather_nun100% (11)

- Magentos Series s20-200Document140 pagesMagentos Series s20-200Julio Palacios Vera100% (3)

- 1350 Series Ica 1Document20 pages1350 Series Ica 1Héctor SánchezNo ratings yet

- TM 9 1095 208 10 1 HR PDFDocument26 pagesTM 9 1095 208 10 1 HR PDFPatrick ThompsonNo ratings yet

- 004-25-125 R00 Dt. 01.06.21Document8 pages004-25-125 R00 Dt. 01.06.21Pradeep K sNo ratings yet

- Coastal Engineering Manual: Overview And Coastal HydrodynamicsFrom EverandCoastal Engineering Manual: Overview And Coastal HydrodynamicsNo ratings yet

- A318/A319/A320/A321: Service BulletinDocument129 pagesA318/A319/A320/A321: Service BulletinPradeep K sNo ratings yet

- SL30 Installation ManualDocument90 pagesSL30 Installation ManualEdu OrtegaNo ratings yet

- A1 Av8bb Wuc 800 PDFDocument198 pagesA1 Av8bb Wuc 800 PDFdasdre75No ratings yet

- Tum Rev 8 28oct20Document106 pagesTum Rev 8 28oct20toiletproductions123No ratings yet

- 0400 Ad Urm 010 - Tum - Rev 06Document87 pages0400 Ad Urm 010 - Tum - Rev 06chou youNo ratings yet

- A1 Av8bb NFM 700Document32 pagesA1 Av8bb NFM 700luis2417No ratings yet

- CVR Ulb Test ProcedureDocument210 pagesCVR Ulb Test Procedureramzi30No ratings yet

- SB-4100 - Pitch Trim Actuator Hawker 400Document7 pagesSB-4100 - Pitch Trim Actuator Hawker 400reginaldo11No ratings yet

- L3 Communications CVR (FA2100) 23-70-04 - Rev 07Document268 pagesL3 Communications CVR (FA2100) 23-70-04 - Rev 07Indiomarcio Ghelardi100% (1)

- LithBatt NAVSEA TMS9310 TechManual Rev2 2010Document94 pagesLithBatt NAVSEA TMS9310 TechManual Rev2 2010VENKATNo ratings yet

- SL 30Document90 pagesSL 30Eric DirksenNo ratings yet

- A318/A319/A320/A321: Service BulletinDocument54 pagesA318/A319/A320/A321: Service BulletinPradeep K sNo ratings yet

- Distribution Statement A Approved For Public Release Distribution UnlimitedDocument12 pagesDistribution Statement A Approved For Public Release Distribution UnlimitedДмитрий ГоршковNo ratings yet

- T9640 Ac DSP 010 - HabDocument176 pagesT9640 Ac DSP 010 - HabjmScriNo ratings yet

- 3710 7uDocument457 pages3710 7uRichard Lund100% (1)

- Service Bulletins S1200-SeriesDocument2 pagesService Bulletins S1200-Seriesmecarservices1No ratings yet

- CFM56 7B SB Rev 72-0579 TSN.09 R 20180816Document23 pagesCFM56 7B SB Rev 72-0579 TSN.09 R 20180816wildanmuhammadnajmiNo ratings yet

- 407TB407TB19129Document9 pages407TB407TB19129e.a.m.v.9.8.1.2No ratings yet

- VPC Erection, Installation, Comm., Operation and Maint. Procedures For Triple Ecc. Butterfly ValvesDocument16 pagesVPC Erection, Installation, Comm., Operation and Maint. Procedures For Triple Ecc. Butterfly ValvesXmanyeyNo ratings yet

- Topic N211 033 Reference - Document - S9310 AQ SAF 010 Rev3Document105 pagesTopic N211 033 Reference - Document - S9310 AQ SAF 010 Rev3chou youNo ratings yet

- TM - 3 4240 346 20P.12645908Document152 pagesTM - 3 4240 346 20P.12645908flyingjohnNo ratings yet

- Bell Boeing MV-22B Osprey Tilt Rotor Pocket ChecklistDocument278 pagesBell Boeing MV-22B Osprey Tilt Rotor Pocket ChecklistウエダMNo ratings yet

- SB 34-3379Document6 pagesSB 34-3379Francisco AriasNo ratings yet

- Sa04491ch - Ica Prpeller - ExampleDocument5 pagesSa04491ch - Ica Prpeller - ExampleKoswara PadmawinataNo ratings yet

- ASBAS350050101ENR0ERRDocument11 pagesASBAS350050101ENR0ERRBatı AkdenizNo ratings yet

- UFC 3-230-11A Water Supply For Special Projects (01!16!2004)Document12 pagesUFC 3-230-11A Water Supply For Special Projects (01!16!2004)Bob VinesNo ratings yet

- Manual de Revisão Geral (X42002) S-20 S-200 SeriesDocument140 pagesManual de Revisão Geral (X42002) S-20 S-200 SeriesDaniel JacobNo ratings yet

- MQ SP M 4048 PDFDocument42 pagesMQ SP M 4048 PDFjaseelNo ratings yet

- SBEC13005026ENR2Document6 pagesSBEC13005026ENR2Impress Production PlanningNo ratings yet

- CF34-8C1/-8C5 Turbofan Technical Manual Index October 1, 2019Document11 pagesCF34-8C1/-8C5 Turbofan Technical Manual Index October 1, 2019Oscar Alexander PérezNo ratings yet

- 71-51-02 (325-029 - Series) Rev 8Document218 pages71-51-02 (325-029 - Series) Rev 8Aviatek Aeronautica100% (1)

- ASBAS365250167ENR0Document13 pagesASBAS365250167ENR0Raymond ZamoraNo ratings yet

- Service Bulletin Information Sheet: MODEL BD-700-1A10 (BD-700)Document29 pagesService Bulletin Information Sheet: MODEL BD-700-1A10 (BD-700)romixrayzenNo ratings yet

- CSN 92 063Document16 pagesCSN 92 063Ovie OkpoduNo ratings yet

- JG40PT4 Manual Single RearDocument107 pagesJG40PT4 Manual Single Rearwmwhelan0% (1)

- As350b Series Single Hydraulics - Ica - 1350-Series-Ica-1 - GDocument19 pagesAs350b Series Single Hydraulics - Ica - 1350-Series-Ica-1 - GAre GeeNo ratings yet

- Master Minimum Equipment List (MMEL) : U.S. Department of Transportation Federal Aviation AdministrationDocument86 pagesMaster Minimum Equipment List (MMEL) : U.S. Department of Transportation Federal Aviation AdministrationCasey KingNo ratings yet

- 5200-780 20140813 PartsSpecsDocument102 pages5200-780 20140813 PartsSpecsUbaldo Enrique Caraballo EstradaNo ratings yet

- H 60 21 Amam 05Document6 pagesH 60 21 Amam 05Mauricio ParraNo ratings yet

- Alert Operators Transmission - Aot: Customer Services DirectorateDocument5 pagesAlert Operators Transmission - Aot: Customer Services DirectorateIbrahim KhalilNo ratings yet

- X42003elec - 2012 04 10 PDFDocument132 pagesX42003elec - 2012 04 10 PDFJose Luis Oliveros100% (1)

