Professional Documents

Culture Documents

T2 Sem 0800100

T2 Sem 0800100

Uploaded by

gadOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

T2 Sem 0800100

T2 Sem 0800100

Uploaded by

gadCopyright:

Available Formats

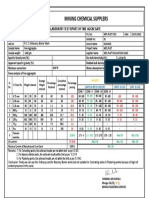

Microsurfacing Mix Design

Date: 7/22/2008 Project: SSR-167A(159)SR

Contractor: Vance Brothers Agency: OK, Seminole County

Mix Design #: T2SEM0800100

Materials

Aggregate S2008.0559

Source: Martin Marietta, Mill Creek

Rock Type: OK Type II

Asphalt Emulsion

Source: SemMaterials, L.P.

Grade: PMCSS-1h (Ralumac® emulsion)

Portland Cement*

Source: Lehigh

Grade: Type I

Set Control Additive

Source: SemMaterials, L.P.

*Note: Alternate sources of this material will be suitable in most cases.

Aggregate

Sieve Analysis % Passing Type II Specification

Sieve % Passing w/1.0% Filler Min Max

1/2" (12.5mm) 100.0 100.0% 100% 100%

3/8" (9.5mm) 100.0 100.0% 99% 100%

#4 (4.75 mm) 90.1 90.2% 80% 94%

#10 (2.00mm) 57.7 58.1% 40% 60%

#40 (425 µm) 23.9 24.7% 12% 30%

#80 (180 µm) 14.9 15.7% 8% 20%

#200 (75μm) 9.3 10.2% 5% 15%

Specification Test Method

Min Max

Sand Equivalence: 73 65 - AASHTO T176

LA Abrasion**: - 40% AASHTO T96

Soundness (MgSO4)**: - 30% AASHTO T104

**Note: This information is available from the aggregate producer

S2008.0559

Field Simulation Tests Specification Test Method

Min Max

Wet Track Abrasion Test:

1 hour soak 20.0 g/ft² - 50g/ft²

6 day soak 48.2 g/ft² - 75 g/ft² ISSA TB 100

Trial Mix Time:

25°C 180 sec 120 sec - ISSA TB 113

Interpretation of Results and Job Mix Formula

Ignition Oven Correction Factor: 0.01%

Design Minimum Maximum

Mineral Filler 1.0% 1.0% 1.5%

Total Water 9.0% 7.0% 11.0%

Field Control Additive*** 0.0% 0.0% 0.2%

CSS-1P Asphalt Emulsion 12.0% 11.5% 12.5%

Residual Content of Emulsion 66.4% 62% -

Residual Asphalt in Mix 7.8% 7.4% 8.2%

*** Typical field control additive is 35 oz. per ton.

Test data reported herein have been secured by reliable testing procedures. As we have

no knowledge of, or control over, the conditions that may affect the use of the materials

from which the samples were taken, we assume no responsibility in furnishing

these data other than to warrant they represent reliable measurement of the properties

of the sample tested.

Signed_________________________

Alan C. Brooker

Design Engineer

You might also like

- Mi-17 ChecklistDocument32 pagesMi-17 Checklistpilot digital100% (11)

- Super Hero Tycoon Script - Inf Money e Muito MaisDocument27 pagesSuper Hero Tycoon Script - Inf Money e Muito MaisAlberto Espinoza ParraNo ratings yet

- Method Statement For Rockfill Works: Doubling Safaga / El Quseir / Marsa Alam Road ProjectDocument4 pagesMethod Statement For Rockfill Works: Doubling Safaga / El Quseir / Marsa Alam Road Projectgad100% (2)

- Harvard University - CAD Standards GuidelineDocument22 pagesHarvard University - CAD Standards Guidelinejuanperez32No ratings yet

- The Chemistry of Process Development in Pharmaceutical Industry 1Document60 pagesThe Chemistry of Process Development in Pharmaceutical Industry 1Venugopal Rao Veeramaneni100% (1)

