Professional Documents

Culture Documents

Decathlon Udl Check

Decathlon Udl Check

Uploaded by

Anonymous Clm40C1Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Decathlon Udl Check

Decathlon Udl Check

Uploaded by

Anonymous Clm40C1Copyright:

Available Formats

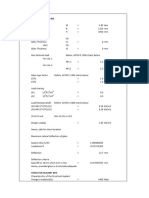

CONCRETE INDUSTRIAL GROUND FLOOR SLAB

DESIGN

In accordance with TR34, 4th Edition 2013

Design summary Load 1 -

UDL 50 kN/m2

Description Unit Provided Required Utilisation Result

Slab capacity in flexure kN/m2 50.9 50.0 0.982 PASS

Slab details

Reinforcement type Steel bar

Concrete class C25

Slab thickness h = 150 mm

Residual strength at CMOD 0.5 fR,1 = 2.200 N/mm2

Residual strength at CMOD 1.5 fR,2 = 2.000 N/mm2

Residual strength at CMOD 2.5 fR,3 = 1.800 N/mm2

Residual strength at CMOD 3.5 fR,4 = 1.500 N/mm2

Mean axial tensile strength relating to CMOD 0.5 r1 = 0.45 fR,1 = 0.990 N/mm2

Mean axial tensile strength relating to CMOD 3.5 r4 = 0.37 fR,4 = 0.555 N/mm2

Characteristic strength of reinforcement fyk = 415 N/mm2

Diameter of reinforcement; s = 8 mm

Spacing of reinforcement; ss = 200 mm

Area of bottom steel provided As,prov = 251 mm2/m

Nominal cover cnom_b = 54 mm

Effective depth of reinforcement d = h - cnom_b - s = 88 mm

Partial safety factors

Concrete (with or without fibre) c = 1.50

Reinforcement (bar or fabric) s = 1.15

Permanent; G = 1.20

Variable Q = 1.50

Dynamic loads D = 1.60

Subgrade reaction

Modulus of subgrade reaction k = 0.030 N/mm3

Concrete details - Table 6.1. Strength properties for concrete

Characteristic compressive cylinder strength fck = 25 N/mm2

Characteristic compressive cube strength fcu = 30

N/mm2

Mean value of compressive cylinder strength fcm = fck + 8 N/mm2 = 33 N/mm2

Mean value of axial tensile strength fctm = 0.3 N/mm2 (fck/ 1 N/mm2)2/3 = 2.6

N/mm2 Flexural tensile strength fctd,fl = fctm (1.6 - h / 1m) / c = 2.5 N/mm2

Design concrete compressive strength (cylinder) fcd = fck / c = 16.7 N/mm2

Secant modulus of elasticity of concrete Ecm = 22 kN/mm2[fcm/ 10 N/mm2]0.3 = 31

kN/mm2 Poisons ratio = 0.2

Radius of relative stiffness (Eqn. 20) l = [Ecm h3 / (12 (1 - 2) k)]0.25 = 745

mm Characteristic of system (Eqn. 33) = (3 k / (Ecm h3))0.25 = 0.959 m-1

Moment capacity

Depth to neutral axis (found by iteration) hux = 13.2 mm

Negative moment capacity (Eqn. 2) Mn = Mun = fctd,fl (h2 / 6) = 9.3 kNm/m

Positive moment capacity (Eqn. 10) Mp = Mu_fib,As = (0.5 (r1 - r4) (h - hux) (0.28 hux + 0.33 h)) / c + (r4

(h - hux) (0.11 hux + 0.5 h)) / c + (As,prov fyk (d - 0.39 hux)) / s =12.4

kNm/m

Ratio of cracked to uncracked mnt of resist (cl.7.4) Mp / Mn = 1.338

PASS - Ratio of cracked to uncracked moment of resistance is greater or equal to 0.5

Load 1 - UDL 50 kN/m2

1637

Maximum positive bending moment loading pattern

3275

1637 3275

Maximum negative bending moment loading pattern

Working load capacity of UDL

UDL Uk = 50.0 kN/m2

Critical aisle width lcrit = / (2 ) = 1637 mm

Loaded width of single UDL (max positive moment); lload_p = / (2 ) = 1637 mm

Loaded width of dual UDL (max nagative moment) lload_n = / = 3275 mm

Working load capcity of slab q = 5.95 2 Mn = 50.9

kN/m2

Utilisation Uk / q = 0.982

PASS - Total slab capacity exceeds applied load

You might also like

- Geomechanics Course BAKER HUGHES 2007 PDFDocument671 pagesGeomechanics Course BAKER HUGHES 2007 PDFFernandoAntonioAlvarezPacheco100% (1)

