Professional Documents

Culture Documents

K-CW-HS-ST-011 Permit To Work 18.0

K-CW-HS-ST-011 Permit To Work 18.0

Uploaded by

Faizan AliCopyright:

Available Formats

You might also like

- Typical Authorisation Test QuestionsDocument11 pagesTypical Authorisation Test QuestionsArchiford Ndhlovu100% (1)

- Amplify 95-SDS - Ampol - Ampol LogoDocument8 pagesAmplify 95-SDS - Ampol - Ampol LogoMeg O'ConnorNo ratings yet

- Substation Safety ManualDocument15 pagesSubstation Safety ManualAnsel Garvey100% (4)

- Qcs 2010 Section 11 Part 2.3.11 She Procedures - Permit To Work SysteDocument20 pagesQcs 2010 Section 11 Part 2.3.11 She Procedures - Permit To Work Systebryanpastor106No ratings yet

- PRE Commissioning Procedures TR Rev01 PGCILDocument52 pagesPRE Commissioning Procedures TR Rev01 PGCILkrishnamanikandan100% (3)

- FSSC22000 Vs4 ChecklistDocument37 pagesFSSC22000 Vs4 ChecklistSary Vazquez Romero100% (1)

- Permit To Work (PTW)Document11 pagesPermit To Work (PTW)simpanan hitamNo ratings yet

- Procedure Title: Land - PTW Procedure: Scope Objective Referenced Documents Associated FormsDocument36 pagesProcedure Title: Land - PTW Procedure: Scope Objective Referenced Documents Associated Formssenator100% (1)

- Permit To WorkDocument11 pagesPermit To WorkKhuda BukshNo ratings yet

- NASA Glenn Safety Manual Chapter 9 - Lockout/Tagout: Revision Date: 11/96Document9 pagesNASA Glenn Safety Manual Chapter 9 - Lockout/Tagout: Revision Date: 11/96Abdul Hameed OmarNo ratings yet

- Permit To WorkDocument39 pagesPermit To Workhaotran68100% (1)

- Energy Isolation ProcedureDocument54 pagesEnergy Isolation Procedureali.malik16778No ratings yet

- Permit To Work Guidance Note SA GN 12 (V1) Nov 2014Document7 pagesPermit To Work Guidance Note SA GN 12 (V1) Nov 2014JAY ROD AWITNo ratings yet

- Pre Commissioning Procedures TR Rev01 Pgcil PDFDocument52 pagesPre Commissioning Procedures TR Rev01 Pgcil PDFChandraNo ratings yet

- CIC Issue 2 - Permit To WorkDocument4 pagesCIC Issue 2 - Permit To WorkMuhammad Shakeel AttariNo ratings yet

- 5.3-Safe Work PermittingDocument12 pages5.3-Safe Work PermittingBsvk Dupana100% (1)

- OHS-PR-02 - 12 Control of Hazardous Work EnergyDocument19 pagesOHS-PR-02 - 12 Control of Hazardous Work Energyasiflalhaira0No ratings yet

- Tugas K3Document5 pagesTugas K3Ronald Adi SaputraNo ratings yet

- 5.4 Work Permit SystemDocument14 pages5.4 Work Permit Systembilo1984100% (1)

- K-CW-HS-ST-013 Dropped Object Prevention Scheme ("DROPS") 3.0Document4 pagesK-CW-HS-ST-013 Dropped Object Prevention Scheme ("DROPS") 3.0Faizan AliNo ratings yet

- Isolation and Lock OffDocument5 pagesIsolation and Lock OffchrisNo ratings yet

- 1-4 (G) Lockout - USDocument9 pages1-4 (G) Lockout - USJennifer HendersonNo ratings yet

- 05EnergyIsolation IOGP577version1.2Document2 pages05EnergyIsolation IOGP577version1.2Ismail SultanNo ratings yet

- Lockout Tag Out ProcedureDocument5 pagesLockout Tag Out ProcedureBart VankeirsbilckNo ratings yet

- NR 12 - Lockout Tagout ProgramDocument19 pagesNR 12 - Lockout Tagout ProgramCPSSTNo ratings yet

- Permit To Work ProceduresDocument3 pagesPermit To Work ProceduresREBAA HatemNo ratings yet

- Hip Plan - Hvac WorkDocument30 pagesHip Plan - Hvac WorksrisetNo ratings yet

- Safe Process Piping, Equipment and Vessel Opening ProcedureDocument14 pagesSafe Process Piping, Equipment and Vessel Opening ProcedureDavid KahnNo ratings yet