- Methodology of StabilizationDocument12 pagesMethodology of StabilizationRISHI SINGHCHHBARA100% (1)

- D1557 PDFDocument8 pagesD1557 PDFgadNo ratings yet

- Evo Ipmvp Core Adherence-Criteria 2016Document4 pagesEvo Ipmvp Core Adherence-Criteria 2016rpercorNo ratings yet

- 14310A ch4 PDFDocument96 pages14310A ch4 PDFmiguelNo ratings yet

- Read Me GenAlEx 6.41Document10 pagesRead Me GenAlEx 6.41ParkNo ratings yet

- Test Report For Sieve Analysis of Fine Aggregate: Posco E & CDocument1 pageTest Report For Sieve Analysis of Fine Aggregate: Posco E & CHasan al MahmudNo ratings yet

- BREN - Mix Design WMMDocument8 pagesBREN - Mix Design WMMJoydeep NeogiNo ratings yet

- Fiberized Micro SurfacingDocument9 pagesFiberized Micro SurfacingharineshpandyaNo ratings yet

- R.E Wall Test SummaryDocument1 pageR.E Wall Test SummaryBiplab dattaNo ratings yet

- Item 346: Item 346 Is A For Stone-Matrix Asphalt (SMA) and Asphalt Rubber Stone-Matrix (SMAR) MixturesDocument34 pagesItem 346: Item 346 Is A For Stone-Matrix Asphalt (SMA) and Asphalt Rubber Stone-Matrix (SMAR) MixturesLam Dao PhucNo ratings yet

- Method of Test For Evaluation of Superplasticizing Admixtures For ConcreteDocument7 pagesMethod of Test For Evaluation of Superplasticizing Admixtures For ConcretejuherrerareunalmedNo ratings yet

- Sieve Analysis For Fine Aggregate - Kico ProjectDocument1 pageSieve Analysis For Fine Aggregate - Kico ProjectMitendra ChauhanNo ratings yet

- Afco Material Teating Laboratory: Extraction and Gradation of Paving MixtureDocument1 pageAfco Material Teating Laboratory: Extraction and Gradation of Paving MixtureEhsanullah HarooniNo ratings yet

- Natural Sand (Jarboo) For Block MortarDocument7 pagesNatural Sand (Jarboo) For Block MortarMGNo ratings yet

- SAPSA102Document2 pagesSAPSA102Honesto BautistaNo ratings yet

- Contoh Form TRIAL COMPACTION ACWCDocument20 pagesContoh Form TRIAL COMPACTION ACWCC-pang MinorityNo ratings yet

- Ultratech Cement Limited: Sieve Analysis of Coarse Aggregate For Concrete (As Per Is: 383 - 1970)Document24 pagesUltratech Cement Limited: Sieve Analysis of Coarse Aggregate For Concrete (As Per Is: 383 - 1970)Mamata BhangaleNo ratings yet

- Combined Gradation of Coarse Aggregate - Astm C33-Size 67-1Document106 pagesCombined Gradation of Coarse Aggregate - Astm C33-Size 67-1Hasan al MahmudNo ratings yet

- M35 Bhole ConstructionDocument6 pagesM35 Bhole ConstructionBIPL REPORT100% (1)

- Laboratory Experiment - Fine AggregateDocument4 pagesLaboratory Experiment - Fine AggregateNajiha KhairiNo ratings yet

- BC Job MixDocument3 pagesBC Job MixSOIGNE ENGINEERING CONSULTANTSNo ratings yet

- 9.marshall Trial Compaction Ac WC25092020Document20 pages9.marshall Trial Compaction Ac WC25092020Ramdan Pramedis SetyaNo ratings yet

- Use of Plastic Waste in Bituminous PavementDocument19 pagesUse of Plastic Waste in Bituminous Pavementparvezahamed563No ratings yet