- Enviro MAN 21 00 08rev17Document85 pagesEnviro MAN 21 00 08rev17mguilbeaultNo ratings yet

- Alert Operators Transmission - Aot: Customer Services DirectorateDocument5 pagesAlert Operators Transmission - Aot: Customer Services DirectorateEray KoçNo ratings yet

- VPC Erection, Installation, Commissioning, Operation and Maintenance Procedures For Floating Ball ValvesDocument21 pagesVPC Erection, Installation, Commissioning, Operation and Maintenance Procedures For Floating Ball ValvesXmanyeyNo ratings yet

- A318/A319/A320/A321: Service BulletinDocument27 pagesA318/A319/A320/A321: Service BulletinPradeep K sNo ratings yet

- Master Minimum Equipment List (MMEL) : U.S. Department of Transportation Federal Aviation AdministrationDocument74 pagesMaster Minimum Equipment List (MMEL) : U.S. Department of Transportation Federal Aviation AdministrationIcyAviatorNo ratings yet

- ASB 407-21-124 Page 1 of 6 Approved For Public ReleaseDocument6 pagesASB 407-21-124 Page 1 of 6 Approved For Public Releasemohammed kareemNo ratings yet

- SB525C 76 01Document8 pagesSB525C 76 01c20509000.fantasyNo ratings yet

- TFM-138B: VHF/FM Airborne Transceiver (S/N's 1500 Onwards Use F14 Software and Up)Document48 pagesTFM-138B: VHF/FM Airborne Transceiver (S/N's 1500 Onwards Use F14 Software and Up)staedtlerpNo ratings yet

- Mandatory: Bollettino TecnicoDocument7 pagesMandatory: Bollettino TecnicomycopteraviationNo ratings yet

- Vessel/S&T Heat Exchanger Standard Details (Metric Units)Document7 pagesVessel/S&T Heat Exchanger Standard Details (Metric Units)Jamil AhmadNo ratings yet

- SHORT - DCR - 2 - 2023-Systolic Blood Pressure ControlDocument1 pageSHORT - DCR - 2 - 2023-Systolic Blood Pressure Controlchou youNo ratings yet

- SHORT - DCR - 5 - 2023-Medical AdministrationDocument1 pageSHORT - DCR - 5 - 2023-Medical Administrationchou youNo ratings yet

- MR1335Document72 pagesMR1335chou youNo ratings yet

- The Symbiotic Relationship Between Operational MilDocument6 pagesThe Symbiotic Relationship Between Operational Milchou youNo ratings yet

- 2021 11CRS新兴军事技术R46458Document37 pages2021 11CRS新兴军事技术R46458chou youNo ratings yet

- Medical Echelon of Care Conceptual Models For Wargaming - SBIR - GovDocument4 pagesMedical Echelon of Care Conceptual Models For Wargaming - SBIR - Govchou youNo ratings yet

- 2020 - 04 - 01 - nasa - hdbk - 1004 - approved-NASA 数字工程采办框架手册Document217 pages2020 - 04 - 01 - nasa - hdbk - 1004 - approved-NASA 数字工程采办框架手册chou youNo ratings yet

- 246 Hause Hart-基于模型的采集Document25 pages246 Hause Hart-基于模型的采集chou youNo ratings yet

- NAVSEA 0905 LP 120 0010 Technical Manual For DSRV SystemDocument135 pagesNAVSEA 0905 LP 120 0010 Technical Manual For DSRV Systemchou youNo ratings yet

- Dokumen - Tips - Pdfus Navy Salvage Manual Volume 2 Pol Docsus Navy Salvage Manual VolumeDocument148 pagesDokumen - Tips - Pdfus Navy Salvage Manual Volume 2 Pol Docsus Navy Salvage Manual Volumechou youNo ratings yet

- Dokumen - Tips - Us Navy Ship Salvage Manual Volume 6 Oil Spill Response 2016 02 18 Us NavyDocument251 pagesDokumen - Tips - Us Navy Ship Salvage Manual Volume 6 Oil Spill Response 2016 02 18 Us Navychou youNo ratings yet

- ReversionaryBonus PDFDocument4 pagesReversionaryBonus PDFPiyush BhartiNo ratings yet

- Spokane Ind WearParts SiTecDocument10 pagesSpokane Ind WearParts SiTecballesterosa545No ratings yet

- Og 24 1715 4056 00000863Document9 pagesOg 24 1715 4056 00000863manjusk0102No ratings yet

- Central Islip To South Shore Mall: Suffolk County Transit Bus Information Suffolk County Transit Fares & InformationDocument2 pagesCentral Islip To South Shore Mall: Suffolk County Transit Bus Information Suffolk County Transit Fares & Informationtang dujkNo ratings yet

- L12 - Variance AnalysisDocument44 pagesL12 - Variance Analysis王宇璇No ratings yet

- Directory RailwayDocument273 pagesDirectory Railwaysharma_d100% (2)

- Macroeconomic Data AnalysisDocument63 pagesMacroeconomic Data AnalysisScott W. Hegerty100% (1)

- Alila 2 BrochureDocument33 pagesAlila 2 BrochureJason Lim NoordinNo ratings yet

- Bulk DealsDocument63 pagesBulk DealsBhavin SagarNo ratings yet

- Agreement For Pledge of SharesDocument5 pagesAgreement For Pledge of SharesPrerikaNo ratings yet

- Sewer Network Data CollectionDocument9 pagesSewer Network Data CollectionSaadman TaswarNo ratings yet

- Learning Curve ExercisesDocument6 pagesLearning Curve ExercisesRosele CabañelezNo ratings yet

- Calcul MH 800Document6 pagesCalcul MH 800Mihai AndreiasNo ratings yet

- GRS Certified PCR, PIR GranulesDocument4 pagesGRS Certified PCR, PIR GranulesDhananjay VishwakarmaNo ratings yet

- No. Requisition / Material Code / Description Quantity Unit Unit Price Disc % AmountDocument3 pagesNo. Requisition / Material Code / Description Quantity Unit Unit Price Disc % AmountMond NaNo ratings yet

- RAB Rumah 2 Lantai SBY + Time ScheduleDocument293 pagesRAB Rumah 2 Lantai SBY + Time ScheduleJefferson WidodoNo ratings yet

- Materials Finishes Catalogue LaskasasDocument65 pagesMaterials Finishes Catalogue LaskasasLalitha TammanaNo ratings yet

- McDonald's GAP AnalysisDocument13 pagesMcDonald's GAP Analysissurappadu67% (3)

- Efficiency Improvement Oppertunities With BLDC Fan PDFDocument14 pagesEfficiency Improvement Oppertunities With BLDC Fan PDFjust_4_u_dear_in9549No ratings yet

- Marine Insurance in BangladeshDocument3 pagesMarine Insurance in BangladeshHasibul BorhanNo ratings yet

- Kaitlin Michelle Egan-3de27314ae8beafDocument8 pagesKaitlin Michelle Egan-3de27314ae8beafkamartinez203No ratings yet

- Brass - The Cost Effective ChoiceDocument2 pagesBrass - The Cost Effective ChoiceRio BuiNo ratings yet

