Professional Documents

Culture Documents

PC300LC-6 (A80001 - )

PC300LC-6 (A80001 - )

Uploaded by

julianoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PC300LC-6 (A80001 - )

PC300LC-6 (A80001 - )

Uploaded by

julianoCopyright:

Available Formats

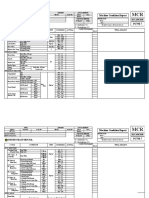

PM-TUNE UP DATA SHEET PC300LC-6

BASE INFORMATION

Customer Name Location

Serial No. (A80001 and up) Engine model Engine No.

SA6D114E-1

Attachment / Shoe Width

Boom Arm Bucket Shoe Width

3

Standard Standard Bucket ( yd )

Super Long Short Ripper ( make)

( mm) Hydraulic Breaker

Other ( )

Kind Of Job

Mining Highway & Road

Forestry Demolition

Construction Water supply

Scrap Others

Kind Of Operation

Land cleaning Digging & Loading Basement digging Foundation

Ditching Feller buncher Delimber Grapple

Grading (Leveling) Pipe laying Log loader Breaker

Magnet Slope finishing Back fill Thumb

Shear Other

Result Report Inspector:_____________________ Date: / /

Inspection result Repair required (Detail in below)

Good Adjustment done (detail below) FIRST AID repair done(detail below)

Adjustment done LS relief valve LS valve (F) LS valve (R) Main Relief valve (F) M. R. V. (R)

TVC valve (F) TVC valve (R) L.H. swing motor safety valve Fuel control linkage

Control pump relief valve & strainer R.H. swing motor safety valve Others________________________

FIRST AID repair Oil leakage repair, O-ring Oil leakage repair, seal tape

Grease nipple replacement Fuse replacement Wire harness repair, connector repair

Repair Solenoid (_________________) Pressure switch (______________)

Diode replacement Others (___________________)

Repair Recommendation _________________________________________________________________

____________________________________________________________________________________________________

____________________________________________________________________________________________________

Customer Signature ______________________________________________________

Care Code: TPC164-0 / 02-97 Page 1 of 3

PC300LC-6 Serial No.

Work Order No. Carried Out Date Service Meter Inspected By

Before Starting, Walk-around Check ............................... SAT UNSAT

Level Checking .................................................................. SAT UNSAT

Engine coolant Engine Oil Hydraulic Oil

Self-Diagnostic Display (Key switch ON)

Service Code (Trouble Data) -- : -- : SAT UNSAT

: -- :

Service Code Elapsed Time

Engine Inspection

Set the MONITORING CODE “10" to Engine Speed (x 10 rpm) on the monitor panel.

Before starting, make tool connection of blow-by and 10 kg/cm2 gauge for lubrication.

# Condition Mode Fuel dial Inspection Standard Permissible Actual U S After Adjust

1 Idling Full Eng. 2000 - 2000 -

(100%) with H/O (rpm) 2100 2100

2 slight travel Auto- Oil pres. Min. 2.11 Min. 2.11

control Deceleration (kg/cm2)

3 Idling Low OFF Eng. 850 - 950 850 - 950

(rpm)

4 Oil pres. Min. 0.7 Min. 0.7

2

(kg/cm )

5 Arm Relief Eng. 1690 - 1640 -

POWER UP (rpm) 1790 1840

6 switch ON Blow-by Max. 152 Max. 635

(mm H20)

7 Auto-Decel H/O Eng. 1300 - 1300 -

Auto-Decel ON (rpm) 1500 1500

Working Speed Inspection (Unit: Sec.)

1 No load H/O, Boom 3.5 - Max. 4.7

Full extend Full RAISE 4.3

2 Arm 3.1 - Max. 4.0

OUT 3.7

3 Boom 3.5 - Max. 4.6

horizontal 4.3

4 position F/O, Arm 4.0 - Max. 5.0

Full IN 5.0

5 L/O, 4.5 - Max. 5.5

Full 5.5

6 Boom & Arm Bucket 2.9 - Max. 3.8

horizontal H/O, CURL 3.5

7 5 turns Full Swing RH 28.5 - Max. 35

after 1 turn LH 31.5

8 5 turns of Speed RH 30.4 - 30.4 -

lifted track HI LH 37.8 41.5

rotation Speed RH 37.3 - 37.3 -

after 1 turn Mid LH 45.9 49.9

Speed RH 44.8 - 44.8 -

Low LH 56.6 62.5

9 Eng. Stop 15 min, Total hyd. Max. Max.

Rated load drift (mm) 450 675

Care Code: TPC164-0 / 02-97 Page 2 of 3

PC300LC-6 Serial No.