- Written Permission Authorisation Carry Out DEFINED WORK Safety of Personnel, Equipment and EnvironmentDocument6 pagesWritten Permission Authorisation Carry Out DEFINED WORK Safety of Personnel, Equipment and EnvironmentRiyas Perumbadan100% (1)

- XXX Revised April 6, 2005 Standard Operating Procedure No. S-100Document12 pagesXXX Revised April 6, 2005 Standard Operating Procedure No. S-100Peter Nai HoNo ratings yet

- What Is A Permit To Work SystemDocument4 pagesWhat Is A Permit To Work SystemJAZPAKNo ratings yet

- PN3-PRO-HSE-010 Work Permit System - Rev 04Document23 pagesPN3-PRO-HSE-010 Work Permit System - Rev 04aymenmoatazNo ratings yet

- Lesson 7 Control of Hazardous Energy: 10 Hour OSHA ConstructionDocument29 pagesLesson 7 Control of Hazardous Energy: 10 Hour OSHA ConstructionCarlos LopézNo ratings yet

- Safe Work Method Statement For Testing & Commissioning of DX Split UnitsDocument5 pagesSafe Work Method Statement For Testing & Commissioning of DX Split Unitsvin ssNo ratings yet

- Permit To Work Guidance Note PDFDocument7 pagesPermit To Work Guidance Note PDFFOZCANNo ratings yet

- Work Permit ImplementationDocument33 pagesWork Permit Implementationsubhan teklingNo ratings yet

- Wmhhs 2016090 V 2Document15 pagesWmhhs 2016090 V 2David RamadhanNo ratings yet

- ER 385-1-31 The Control of Hazardous EnergyDocument31 pagesER 385-1-31 The Control of Hazardous EnergyNNo ratings yet

- Vessel Cleaning ProcedureDocument9 pagesVessel Cleaning ProcedureAbdul Hakam Mohamed Yusof100% (1)

- Factory Acts (AutoRecovered)Document7 pagesFactory Acts (AutoRecovered)Solomon kwesi MensahNo ratings yet

- Qualitas Golden Rules of SafetyDocument1 pageQualitas Golden Rules of SafetyQualitas RemosNo ratings yet

- Work Permit System Project ReportDocument16 pagesWork Permit System Project Reportsachin mathewNo ratings yet

- 5.1line & Equipment Opening (L&EO) : PurposeDocument8 pages5.1line & Equipment Opening (L&EO) : PurposeBsvk DupanaNo ratings yet

- Permit To WorkDocument3 pagesPermit To WorkMuStafaAbbasNo ratings yet

- Confined-Space Entry ProgramDocument16 pagesConfined-Space Entry Programamjadkhan6573833No ratings yet

- Lock Out Tag Out PolicyDocument11 pagesLock Out Tag Out Policymalinga100% (1)

- Work PermitDocument17 pagesWork PermitRiccar303No ratings yet

- Electrical Safety: Casimiro L. Flores JRDocument23 pagesElectrical Safety: Casimiro L. Flores JRJoseph CeaNo ratings yet

- SampleDocument5 pagesSampleWaqas Alam KhanNo ratings yet

- Task 1,2,3Document8 pagesTask 1,2,3Waqas Alam KhanNo ratings yet

- Task 1,2,3,4,6,7Document17 pagesTask 1,2,3,4,6,7Waqas Alam KhanNo ratings yet

- Power Transformer Assembly PROCEDUREDocument20 pagesPower Transformer Assembly PROCEDUREScribdTranslationsNo ratings yet

- Electrical Safety Management Procedure May 2013Document35 pagesElectrical Safety Management Procedure May 2013Roni Enjelani100% (2)

- 550KV GIS On-Site Commissioning Procedure (ELK-03) SF Gas Insulated SwitchgearDocument25 pages550KV GIS On-Site Commissioning Procedure (ELK-03) SF Gas Insulated SwitchgearDeiby Peña CaicedoNo ratings yet

- Safe Work PermitDocument6 pagesSafe Work PermitMalefane Cortez TlatlaneNo ratings yet

- S WHS 001 V5 High Risk Standard Electrical WorkDocument4 pagesS WHS 001 V5 High Risk Standard Electrical WorkshabazilhamNo ratings yet