- Report 3523 M40 08 12 2019Document20 pagesReport 3523 M40 08 12 2019Imran KhanNo ratings yet

- ITP ConcreteDocument9 pagesITP ConcreteTwin Bulls100% (1)

- C15....... Concrete Mix DesignDocument18 pagesC15....... Concrete Mix DesignAbu FalasiNo ratings yet

- Test Results Reference Sample 1 Sample 2: IS 2720 (Part 4) - 1985 (RA 2006)Document1 pageTest Results Reference Sample 1 Sample 2: IS 2720 (Part 4) - 1985 (RA 2006)Mohan MylarappaNo ratings yet

- Micro Surfacing: Cost Effective Solution For Pavement Preservation and RenewalDocument16 pagesMicro Surfacing: Cost Effective Solution For Pavement Preservation and RenewalCristhian Riveros RojasNo ratings yet

- ML12153A333Document67 pagesML12153A333HKDOCUMENTNo ratings yet

- Ball Mill SimulatorDocument4 pagesBall Mill SimulatorIrshad HussainNo ratings yet

- Afco Material Teating Laboratory: Extraction and Gradation of Paving MixtureDocument4 pagesAfco Material Teating Laboratory: Extraction and Gradation of Paving MixtureEhsanullah HarooniNo ratings yet

- Design and Production Control of SMA MixesDocument168 pagesDesign and Production Control of SMA Mixesibrahim tanko abeNo ratings yet

- Impact of Ferrochrome Jricehusk Jflyash Aggrigate On ConcreateDocument17 pagesImpact of Ferrochrome Jricehusk Jflyash Aggrigate On ConcreateDaina MallikNo ratings yet

- An Experimental Study of Using Manufactured Sand in ConcreteDocument7 pagesAn Experimental Study of Using Manufactured Sand in Concretenught surNo ratings yet

- Ficha Tecnica PET - 24mm 07 - 21 PDFDocument5 pagesFicha Tecnica PET - 24mm 07 - 21 PDFXimena MirandaNo ratings yet

- 1304..mix Design m25 Dalmia Cement... Mes JorhatDocument16 pages1304..mix Design m25 Dalmia Cement... Mes JorhatAbhishek KumarNo ratings yet

- A105 - Slurry SealDocument16 pagesA105 - Slurry SealRaAl GaRuNo ratings yet

- Afco Material Teating Laboratory: Extraction and Gradation of Paving MixtureDocument4 pagesAfco Material Teating Laboratory: Extraction and Gradation of Paving MixtureEhsanullah HarooniNo ratings yet

- M-30 (PQC) 612 (Opc - 53, N.sand) Msa 31.5Document89 pagesM-30 (PQC) 612 (Opc - 53, N.sand) Msa 31.5rahul pardeshiNo ratings yet

- Meltgradient Filter-Cobetter-MBCYDocument2 pagesMeltgradient Filter-Cobetter-MBCYAli BiomyNo ratings yet

- Recommended Performance Guideline For Chip Seal: NoticeDocument9 pagesRecommended Performance Guideline For Chip Seal: NoticeAnna KLNo ratings yet

- Guidelines of Bituminous ConcreteDocument5 pagesGuidelines of Bituminous ConcreteBRVNo ratings yet

- Inspection & Testing Plan For Crusher Production-Sub Base: INF-AP-QUA-ITP-08 Rev. 0 Date: 04.07.2018Document2 pagesInspection & Testing Plan For Crusher Production-Sub Base: INF-AP-QUA-ITP-08 Rev. 0 Date: 04.07.2018jerin sam kurianNo ratings yet

- Hand Book On Road PDFDocument56 pagesHand Book On Road PDFrajan sharma100% (1)

- Concortta Tyrl:R/A: QualityDocument3 pagesConcortta Tyrl:R/A: QualityAung Naing Latt AungNo ratings yet