- OnlineChallan (N)Document1 pageOnlineChallan (N)Nikhil JainNo ratings yet

- DMAS Financial Statement 31 Mar 2022Document82 pagesDMAS Financial Statement 31 Mar 2022Fendy HendrawanNo ratings yet

- Tax Invoice: AB Cartridge Private LimitedDocument1 pageTax Invoice: AB Cartridge Private LimitedSunil PatelNo ratings yet

- Description: S&P Bse TeckDocument5 pagesDescription: S&P Bse TeckNeelkanth DaveNo ratings yet

- Standarvd Cost & VarianceDocument3 pagesStandarvd Cost & Variancemohammad bilalNo ratings yet

- Mathematics of Finance Canadian 8th Edition Brown Kopp Solution ManualDocument41 pagesMathematics of Finance Canadian 8th Edition Brown Kopp Solution Manualflorence100% (34)

- Cremation Shed 2019-20Document29 pagesCremation Shed 2019-20Amjid ManhasNo ratings yet

- The Impact of Rapid Population Growth On Economic Development in Ethiopia - 045539Document51 pagesThe Impact of Rapid Population Growth On Economic Development in Ethiopia - 045539ABAYNEGETAHUN getahun100% (1)

J-11 8010 Manual ACN-3-A

J-11 8010 Manual ACN-3-A

Uploaded by

chou youOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

J-11 8010 Manual ACN-3-A

J-11 8010 Manual ACN-3-A

Uploaded by

chou youCopyright:

Available Formats

FOR OFFICIAL USE ONLY S0570-AC-CCM-010/8010

ACN 3/A

S0570-AC-CCM-010/8010

REVISION 0 ACN 3/A

NAVSEA TECHNICAL PUBLICATION

INDUSTRIAL SHIP SAFETY MANUAL FOR FIRE

PREVENTION AND RESPONSE

DISTRIBUTION STATEMENT D: DISTRIBUTION AUTHORIZED TO DoD AND U.S. DoD CONTRACTORS ONLY (06 February

2014). OTHER REQUESTS FOR THIS DOCUMENT SHALL BE REFERRED TO NAVAL SEA SYSTEMS COMMAND (SEA 04X6).

DESTRUCTION NOTICE: DESTROY BY ANY METHOD THAT WILL PREVENT DISCLOSURE OF CONTENTS OR

RECONSTRUCTION OF THE DOCUMENT

PUBLISHED BY DIRECTION OF COMMANDER, NAVAL SEA SYSTEMS COMMAND

11 February 2021

FOR OFFICIAL USE ONLY

FOR OFFICIAL USE ONLY S0570-AC-CCM-010/8010

ACN 3/A

THIS PAGE INTENTIONALLY LEFT BLANK.

FOR OFFICIAL USE ONLY

FOR OFFICIAL USE ONLY S0570-AC-CCM-010/8010

ACN 3/A

NAVSEA TECHNICAL MANUAL CERTIFICATION SHEET 1 of 1

Certification Applies to: New Manual Revision Change

Applicable TMINS/Pub. No.

NAVSEA S0570-AC-CCM-010/8010

Publication Date (Mo, Da, Yr)

07/17/2018

Title: INDUSTRIAL SHIP SAFETY MANUAL FOR FIRE PREVENTION AND RESPONSE

TMCR/TMSR/Specification No: N/A

CHANGES AND REVISIONS: See the following pages ii thru v.

Continue on reverse side or add pages as needed.

CERTIFICATION STATEMENT

This is to certify that responsible NAVSEA activities have revised the above identified document for

acquisition compliance, technical coverage, and printing quality. This form is for internal NAVSEA

management use only, and does not imply contractual approval or acceptance of the technical manual by

the Government, nor relieve the contractor of any responsibility for delivering the technical manual in

accordance with the contract requirement.

Authority Name Signature Organization Code Date

Acquisition William /S/ W.Gembach NAVSEA 04X6 11Feb21

Gembach

Technical William /S/ W.Gembach NAVSEA 04X6 11Feb21

Gembach

Printing NA NA NA NA NA

Release

FOR OFFICIAL USE ONLY i

FOR OFFICIAL USE ONLY S0570-AC-CCM-010/8010

ACN 3/A

CHANGES AND REVISIONS:

List of Effective Pages: Updated page numbers.

Table of Contents: Updated page numbers and paragraph titles.

List of Illustrations: Updated page numbers and figure titles.

List of Tables: Updated page numbers and table titles.

Chapter 2

Added the following reference:

(b) S9AA0-AB-GOS-010, REV. 7 General Specifications for Overhaul of Surface Ships.

2.1.1.5 Added requirement for the FSC to use and maintain the ship plan of the day (SPOD) as an active tracking

document. Additionally, added specific SPOD requirements list 2.1.1.5a through 2.1.1.5l for FSC use and maintenance of

the ship plan of the day (SPOD) when invoked.

2.1.1.8 Added requirements for NSA to establish processes to ensure all work, testing, and evolutions that impact fire

safety are routed to the FSO and FSC for review and approval.

2.1.2 through 2.1.2.2 Added clarification to the duties and responsibilities prescribed for the fire safety officer (FSO) as

well as assignment criteria.

2.1.3 through 2.1.3.3 Added clarification to the duties and responsibilities prescribed for the fire safety watch (FSW) as

well as assignment criteria.

2.3 Added new subsections to clarify NSA, RA, and Host Facility briefing requirements for fire prevention and response.

Additionally, clarified FSO and FSW training and qualification requirements.

2.3.1 Added clarification to training requirements for FSO and FSW personnel.

2.3.2 Added specific briefing and training requirements for RA personnel, NSA and host facility personnel, FSWs, and

ship’s force personnel necessary to support fire response.

2.3.3 Added practical and knowledge based training requirements necessary for FSO qualifications.

2.3.4 Added practical and knowledge based training requirements necessary for lead maintenance activity (LMA) FSW

qualifications.

2.3.5 Added training requirements necessary for ship’s force FSW qualifications.

2.4 Added new administration subsection.

2.4.1 Added FSO duties and responsibilities and distribution requirements for the FSO assignment memorandum.

2.4.2 Added qualification program requirements that include: written exams, maintenance of records, and the upkeep of

qualification lists.

NAVSEA TECHNICAL MANUAL CERTIFICATION SHEET 1 of 4

FOR OFFICIAL USE ONLY ii

FOR OFFICIAL USE ONLY S0570-AC-CCM-010/8010

ACN 3/A

CHANGES AND REVISIONS:

Chapter 3

Added the following reference:

(x) OPNAVINST 3440.18, Procedures and Reporting Requirements for Major Shipboard Nonnuclear Casualties While in

Port at a U.S. Naval Installation or a U.S. Ship Repair or Construction Activity.

3.2.2.1 and 3.2.17 Invoked reverence (x) where applicable.

3.4 Added training requirements necessary for shipyard emergency response managers prior to assignment to an

emergency response team (ERT) role.

3.4.1 Added clarification for personnel that are assigned to the ERT.

3.4.2 Added initial training requirements for personnel assigned to the ERT.

Updated table 3-2 “FEMA On-Line Training Courses “ to reflect current Federal Emergency Response Agency (FEMA)

course numbers and titles.