- Safety StandardDocument12 pagesSafety StandardGAURAHARI PATRANo ratings yet

- Att 01, GTR-GeneralDocument26 pagesAtt 01, GTR-GeneralSiriepathi SeetharamanNo ratings yet

- Permit To Work DCPLDocument8 pagesPermit To Work DCPLRajat SonkarNo ratings yet

- 00-SATP-busway, Rev01Document9 pages00-SATP-busway, Rev01islam mohamedNo ratings yet

- Toolbox Talks Lockout Tagout Awareness EnglishDocument1 pageToolbox Talks Lockout Tagout Awareness EnglishAshpakNo ratings yet

- Short AnsDocument10 pagesShort AnsFaizan AliNo ratings yet

- (HSE) Cold Work Permit-FormDocument2 pages(HSE) Cold Work Permit-FormFaizan AliNo ratings yet

- K-CW-HS-ST-016 Vehicle Safety and Journey Management 1.04Document3 pagesK-CW-HS-ST-016 Vehicle Safety and Journey Management 1.04Faizan AliNo ratings yet

- K-CW-HS-ST-012 HSE WWS - HSE Induction and Expectation Setting 14.0Document3 pagesK-CW-HS-ST-012 HSE WWS - HSE Induction and Expectation Setting 14.0Faizan AliNo ratings yet

- K-CW-HS-ST-008 Incident Reporting, Investigation and CommunicationDocument2 pagesK-CW-HS-ST-008 Incident Reporting, Investigation and CommunicationFaizan AliNo ratings yet

- K-CW-ST-006 Task Risk Assessment 14.0Document2 pagesK-CW-ST-006 Task Risk Assessment 14.0Faizan AliNo ratings yet

- K-CW-HS-ST-002 Contingency Plans and Crisis Response 15.0Document2 pagesK-CW-HS-ST-002 Contingency Plans and Crisis Response 15.0Faizan AliNo ratings yet

- Ice Storage ThesisDocument8 pagesIce Storage Thesisvaj0demok1w2100% (2)

- SDS MG3DF 2020Document11 pagesSDS MG3DF 2020deevaneshNo ratings yet

- Webinar UNMUL-Mitigasi Bencana Banjir-TMSDocument26 pagesWebinar UNMUL-Mitigasi Bencana Banjir-TMSReicha - PLC20 - 007No ratings yet

- ICN PS Nurses and Disaster Risk Reduction Response and RecoveryDocument5 pagesICN PS Nurses and Disaster Risk Reduction Response and Recoveryfauziah yulianaNo ratings yet

- MS1480 2007Document31 pagesMS1480 2007syahdantolipackagingNo ratings yet

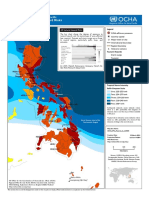

- Phil Natural Hazard Map PDFDocument1 pagePhil Natural Hazard Map PDFmarcamilleNo ratings yet

- Pengoperasian Compressor Ingersoll Rand P90CWIRDocument24 pagesPengoperasian Compressor Ingersoll Rand P90CWIRelvandiNo ratings yet

- Occupational Diseases 302-04280 enDocument19 pagesOccupational Diseases 302-04280 enJithesh S VNo ratings yet

- Samsung WashingMachine ManualDocument72 pagesSamsung WashingMachine ManualAli KhanNo ratings yet

- Epiroc t35Document48 pagesEpiroc t35Ronell Jay TumulakNo ratings yet

- Planificarea Intervenției de Urgență Pentru Pericolele de Accidente ChimiceDocument110 pagesPlanificarea Intervenției de Urgență Pentru Pericolele de Accidente ChimiceForum PompieriiNo ratings yet

- Risk Assessment (Hira) Form: Identifikasi Bahaya Evaluasi Risiko Pengendalian RisikoDocument20 pagesRisk Assessment (Hira) Form: Identifikasi Bahaya Evaluasi Risiko Pengendalian RisikoandykaNo ratings yet

- Medical Device RecallDocument27 pagesMedical Device RecallTZ LABNo ratings yet

- Installation, Operation, and Maintenance ManualDocument28 pagesInstallation, Operation, and Maintenance ManualAmir KhanNo ratings yet

- TM - CookeryDocument32 pagesTM - Cookeryjhon lester janalaNo ratings yet

- Operating Instructions: IO-LinkDocument36 pagesOperating Instructions: IO-LinkRenan SonciniNo ratings yet