- Access Scaffolding CalculationDocument8 pagesAccess Scaffolding CalculationOsama Tahir100% (4)

- Design of Curtain WallDocument2 pagesDesign of Curtain WallRaju Saini100% (1)

- Design Calculation of Pile FoundationDocument3 pagesDesign Calculation of Pile Foundationkavitha100% (5)

- Concrete Industrial Ground Floor Slab (TR34)Document3 pagesConcrete Industrial Ground Floor Slab (TR34)David Thomson100% (5)

- 9.design of JIB Crane Supporting StructuresDocument14 pages9.design of JIB Crane Supporting Structuresepe civilNo ratings yet

- New Microsoft Excel WorksheetDocument4 pagesNew Microsoft Excel Worksheetvenu manikantaNo ratings yet

- WARNING - Reinforcement Exceeds Maximum Recommended 0.125%: TEDDS Calculation Version 1.0.05Document3 pagesWARNING - Reinforcement Exceeds Maximum Recommended 0.125%: TEDDS Calculation Version 1.0.05muhammed sabir v aNo ratings yet

- Concrete Industrial Ground Floor Slab Desig1Document3 pagesConcrete Industrial Ground Floor Slab Desig1Mahata PriyabrataNo ratings yet

- Engineering and Development Corporation of The PhilippinesDocument4 pagesEngineering and Development Corporation of The Philippinesmark ignacioNo ratings yet

- 200 THK Grade Slab-50kn Variable Load-With FibreDocument7 pages200 THK Grade Slab-50kn Variable Load-With FibreFazilat Mohammad Zaidi0% (1)

- Design of Transom: Wind LoadDocument2 pagesDesign of Transom: Wind LoadRaju SainiNo ratings yet

- Busugan Part 2 Design BSDSDocument257 pagesBusugan Part 2 Design BSDSmarco miguelNo ratings yet

- Access Scaffolding CalculationDocument8 pagesAccess Scaffolding CalculationSarah HaiderNo ratings yet

- Client: Reem General Contracting Est. Al Jubail, Dammam, Commercial Street Kingdom of Saudi Arabia Al KhobarDocument3 pagesClient: Reem General Contracting Est. Al Jubail, Dammam, Commercial Street Kingdom of Saudi Arabia Al KhobarUday UdmaleNo ratings yet

- Design of 200KL CWRDocument8 pagesDesign of 200KL CWRRajendra MittalNo ratings yet

- Slab CrackwidthDocument15 pagesSlab CrackwidthMohammed Saleem Syed KhaderNo ratings yet

- Slab 2Document13 pagesSlab 2nr.husninathirahNo ratings yet

- Structure Analysis Design Report FinalDocument21 pagesStructure Analysis Design Report FinalRajendra MittalNo ratings yet

- S-1 Stilt Floor: Edge ConditionDocument7 pagesS-1 Stilt Floor: Edge ConditionMohdDanishNo ratings yet

- Slab and StaircaseDocument8 pagesSlab and StaircaseSamikshya ShahNo ratings yet

- Prestressed Solid Slab Design As Per Aci CodeDocument4 pagesPrestressed Solid Slab Design As Per Aci CodeAamir SuhailNo ratings yet

- Fence Type-3: Design Calculation Sheet HYD-121 FenceDocument18 pagesFence Type-3: Design Calculation Sheet HYD-121 FenceAbhilash KowndinyaNo ratings yet

- Composite BeamDocument2 pagesComposite BeamJustin MusopoleNo ratings yet

- FRP LaminatesDocument9 pagesFRP LaminatesAnhera enterpriseNo ratings yet

- Elevated Service ReservoirDocument35 pagesElevated Service ReservoirRamachandra SahuNo ratings yet

- Composite Slab For Proposed Residential House-1Document7 pagesComposite Slab For Proposed Residential House-1JosephNo ratings yet