Hydraulic Pressure(Unit: kg/cm2)

# Checking Checking Mode Stan- Permis- Control Main (F) TVC o/p Main (R) TVC o/p Result After

Item Condition fuel dial dard sible 60K 600K (F) 600K 600K (R) 600K S U Adjust

Control All levers in H/O, 30 - 30 -

1 pump & NEUTRAL Slow 36 36

Relief valve H/O, 30 - 30 -

Full 36 36

2 Main Unload All levers in H/O 30 - 30 -

valve NEUTRAL Full 50 50

3 Front sub- Swing accel 30 - 30 -

unload valve Boom RAISE 50 50

4 Rear sub- Swing accel 30 - 30 -

unload valve Arm in 50 50

5 2-pumps Boom RAISE 335 - 330 -

Main & Safety V 355 365

6 2-pumps Boom RAISE 345 - 340 -

Main & Safety V Power Up on 365 370

7 2-pumps Arm IN 335 - 330 -

Main & Safety V 355 365

8 2-pumps Arm IN 345 - 340 -

Main & Safety V Power Up on 365 370

9 2-pumps Bucket CURL 335 - 330 -

Main & Safety V 355 365

10 2-pumps merge Bucket CURL 345 - 340 -

Main & Safety V Power Up on 365 370

11 1-pump (Front) Swing Lock off 300 - 290 -

Valve & swing Swing RH 325 330

12 relief valve Swing Lock off 300 - 290 -

(LH & RH) Swing LH 325 330

13 1-pump (Front), LH travel 345 - 340 -

Motor, Main rel., FORWARD 375 380

14 Port safety V & LH travel 345 - 340 -

Swivel joint REVERSE 375 380

15 1-pump (Rear) RH travel 345 - 340 -

Motor, Main rel., FORWARD 375 380

16 Port safety V & RH travel 345 - 340 -

Swivel joint REVERSE 375 380

Main Pump (Unit: kg/cm2)

1 Main pump During arm H/O, Full

servo piston OUT

2 & TVC valve Arm relieved

w/ Power Up

3 LS valve During H/O, Full,

(F & R) Swing (F) Lever

4 During ½ stroke

Curl (R)

Care Code: TPC164-0 / 02-97 Page 3 of 3

You might also like

- 210GLC Catálogo de PeçasDocument1,104 pages210GLC Catálogo de Peçasjuliano100% (4)

- 230 Magma Crack Sealer Operator ManualDocument44 pages230 Magma Crack Sealer Operator Manualdominicparramore100% (2)

- Axial Piston Variable Motor A6Vm: Series 71Document40 pagesAxial Piston Variable Motor A6Vm: Series 71juliano100% (1)

- S6R2 T2MPTK 3Document18 pagesS6R2 T2MPTK 3Stenny Lumi100% (5)

- Sumitomo SH130-5 EMDocument79 pagesSumitomo SH130-5 EMLin Lin100% (3)

- 2010 Toyota Corolla Le 1.8l Common Specs & ProceduresDocument4 pages2010 Toyota Corolla Le 1.8l Common Specs & ProceduresRuben100% (1)

- Oreda Volume 1 PDFDocument794 pagesOreda Volume 1 PDFdigeca100% (2)

- RCH +D + +F+¡ (+ ) PDFDocument38 pagesRCH +D + +F+¡ (+ ) PDFSyamil DzulfidaNo ratings yet

- De2435 5780Document3 pagesDe2435 5780Edinson Ariel Chavarro QuinteroNo ratings yet

- 04-SAMSS-048 Valve Inspection and Testing RequirementsDocument8 pages04-SAMSS-048 Valve Inspection and Testing RequirementsHAYKEL79100% (1)

- SCOPE-1 SECTION-2 CommssinoingDocument109 pagesSCOPE-1 SECTION-2 Commssinoingahmed100% (1)