- PPC - MTCDocument1 pagePPC - MTCNaresh KumarNo ratings yet

- Pond AshDocument1 pagePond AshRavindra singh TanwarNo ratings yet

- Chapter 3 PDFDocument8 pagesChapter 3 PDFHatim ValiNo ratings yet

- TABEL ANSAR Kelompok 13Document51 pagesTABEL ANSAR Kelompok 13Muhammad Dewangga RamadanNo ratings yet

- Concrete Mix DesignDocument12 pagesConcrete Mix DesignAnand.5No ratings yet

- Portland Cement I-II Mill CertDocument1 pagePortland Cement I-II Mill CertFiras Ashraf100% (1)

- ESW - Type I II 2017 04 PDFDocument2 pagesESW - Type I II 2017 04 PDFVictor MontaNo ratings yet

- Cement Manufacturing Specifications Guide: RapidcureDocument9 pagesCement Manufacturing Specifications Guide: RapidcureHeramb TrifaleyNo ratings yet

- Exercise HighwayDocument7 pagesExercise HighwayOmar AbdelnabyNo ratings yet

- WMM Calibration 05.01.2016Document8 pagesWMM Calibration 05.01.2016SRR QAQCNo ratings yet

- Garima Global Pvt. LTD.: Material Test CertificateDocument2 pagesGarima Global Pvt. LTD.: Material Test CertificateRima AroraNo ratings yet

- Chapter Three Material Characterization and Laboratory TestsDocument25 pagesChapter Three Material Characterization and Laboratory TestsHANAN HUSSNo ratings yet

- Pasir 1 Pasir 2 Pasir 3 Pasir 4 Pasir 5 Split 1 Split 2 Combine SNIDocument37 pagesPasir 1 Pasir 2 Pasir 3 Pasir 4 Pasir 5 Split 1 Split 2 Combine SNItaufikNo ratings yet

- Particle Size DistributionDocument10 pagesParticle Size DistributionSaraswati Noor100% (1)

- A1 Lime PlasterDocument2 pagesA1 Lime PlasterCharles Vladimir SolvaskyNo ratings yet

- Мембрана TM810 SpecDocument2 pagesМембрана TM810 SpecAlexanderNo ratings yet

- Pavement TechniquesDocument20 pagesPavement Techniquesഅരശുമൂട്ടിൽ അപ്പുക്കുട്ടൻNo ratings yet

- Week No 40,43 GR, 3 Day'sDocument1 pageWeek No 40,43 GR, 3 Day'sshinde rushiNo ratings yet

- Clay LumpsDocument1 pageClay LumpsgadNo ratings yet

- GCP110Document2 pagesGCP110gadNo ratings yet

- BS 1041 - 7-Temperature MeasureDocument19 pagesBS 1041 - 7-Temperature MeasuregadNo ratings yet

- PC1000Document13 pagesPC1000gadNo ratings yet

- Supplied by Billed ToDocument2 pagesSupplied by Billed TogadNo ratings yet

- GCP70Document8 pagesGCP70gadNo ratings yet

- Ismail Ali Ismail Mohamed SaadaDocument2 pagesIsmail Ali Ismail Mohamed SaadagadNo ratings yet

- BS 7334-8-Measuring Instruments For BuildingDocument25 pagesBS 7334-8-Measuring Instruments For BuildinggadNo ratings yet

- C 1245 - 93 - QzeyndutotmDocument7 pagesC 1245 - 93 - QzeyndutotmgadNo ratings yet

- BS 1041 - 4-Temperature MeasureDocument33 pagesBS 1041 - 4-Temperature MeasuregadNo ratings yet

- NCHRP Project 9-33: A Mix Design Manual For Hot Mix Asphalt: NEAUPG Fall Meeting October 18, 2007 Mystic, ConnecticutDocument20 pagesNCHRP Project 9-33: A Mix Design Manual For Hot Mix Asphalt: NEAUPG Fall Meeting October 18, 2007 Mystic, ConnecticutgadNo ratings yet