- Strut Analysis and Design at - 0.5Document4 pagesStrut Analysis and Design at - 0.5SGOCTNo ratings yet

- Aci 95Document14 pagesAci 95Joseph AsfourNo ratings yet

- Concrete Industrial Ground Floor Slab Design (TR34)Document3 pagesConcrete Industrial Ground Floor Slab Design (TR34)Nihar ShahNo ratings yet

- 150mm Thick FloorDocument11 pages150mm Thick FloorAnil UdaleNo ratings yet

- Floor Details: Tatprofiled SteelDocument14 pagesFloor Details: Tatprofiled SteelshaimenneNo ratings yet

- Floor Details: Tatprofiled SteelDocument14 pagesFloor Details: Tatprofiled SteelshaimenneNo ratings yet

- ACCESS EnjazDocument21 pagesACCESS Enjazmoh abobajeeNo ratings yet

- ASASDocument18 pagesASASmohamadNo ratings yet

- Strut Analysis and Design at - 10.00Document4 pagesStrut Analysis and Design at - 10.00SGOCTNo ratings yet

- Design of Prestressed Concrete SlabsDocument6 pagesDesign of Prestressed Concrete SlabsRaveendra Babu CherukuriNo ratings yet

- Report 30 TonDocument10 pagesReport 30 TonMARYANo ratings yet

- Report 30 TonDocument10 pagesReport 30 TonMARYANo ratings yet

- Design of One Way Slab (Continuous) : Given DataDocument3 pagesDesign of One Way Slab (Continuous) : Given DataParwan ExceltechNo ratings yet

- Plank DesignDocument2 pagesPlank DesignManinder ChaudharyNo ratings yet

- Design of SlabDocument26 pagesDesign of SlabMukesh Jangid100% (2)

- DG - Slab Design SDocument7 pagesDG - Slab Design Ssaaz adil100% (1)

- Design of Two Way SlabDocument8 pagesDesign of Two Way SlabdhanarajNo ratings yet

- Job No Name Calculation For Long Term Deflection: CK 2 y 2 2 S 2Document4 pagesJob No Name Calculation For Long Term Deflection: CK 2 y 2 2 S 2Gaurav MalyaNo ratings yet

- BS5400 R.C Design With Crack WidthDocument9 pagesBS5400 R.C Design With Crack WidthWangTF100% (4)

- Concrete Industrial Ground Floor Design To Tr34 Third EditionDocument3 pagesConcrete Industrial Ground Floor Design To Tr34 Third EditionRuemu Godwin InikoriNo ratings yet

- Two Short Edge Discontinuous Slab 3x3 M (OK)Document4 pagesTwo Short Edge Discontinuous Slab 3x3 M (OK)M. YUNIZAR ADIWIBOWONo ratings yet

- Design of Isolated Footing For Security Room: Node No. XDDocument12 pagesDesign of Isolated Footing For Security Room: Node No. XDvenu manikantaNo ratings yet

- Box CulvertDocument9 pagesBox CulvertVarun TyagiNo ratings yet

- FCK XR Xfy FCK FCK XR Xfy FCKDocument5 pagesFCK XR Xfy FCK FCK XR Xfy FCKAnonymous jLLjBdrNo ratings yet

- 04 - Design of PS-33Document5 pages04 - Design of PS-33karthiNo ratings yet

- Design of Two Way Slab (Continuous) : Given DataDocument3 pagesDesign of Two Way Slab (Continuous) : Given DataParwan ExceltechNo ratings yet

- 2 Way Slab Design-Roof SlabDocument120 pages2 Way Slab Design-Roof SlabSambhav PoddarNo ratings yet

- Design of Trade Off III Precast ConcreteDocument9 pagesDesign of Trade Off III Precast ConcretemateojullieanneNo ratings yet

- Pavement Slab Design For RTGDocument2 pagesPavement Slab Design For RTGBishal karki100% (1)

- 2 Way Slab DesignDocument66 pages2 Way Slab DesignSambhav PoddarNo ratings yet

- 2 Way Slab DesignDocument6 pages2 Way Slab DesignAditya singhNo ratings yet

- Structural Cals For UCWDocument11 pagesStructural Cals For UCWShubham SoniNo ratings yet