- PC150LC-6 (K30001 - K31999)Document3 pagesPC150LC-6 (K30001 - K31999)julianoNo ratings yet

- PM Clinic Excavator PDFDocument3 pagesPM Clinic Excavator PDFjheison valencia100% (1)

- Pm-Clinic Data Sheet Wd900-3 Base Information: Customer Name LocationDocument3 pagesPm-Clinic Data Sheet Wd900-3 Base Information: Customer Name LocationJuan Pablo Muñante Palacin100% (1)

- PM Clinic WA500-3LEDocument3 pagesPM Clinic WA500-3LEJheison ValenciaNo ratings yet

- PM Clinic Dozers KomatsuDocument3 pagesPM Clinic Dozers Komatsujheison valencia100% (1)

- Pm-Clinic Data Sheet Wa180-3L Base Information: Customer Name LocationDocument3 pagesPm-Clinic Data Sheet Wa180-3L Base Information: Customer Name LocationjulianoNo ratings yet

- PM ClinicDocument2 pagesPM CliniccristianNo ratings yet

- Specification Sheet of S6R2-T2MPTK Marine Diesel Engine: Item No. M0209-0012E Date April 2013Document4 pagesSpecification Sheet of S6R2-T2MPTK Marine Diesel Engine: Item No. M0209-0012E Date April 2013Nguyễn Văn CảnhNo ratings yet

- Machine Inspection Form ExcavatorDocument27 pagesMachine Inspection Form ExcavatorAwanNo ratings yet

- S6R2 T2MPTK 3 2019Document17 pagesS6R2 T2MPTK 3 2019strts100% (1)

- Appendix A - Factory Specifications PDFDocument40 pagesAppendix A - Factory Specifications PDFRobert RooseNo ratings yet

- S6R Z3mptawDocument14 pagesS6R Z3mptawbachcongphuocNo ratings yet

- Al1e8c5a PDFDocument1 pageAl1e8c5a PDFlucian07No ratings yet

- Pmeh103000 - PC200 (LC) - 7 200001Document3 pagesPmeh103000 - PC200 (LC) - 7 200001phengNo ratings yet

- Pm-Clinic Service: PMEH102200Document3 pagesPm-Clinic Service: PMEH102200Naughty VongNo ratings yet

- 1a3 Двигатель. Общая ИнформацияDocument15 pages1a3 Двигатель. Общая ИнформацияLuis Alberto BernalNo ratings yet

- MMR4 6105 Series Operation and Service ManualDocument46 pagesMMR4 6105 Series Operation and Service ManualJavier H Durán ValeroNo ratings yet

- SH330-3B Product Training: Sumitomo (S.H.I) Construction Machinery Manufacturing Co.,LtdDocument56 pagesSH330-3B Product Training: Sumitomo (S.H.I) Construction Machinery Manufacturing Co.,LtdsuriantoNo ratings yet

- Data Book: Automotive TechnicalDocument1 pageData Book: Automotive TechnicalDan RosoiuNo ratings yet

- Denso Bomba 092000-3690Document3 pagesDenso Bomba 092000-3690Superlativo Igv100% (1)

- Mitsubishi Generator Engine SpecDocument5 pagesMitsubishi Generator Engine SpechuynhuanNo ratings yet

- Pm-Clinic Service: SEPD308400Document5 pagesPm-Clinic Service: SEPD308400Naughty VongNo ratings yet

- Chassis PDFDocument1,037 pagesChassis PDFDamir MilisaNo ratings yet

- Service Manual: 26000lb-35000lb (12t-16t)Document49 pagesService Manual: 26000lb-35000lb (12t-16t)lcravenNo ratings yet

- 14 PDFDocument4 pages14 PDFKrzyś UrynowiczNo ratings yet

- Specification: Model: Hyd. Crawler Drill (JD-1400E) CustomerDocument10 pagesSpecification: Model: Hyd. Crawler Drill (JD-1400E) CustomerSerkanAlNo ratings yet

- MCR PC200-8Document7 pagesMCR PC200-8FaridNo ratings yet

- Data Book: Automotive TechnicalDocument1 pageData Book: Automotive TechnicalmasakpNo ratings yet

- Technical Service Bulletin: Service Action: Inspection For Noise From Engine Under Specific Conditions (Sa 141)Document5 pagesTechnical Service Bulletin: Service Action: Inspection For Noise From Engine Under Specific Conditions (Sa 141)Diego Fabian Vega AlpizarNo ratings yet

