Professional Documents

Culture Documents

3.1 50 Users-1

3.1 50 Users-1

Uploaded by

RaamCopyright:

Available Formats

You might also like

- Yamuna Nagar - Plywood FactoriesDocument16 pagesYamuna Nagar - Plywood Factoriesasif_hope83% (6)

- Concrete Pool Design Based On ACI 318-14: Input Data & Design SummaryDocument6 pagesConcrete Pool Design Based On ACI 318-14: Input Data & Design Summaryadmin cabuildersNo ratings yet

- Site Engineers Manual PDFDocument3 pagesSite Engineers Manual PDFFahadNo ratings yet

- Clarifier Tank Structural PDFDocument3 pagesClarifier Tank Structural PDFBenderlip CortezNo ratings yet

- Venkat - MoRTH 5th Revision Essential Tables For Highway Field EngineersDocument68 pagesVenkat - MoRTH 5th Revision Essential Tables For Highway Field EngineersV Venkata Narayana96% (28)

- ASTM C1116M-10a PDFDocument7 pagesASTM C1116M-10a PDFPablo MenendezNo ratings yet

- Foundation Plan Roof Beam and Roof Framing Plan: Detail of TrussDocument1 pageFoundation Plan Roof Beam and Roof Framing Plan: Detail of TrussPrincess DimayacyacNo ratings yet

- Sorsogon City Bulk Water Supply As-Built Plan For Water Treatment PlantDocument1 pageSorsogon City Bulk Water Supply As-Built Plan For Water Treatment PlantAlphaMae DitanNo ratings yet

- Plan 3 BuildingDocument1 pagePlan 3 BuildingcimpstazNo ratings yet

- Sub Surface Dam - PDF 1Document1 pageSub Surface Dam - PDF 1Ric ReeNo ratings yet

- Corte Longitudinal A-A Corte Transversal B-B: Puerta DE EmergenciaDocument1 pageCorte Longitudinal A-A Corte Transversal B-B: Puerta DE EmergenciaPaul GmcNo ratings yet

- ARCHITECTURAL10Document1 pageARCHITECTURAL10zaccNo ratings yet

- General Notes: A B A' A B A'Document1 pageGeneral Notes: A B A' A B A'Jaycee RollanNo ratings yet

- Working Drawing: Wooden Window (W2) Wooden Ventilator (V) Wooden Window (W1)Document1 pageWorking Drawing: Wooden Window (W2) Wooden Ventilator (V) Wooden Window (W1)harishNo ratings yet

- Rapter & Conc. Box Gutter Detail: Proposed Fence and Extension PlanDocument1 pageRapter & Conc. Box Gutter Detail: Proposed Fence and Extension PlanCresdenn FuentesNo ratings yet

- TQ Cisterna y TQ Elevado EstructurasDocument1 pageTQ Cisterna y TQ Elevado EstructurasjhonelNo ratings yet

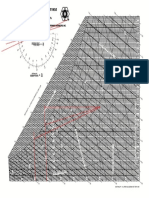

- Ashrae ChartDocument1 pageAshrae ChartHamza FayyazNo ratings yet

- Ashrae-Chart RemovedDocument1 pageAshrae-Chart RemovedSjsinssjNo ratings yet

- Psychrometric Chart - ASHRAEDocument1 pagePsychrometric Chart - ASHRAEeva.ebcedoesNo ratings yet

- Footing 03 (F3) Detail: 125Mm. Thk. Concrete SlabDocument1 pageFooting 03 (F3) Detail: 125Mm. Thk. Concrete SlabLab Dema-alaNo ratings yet

- Proposed PlansDocument1 pageProposed PlansJeremyNo ratings yet

- A-07-009 - Enlarged 1-Bedroom Units PlanDocument1 pageA-07-009 - Enlarged 1-Bedroom Units PlanzizojundiNo ratings yet

- Fachadas de La Vivienda UnifamiliarDocument1 pageFachadas de La Vivienda UnifamiliarMauricio MeloNo ratings yet

- A10-22 FARHAN KHAN (FINAL) - ModelDocument1 pageA10-22 FARHAN KHAN (FINAL) - ModelAlok VermaNo ratings yet

- Plantas Corte AmbientacionDocument1 pagePlantas Corte AmbientacionJhampool NeiraNo ratings yet