3.4.3 Added continuing training requirements for ERT assigned personnel.

3.5 Added ship’s force (SF) ERT training requirements.

3.5.1 Added clarification to SF personnel assignment to the ERT.

3.5.2 Added pre-availability training requirements for SF ERT assigned personnel.

Added table 3-3 “SF Pre-Availability Firefighting Training Topics.” Table provides general topics from reference (b) and

(c) of chapter three of this manual.

Added table 3-4 “NSA Conducted Firefighting Training Topics.” Table provides general topics from reference (b) and (c)

of chapter three of this manual.

3.5.3 Added continuing training requirements for SF ERT assigned personnel.

3.6.1 Added the following sentences: “When damage control equipment on submarines shall be removed from service for

maintenance (e.g., SCBA cylinder hydrostatic testing), the NSA shall provide replacement equipment. Daily fire safety

inspections will spot check ship’s damage control equipment to determine if the equipment is available and properly

maintained.”

3.6.9 Added requirements for NSA provided supplementary damage control (DC) equipment.

3.6.10 Added requirement for DC locker equipment custody and accessibility.

Chapter 4

Added the following references:

(j) United States Navy Regulations (k) NAVSEA 389-0288, Radiological Controls (NOTAL)

(l) NAVSEAINST 9210.22F, Security and Safety of Nuclear Reactors and Special Nuclear Material (NOTAL)

(m) S9223-AJ-OMP-010, Battery, Submarine Main Storage - Submarine Valve Regulated Lead Acid (SVRLA) Technical

Manual

(n) S9223-AC-OMP-010, Battery, Submarine Main Storage - Submarine Valve Regulated Lead Acid (SVRLA) Technical

Manual

NAVSEA TECHNICAL MANUAL CERTIFICATION SHEET 2 of 4

FOR OFFICIAL USE ONLY iii

FOR OFFICIAL USE ONLY S0570-AC-CCM-010/8010

ACN 3/A

CHANGES AND REVISIONS:

Chapter 4 (Continued)

4.1.2 Added additional requirements in subsection 4.1.2c for MOA concurrence process.

4.2.1 Added subsection 4.1.2j to provide clarification for the hot work authorization notification process.

4.2.2 Added requirements and clarification for permit approval authority process.

4.3.7 Added clarification to submarine battery charging requirements to define when a charge is considered a gassing

charge requiring hotwork to be secured.

Chapter 7

Introduction: Added the following sentence: “The FSC shall review for likely single-point failure scenarios (e.g., ships

with a single shore power location cannot rely on two off-hull power supplies since a catastrophic failure of the only shore

power switchboard could result in a major fire and loss of all ship systems, as well as the plan enacted to maintain

firefighting capability).”

7.1.1 Added the following sentence: “For the purposes of this manual, a submarine’s trim system and any interconnected

drain pumps are considered components of the fire main.”

7.1.1.6 Added electrical power redundancy criteria and requirements for ship’s fire main.

7.1.1.7 Added redundancy criteria and requirements for ship’s fire main.

7.1.1.8 Added NFPA-20 requirements for the use of booster pumps when installed to boost shore firefighting supply to

ship or temporary firefighting system.

Chapter 8

8.2.5 Added the following sentences: “Any facility attached to the ship, enclosed structures (e.g., offices) placed inside or

on the ship, and all crew berthing barges shall be connected to the ship general announcing system or have a direct-dial

phone connecting the ship and a continuously manned watch station. Industrial facility watches will be continuously

manned when the facility is occupied.”

Chapter 10

10.4.7 Added the following sentence to existing quick disconnect fitting (QDF) requirement: “QDFs and associated

isolations, shall be installed in such way that emergency responders can readily access the QDF without assistance, operate

without tools, and be…”

Chapter 11

Introduction: Removed reference to maintaining “fire and smoke boundaries” to narrow scope to only fire zone

boundaries. Added the following sentence: “This chapter provides requirements for sustaining fire zone boundaries

during industrial availabilities. This chapter applies to all platforms – submarines, surface ships, and aircraft carriers.”

NAVSEA TECHNICAL MANUAL CERTIFICATION SHEET 3 of 4

FOR OFFICIAL USE ONLY iv

FOR OFFICIAL USE ONLY S0570-AC-CCM-010/8010

ACN 3/A

CHANGES AND REVISIONS:

Chapter 12

12.2.2 Added subsection 12.2.2g through 12.2.2l to provide additional selective drill attributes.

12.5.3 Added requirements for drill periodicity waver.

Appendix O

Added appendix O to provide SPOD requirements and sample illustrations for clarification of SPOD format .

NAVSEA TECHNICAL MANUAL CERTIFICATION SHEET 4 of 4

FOR OFFICIAL USE ONLY v

FOR OFFICIAL USE ONLY S0570-AC-CCM-010/8010

ACN 3/A

THIS PAGE INTENTIONALLY LEFT BLANK

FOR OFFICIAL USE ONLY vi

FOR OFFICIAL USE ONLY S0570-AC-CCM-010/8010

ACN 3/A

LIST OF EFFECTIVE PAGES

Dispose of superseded pages in accordance with applicable regulations.

Dates of issue for original and subsequent revisions:

Original……………………………06 February 2014

ACN 1/A…………………………..19 April 2016

ACN 2/A…………………………..17 July 2018

ACN 3/A…………………………..11 February 2021

TOTAL NUMBER OF PAGES IN THIS TECHNICAL MANUAL IS 198,

CONSISTING OF THE FOLLOWING:

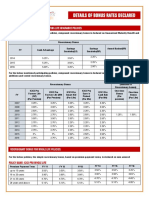

PAGES REV CHANGE #

Cover Sheet --- 00 ACN 3/A

Certification Sheet i 00 ACN 3/A

Changes and Revisions ii through vi 00 ACN 3/A

List of Effective Pages viii through ix 00 ACN 3/A

Record of Changes x 00 ACN 3/A

Table of Contents xi through xix 00 ACN 3/A

List of Figures and List of Tables xx through xxi 00 ACN 3/A

Commander’s Guidance xxiii 00 Original

Foreword xxv 00 Original

Chapter 1 1-1 through 1-4 00 Original

Chapter 2 2-1 through 2-8 00 ACN 3/A

FOR OFFICIAL USE ONLY vii

FOR OFFICIAL USE ONLY S0570-AC-CCM-010/8010

ACN 3/A

Chapter 3 3-1 through 3-18 00 ACN 3/A

Chapter 4 4-1 through 4-6 00 ACN 3/A

Chapter 5 5-1 through 5-8 00 ACN 2/A

Chapter 6 6-1 through 6-6 00 ACN 2/A

Chapter 7 7-1 through 7-18 00 ACN 3/A

Chapter 8 8-1 through 8-6 00 ACN 3/A

Chapter 9 9-1 through 9-2 00 ACN 1/A

Chapter 10 10-1 through 10-6 00 ACN 3/A

Chapter 11 11-1 through 11-2 00 ACN 3/A

Chapter 12 12-1 through 12-6 00 ACN 3/A

Chapter 13 13-1 through 13-6 00 ACN 2/A

Chapter 14 14-1 through 14-4 00 Original

Appendix A A-1 through A-4 00 ACN 2/A

Appendix B B-1 through B-4 00 Original

Appendix C C-1 through C-4 00 ACN 2/A

Appendix D D-1 through D-4 00 ACN 2/A

FOR OFFICIAL USE ONLY viii

FOR OFFICIAL USE ONLY S0570-AC-CCM-010/8010

ACN 3/A

Appendix E E-1 through E-2 00 Original

Appendix F F-1 through F-4 00 Original

Appendix G G-1 through G-2 00 Original

Appendix H H-1 through H-6 00 Original

Appendix I I-1 through I-2 00 Original

Appendix J J-1 through J-6 00 Original

Appendix K K-1 through K-2 00 Original

Appendix L L-1 through L-6 00 ACN 2/A

Appendix M M-1 through M-4 00 ACN 2/A

Appendix N N-1 through N-2 00 ACN 2/A

Appendix O O-1 through O-16 00 ACN 3/A

TMDER Last Page - -

FOR OFFICIAL USE ONLY ix

FOR OFFICIAL USE ONLY S0570-AC-CCM-010/8010

ACN 3/A

RECORD OF CHANGES

CHANGE DATE OF TITLE OR BRIEF DESCRIPTION ENTERED

NO. CHANGE BY

(INITIALS)

ACN 3/A These changes are intended to address outstanding

OSCAR AUSTIN action items from the fire review

board. Additionally, these changes provide immediate

corrective actions and clarifications from the preliminary

review of the BONHOMME RICHARD failure as

directed by joint CPF/USFF Naval Message

COMPACFLT 220242Z OCT 2020.

FOR OFFICIAL USE ONLY x

FOR OFFICIAL USE ONLY S0570-AC-CCM-010/8010

ACN 3/A

TABLE OF CONTENTS

LIST OF FIGURES .................................................................................................................................................... xvi

LIST OF TABLES.....................................................................................................................................................xvii

COMMANDER’S GUIDANCE ................................................................................................................................ xix

FORWARD ................................................................................................................................................................ xxi

Chapter 1 INTRODUCTION

1.1 Purpose .........................................................................................................................................................1-1

1.2 Scope ............................................................................................................................................................1-1

1.2.1 CNO Scheduled Availabilities ...........................................................................................................1-1

1.2.2 Non-CNO Availabilities .....................................................................................................................1-1

1.2.3 New Construction and Repair Availabilities in Private Shipyards .....................................................1-2

1.2.4 Ship’s Force........................................................................................................................................1-2

1.3 Background ..................................................................................................................................................1-2

1.4 Responsibilities.............................................................................................................................................1-2

1.4.1 General Guidance ...............................................................................................................................1-2

1.4.2 NSA Responsibilities .........................................................................................................................1-2

1.4.3 Director of Nuclear Propulsion Responsibilities. ...............................................................................1-2

1.4.4 Director, Strategic Systems Programs Responsibilities ......................................................................1-2

1.4.5 Executive Agent for Damage Control Responsibilities ......................................................................1-2

1.5 Fire Safety Plan ............................................................................................................................................1-3

1.6 Glossary of Terms ........................................................................................................................................1-3

Chapter 2 ORGANIZATIONAL REQUIREMENTS

2.1 Fire Safety Organization ...............................................................................................................................2-1

2.1.1 Fire Safety Council .............................................................................................................................2-1

2.1.2 Fire Safety Officer ..............................................................................................................................2-3

2.1.3 Fire Safety Watch ...............................................................................................................................2-4

2.2 Emergency Management ..............................................................................................................................2-5

2.3 Training and Qualification Requirements.....................................................................................................2-5

2.3.1 Discussion ..........................................................................................................................................2-5

2.3.2 Briefing and Training Requirements ..................................................................................................2-5

2.3.3 FSO Qualification...............................................................................................................................2-5

2.3.4 LMA FSW Qualification ....................................................................................................................2-6

2.3.5 Ship’s Force FSW Training ................................................................................................................2-6

2.4 Administration ..............................................................................................................................................2-7

2.4.1 FSO Assignment Memorandum .........................................................................................................2-7

2.4.2 Qualification Program ........................................................................................................................2-7

2.5 Fire Data Tracking and Analyses .................................................................................................................2-7

2.5.1 Reportable Fires .................................................................................................................................2-7

2.5.2 Reporting of Shipboard Fires .............................................................................................................2-7

2.5.3 Trend Analysis of Fires and Fire Related Problems ...........................................................................2-8

FOR OFFICIAL USE ONLY xi

FOR OFFICIAL USE ONLY S0570-AC-CCM-010/8010

ACN 3/A

2.5.4 Quarterly Reports ...............................................................................................................................2-8

2.6 Trouble Reports and Mishap Reports ...........................................................................................................2-8

2.7 Audits ...........................................................................................................................................................2-8

2.7.1 Local Audits .......................................................................................................................................2-8

2.7.2 NAVSEA and CNIC Audits ...............................................................................................................2-8

Chapter 3 FIRE RESPONSE PLANNING

3.1 Background ..................................................................................................................................................3-2

3.2 Fire Safety Plan ............................................................................................................................................3-2

3.2.1 Firefighting Principles .........................................................................................................................3-2

3.2.2 Command and Control .......................................................................................................................3-2

3.2.3 Designation of Responsibility and Authority .....................................................................................3-6

3.2.4 Assignment of Designated Personnel to Specific Positions in the Emergency

Response Team (ERT).......................................................................................................................3-7

3.2.5 Training and Integration of Firefighting Services ..............................................................................3-7

3.2.6 Personnel Accountability....................................................................................................................3-8

3.2.7 Response Actions ...............................................................................................................................3-8

3.2.8 Firefighting Doctrine ..........................................................................................................................3-8

3.2.9 Logistic and In-Hull Support Requirements .......................................................................................3-8

3.2.10 SCBA Recharge Capability ...............................................................................................................3-9

3.2.11 Medical Triage and Treatment ..........................................................................................................3-9

3.2.12 Management of Firefighting Effluents ..............................................................................................3-9

3.2.13 Firefighting Equipment ...................................................................................................................3-10

3.2.14 Technical Assistance and Coordination ..........................................................................................3-10

3.2.15 Extended Operations Plan ...............................................................................................................3-10

3.2.16 Ship Conditions ...............................................................................................................................3-10

3.2.17 Reporting Procedures ......................................................................................................................3-10

3.2.18 Procedures for Liaison with Civil Authorities .................................................................................3-11

3.2.19 Public Affairs ..................................................................................................................................3-11

3.2.20 Accident Information Collection and Storage .................................................................................3-11

3.2.21 Roles and Responsibilities of Activities ..........................................................................................3-11

3.2.22 Radio Communications ...................................................................................................................3-11

3.3 Training ......................................................................................................................................................3-12

3.3.1 F&ES Training .................................................................................................................................3-12

3.4 Shipyard Emergency Response Managers Training ...................................................................................3-12

3.4.1 ERT Assignment ..............................................................................................................................3-12

3.4.2 Initial ERT Training .........................................................................................................................3-12

3.4.3 Continuing ERT Training .................................................................................................................3-13

3.5 SF ERT Training ........................................................................................................................................3-13