- HY2DCDFDocument1 pageHY2DCDFRobin Taylor EderNo ratings yet

- IsuzuDocument1 pageIsuzuFarhan Sheikh100% (1)

- Data Book: Automotive TechnicalDocument1 pageData Book: Automotive TechnicalFelipe Arantes LoboNo ratings yet

- United Tractors TBK.: Machine Condition ReportDocument3 pagesUnited Tractors TBK.: Machine Condition Reportonthel rastafaraNo ratings yet

- GV Aaa vr6 92-97Document1 pageGV Aaa vr6 92-97PETER PRAVUYNo ratings yet

- Fiat Cinquecento 1992 1993 User ManualDocument1 pageFiat Cinquecento 1992 1993 User ManualJORGE ORTEGANo ratings yet

- VV4F6244 PDFDocument1 pageVV4F6244 PDFMorizuki TatsumiNo ratings yet

- VV4F6244 PDFDocument1 pageVV4F6244 PDFMorizuki TatsumiNo ratings yet

- G1190bev11 353 PDFDocument33 pagesG1190bev11 353 PDFRogérioFreitasNo ratings yet

- Test Specifications Test Injector: Opening Pressure: For Field Service OnlyDocument2 pagesTest Specifications Test Injector: Opening Pressure: For Field Service OnlyAadil KhanNo ratings yet

- Data Book: Automotive TechnicalDocument1 pageData Book: Automotive TechnicalPercy Cruz CarbajalNo ratings yet

- Important Information: Section 1B - MaintenanceDocument20 pagesImportant Information: Section 1B - Maintenanceibrahimvisham99No ratings yet

- Inbound 1217643508344806349Document165 pagesInbound 1217643508344806349miha.9941No ratings yet

- Injection Pump Test SpecificationsDocument1 pageInjection Pump Test SpecificationsMiguel RojasNo ratings yet

- PLC Aft 1.6 96-97Document1 pagePLC Aft 1.6 96-97gvmarianoNo ratings yet

- Technical Data Mitshubishi S12R-PTA-CDocument4 pagesTechnical Data Mitshubishi S12R-PTA-CAbazhNo ratings yet

- Reporting PPM D155A-6 Baskhara Sinar SaktiDocument9 pagesReporting PPM D155A-6 Baskhara Sinar SaktiCandy 888No ratings yet

- HYF6E6FDocument1 pageHYF6E6FRobin Taylor EderNo ratings yet

- Data Book: Automotive TechnicalDocument1 pageData Book: Automotive TechnicalDan RosoiuNo ratings yet

- PM Tune Up Service: SEPD3077Document5 pagesPM Tune Up Service: SEPD3077rohmin ibrahimNo ratings yet

- Heavy FV 51 MWB - 13sp Manual 12sp AMT Steel SuspensionDocument4 pagesHeavy FV 51 MWB - 13sp Manual 12sp AMT Steel Suspensionajay dattNo ratings yet

- 05 - Fuel SystemDocument119 pages05 - Fuel SystemWimpie KeyterNo ratings yet

- Marine Gyro-Compasses and Automatic Pilots: A Handbook for Merchant Navy OfficersFrom EverandMarine Gyro-Compasses and Automatic Pilots: A Handbook for Merchant Navy OfficersRating: 5 out of 5 stars5/5 (2)

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- PC150LC-6 (K30001 - K31999)Document3 pagesPC150LC-6 (K30001 - K31999)julianoNo ratings yet

- Pc78us-6 (4001 - )Document4 pagesPc78us-6 (4001 - )julianoNo ratings yet

- Motor Saa6d107e 1cc S N 26540705 Up (Motor)Document165 pagesMotor Saa6d107e 1cc S N 26540705 Up (Motor)julianoNo ratings yet

- Gd655 5 S N b40001 Up (1º Parte)Document240 pagesGd655 5 S N b40001 Up (1º Parte)juliano100% (1)

- Gd655 5 S N b40001 Up (2º Parte)Document237 pagesGd655 5 S N b40001 Up (2º Parte)juliano100% (1)

- SM 95E-5 Series SEN01966-01Document311 pagesSM 95E-5 Series SEN01966-01julianoNo ratings yet