- Legend:: A. P. Garcia & AssociatesDocument1 pageLegend:: A. P. Garcia & AssociatesDominic Robiso DatuinNo ratings yet

- GF For Rcc-ModelDocument1 pageGF For Rcc-Modelharshad bahikarNo ratings yet

- Section Thru - A: Scale: 1:50MDocument1 pageSection Thru - A: Scale: 1:50MMhelvin MagdalenaNo ratings yet

- Planta Tratamiento A.residualesDocument1 pagePlanta Tratamiento A.residualesAqeel SaleemNo ratings yet

- Elevation A Elevation A: Elevation D Elevation DDocument1 pageElevation A Elevation A: Elevation D Elevation DKhushi RathodNo ratings yet

- La 6Document1 pageLa 6YASMIN ENERONo ratings yet

- Koregaon PDFDocument1 pageKoregaon PDFsskharadeNo ratings yet

- Training Center Retaining Wall PlanDocument1 pageTraining Center Retaining Wall PlanRODEL YUNTINGNo ratings yet

- Cimentación de Cisterna: Taller de Desarrollo de Proyectos I - Grupo 02Document1 pageCimentación de Cisterna: Taller de Desarrollo de Proyectos I - Grupo 02Masi Mejia SanoniNo ratings yet

- Cimentación de Cisterna: Taller de Desarrollo de Proyectos I - Grupo 02Document1 pageCimentación de Cisterna: Taller de Desarrollo de Proyectos I - Grupo 02Masi Mejia SanoniNo ratings yet

- Pl-Herbert Yu-P-2 PDFDocument1 pagePl-Herbert Yu-P-2 PDFSoy DesignoNo ratings yet

- 1 0 Denahlama (MR Afui) - ModelDocument1 page1 0 Denahlama (MR Afui) - ModelTiffany OktavianaNo ratings yet

- Primer Piso: Cuadro de ColumnasDocument1 pagePrimer Piso: Cuadro de ColumnasJonathan Valenzuela AndiaNo ratings yet

- Planta 1 Esc 1:50: Los SaucesDocument1 pagePlanta 1 Esc 1:50: Los SaucesBoris Martin Barrios LoayzaNo ratings yet

- Truss 01: Mr. & Mrs. Sire Henrik Andersson A Proposed Penthouse ExtensionDocument1 pageTruss 01: Mr. & Mrs. Sire Henrik Andersson A Proposed Penthouse ExtensionChrysler DuasoNo ratings yet

- TV ATC DysonDocument1 pageTV ATC DysonJean Lindley JosonNo ratings yet

- ASHRAE Psychrometric ChartDocument1 pageASHRAE Psychrometric ChartKenneth Dale San JuanNo ratings yet

- Ashrae Psychrometric Chart No 1 Normal TDocument1 pageAshrae Psychrometric Chart No 1 Normal TFelipe ProcopioNo ratings yet

- FCS PDFDocument1 pageFCS PDFJose Daniel Andrades del ÁguilaNo ratings yet

- PSYCHROMETRIC - CHART-Condiciones de ProyectoDocument1 pagePSYCHROMETRIC - CHART-Condiciones de Proyectoalvarellos92No ratings yet

- 11-01-2024 Grill Detail 2Document1 page11-01-2024 Grill Detail 2ABDUL SAMADNo ratings yet

- Structural 1Document1 pageStructural 1Ryan LimboNo ratings yet

- Bosa Cra 82c V1-ModelDocument1 pageBosa Cra 82c V1-ModelAlvaroSartoNo ratings yet

- Plan of Samrat ChowkDocument1 pagePlan of Samrat Chowkshivshankar kushwahaNo ratings yet

- Tempfacil Loctob Spring LobocDocument5 pagesTempfacil Loctob Spring LobocRichli HarleyNo ratings yet

- Construction Estimate 2Document1 pageConstruction Estimate 2Christopher Narvato PostigoNo ratings yet

- Roof Plan: Two-Storey Residential House Oliver B. Patupat Oliver B. PatupatDocument1 pageRoof Plan: Two-Storey Residential House Oliver B. Patupat Oliver B. Patupatbenj panganibanNo ratings yet

