Professional Documents

Culture Documents

385 2 Internal Gtaw+Smaw

385 2 Internal Gtaw+Smaw

Uploaded by

subash1688Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

385 2 Internal Gtaw+Smaw

385 2 Internal Gtaw+Smaw

Uploaded by

subash1688Copyright:

Available Formats

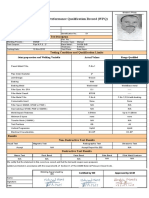

WELDER PERFORMANCE QUALIFICATION (WPQ)

Welder name ABHILASH POULOSE Identification No W-385

Certificate No W-385-02

Test Discription

Identification of WPS followed FFZ/WPS/59, Rev.0 Production

✘ Test Coupon

Weld

Specipication and type/grade or UNS Number of base metal (s) SA 106 Gr.B, 2" SCH 80 PIPE. Thickness 5.54 mm.

Testing Varibales and Qualification Limits

Welding Variables (QW-350) Actual Values Range Qualified

Welding process (es) GTAW SMAW GTAW SMAW

Type (i.e.;manual, semi-automatic) used Manual Manual Manual Manual

With or

Backing (with/without) Without With With

Without

Plate ✘ Pipe (enter diameter if pipe or tube) 60.30 mm OD 25 mm OD And Above

Base metal P-Number to P-Number P-1 P-1 to P-15F

Filler metal or electrode specification (s) (SFA) (info.only) SFA 5.18 SFA 5.1 -- --

Filler metal or electrode classification (s) (inf.only) ER70S6 7018-1 -- --

Filler metal F-Number (s) 6 4 All F6 4,3,2,1

Consumable insert (GTAW or PAW) Not Used Not Used Not Used Not Used

Filler Metal Product form (solid/metal or flux cored/powder) GTAW OR PAW) Solid Solid Solid Solid

Deposit thickness for each process 2mm 3.54mm 4mm 7.08mm

Process 1 GTAW 3layer minimum ✘ Yes No 3 -- -- --

Process 2 SMAW 3layer minimum Yes ✘ No -- 2 -- --

Position Qualified (2G,6G,3F,etc) 6G 6G All All

Vertical progression (uphill or downhill) Uphill Uphill Uphill Uphill

Type of fuel gas (OFW) -- -- -- --

Insert gas backing (GTAW, PAW, GMAW) None None None None

Trasnfer mode (spray, globular or pulse to short circuit -GMAW) -- -- -- --

GTAW current type/polarity (AC, DCEP,DCEN) DCEN DCEP DCEN DCEP

RESULT

Visual examination of complated weld(QW-302.4) Visual examination found satisfactory

Transeverse face and root bends [QW- Logitudinal bends [QW- Side bends (QW-

462.3 (a)] specimen, corrosion-resistant weld metal overlay [QW-

Pipe bend 462.3(b)] 462.2)

462.5(c) ] specimen, corrosion-resistant weld metal overlay [QW-

Plate bend

462.5(d) ]

Pipe specimen, micro test for fusion [QW-462.5(b)] Plate specimen, micro test for fusion [QW-462.5(e)]

Type Result Type Result Type Result

-- -- -- -- -- --

-- -- -- -- -- --

Altrenative Volumatric Examination Result (QW-191) : Report No.FF/WPQ/RT-324, Accepted ✘ RT OR UT (Check one)

Fillet weld-fracture test (QW-181.2) -- Legth and percent of deffects --

Fillet weld in plate [QW- Fillet weld in pipe [QW-

462.4(b)] 462.4(c)]

Macro examinination (QW-184) -- FILLET SIZE (IN.) -- x -- Concavity/convexity(in)

Other tests None

Film or specimens evaluated by Mr. Arun Kumar Company Interface Technical Services

Mechanical test conducted by -- Laboratory test no. --

Welding supervised by Mr.SIVAKUMAR

We certify that the statements in this record are corrected and that the test coupon were prapered, welded, and tested in accordance with the

requirments of Sec IX of the ASME BOILER AND PRESSURE VESSEL CODE.