- 2PX4 Table Staad Report DocumentsDocument23 pages2PX4 Table Staad Report DocumentsEr Prabhanjan ChigareNo ratings yet

- O level Physics Questions And Answer Practice Papers 2From EverandO level Physics Questions And Answer Practice Papers 2Rating: 5 out of 5 stars5/5 (1)

- GridDataReport-tumb Left OutDocument7 pagesGridDataReport-tumb Left OutAnonymous Clm40C1No ratings yet

- Pipe Rack Vba OpenstaadDocument3 pagesPipe Rack Vba OpenstaadAnonymous Clm40C1No ratings yet

- Hotel To OfcDocument1 pageHotel To OfcAnonymous Clm40C1No ratings yet

- Ofc To HotelDocument1 pageOfc To HotelAnonymous Clm40C1No ratings yet

- MOJO Stock SmallcapDocument3 pagesMOJO Stock SmallcapAnonymous Clm40C1No ratings yet

- CRN6755445007Document3 pagesCRN6755445007Anonymous Clm40C1No ratings yet

- MOJO StockDocument3 pagesMOJO StockAnonymous Clm40C1No ratings yet

- Ofc To HotelDocument1 pageOfc To HotelAnonymous Clm40C1No ratings yet

- MOJO Stock LargecapDocument3 pagesMOJO Stock LargecapAnonymous Clm40C1No ratings yet

- Hotel To OfcDocument1 pageHotel To OfcAnonymous Clm40C1No ratings yet

- CRN7019262209Document3 pagesCRN7019262209Anonymous Clm40C1No ratings yet

- Current Age: Existing ExpensesDocument13 pagesCurrent Age: Existing ExpensesAnonymous Clm40C1No ratings yet

- Drawing Limit N 4748.000: NotesDocument1 pageDrawing Limit N 4748.000: NotesAnonymous Clm40C1No ratings yet

- CRN 7019407483Document3 pagesCRN 7019407483Anonymous Clm40C1No ratings yet

- CRN 7019717230Document3 pagesCRN 7019717230Anonymous Clm40C1No ratings yet

- Engineering Design BasisDocument70 pagesEngineering Design BasisAnonymous Clm40C1100% (1)

- CRN6680700505Document3 pagesCRN6680700505Anonymous Clm40C1No ratings yet

- B224 Cdu TPL 101 CV DW 0097 1Document2 pagesB224 Cdu TPL 101 CV DW 0097 1Anonymous Clm40C1No ratings yet

- Income Tax Calculator Fy 2020 21 v2Document12 pagesIncome Tax Calculator Fy 2020 21 v2Anonymous Clm40C1No ratings yet

- B224 Cdu TPL 101 CV DW 0097 1Document2 pagesB224 Cdu TPL 101 CV DW 0097 1Anonymous Clm40C1No ratings yet

- TPL 3452 X9990 Ec RC 6370 SHT1 R1Document1 pageTPL 3452 X9990 Ec RC 6370 SHT1 R1Anonymous Clm40C1No ratings yet

- GST Factor CalculationDocument1 pageGST Factor CalculationAnonymous Clm40C1No ratings yet

- B1286 PX TPL Tecno-Commerical R0Document25 pagesB1286 PX TPL Tecno-Commerical R0Anonymous Clm40C1No ratings yet

- Gautam Acharyya: Tata Projects LTD, MumbaiDocument3 pagesGautam Acharyya: Tata Projects LTD, MumbaiAnonymous Clm40C1No ratings yet

- Project MonitoringDocument37 pagesProject MonitoringAnonymous Clm40C1No ratings yet

- DWG Plan N Section Details @7.160 KM 1of2 R1 - 13.07.18-ModelDocument1 pageDWG Plan N Section Details @7.160 KM 1of2 R1 - 13.07.18-ModelAnonymous Clm40C1No ratings yet

- Trilokpurifarematrix 311018Document406 pagesTrilokpurifarematrix 311018Anonymous Clm40C1No ratings yet

- RC 700 To 800 Level-Merged PDFDocument119 pagesRC 700 To 800 Level-Merged PDFAnonymous Clm40C1No ratings yet

- Edge Road Cordinate 475.653e,-5480.263 N To 433.802e,-5301.647nDocument24 pagesEdge Road Cordinate 475.653e,-5480.263 N To 433.802e,-5301.647nAnonymous Clm40C1No ratings yet