- Service ManualDocument44 pagesService ManualjulianoNo ratings yet

- Catálogo de Operação e Manut. WA180-3Document200 pagesCatálogo de Operação e Manut. WA180-3julianoNo ratings yet

- Escavadeira 200DLCDocument16 pagesEscavadeira 200DLCjulianoNo ratings yet

- Proportional Valve GroupDocument36 pagesProportional Valve GroupjulianoNo ratings yet

- Valve Automation NEWDocument24 pagesValve Automation NEWNyoman RakaNo ratings yet

- US9010371 - Anti Cavitation TrimDocument14 pagesUS9010371 - Anti Cavitation Trimshan07011984No ratings yet

- Solenoid Valve For Aggressive Fluids,: Direct ActingDocument4 pagesSolenoid Valve For Aggressive Fluids,: Direct ActingimtiyazNo ratings yet

- Mold Cooling SystemDocument8 pagesMold Cooling SystemImedooImedNo ratings yet

- CT WKM Gate Saf T Seal 01 PDFDocument36 pagesCT WKM Gate Saf T Seal 01 PDFchonubobbyNo ratings yet

- AVK MY PricelistDocument41 pagesAVK MY Pricelistmaxsteel05No ratings yet

- LogixPro CISE 313 Automation Devices and Electronics Lab ManualDocument36 pagesLogixPro CISE 313 Automation Devices and Electronics Lab ManualHelder NascimentoNo ratings yet

- Circ Water System VoDocument89 pagesCirc Water System Vomahesh6agNo ratings yet

- Cash Valve Type FRDocument8 pagesCash Valve Type FRHilario GomezNo ratings yet

- High Purity SeriesDocument20 pagesHigh Purity SeriesPolmaNo ratings yet

- SWG-22-8571 Ersatzteile Fahrmischer en RZDocument9 pagesSWG-22-8571 Ersatzteile Fahrmischer en RZsantoshNo ratings yet

- BroilerDocument35 pagesBroilerFernandoPitangaQuirinoNo ratings yet

- D100025X012 PDFDocument28 pagesD100025X012 PDFJairo andres Guarnizo SuarezNo ratings yet

- DD Electric Driven Fire Pump SpecificationDocument16 pagesDD Electric Driven Fire Pump SpecificationNurcahyo Djati WNo ratings yet

- Manual de Instalación Bomba Quintuplex Pentair MA-300Document32 pagesManual de Instalación Bomba Quintuplex Pentair MA-300zayagoraNo ratings yet

- Hy17 8537Document12 pagesHy17 8537thierrylindoNo ratings yet

- APPENDIX 1-1. Preferred Manufacturers List InstrumentationDocument4 pagesAPPENDIX 1-1. Preferred Manufacturers List InstrumentationMarcos Nava BarbozaNo ratings yet

- Activity 2Document3 pagesActivity 2ron Joshua QuirapNo ratings yet

- Rolairtrol/SRS Manual Blowdown Valve: Submittal A-329ADocument1 pageRolairtrol/SRS Manual Blowdown Valve: Submittal A-329AissamalhitiNo ratings yet

- Simplex HandpumpsDocument11 pagesSimplex HandpumpsMichalis GeorgiouNo ratings yet

- Hydraulic Power UnitDocument44 pagesHydraulic Power UnitDustin WhiteNo ratings yet

- AIGA 090 - 14 - Reference Guide For Requalification of Gas CylindersDocument13 pagesAIGA 090 - 14 - Reference Guide For Requalification of Gas CylindersEmran UmerNo ratings yet

- EH750-3 Hitachi Euclid Rigid Hauler Hydraulic Training 2nd PartDocument15 pagesEH750-3 Hitachi Euclid Rigid Hauler Hydraulic Training 2nd Partthan zaw win100% (1)

- Overview Eng CD PDFDocument20 pagesOverview Eng CD PDFRafael Cortes100% (1)

- Doosan DX027Z Parts ManualDocument350 pagesDoosan DX027Z Parts Manualmccqadi100% (2)

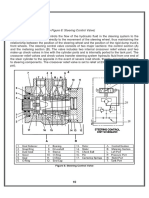

- Directional Control ValveDocument25 pagesDirectional Control Valvelittle khansaNo ratings yet