- Disaster Nursing SeminarDocument41 pagesDisaster Nursing Seminartanmai nooluNo ratings yet

- Planning For Pet Evacuations During Disasters 2008Document21 pagesPlanning For Pet Evacuations During Disasters 2008Amari SolisNo ratings yet

- 14 IshmDocument129 pages14 IshmNIKHIL SUNDARNo ratings yet

- CHAPTER I (Cidro)Document20 pagesCHAPTER I (Cidro)Czindy MoradosNo ratings yet

- UD18756B A - Baseline - DS TMG4BX Series Barrier Gate User Manual - V1.0.0 - 20230324Document26 pagesUD18756B A - Baseline - DS TMG4BX Series Barrier Gate User Manual - V1.0.0 - 20230324shahmurad.iNo ratings yet

- 1 - Final LMC 3 - AY 2021 2022Document34 pages1 - Final LMC 3 - AY 2021 2022Sharmaine MartirezNo ratings yet

- Week 1 Disaster-Readiness-and-Risk-ReductionDocument20 pagesWeek 1 Disaster-Readiness-and-Risk-ReductionShen EugenioNo ratings yet

- Aquaculture: Technology and Livelihood Education Apply Appropriate Safety MeasuresDocument32 pagesAquaculture: Technology and Livelihood Education Apply Appropriate Safety MeasuresMary Joy Lucob TangbawanNo ratings yet

- DPPM - Objective QBDocument77 pagesDPPM - Objective QBdineshkumar rNo ratings yet

- Handouts COSH G9Document1 pageHandouts COSH G9Faidah BazeronNo ratings yet

- Research DavaoDocument11 pagesResearch DavaoDonnabelle AliwalasNo ratings yet

- Workplace Written Assessment Cover Sheet: HLTWHS003 Maintain Workplace Health and SafetyDocument27 pagesWorkplace Written Assessment Cover Sheet: HLTWHS003 Maintain Workplace Health and SafetyRachel CalinisanNo ratings yet

K-CW-HS-ST-011 Permit To Work 18.0

K-CW-HS-ST-011 Permit To Work 18.0

Uploaded by

Faizan AliOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

K-CW-HS-ST-011 Permit To Work 18.0

K-CW-HS-ST-011 Permit To Work 18.0

Uploaded by

Faizan AliCopyright:

Available Formats

WORLDWIDE STANDARD

Function Health, Safety, Security and Environment

Standard No. K-CW-HS-ST-011 Revision 18.0 Date 07/06/2017

Title Permit to Work

Purpose

An adequate permit to work system co-ordinates non-routine or high risk activities with other concurrent

operations to ensure the safety of all personnel and all operations. A permit to work ensures that work is properly

co-ordinated, assessed and authorised by competent and responsible personnel that worksite safety checks take

place and that safety precautions are in place before work commences.

All KCA Deutag locations where non-routine or otherwise high-risk work may take place concurrently with other

ongoing operations will operate a permit to work system.

Requirements

1.0 Execution

1.1 Permits to work shall be used for the following operations.

Hot work of any type where heat is used or generated, except in designated areas which must be

controlled, safe locations away from flammable substances and / or explosive atmospheres.

Confined space and vessel entry.

Hydrostatic testing or pressure testing by other means, of all piping and/or equipment.

Opening of explosion proof or purged enclosures in classified areas.

Invasive maintenance work on items of plant machinery such as agitators and mud pumps.

(“Invasive” means that personnel may be exposed to moving parts, harmful substances, electrical

energy or pressures by opening piping or machinery casings or removing guards. It does not include

non-invasive methods such as inspection, greasing through grease nipples.)

Erection of scaffolding.

Work carried out at height, except for routine jobs performed by the derrickman.

Work with ionising radiation.

Work with explosives.

Work on electrical systems and equipment.

Heavy lifts (e.g. extraordinary long or big loads) .

Maintenance operations which compromise critical safety systems or which remove them from

service e.g. fire and gas detection systems, firefighting equipment.

Any other work where a permit is considered necessary by the senior KCA Deutag representative on-

site.

1.2 The permit to work system shall be managed and audited by the senior KCA Deutag representative based at

the worksite.

1.3 Permits shall contain the following information as a minimum:

Identification of the specific competent people who are to conduct the work.