- Understanding The Bailey Method - Asphalt MagazineDocument3 pagesUnderstanding The Bailey Method - Asphalt MagazinegadNo ratings yet

- Full-Scale Experimental Study of An Embankment Reinforced by GeosyntheticsDocument8 pagesFull-Scale Experimental Study of An Embankment Reinforced by GeosyntheticsgadNo ratings yet

- Addition of Polymer To Improve Efficiency of Asphalt Concrete MixDocument2 pagesAddition of Polymer To Improve Efficiency of Asphalt Concrete MixgadNo ratings yet

- Specific Gravity of Soils: Standard Test Method ForDocument4 pagesSpecific Gravity of Soils: Standard Test Method ForgadNo ratings yet

- Cellular Raft FoundationDocument2 pagesCellular Raft FoundationAvaniShah100% (2)

- Web Development - Wikipedia, The Free EncyclopediaDocument5 pagesWeb Development - Wikipedia, The Free EncyclopediaJeromeGarcia2013No ratings yet

- Baxter Colleague - Service ManualDocument422 pagesBaxter Colleague - Service ManualErik Van HalenNo ratings yet

- Hostalen H 2150Document3 pagesHostalen H 2150Silviu PadureanuNo ratings yet

- m vr vr r r d d m T T P P d d = = ± = ± = ± ω ω ω ω ω ω / / / /Document10 pagesm vr vr r r d d m T T P P d d = = ± = ± = ± ω ω ω ω ω ω / / / /ManashaaNo ratings yet

- Aac Block Plant 100m3 DayDocument32 pagesAac Block Plant 100m3 DaysantocreatoraNo ratings yet

- Wa250 5Document12 pagesWa250 5Andrea797No ratings yet

- Bcs Example 5Document4 pagesBcs Example 5RichardNo ratings yet

- Air CannonDocument9 pagesAir Cannonkarthikraja21100% (1)

- Technical Paper - CIGREDocument12 pagesTechnical Paper - CIGREGobinath BalasubramanianNo ratings yet

- ALSMLST6Document2 pagesALSMLST6troves12No ratings yet

- PIRMH Rigging Techniques PIDocument9 pagesPIRMH Rigging Techniques PITri SubaktiNo ratings yet

- L (-) 02 Ground Floor Waste Water Drainage Flow PlanDocument1 pageL (-) 02 Ground Floor Waste Water Drainage Flow PlanJeremiah MangeniNo ratings yet

- 02 - Upa 150S-34Document2 pages02 - Upa 150S-34Rojo ArrebolNo ratings yet

- Isambard Kingdom BrunelDocument13 pagesIsambard Kingdom Brunelcesperon39No ratings yet

- Hindustan Petroleum Corporation LimitedDocument1 pageHindustan Petroleum Corporation LimitedDinakarSatyaNo ratings yet

- 1SDA068059R1 xt3n 250 TMD 250 2500 3p F FDocument4 pages1SDA068059R1 xt3n 250 TMD 250 2500 3p F FSoporte ANDET SACNo ratings yet

- Bosch GSBDocument13 pagesBosch GSBLungisaniNo ratings yet

- Urban DesignDocument5 pagesUrban DesignBhoomika Khanna100% (1)

- Mathematical Modelling of GTAW and GMAWDocument240 pagesMathematical Modelling of GTAW and GMAWferayNo ratings yet

- Short Literature Review On T5 Lighting SystemDocument2 pagesShort Literature Review On T5 Lighting SystemChing Wai YongNo ratings yet

- Artículo Sobre XC Publicado en La Revista de Kitware.Document24 pagesArtículo Sobre XC Publicado en La Revista de Kitware.Luis C. Pérez TatoNo ratings yet

- TBMR 711 InstallAndLicenseGuideDocument31 pagesTBMR 711 InstallAndLicenseGuideamshadab3199No ratings yet