3.5.1 ERT Assignment ..............................................................................................................................3-13

3.5.2 ERT Pre-Availability Training .........................................................................................................3-13

3.5.3 SF Continuing ERT Training ...........................................................................................................3-14

3.5.4 Knowledge .......................................................................................................................................3-14

3.5.5 Practical Abilities .............................................................................................................................3-14

FOR OFFICIAL USE ONLY xii

FOR OFFICIAL USE ONLY S0570-AC-CCM-010/8010

ACN 3/A

3.5.6 Re-verification ..................................................................................................................................3-14

3.5.7 Mutual Aid Agreements ...................................................................................................................3-14

3.6 Rapid Response Damage Control CONEX Box.........................................................................................3-14

3.6.1 Damage Control (DC) Equipment ....................................................................................................3-15

3.6.2 Storage of DC Equipment ................................................................................................................3-15

3.6.3 Custody of DC Equipment ...............................................................................................................3-15

3.6.4 Alternate Storage Location ...............................................................................................................3-15

3.6.5 Staging of DC Equipment ................................................................................................................3-15

3.6.6 Accessibility of DC Equipment ........................................................................................................3-15

3.6.7 Transition to Habitability .................................................................................................................3-15

3.6.8 Rapid Response Damage Control Equipment for CVNs and Surface Ships ....................................3-15

3.6.9 NSA Supplementary DC Equipment ................................................................................................3-16

3.6.10 Custody of NSA Damage Control Equipment.................................................................................3-16

3.7 Fire Lanes ...................................................................................................................................................3-17

3.7.1 Fire Lane Width and Markings .........................................................................................................3-17

3.7.2 Vertical Clearance ............................................................................................................................3-17

3.7.3 Angle of Approach/Departure ..........................................................................................................3-18

3.7.4 Wintertime Maintenance ..................................................................................................................3-18

3.7.5 Waiver Request ................................................................................................................................3-18

3.7.6 Approval to Temporarily Block a Fire Lane ....................................................................................3-18

Chapter 4 HOT WORK AND FIRE WATCH

4.1 Hot Work Memorandum Of Agreement .......................................................................................................4-1

4.1.1 Classifications of Hot Work ...............................................................................................................4-1

4.1.2 Hot Work MOA..................................................................................................................................4-2

4.2 Hot Work Authorization ...............................................................................................................................4-2

4.2.1 Written Notice ....................................................................................................................................4-2

4.2.2 Permit Approval Authority .................................................................................................................4-3

4.2.3 Posting of Notice ................................................................................................................................4-3

4.2.4 Notice to the CO’s Representative. ....................................................................................................4-3

4.3 Gas-Free Procedures And Special Hazards ..................................................................................................4-3

4.3.1 Governance for Gas Free Procedures .................................................................................................4-3

4.3.2 Restricted Areas for Hot Work ...........................................................................................................4-3

4.3.3 Coverings ...........................................................................................................................................4-3

4.3.4 Hot Work in the Presence of Lines/Piping Containing Flammable or Combustible Fluids ...............4-3

4.3.5 Proximity of Flammables and Combustibles ......................................................................................4-3

4.3.6 Ammunition or Explosives .................................................................................................................4-3

4.3.7 Submarine Main Storage Battery Operations .....................................................................................4-4

4.3.8 Additional Precautions .......................................................................................................................4-4

4.4 Fire Watch Requirements And Training .......................................................................................................4-4

4.4.1 Fire Watch Policy ...............................................................................................................................4-4

4.4.2 Additional Duties During Hot Work ..................................................................................................4-4

4.4.3 Limitations to Single Fire Watch with Multiple Hot Workers ...........................................................4-4

4.4.4 Hot Work Involving Multiple Levels .................................................................................................4-4

FOR OFFICIAL USE ONLY xiii

FOR OFFICIAL USE ONLY S0570-AC-CCM-010/8010

ACN 3/A

4.4.5 Bulkhead, Overhead, or Deck Hot Work............................................................................................4-4

4.4.6 Blind Compartment Hot Work ...........................................................................................................4-4

4.4.7 Communication Between Fire Watches .............................................................................................4-4

4.4.8 Fire Extinguishers...............................................................................................................................4-4

4.4.9 Fire Watch Training ...........................................................................................................................4-5

4.4.10 Fire Watch Portable Extinguishers ....................................................................................................4-5

Chapter 5 SHIPBOARD INDUSTRIAL MATERIAL USE AND STORAGE

5.1 Flammable and Combustible Material..........................................................................................................5-2

5.1.1 Materials Used Shipboard By Maintenance Activities .......................................................................5-2

5.1.2 Consumable Materials ........................................................................................................................5-2

5.1.3 Fire Resistant Materials ......................................................................................................................5-3

5.1.4 Plastic Trash Cans .............................................................................................................................5-3

5.1.5 Plastic Bodied Tools ...........................................................................................................................5-3

5.1.6 Metal Canister Vacuum Cleaners .......................................................................................................5-3

5.1.7 Smoking Policies ................................................................................................................................5-4

5.1.8 Flammable Compressed Gas Cylinders ..............................................................................................5-4

5.1.9 Flammable and Combustible Liquid Usage .......................................................................................5-4

5.1.10 Combustible Materials and Waste .....................................................................................................5-4

5.1.11 Large Quantity Drums .......................................................................................................................5-4

5.1.12 Fueled Equipment-Moving Vehicles .................................................................................................5-4

5.1.13 Fueling Operations ............................................................................................................................5-4

5.1.14 Openings Above the Reactor Compartment. .....................................................................................5-5

5.2 Stowage of Ship’s Flammable and Combustible Material ...........................................................................5-5

5.2.1 Flammable Gas Stowage ....................................................................................................................5-5

5.2.2 Oxidizers ............................................................................................................................................5-5

5.2.3 CO2 Absorption Chemicals ................................................................................................................5-5

5.2.4 Refrigerant and Air Conditioning Gas Cylinders (R134, R114, R12, etc.) ........................................5-5

5.2.5 Ammunitions and Explosives .............................................................................................................5-5

5.2.6 Ship’s Hazardous Material Storage Facilities .....................................................................................5-5

5.3 Temporary Structures and Laydown Areas ..................................................................................................5-6

5.3.1 Temporary Structures ..........................................................................................................................5-6

5.3.2 Use of Wood........................................................................................................................................5-6

5.3.3 Sizing and Positioning of Structures ...................................................................................................5-7

5.3.4 Storage of Material ..............................................................................................................................5-7

FOR OFFICIAL USE ONLY xiv

FOR OFFICIAL USE ONLY S0570-AC-CCM-010/8010

ACN 3/A

5.4 Fire Safety Inspections .................................................................................................................................5-7

5.4.1 Fire Prevention And Safety Inspections .............................................................................................5-7

5.4.2 Minimum Requirements for Inspection ..............................................................................................5-7

Chapter 6 FIRE DETECTION...................................................................................................................................6-1

6.1 Temporary Installation Of Automatic Fire Detection System On Submarines. ...........................................6-1

6.1.1 Applicability .......................................................................................................................................6-1

6.1.2 Combination Smoke and Heat Detector Hardware Requirements......................................................6-2

6.1.3 Alarm Panel Hardware Requirements. ...............................................................................................6-3