A description of the work to be performed;

The location the work is to be performed including clear identification of the specific plant or

equipment being worked on;

Hazard identification or risk assessment of both the work and the worksite which specifies the

precautions necessary, protective equipment (including emergency equipment etc.)

1.4 Work can only begin after signed authorisation by the senior KCA Deutag representative or his designated

deputy that the worksite is in a fit condition and that all identified precautions are in place. Plant and

equipment can only be put back into service on the signed authorisation of the senior KCA Deutag

representative or his designated deputy that it is safe to do so.

1.5 If work is to continue being performed and supervised by different people to those that started the work (for

example after a shift change) then a full and formal handover must take place between all involved personnel.

1.6 Where work is to be undertaken on equipment or plant which normally contains electricity, pressure or

UNLESS OTHERWISE INDICATED, PAPER COPIES OF THIS DOCUMENT ARE

UNCONTROLLED

Page 1 of 2

WORLDWIDE STANDARD

mechanical energy, or hazardous substances or gases then it must be adequately isolated before work

begins. Equipment or plant containing pressure or hazardous substances must be de-pressurised, drained

and purged where necessary to remove all traces of these hazards before work commences. Any normally

pressurized system must be left open to atmosphere to ensure no unintentional pressure build up whilst the

isolations are in place and work is on-going. In all cases, verification of the required isolation, including

depressurization, is to be demonstrated to the Permit to Work area responsible person prior to

commencement of work.

1.7 Plant or equipment which may contain gas or otherwise hazardous atmospheres (for example oxygen

depletion) is to be confirmed "gas free" and with a normal atmosphere prior to the commencement of work.

Proper functional detection equipment is to be used to ensure the work site is "gas free". The same

precautions shall be taken for confined space entry.

1.8 Isolations shall be controlled by lock and key or other positive method of ensuring that plant and equipment

cannot be restarted until it is safe to do so.

2.0 Governance

Assurance

Operational Integrity Reviews (OIRs) and Operational Readiness Reviews (ORRs)

Internal or External Audits

References

K-CW-TD-GU-003 Confined Space Entry

K-CW-TD-GU-006 Fire Watcher

K-CW-TD-GU-007 Gas Testing

K-CW-TD-GU-015 Permit To Work

Approver Note:

This WWStd is a description of mandatory activities which must be

carried out in the execution of any relevant KCA Deutag workscope

and/or a description of mandatory conditions which must be adhered

to in the execution of KCA Deutag’s work activities. In instances

where local legislation conflicts with this WWStd an exemption shall

be obtained.

-------------------------------------------------

Gavin Sutherland,

Group Head of HSSE and Operational Integrity

UNLESS OTHERWISE INDICATED, PAPER COPIES OF THIS DOCUMENT ARE

UNCONTROLLED

Page 2 of 2

You might also like

- Typical Authorisation Test QuestionsDocument11 pagesTypical Authorisation Test QuestionsArchiford Ndhlovu100% (1)

- Amplify 95-SDS - Ampol - Ampol LogoDocument8 pagesAmplify 95-SDS - Ampol - Ampol LogoMeg O'ConnorNo ratings yet

- Substation Safety ManualDocument15 pagesSubstation Safety ManualAnsel Garvey100% (4)

- Qcs 2010 Section 11 Part 2.3.11 She Procedures - Permit To Work SysteDocument20 pagesQcs 2010 Section 11 Part 2.3.11 She Procedures - Permit To Work Systebryanpastor106No ratings yet

- PRE Commissioning Procedures TR Rev01 PGCILDocument52 pagesPRE Commissioning Procedures TR Rev01 PGCILkrishnamanikandan100% (3)

- FSSC22000 Vs4 ChecklistDocument37 pagesFSSC22000 Vs4 ChecklistSary Vazquez Romero100% (1)

- Permit To Work (PTW)Document11 pagesPermit To Work (PTW)simpanan hitamNo ratings yet

- Procedure Title: Land - PTW Procedure: Scope Objective Referenced Documents Associated FormsDocument36 pagesProcedure Title: Land - PTW Procedure: Scope Objective Referenced Documents Associated Formssenator100% (1)

- Permit To WorkDocument11 pagesPermit To WorkKhuda BukshNo ratings yet

- NASA Glenn Safety Manual Chapter 9 - Lockout/Tagout: Revision Date: 11/96Document9 pagesNASA Glenn Safety Manual Chapter 9 - Lockout/Tagout: Revision Date: 11/96Abdul Hameed OmarNo ratings yet