PREPARED BY CERTIFIED BY WITNESSED BY

NAME B.SIVAKUMAR K N MURTHY

SIGNATURE

DATE 18-Oct-14 18-Oct-14

You might also like

- Ilcs-Smaw-D1.3-Deck (G) WPSDocument3 pagesIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- Joints: (QW - 402) : Wps No.: Bpscl/Shel/Wps - 04 DateDocument3 pagesJoints: (QW - 402) : Wps No.: Bpscl/Shel/Wps - 04 DateAmjad PathanNo ratings yet

- Cajon-001 WPSDocument2 pagesCajon-001 WPSDanem HalasNo ratings yet

- I-963 Welder Certificate Smaw-Gtaw-1Document1 pageI-963 Welder Certificate Smaw-Gtaw-1nivedithdigitals onlineservices100% (1)

- Qw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageQw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)ventas ventasNo ratings yet

- Pt. Vista Bangun Utama: in Accordance With Section IX, ASME Boiler and Pressure Vessel Code 2013 EditionDocument1 pagePt. Vista Bangun Utama: in Accordance With Section IX, ASME Boiler and Pressure Vessel Code 2013 EditionHaryanto RNo ratings yet

- Wip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreDocument3 pagesWip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreVijayabaraniNo ratings yet

- Slamet WPQRDocument1 pageSlamet WPQRChandra Bintang W.PNo ratings yet

- 171 Gtaw&Smaw Zug Asme (Ade S 5g) WPQDocument4 pages171 Gtaw&Smaw Zug Asme (Ade S 5g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Format WPQDocument2 pagesFormat WPQAkash Singh TomarNo ratings yet

- Cert Piping W54.5Document2 pagesCert Piping W54.5SANU0% (1)

- Sa 516 WPQDocument1 pageSa 516 WPQElgen IgloriaNo ratings yet

- Welder Performance Qualification Record (WPQ) : Testing Condition and Qualification LimitsDocument9 pagesWelder Performance Qualification Record (WPQ) : Testing Condition and Qualification Limitsahmed mohamed100% (1)

- Procedure Qualification Record (PQR) : JointDocument2 pagesProcedure Qualification Record (PQR) : JointBalkishan DyavanapellyNo ratings yet

- WPS Reg Rev.0Document3 pagesWPS Reg Rev.0Ed FangNo ratings yet

- Astm A36 Chapa Grossa Ate 19mm PDFDocument1 pageAstm A36 Chapa Grossa Ate 19mm PDFHugo RodriguezNo ratings yet

- WPQ-1083 3G PDFDocument2 pagesWPQ-1083 3G PDFduendex360100% (1)

- PQR-04 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless Steel PDFDocument1 pagePQR-04 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless Steel PDFchandraNo ratings yet

- Welding SAF2205 Tubes To CS TubesheetDocument2 pagesWelding SAF2205 Tubes To CS Tubesheetmasterdol1983No ratings yet

- WPS - 006Document13 pagesWPS - 006MAT-LIONNo ratings yet

- Manual Joints (QW - 402) : Page 1 of 12Document12 pagesManual Joints (QW - 402) : Page 1 of 12miteshpatel191No ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- JTS Series High Speed Bevel Gear Screw Jack, Bevel Gear Driven Screw Jack, Bevel Gearbox Jack, Bevel Screw Jack Travel Speed, Screw Jack Bevel, Jack Screw Bevel Gearbox, Quick Lifting Screw JackDocument19 pagesJTS Series High Speed Bevel Gear Screw Jack, Bevel Gear Driven Screw Jack, Bevel Gearbox Jack, Bevel Screw Jack Travel Speed, Screw Jack Bevel, Jack Screw Bevel Gearbox, Quick Lifting Screw JackWarren LeeNo ratings yet

- 1 5 1Document5 pages1 5 1daemsalNo ratings yet

- Welder I.D CardDocument2 pagesWelder I.D Cardvhung TranNo ratings yet

- QW 482 WPSDocument2 pagesQW 482 WPSsmit patelNo ratings yet

- Welding Procedure Welding Procedure Specification SpecificationDocument2 pagesWelding Procedure Welding Procedure Specification SpecificationHamid MansouriNo ratings yet

- HHHHHHHHJJJJJJ: O O O ODocument1 pageHHHHHHHHJJJJJJ: O O O OAli MoosaviNo ratings yet