- Lámina A1Document1 pageLámina A1Arq Marcelo CardenasNo ratings yet

- PlanoDocument1 pagePlanojotaNo ratings yet

- 1 Storey Archl Model 1Document1 page1 Storey Archl Model 1Joenifer Jr MontebonNo ratings yet

- Typical Single Slab CulvertDocument1 pageTypical Single Slab CulvertAshok DhakalNo ratings yet

- Rchitects: V e R G A Ra V e R G A Ra V e R G A RaDocument1 pageRchitects: V e R G A Ra V e R G A Ra V e R G A RaMay Ann DuronNo ratings yet

- Drainage Details: National Housing Authority Salcedo Housing Project Variation No. 1Document1 pageDrainage Details: National Housing Authority Salcedo Housing Project Variation No. 1Jayson DaiganNo ratings yet

- Sitio Y Techos: UbicacionDocument1 pageSitio Y Techos: UbicacionJose Carlos ChuraNo ratings yet

- LO AD 2 LOWW 9-4-1 enDocument8 pagesLO AD 2 LOWW 9-4-1 enjoseph.mangan1892No ratings yet

- D C B A 1 3 2: Longitudinal Secttion Cross Section Window Grills DetailDocument1 pageD C B A 1 3 2: Longitudinal Secttion Cross Section Window Grills DetailImel Aguado TalagNo ratings yet

- Plan Armare Radier - 3Document1 pagePlan Armare Radier - 3Vlad JoldesNo ratings yet

- Proposed 4-Storey Apartment: Schedule of Doors & WindowDocument1 pageProposed 4-Storey Apartment: Schedule of Doors & WindowArch. John Bernard AbadNo ratings yet

- Comedores: Corte Transvesal C - C'Document1 pageComedores: Corte Transvesal C - C'WILDER LEQQUE QUISPENo ratings yet

- Https SLPRB - Ap.gov - in UI SIResultsDocument1 pageHttps SLPRB - Ap.gov - in UI SIResultsRaamNo ratings yet

- Ap 10220220032147Document1 pageAp 10220220032147RaamNo ratings yet

- R6.8.1 Roof Slab Water ProofingDocument88 pagesR6.8.1 Roof Slab Water ProofingRaamNo ratings yet

- HUME PIPE Mar 2018 SCHEDULEDocument11 pagesHUME PIPE Mar 2018 SCHEDULERaamNo ratings yet

- Temporary PassDocument1 pageTemporary PassRaamNo ratings yet

- Concrete Mix Design - ExcelDocument1 pageConcrete Mix Design - ExcelTijani MohammedNo ratings yet

- ACI 304R-00 Guide For Measuring, Mixing, Transporting, and Placing Concrete - MyCivil - IrDocument41 pagesACI 304R-00 Guide For Measuring, Mixing, Transporting, and Placing Concrete - MyCivil - IrAyman ZakariaNo ratings yet

- Septic Tank Estimate Copy: S.No (In Feet) (In Feet) (In Feet)Document1 pageSeptic Tank Estimate Copy: S.No (In Feet) (In Feet) (In Feet)manojNo ratings yet

- MS For Raft Concrete Works (3 Files Merged)Document13 pagesMS For Raft Concrete Works (3 Files Merged)Himanshu KumarNo ratings yet

- Precast Mix Design 2020Document2 pagesPrecast Mix Design 2020Dilhara WickramaarachchiNo ratings yet

- 1 1 High: Amendment NO. 1 June 2001 TO IS 456:2000 Plain and Reinforced Concrete - Code of Practice (FourthDocument10 pages1 1 High: Amendment NO. 1 June 2001 TO IS 456:2000 Plain and Reinforced Concrete - Code of Practice (FourthPankaj Garg100% (1)

- Book 9Document1 pageBook 9Anal BiswasNo ratings yet

- Shotcrete 3 PDFDocument18 pagesShotcrete 3 PDFCarlos GuerraNo ratings yet

- ms1314-2004 - Compress 2Document28 pagesms1314-2004 - Compress 2Robbie LimbiNo ratings yet

- Palomar Ojt - Bom FootingDocument1 pagePalomar Ojt - Bom FootingJayjay PalomarNo ratings yet

- 010 Frank Stremaform BRDocument32 pages010 Frank Stremaform BRdiogesodreNo ratings yet