- Permit To WorkDocument39 pagesPermit To Workhaotran68100% (1)

- Energy Isolation ProcedureDocument54 pagesEnergy Isolation Procedureali.malik16778No ratings yet

- Permit To Work Guidance Note SA GN 12 (V1) Nov 2014Document7 pagesPermit To Work Guidance Note SA GN 12 (V1) Nov 2014JAY ROD AWITNo ratings yet

- Pre Commissioning Procedures TR Rev01 Pgcil PDFDocument52 pagesPre Commissioning Procedures TR Rev01 Pgcil PDFChandraNo ratings yet

- CIC Issue 2 - Permit To WorkDocument4 pagesCIC Issue 2 - Permit To WorkMuhammad Shakeel AttariNo ratings yet

- 5.3-Safe Work PermittingDocument12 pages5.3-Safe Work PermittingBsvk Dupana100% (1)

- OHS-PR-02 - 12 Control of Hazardous Work EnergyDocument19 pagesOHS-PR-02 - 12 Control of Hazardous Work Energyasiflalhaira0No ratings yet

- Tugas K3Document5 pagesTugas K3Ronald Adi SaputraNo ratings yet

- 5.4 Work Permit SystemDocument14 pages5.4 Work Permit Systembilo1984100% (1)

- K-CW-HS-ST-013 Dropped Object Prevention Scheme ("DROPS") 3.0Document4 pagesK-CW-HS-ST-013 Dropped Object Prevention Scheme ("DROPS") 3.0Faizan AliNo ratings yet

- Isolation and Lock OffDocument5 pagesIsolation and Lock OffchrisNo ratings yet

- 1-4 (G) Lockout - USDocument9 pages1-4 (G) Lockout - USJennifer HendersonNo ratings yet

- 05EnergyIsolation IOGP577version1.2Document2 pages05EnergyIsolation IOGP577version1.2Ismail SultanNo ratings yet

- Lockout Tag Out ProcedureDocument5 pagesLockout Tag Out ProcedureBart VankeirsbilckNo ratings yet

- NR 12 - Lockout Tagout ProgramDocument19 pagesNR 12 - Lockout Tagout ProgramCPSSTNo ratings yet

- Permit To Work ProceduresDocument3 pagesPermit To Work ProceduresREBAA HatemNo ratings yet

- Hip Plan - Hvac WorkDocument30 pagesHip Plan - Hvac WorksrisetNo ratings yet

- Safe Process Piping, Equipment and Vessel Opening ProcedureDocument14 pagesSafe Process Piping, Equipment and Vessel Opening ProcedureDavid KahnNo ratings yet

- Written Permission Authorisation Carry Out DEFINED WORK Safety of Personnel, Equipment and EnvironmentDocument6 pagesWritten Permission Authorisation Carry Out DEFINED WORK Safety of Personnel, Equipment and EnvironmentRiyas Perumbadan100% (1)

- XXX Revised April 6, 2005 Standard Operating Procedure No. S-100Document12 pagesXXX Revised April 6, 2005 Standard Operating Procedure No. S-100Peter Nai HoNo ratings yet

- What Is A Permit To Work SystemDocument4 pagesWhat Is A Permit To Work SystemJAZPAKNo ratings yet

- PN3-PRO-HSE-010 Work Permit System - Rev 04Document23 pagesPN3-PRO-HSE-010 Work Permit System - Rev 04aymenmoatazNo ratings yet

- Lesson 7 Control of Hazardous Energy: 10 Hour OSHA ConstructionDocument29 pagesLesson 7 Control of Hazardous Energy: 10 Hour OSHA ConstructionCarlos LopézNo ratings yet

- Safe Work Method Statement For Testing & Commissioning of DX Split UnitsDocument5 pagesSafe Work Method Statement For Testing & Commissioning of DX Split Unitsvin ssNo ratings yet

- Permit To Work Guidance Note PDFDocument7 pagesPermit To Work Guidance Note PDFFOZCANNo ratings yet

- Work Permit ImplementationDocument33 pagesWork Permit Implementationsubhan teklingNo ratings yet

- Wmhhs 2016090 V 2Document15 pagesWmhhs 2016090 V 2David RamadhanNo ratings yet

- ER 385-1-31 The Control of Hazardous EnergyDocument31 pagesER 385-1-31 The Control of Hazardous EnergyNNo ratings yet