6.1.4 Automatic Fire Detection System Installation Criteria. ......................................................................6-3

6.1.5 Automatic Fire Detection System Testing. .........................................................................................6-4

6.1.6 Automatic Fire Detection System Protection. ....................................................................................6-5

6.1.7 Automatic Fire Detection System Installation and Removal. .............................................................6-5

6.2 Temporary Installation Of Automatic Fire Detection Systems On Surface Ships And Aircraft Carriers. ..6-6

6.2.1 Fire Detection System. .......................................................................................................................6-6

6.2.2 Fire Detection System Protection. ......................................................................................................6-6

Chapter 7 FIREFIGHTING SYSTEMS ....................................................................................................................7-1

7.1 Fire Protection Systems. ...............................................................................................................................7-2

7.1.1 Firefighting Systems. ..........................................................................................................................7-2

7.1.2 Hazards of Fixed Extinguishing Systems. ........................................................................................7-10

7.1.3 Pumping and Dewatering Capability. ...............................................................................................7-11

7.1.4 Operation of Major Machinery in Engineering Spaces. ...................................................................7-11

7.1.5 Liquid Fuel Pumping and Transfer. ..................................................................................................7-11

7.1.6 Mechanical Aqueous Film Forming Foam Producing Equipment. ..................................................7-11

7.1.7 Portable Fire Extinguisher Requirements. ........................................................................................7-11

7.1.8 Hose and Hose Reel Protection. .......................................................................................................7-12

7.1.9 Dry Dock Firefighting Requirements. ..............................................................................................7-12

7.2 Submarines. ................................................................................................................................................7-13

7.2.1 General. ............................................................................................................................................7-13

7.2.2 Temporary Firemain and Water Supply. ..........................................................................................7-13

7.2.3 Temporary Topside Hose Station Manifolds. ...................................................................................7-14

7.2.4 Temporary Internal Hose Reels. .......................................................................................................7-15

7.2.5 Temporary Firemain, Hose Station, and Hose Reel Testing. ...........................................................7-16

7.2.6 Strategically Loaded SSBNs. ...........................................................................................................7-17

7.3 Surface Ships. .............................................................................................................................................7-18

7.3.1 General. ............................................................................................................................................7-18

7.3.2 Water Supply Requirements for Firefighting. ..................................................................................7-18

Chapter 8 ALARMS AND COMMUNICATIONS ...................................................................................................8-1

8.1 Shipboard Fire Reporting System.................................................................................................................8-1

8.1.1 Fire Reporting Devices. ......................................................................................................................8-1

8.1.2 Annunciator Panel. .............................................................................................................................8-2

8.1.3 Reporting to Emergency Dispatch Center. .........................................................................................8-2

8.1.4 Defective or Inoperative Alarms. .......................................................................................................8-2

8.1.5 Fire Reporting in Dry Dock. ...............................................................................................................8-2

FOR OFFICIAL USE ONLY xv

FOR OFFICIAL USE ONLY S0570-AC-CCM-010/8010

ACN 3/A

8.2 Casualty General Announcing System. ........................................................................................................8-2

8.2.1 Temporary System. ............................................................................................................................8-2

8.2.2 Testing of Systems. ............................................................................................................................8-2

8.2.3 Brief Outages. .....................................................................................................................................8-2

8.2.4 Hot Work. ...........................................................................................................................................8-2

8.2.5 Announcing on Barges and attached Structures .................................................................................8-2

8.3 Damage Control Central/CASCON Station, Submarines .............................................................................8-3

8.3.1 Location of CASCON Station. ...........................................................................................................8-3

8.3.2 Fire Detection System Alarm Panel. ..................................................................................................8-3

8.3.3 Required Items at CASCON Station. .................................................................................................8-3

8.4 Damage Control Central/Quarterdeck, Surface Ships. .................................................................................8-3

8.4.1 Damage Control Policies and Procedures. .........................................................................................8-3

8.4.2 Alternate DCC. ...................................................................................................................................8-3

8.4.3 DCC Located Off Ship. ......................................................................................................................8-3

8.4.4 Receiving and Escorting F&ES Officers. ...........................................................................................8-4

8.4.5 Required Items at DCC/Quarterdeck. .................................................................................................8-4

8.5 Stop Hot Work Alarm System. .....................................................................................................................8-4

8.5.1 Requirements. .....................................................................................................................................8-4

8.5.2 Installed Alarm and Announcing System. ..........................................................................................8-4

8.6 Evacuate Ship Alarm System. ......................................................................................................................8-4

8.6.1 Requirements. .....................................................................................................................................8-4

8.6.2 Installed Alarm and Announcing System. ..........................................................................................8-4

8.7 Portable Radios.............................................................................................................................................8-5

Chapter 9 LIGHTING ................................................................................................................................................9-1

9.1 Permanent Lighting Requirements ...............................................................................................................9-1

9.2 Temporary Lighting Requirements...............................................................................................................9-1

9.2.1 Lighting Guards. .................................................................................................................................9-1

9.2.2 Electric Cords. ....................................................................................................................................9-1

9.2.3 Exposed Non-current-carrying Metal Parts. .......................................................................................9-1

9.2.4 Portable Emergency Lighting Equipment. .........................................................................................9-1

9.2.5 Dark Spaces. .......................................................................................................................................9-1

9.2.6 Restricted Usage. ................................................................................................................................9-1

Chapter 10 SHIPBOARD ACCESS/EGRESS AND ROUTING OF TEMPORARY SERVICES .........................10-1

10.1 Shipboard Access And Egress Number And Location .............................................................................10-1

10.1.1 Egress Requirements (Submarines). ...............................................................................................10-1

10.1.2 Shipboard Access (Submarines). ....................................................................................................10-1

10.1.3 Access to Machinery Space (Surface Ships). .................................................................................10-2

10.1.4 Shipboard Access (Surface Ships). .................................................................................................10-2

10.1.5 Securing of Brow/Gangway. ..........................................................................................................10-2

10.2 Maintaining Access And Egress Condition ..............................................................................................10-2

10.2.1 Brow/Gangway Requirements. .......................................................................................................10-2

10.2.2 Safety Nets. ....................................................................................................................................10-2

10.2.3 Condition of Brow/Gangways. .......................................................................................................10-2

FOR OFFICIAL USE ONLY xvi

FOR OFFICIAL USE ONLY S0570-AC-CCM-010/8010

ACN 3/A

10.2.4 Marking Routes of Escape..............................................................................................................10-2

10.2.5 Use of Announcing System for Access and Egress Routes. ...........................................................10-2

10.2.6 Fall Protection. ...............................................................................................................................10-2

10.3 Emergency Air Breathing System (Submarines) ......................................................................................10-3

10.3.1 Required Emergency Air Breathing System...................................................................................10-3

10.3.2 Service to Maneuvering. .................................................................................................................10-3

10.3.3 Breathing Air Supply for Egress. ...................................................................................................10-3

10.4 Routing Of Temporary Services ...............................................................................................................10-3

10.4.1 Pre-plan for Temporary Services. ...................................................................................................10-3