- Laboratory 5 - EntropyDocument5 pagesLaboratory 5 - EntropyzaqbasalmauNo ratings yet

- Lab Report 2Document7 pagesLab Report 2HarwinderNo ratings yet

- 2021 Ijspacese-69279 Tafpv ReplyDocument13 pages2021 Ijspacese-69279 Tafpv ReplyJatin KambleNo ratings yet

- Fundamentals of Energy Conversion P1 PDFDocument260 pagesFundamentals of Energy Conversion P1 PDFSienna SabadoNo ratings yet

- Bearing Capacity of Shalow FoundationDocument73 pagesBearing Capacity of Shalow FoundationMè ŘąNo ratings yet

- Vega Vegabar 82 Vac TestcertificateDocument1 pageVega Vegabar 82 Vac Testcertificatephankhoa83-1No ratings yet

- Natural Fracture Characterization in Tgiht SandstonesDocument16 pagesNatural Fracture Characterization in Tgiht SandstonesTolga SipahiNo ratings yet

- Iso 9200 en PDFDocument6 pagesIso 9200 en PDFIntertronickNo ratings yet

- Lab 3Document5 pagesLab 3Oliver RajNo ratings yet

- Thesis K Thomsen 1997Document131 pagesThesis K Thomsen 1997jafobr4152No ratings yet

- Basics of Gas TurbinesDocument5 pagesBasics of Gas TurbinesRammireszNo ratings yet

- Bending, Vibration and Buckling of Simply Supported Thick Orthotropic Rectangular Plates and LaminatesDocument19 pagesBending, Vibration and Buckling of Simply Supported Thick Orthotropic Rectangular Plates and LaminatesLaxmith ShettyNo ratings yet

- Stability Lect 1Document15 pagesStability Lect 1بركان معتصم مطشرNo ratings yet

- Lectures in Thermodynamics Claus BorgnakkeDocument38 pagesLectures in Thermodynamics Claus BorgnakkeJkun gamingNo ratings yet

- 3 - Pump-Pipeline System Analyses and DesignDocument9 pages3 - Pump-Pipeline System Analyses and DesignAnonymous 7oXNA46xiNNo ratings yet

- Expanded Polystyrene Geofoam in Pavement ConstructionDocument11 pagesExpanded Polystyrene Geofoam in Pavement Constructionminsara madtNo ratings yet

- Examples 1 - ManometersDocument3 pagesExamples 1 - Manometers27061988No ratings yet

- Ohta, Goto, Empirical Shear Wave Velocity Equations in Terms of Characteristic Soil IndexesDocument21 pagesOhta, Goto, Empirical Shear Wave Velocity Equations in Terms of Characteristic Soil IndexesAngelica MartinezNo ratings yet

- DLL-earth-and-life - 5Document4 pagesDLL-earth-and-life - 5Marilla ReybethNo ratings yet

- Ch6-Long ColumnDocument24 pagesCh6-Long ColumnCho Wing So100% (1)

- Restriction Orifice Sizing PDFDocument5 pagesRestriction Orifice Sizing PDFsaka dewaNo ratings yet

- L-07 EQ Resistant Design of Concrete - Seismic For PrintDocument62 pagesL-07 EQ Resistant Design of Concrete - Seismic For PrintkktttNo ratings yet

- C 168 - 15aDocument7 pagesC 168 - 15aRoberto Colonia50% (2)

- Fluid Kinematics - 75Document13 pagesFluid Kinematics - 75prasaddeshmukh2312No ratings yet

- Cane Syrup EvapourationDocument22 pagesCane Syrup EvapourationAnil Kumar SinghNo ratings yet

- 07 Chapter 2Document36 pages07 Chapter 2DevNo ratings yet

- (Colored) Refrigerant 134a P-H Diagram (SI Units)Document1 page(Colored) Refrigerant 134a P-H Diagram (SI Units)Mc Jason LaureteNo ratings yet

- Flow MwassurementDocument2 pagesFlow MwassurementAditi SharmaNo ratings yet

- Orthogonally Stiffened Plates Hoppman W.H. 1953Document46 pagesOrthogonally Stiffened Plates Hoppman W.H. 1953Iliyah87No ratings yet