- Vessel Cleaning ProcedureDocument9 pagesVessel Cleaning ProcedureAbdul Hakam Mohamed Yusof100% (1)

- Factory Acts (AutoRecovered)Document7 pagesFactory Acts (AutoRecovered)Solomon kwesi MensahNo ratings yet

- Qualitas Golden Rules of SafetyDocument1 pageQualitas Golden Rules of SafetyQualitas RemosNo ratings yet

- Work Permit System Project ReportDocument16 pagesWork Permit System Project Reportsachin mathewNo ratings yet

- 5.1line & Equipment Opening (L&EO) : PurposeDocument8 pages5.1line & Equipment Opening (L&EO) : PurposeBsvk DupanaNo ratings yet

- Permit To WorkDocument3 pagesPermit To WorkMuStafaAbbasNo ratings yet

- Confined-Space Entry ProgramDocument16 pagesConfined-Space Entry Programamjadkhan6573833No ratings yet

- Lock Out Tag Out PolicyDocument11 pagesLock Out Tag Out Policymalinga100% (1)

- Work PermitDocument17 pagesWork PermitRiccar303No ratings yet

- Electrical Safety: Casimiro L. Flores JRDocument23 pagesElectrical Safety: Casimiro L. Flores JRJoseph CeaNo ratings yet

- SampleDocument5 pagesSampleWaqas Alam KhanNo ratings yet

- Task 1,2,3Document8 pagesTask 1,2,3Waqas Alam KhanNo ratings yet

- Task 1,2,3,4,6,7Document17 pagesTask 1,2,3,4,6,7Waqas Alam KhanNo ratings yet

- Power Transformer Assembly PROCEDUREDocument20 pagesPower Transformer Assembly PROCEDUREScribdTranslationsNo ratings yet

- Electrical Safety Management Procedure May 2013Document35 pagesElectrical Safety Management Procedure May 2013Roni Enjelani100% (2)

- 550KV GIS On-Site Commissioning Procedure (ELK-03) SF Gas Insulated SwitchgearDocument25 pages550KV GIS On-Site Commissioning Procedure (ELK-03) SF Gas Insulated SwitchgearDeiby Peña CaicedoNo ratings yet

- Safe Work PermitDocument6 pagesSafe Work PermitMalefane Cortez TlatlaneNo ratings yet

- S WHS 001 V5 High Risk Standard Electrical WorkDocument4 pagesS WHS 001 V5 High Risk Standard Electrical WorkshabazilhamNo ratings yet

- Safety StandardDocument12 pagesSafety StandardGAURAHARI PATRANo ratings yet

- Att 01, GTR-GeneralDocument26 pagesAtt 01, GTR-GeneralSiriepathi SeetharamanNo ratings yet

- Permit To Work DCPLDocument8 pagesPermit To Work DCPLRajat SonkarNo ratings yet

- 00-SATP-busway, Rev01Document9 pages00-SATP-busway, Rev01islam mohamedNo ratings yet

- Toolbox Talks Lockout Tagout Awareness EnglishDocument1 pageToolbox Talks Lockout Tagout Awareness EnglishAshpakNo ratings yet

- Short AnsDocument10 pagesShort AnsFaizan AliNo ratings yet

- (HSE) Cold Work Permit-FormDocument2 pages(HSE) Cold Work Permit-FormFaizan AliNo ratings yet

- K-CW-HS-ST-016 Vehicle Safety and Journey Management 1.04Document3 pagesK-CW-HS-ST-016 Vehicle Safety and Journey Management 1.04Faizan AliNo ratings yet

- K-CW-HS-ST-012 HSE WWS - HSE Induction and Expectation Setting 14.0Document3 pagesK-CW-HS-ST-012 HSE WWS - HSE Induction and Expectation Setting 14.0Faizan AliNo ratings yet

- K-CW-HS-ST-008 Incident Reporting, Investigation and CommunicationDocument2 pagesK-CW-HS-ST-008 Incident Reporting, Investigation and CommunicationFaizan AliNo ratings yet

- K-CW-ST-006 Task Risk Assessment 14.0Document2 pagesK-CW-ST-006 Task Risk Assessment 14.0Faizan AliNo ratings yet

- K-CW-HS-ST-002 Contingency Plans and Crisis Response 15.0Document2 pagesK-CW-HS-ST-002 Contingency Plans and Crisis Response 15.0Faizan AliNo ratings yet