10.4.2 Routing of Temporary Services Through Installed Ship Hull Openings. .......................................10-3

10.4.3 Additional Hull Cuts. .....................................................................................................................10-4

10.4.4 Materials used for Suspending Temporary Services. .....................................................................10-4

10.4.5 Temporary Services Isolation List. .................................................................................................10-4

10.4.6 Marking Temporary Services. ........................................................................................................10-4

10.4.7 Quick Disconnect Fittings. .............................................................................................................10-4

10.4.8 Air Flow Control. ...........................................................................................................................10-4

10.4.9 Service Lines Crossing Fire Zone Boundaries. ..............................................................................10-5

10.4.10 Protection during Installation, Operation and Removal of Temporary Services. .........................10-5

Chapter 11 FIRE AND SMOKE BOUNDARIES ....................................................................................................11-1

11.1 Fire Zone Boundaries. ..............................................................................................................................11-1

11.1.1 Requirements for Fire Zone Boundaries.........................................................................................11-1

11.1.2 Fire Zone Boundaries (Submarines). ..............................................................................................11-1

11.1.3 Temporary Access Cuts through Fire Zone Boundaries. ................................................................11-1

11.1.4 Disabling/Degrading Fire Zone Boundaries. ..................................................................................11-1

11.1.5 Marking Fire Zone Boundaries.......................................................................................................11-1

11.1.6 Record of Boundary Openings. ......................................................................................................11-1

11.1.7 Boundaries on Carrier Type Ships. .................................................................................................11-1

Chapter 12 FIRE DRILL REQUIREMENTS...........................................................................................................12-1

12.1 Periodic Fire Drills. ..................................................................................................................................12-1

12.2 Drill Attribute Requirements. ...................................................................................................................12-1

12.2.1 Attributes For All Fire Drills. .........................................................................................................12-1

12.2.2 Selective Attributes For Fire Drills. ...............................................................................................12-2

12.2.3 Burden Of Requirements. ................................................................................................................12-3

12.3 Drill Evaluation. .......................................................................................................................................12-4

12.4 Drill Team, Guides, And Post-Event Evaluation. ..............................................................................12-4

12.4.1 SRCA Drill Team. ..........................................................................................................................12-4

12.4.2 Drill Guide......................................................................................................................................12-4

12.4.3 Drill Termination. ...........................................................................................................................12-4

12.4.4 Response To Actual Casualty. ........................................................................................................12-4

12.4.5 Realistic Fire Scenario. ...................................................................................................................12-4

12.4.6 Minimize Simulations. ...................................................................................................................12-5

12.4.7 SRCA Response. ............................................................................................................................12-5

12.4.8 Drill Hotwash. ................................................................................................................................12-5

FOR OFFICIAL USE ONLY xvii

FOR OFFICIAL USE ONLY S0570-AC-CCM-010/8010

ACN 3/A

12.4.9 Drill Evaluation. .............................................................................................................................12-5

12.4.10 Written Report. .............................................................................................................................12-5

12.4.11 Action For An Unsatisfactory Grade. ...........................................................................................12-5

12.4.12 Submitting The Report. ................................................................................................................12-5

12.4.13 Fire Response Capabilities During The Drill. ..............................................................................12-5

12.4.14 Duration Of Drills. .......................................................................................................................12-5

12.5 Drill Frequency. ........................................................................................................................................12-6

12.5.1 Back-Shift Drill. .............................................................................................................................12-6

12.5.2 Waiver Of Drill Requirements. ......................................................................................................12-6

12.5.3 Periodicity Waiver ..........................................................................................................................12-6

Chapter 13 MAJOR FIRE DRILL REQUIREMENTS ............................................................................................13-1

13.1 Drill Attribute Requirements. ...................................................................................................................13-1

13.2 Drill Evaluation. .......................................................................................................................................13-3

13.3 DRILL TEAM, GUIDES, AND POST-EVENT EVALUATION. ..........................................................13-4

13.3.1 Major Fire Drill Team. ...................................................................................................................13-4

13.3.2 Drill Evaluators. .............................................................................................................................13-4

13.3.3 Drill Guide......................................................................................................................................13-4

13.3.4 Drill Hotwash. ................................................................................................................................13-5

13.3.5 Drill Evaluation Team. ...................................................................................................................13-5

13.3.6 Evaluation of Simulated Press Conference/Availability. ...............................................................13-6

13.3.7 NAVSEA and CNIC Review. ........................................................................................................13-6

13.3.8 Drill Brief, Execution, and Debrief Schedule. ................................................................................13-6

13.3.9 Written Evaluations/Reports. .........................................................................................................13-6

13.3.10 Nuclear Powered Warships. .........................................................................................................13-6

13.3.11 Nonnuclear Powered Warships At Private Repair SRCAs. ..........................................................13-6

Chapter 14 SPECIAL SUBMARINE SHIPBOARD FIRE HAZARDS ..................................................................14-1

14.1 General. ....................................................................................................................................................14-1

14.2 Battery Compartment Casualties ..............................................................................................................14-1

14.2.1 General. ..........................................................................................................................................14-1

14.2.2 Hydrogen Explosion. ......................................................................................................................14-1

14.3 Special Hull Treatment (SHT) Fires in Dry Dock ....................................................................................14-2

14.3.1 General. ..........................................................................................................................................14-2

14.3.2 SHT Materials. ...............................................................................................................................14-2

14.3.3 Flammability and Fire Spread. .......................................................................................................14-2

14.3.4 SHT Flammability. .........................................................................................................................14-2

14.3.5 Fire Spread. ....................................................................................................................................14-2

14.3.6 Extinguishing Methods. ..................................................................................................................14-2

14.3.7 Fire Attack. .....................................................................................................................................14-3

FOR OFFICIAL USE ONLY xviii

FOR OFFICIAL USE ONLY S0570-AC-CCM-010/8010

ACN 3/A

Appendix A

Principles of Emergency Response for a Shipboard Fire ...................................................................................A-1

Appendix B

Fully Developed Incident Management Structure for Shipboard Fire Emergency............................................. B-1

Appendix C

Engineered Fire Response Strategy .................................................................................................................... C-1

Appendix D

Rapid Response Damage Control CONEX Box, Submarines ............................................................................D-1

Appendix E

SSN-688 Class; Approximate Locations for Combination Smoke and Heat Detectors ..................................... E-1

Appendix F

SSN-21 Class; Approximate Locations for Combination Smoke and Heat Detectors ....................................... F-1

Appendix G

SSN-774 Class; Approximate Locations for Combination Smoke and Heat Detectors .....................................G-1

Appendix H

SSBN/SSGN-726 Class; Approximate Locations for Combination Smoke and Heat Detectors ......................H-1

Appendix I

Combination

Smoke and Heat Detector Spacing ...................................................................................................................... I-1

Appendix J

Sample Air and Smoke Control Curtain and Sock .............................................................................................. J-1

Appendix K

Drill Guide and Authorization Forms .................................................................................................................K-1

Appendix L

Glossary .............................................................................................................................................................. L-1

Appendix M

List of Acronyms ............................................................................................................................................... M-1

Appendix N

Press Statement...................................................................................................................................................N-1

Appendix O

Ship Plan of the Day ...........................................................................................................................................O-1