- Utilization of Geopolymer Fly Ash As Concrete BinderDocument50 pagesUtilization of Geopolymer Fly Ash As Concrete BinderRonald PanaliganNo ratings yet

- Concreting Operations: OutlineDocument12 pagesConcreting Operations: OutlineanjalidilipthoraveNo ratings yet

- Review of Related Literature and Studies: Default - AspxDocument2 pagesReview of Related Literature and Studies: Default - AspxHallel John G. TangonanNo ratings yet

- Ready Mix ConcreteDocument17 pagesReady Mix ConcreteAbhishek KoulNo ratings yet

- Effect of Nano Silica On The Compressive Strength of ConcreteDocument4 pagesEffect of Nano Silica On The Compressive Strength of ConcreteEditor IJTSRDNo ratings yet

- Permissible Limit For SolidsDocument3 pagesPermissible Limit For SolidssabishanuNo ratings yet

- Supplementary Cementing MaterialsDocument23 pagesSupplementary Cementing MaterialsMIL RABNo ratings yet

- CIVIL-Concrete-Defects & Quality ControlDocument11 pagesCIVIL-Concrete-Defects & Quality ControlNeeraj VermaNo ratings yet

- A Review in High Early Strength Concrete and Local PDFDocument10 pagesA Review in High Early Strength Concrete and Local PDFAgikx ChabeNo ratings yet

- Effect of Starch Admixtures On Fresh and Hardened Properties of ConcreteDocument4 pagesEffect of Starch Admixtures On Fresh and Hardened Properties of ConcreteRockstar SantyNo ratings yet

- Master Drain Drawing From 406 To 512 (Yet To Submit)Document1 pageMaster Drain Drawing From 406 To 512 (Yet To Submit)Anal BiswasNo ratings yet

- Gambella University: Department of Civil Engineering Construction Material Chapter Three (B) - ConcreteDocument117 pagesGambella University: Department of Civil Engineering Construction Material Chapter Three (B) - ConcreteGetahun TadesseNo ratings yet

- Sector Group Sub - GroupDocument5 pagesSector Group Sub - GroupRakesh GoitNo ratings yet

- 7.RC Ditch PDFDocument2 pages7.RC Ditch PDFMuhammad IrfanNo ratings yet

3.1 50 Users-1

3.1 50 Users-1

Uploaded by

RaamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3.1 50 Users-1

3.1 50 Users-1

Uploaded by

RaamCopyright:

Available Formats

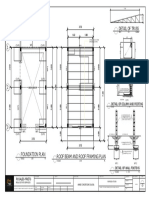

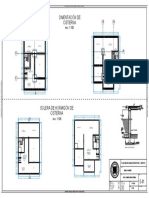

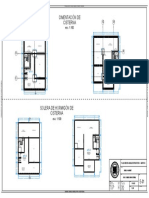

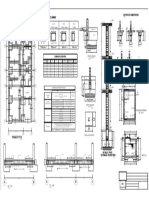

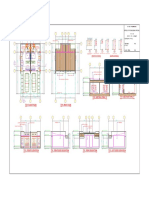

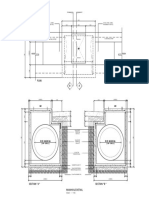

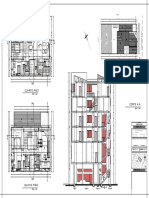

NOTES:-

1. DO NOT SCALE THE DRAWING.READ

Y FIGURED DIMENSIONS ONLY.

0.45 2.10 0.45 2. REFERENCE BENCH MARKS SHALL BE AS

0.175 0.175 PER SITE CONDITIONS.

5.00

3. USE NOMINAL MIX (1:1(12):3) PRO.OF CONCRETE

0.45

0.175

3.20 1.60 FOR ALL R.C.C MEMBERS.