- Wps For Aluminium WeldingDocument8 pagesWps For Aluminium WeldingMohammed MusaNo ratings yet

- Welder Qualification Test Record (Email)Document1 pageWelder Qualification Test Record (Email)walitedisonNo ratings yet

- Welding Procedure Specification For GTAW & GMAWDocument4 pagesWelding Procedure Specification For GTAW & GMAWanh thoNo ratings yet

- Spec Sheet - Handler 187Document4 pagesSpec Sheet - Handler 187Hobart Welding ProductsNo ratings yet

- Gta+sma PQRDocument3 pagesGta+sma PQRRahul MoottolikandyNo ratings yet

- Hot Tap Welding ParametersDocument7 pagesHot Tap Welding ParametersSiva RamNo ratings yet

- Preliminary Welding Procedure Specification (PWPS)Document1 pagePreliminary Welding Procedure Specification (PWPS)AzriNo ratings yet

- 131.4.1-1 Temperaturas de PreaquecimentoDocument1 page131.4.1-1 Temperaturas de PreaquecimentoRodrigo CarneiroNo ratings yet

- WPS 84281 R06Document1 pageWPS 84281 R06Ritesh kumarNo ratings yet

- 188-Gmaw-Zug-Asme (Rivaldy Hendrawan-3g) - WPQDocument1 page188-Gmaw-Zug-Asme (Rivaldy Hendrawan-3g) - WPQMuhammad Fitransyah Syamsuar Putra100% (1)

- Visual Inspection ReportDocument42 pagesVisual Inspection ReportEr Pralabh ShahNo ratings yet

- WPS No. GT-SM-5B (F43) WPS No. GT-SM-5B (F43)Document4 pagesWPS No. GT-SM-5B (F43) WPS No. GT-SM-5B (F43)Amir Surya Hidayah100% (1)

- Filler Wires PDFDocument7 pagesFiller Wires PDFJayaram MVNo ratings yet

- Piping WPS SMAWDocument2 pagesPiping WPS SMAWJk KarthikNo ratings yet

- ASTM A36 DatasheetDocument4 pagesASTM A36 DatasheetRene D. ArrietaNo ratings yet

- PQR - PipeDocument3 pagesPQR - PipeAdvanced Quality Centre AQC100% (1)

- Company Name Key Information Questions Answers File Reference Reviews & ApprovalsDocument7 pagesCompany Name Key Information Questions Answers File Reference Reviews & ApprovalsMAT-LIONNo ratings yet

- WPS 05Document4 pagesWPS 05Naqqash SajidNo ratings yet

- DIN en ISO 6947-1997 Welds-Working Positions Definitions of Angles of Slope and RotationDocument12 pagesDIN en ISO 6947-1997 Welds-Working Positions Definitions of Angles of Slope and RotationHector Flores GarciaNo ratings yet

- PQR - 152Document3 pagesPQR - 152MAT-LIONNo ratings yet

- Sample Wps Carbon Steel GTAW SMAW PDFDocument2 pagesSample Wps Carbon Steel GTAW SMAW PDFirwanNo ratings yet

- Welding Procedure Specification (WPS) Welding Procedure Specification No Supporting PQR Welding Process Preheat Applicable CodeDocument5 pagesWelding Procedure Specification (WPS) Welding Procedure Specification No Supporting PQR Welding Process Preheat Applicable Codeanon_499770No ratings yet

- WPS & Materials Applicable MatrixDocument5 pagesWPS & Materials Applicable Matrixundeath123100% (1)

- DTI Installation Instructions PDFDocument3 pagesDTI Installation Instructions PDFBrad BorgesNo ratings yet

- WPS Updated PDFDocument2 pagesWPS Updated PDFRaja Muaz Ahmad KhanNo ratings yet

- QW-484A (WPQ) GTAW 4MM FilletDocument2 pagesQW-484A (WPQ) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- AUT-1023 A2 Multitrac PEKDocument1 pageAUT-1023 A2 Multitrac PEKcarlosNo ratings yet

- WPS & PQR (E Co Cr-E)Document3 pagesWPS & PQR (E Co Cr-E)HossamSAshourNo ratings yet