- Ice Storage ThesisDocument8 pagesIce Storage Thesisvaj0demok1w2100% (2)

- SDS MG3DF 2020Document11 pagesSDS MG3DF 2020deevaneshNo ratings yet

- Webinar UNMUL-Mitigasi Bencana Banjir-TMSDocument26 pagesWebinar UNMUL-Mitigasi Bencana Banjir-TMSReicha - PLC20 - 007No ratings yet

- ICN PS Nurses and Disaster Risk Reduction Response and RecoveryDocument5 pagesICN PS Nurses and Disaster Risk Reduction Response and Recoveryfauziah yulianaNo ratings yet

- MS1480 2007Document31 pagesMS1480 2007syahdantolipackagingNo ratings yet

- Phil Natural Hazard Map PDFDocument1 pagePhil Natural Hazard Map PDFmarcamilleNo ratings yet

- Pengoperasian Compressor Ingersoll Rand P90CWIRDocument24 pagesPengoperasian Compressor Ingersoll Rand P90CWIRelvandiNo ratings yet

- Occupational Diseases 302-04280 enDocument19 pagesOccupational Diseases 302-04280 enJithesh S VNo ratings yet

- Samsung WashingMachine ManualDocument72 pagesSamsung WashingMachine ManualAli KhanNo ratings yet

- Epiroc t35Document48 pagesEpiroc t35Ronell Jay TumulakNo ratings yet

- Planificarea Intervenției de Urgență Pentru Pericolele de Accidente ChimiceDocument110 pagesPlanificarea Intervenției de Urgență Pentru Pericolele de Accidente ChimiceForum PompieriiNo ratings yet

- Risk Assessment (Hira) Form: Identifikasi Bahaya Evaluasi Risiko Pengendalian RisikoDocument20 pagesRisk Assessment (Hira) Form: Identifikasi Bahaya Evaluasi Risiko Pengendalian RisikoandykaNo ratings yet

- Medical Device RecallDocument27 pagesMedical Device RecallTZ LABNo ratings yet

- Installation, Operation, and Maintenance ManualDocument28 pagesInstallation, Operation, and Maintenance ManualAmir KhanNo ratings yet

- TM - CookeryDocument32 pagesTM - Cookeryjhon lester janalaNo ratings yet

- Operating Instructions: IO-LinkDocument36 pagesOperating Instructions: IO-LinkRenan SonciniNo ratings yet

- Disaster Nursing SeminarDocument41 pagesDisaster Nursing Seminartanmai nooluNo ratings yet

- Planning For Pet Evacuations During Disasters 2008Document21 pagesPlanning For Pet Evacuations During Disasters 2008Amari SolisNo ratings yet

- 14 IshmDocument129 pages14 IshmNIKHIL SUNDARNo ratings yet

- CHAPTER I (Cidro)Document20 pagesCHAPTER I (Cidro)Czindy MoradosNo ratings yet

- UD18756B A - Baseline - DS TMG4BX Series Barrier Gate User Manual - V1.0.0 - 20230324Document26 pagesUD18756B A - Baseline - DS TMG4BX Series Barrier Gate User Manual - V1.0.0 - 20230324shahmurad.iNo ratings yet

- 1 - Final LMC 3 - AY 2021 2022Document34 pages1 - Final LMC 3 - AY 2021 2022Sharmaine MartirezNo ratings yet

- Week 1 Disaster-Readiness-and-Risk-ReductionDocument20 pagesWeek 1 Disaster-Readiness-and-Risk-ReductionShen EugenioNo ratings yet

- Aquaculture: Technology and Livelihood Education Apply Appropriate Safety MeasuresDocument32 pagesAquaculture: Technology and Livelihood Education Apply Appropriate Safety MeasuresMary Joy Lucob TangbawanNo ratings yet

- DPPM - Objective QBDocument77 pagesDPPM - Objective QBdineshkumar rNo ratings yet

- Handouts COSH G9Document1 pageHandouts COSH G9Faidah BazeronNo ratings yet

- Research DavaoDocument11 pagesResearch DavaoDonnabelle AliwalasNo ratings yet

- Workplace Written Assessment Cover Sheet: HLTWHS003 Maintain Workplace Health and SafetyDocument27 pagesWorkplace Written Assessment Cover Sheet: HLTWHS003 Maintain Workplace Health and SafetyRachel CalinisanNo ratings yet