- Sample Forms WPS PQRDocument22 pagesSample Forms WPS PQRGMNo ratings yet

- Premier Engineering Industries: List of WPS/PQRDocument1 pagePremier Engineering Industries: List of WPS/PQRBalkishan DyavanapellyNo ratings yet

- WPQ Asme IxDocument1 pageWPQ Asme IxEDEN GONZALEZNo ratings yet

- DS-1 4th Ed - Volume 3 - Addendum 2Document7 pagesDS-1 4th Ed - Volume 3 - Addendum 2MARVELNo ratings yet

- Setting of Cement Chemistry Project Class 12Document18 pagesSetting of Cement Chemistry Project Class 12Hari KrishnanNo ratings yet

- Cameron Type F Cup Tester 2 - 3,8Document2 pagesCameron Type F Cup Tester 2 - 3,8rizjogarNo ratings yet

- How To Remove Rust From A Gun Without Damaging BluingDocument4 pagesHow To Remove Rust From A Gun Without Damaging BluingFrank MeekerNo ratings yet

- Aviation Storage TanksDocument6 pagesAviation Storage Tanksram71990No ratings yet

- SFT 0090 Control PlanDocument24 pagesSFT 0090 Control PlanspdhimanNo ratings yet

- CHE421Document1 pageCHE421Eko SuherNo ratings yet

- Bulldog Abrasives Price List 01 February 2023Document100 pagesBulldog Abrasives Price List 01 February 2023Tebogo MaposaNo ratings yet

- Chemistry 12TH ProjectDocument12 pagesChemistry 12TH Projectamitmurmu3330No ratings yet

- R. D. S. O.: Rdso/b - 10408/8Document1 pageR. D. S. O.: Rdso/b - 10408/8MUTHU PANDINo ratings yet

- Fischer Construction ScrewsDocument6 pagesFischer Construction ScrewsSimon KennyNo ratings yet

- Corrosion On AircraftDocument59 pagesCorrosion On Aircraftprakash100% (2)

- Ebook Ipal Diagram Alir PDFDocument14 pagesEbook Ipal Diagram Alir PDFDanang M AbroriNo ratings yet

- MT 633 Online Activity 2 1Document2 pagesMT 633 Online Activity 2 1Alyssa CubillaNo ratings yet

- Afi RT 014Document1 pageAfi RT 014ArhamNo ratings yet

- A2 Envirobase Plastics Chart PosterDocument1 pageA2 Envirobase Plastics Chart PosterBex'sNo ratings yet

- Glass Stair RailingsDocument1 pageGlass Stair RailingsRenz ChuaNo ratings yet

- 300 Series: FLAT Metal Hinge WITH BORE Right ThroughDocument2 pages300 Series: FLAT Metal Hinge WITH BORE Right ThroughbenciusilviuNo ratings yet

- Gas Lift EquipmentDocument23 pagesGas Lift EquipmentJose Jasso100% (1)

- FUS 3D Flanges FZF, FUFDocument1 pageFUS 3D Flanges FZF, FUFArunKumar RajendranNo ratings yet

- Hight Speep Tool SteelDocument11 pagesHight Speep Tool SteelcadcamtaiNo ratings yet

- Vendetta Mask LapaStudios 5pDocument9 pagesVendetta Mask LapaStudios 5pmarquin84No ratings yet

- Din 1.2714Document3 pagesDin 1.2714harieduidNo ratings yet

- Special Steel StripDocument18 pagesSpecial Steel Striprakesh guptaNo ratings yet

- Afilador Cuchillos Edgeselect Diamond Hone 120Document48 pagesAfilador Cuchillos Edgeselect Diamond Hone 120GonzaloNo ratings yet

- 6000+ Woodworking Projects PagesDocument1,079 pages6000+ Woodworking Projects Pagesmnboks100% (6)

- Introduction To Polymer ProcessingDocument43 pagesIntroduction To Polymer ProcessingShushil KumarNo ratings yet

- SikaMelt 9670Document2 pagesSikaMelt 9670Gicuţă Şi Geta ZvîncăNo ratings yet

- EAT227-Lecture 2.1 - Metal CastingDocument42 pagesEAT227-Lecture 2.1 - Metal CastingQim SvNo ratings yet

- C53 Technical CardDocument1 pageC53 Technical CardAnonymous umabEI6No ratings yet