4. GRADE OF STEEL SHALL BE Fe500.

0.175

INLET OUTLET

CHAMBER CHAMBER 5. CLEAR COVER FOR

MANHOLE

0.15 0.15 MAIN REINFORCEMENT:

COVER 0.6mx0.6m

1.00 BAFFLE WALL SCUM BOARD 1.00 FACE SIDE WALLS BASE SLAB

0.45 WATER FACE 25mm 25mm

MANHOLE COVER MANHOLE COVER

2.10

0.3mx0.15m EARTH FACE 40mm 40mm

X 0.6mx0.6m OPENINGS 0.6mx0.6m X

0.90 OUTLET PIPE 6. FIELD AUTHORITIES ARE REQUESTED TO

0.60

0.60

0.90

0.45

1.60

ENSURE THE DIMENSIONS BEFORETAKEN

UP FOR EXECUTION.

7. PROVIDE CLIPS TO SEPARATE REINF.

GRILLS ON FACES OF SIDE WALLS.

0.115 BRICK 8. THE PROVISIONS MADE IN IS 456-2000,

CHAMBER 3370, SP34,IS 2470 (PART 1&2)-1985 AND

0.175

OTHER RELEVANT CODES SHOULD BE

STRICTLY ADHERED DURING EXECUTION.

9. SLEEVES FOR ALL PIPE CONNECTIONS

0.45

TYPICAL RUNGS TYPICAL RUNGS

INLET & OUTLET SHALL BE PROVIDED

Y BEFORE CONCRETING.

PLAN

10.REINFORCEMENT IN SLABS ARE

CRANKED AT 0.25L NEAR CONTINUOUS

EDGE AND 0.15L NEAR DISCONTINUOUS

EDGE.(L=SPAN FROM c/c OF SUPPORT) THE

CRANKED BARS AND OTHER EXTRA BARS

VENT PIPE 0.3mx0.3mx0.45m OVER CONTINUOUS EDGE SHOULD BE

COVER SLAB IN COVER SLAB IN

PCC(1:3:6) FILLER TAKEN UPTO 0.3L FROM FACE OF SUPPORT

TWO PIECES TWO PIECES

0.05

0.05

ON EITHER SIDE OF THE BEAM SUPPORTS

0.05

0.05

0.125

0.125

0.175 @200 c/c @200 c/c

@200 c/c

0.175

@200 c/c

0.175 UNLESS OTHERWISE INDICATED IN THE

@200 c/c @200 c/c

DRAWING.

11. CHECK ALL THE REINFORCEMENT BARS

0.30

0.30

0.15 as per site

condition

as per site

condition

0.30(min)

G.L BEFORE POURING THE CONCRETE INTO

varies as

condition

per site

0.15 0.15 RC MEMBERS.

@150 c/c @150 c/c

(min)

12. CONTINUOUS CURING SHALL BE DONE

0.15

0.45 0.45

0.15

0.90

T.W.L

0.05

R.R MASONRY FOR ATLEAST 15DAYS.

0.30

0.15

IN CM(1:8) 13. DEVELOPMENT LENGTH OF RODS IS

0.60

0.60

SLOPE 1 IN

20 49 TIMES OF Dia.

1.15 @100 c/c

14. INLET & OUTLET PIPES LOCATION

0.15

1.15

0.15

0.10m thk BAFFLE WALL SCUM BOARD 0.10m thk SHOWN ARE REPRESENTATIVE OR

1.30

P.C.C 0.3mx0.15m P.C.C BRICK CHAMBER

0.10 INDICATIVE AND TO BE PROVIDED AS PER

0.10 OPENING @150 c/c WITH DRY JOINTS

@100 c/c

@150 c/c DEFLECTOR 0.15 REQUIREMENT AT SITE.

0.3mx0.3m @100 c/c 15. PROVIDE 600X600 PRECAST MANHOLE

@150 c/c HAUNCH @150 c/c 0.20 COVER FOR SUMP

@150 c/c R.R STONE

2.00

0.3mx0.3m WITH DRY JOINTS

0.25

0.20 HAUNCH DRG NO:

0.25

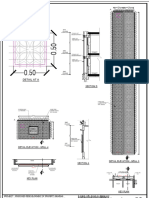

0.10m thk @125 c/c @125 c/c 75mm STONE 01/CE/APEWIDC/50 USERS/SEPTIC TANK DETAILS-1

@125 c/c P.C.C AGGREGATE

@125 c/c PROJECT:

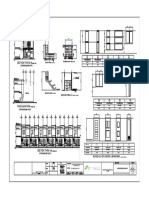

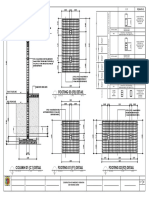

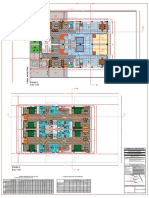

SECTION - "X X"

CONSTRUCTION OF SEPTIC TANKS

0.65 0.65

0.10m thk FOR PRIMARY/UPPER PRIMARY

P.C.C

SCHOOL UNDER MANABADI:

NAADU-NEDU IN AP STATE

VENT PIPE

0.3mX0.3mX0.45m

PCC(1:3:6) FILLER

SHEET TITLE:

0.45 2.10 0.45 0.065 0.075 HOOK BAR

0.175 @200 c/c

@200 c/c 0.175

varies as 0.125

0.45

0.30

condition

G.L MODEL DRAWING FOR

per site

T.W.L

0.60

@175c/c

SEPTIC TANK DETAILS-1

TYPICAL MANHOLE OPENING DETAILS

@150c/c (FOR 50 USERS)

@150c/c

@100 c/c @100 c/c 0.075

@200 c/c

1.30

2.10

@150 c/c @150 c/c //APPROVED//

varies

0.3mx0.3m 1.15

@150 c/c HAUNCH

INLET & OUTLET COVER SLAB

Sd/-xxxxx

0.20

@125 c/c

0.20 CHIEF ENGINEER

TYPICAL RUNGS DETAILS A.P.E.W.I.D.C,

0.25

VIJAYAWADA.

0.45

0.10m thk

P.C.C @125 c/c

SOAKPIT TOP SLAB

SECTION - "YY" REINFORCEMENT DETAILS

//TRUE COPY//

**NOTES:-

1. WHILE EXECUTING THE SEPTIC TANK, INVERT LEVEL AT INLET CHAMBER SHALL BE

ENSURED WITH RESPECT TO THE INVERT LEVEL OF THE CONNECTING MANHOLE.

2. WHERE THERE IS EXISTING DRAINAGE SYSTEM OUTLET PIPE FROM SEPTIC TANK

SHALL BE CONNECTED DIRECTLY TO THE DRAIN.(i.e NO SEEPAGE PIT IS REQUIRED). EXECUTIVE ENGINEER

A.P.E.W.I.D.C, VIJAYAWADA.

THE DRAWING IS PROPERTY OF CONSULTANT, IT SHOULD NOT BE USED, COPIED OR REPRODUCED WITHOUT THEIR WRITTEN PERMISSION.

You might also like

- Yamuna Nagar - Plywood FactoriesDocument16 pagesYamuna Nagar - Plywood Factoriesasif_hope83% (6)

- Concrete Pool Design Based On ACI 318-14: Input Data & Design SummaryDocument6 pagesConcrete Pool Design Based On ACI 318-14: Input Data & Design Summaryadmin cabuildersNo ratings yet

- Site Engineers Manual PDFDocument3 pagesSite Engineers Manual PDFFahadNo ratings yet

- Clarifier Tank Structural PDFDocument3 pagesClarifier Tank Structural PDFBenderlip CortezNo ratings yet

- Venkat - MoRTH 5th Revision Essential Tables For Highway Field EngineersDocument68 pagesVenkat - MoRTH 5th Revision Essential Tables For Highway Field EngineersV Venkata Narayana96% (28)

- ASTM C1116M-10a PDFDocument7 pagesASTM C1116M-10a PDFPablo MenendezNo ratings yet

- Foundation Plan Roof Beam and Roof Framing Plan: Detail of TrussDocument1 pageFoundation Plan Roof Beam and Roof Framing Plan: Detail of TrussPrincess DimayacyacNo ratings yet

- Sorsogon City Bulk Water Supply As-Built Plan For Water Treatment PlantDocument1 pageSorsogon City Bulk Water Supply As-Built Plan For Water Treatment PlantAlphaMae DitanNo ratings yet

- Plan 3 BuildingDocument1 pagePlan 3 BuildingcimpstazNo ratings yet

- Sub Surface Dam - PDF 1Document1 pageSub Surface Dam - PDF 1Ric ReeNo ratings yet

- Corte Longitudinal A-A Corte Transversal B-B: Puerta DE EmergenciaDocument1 pageCorte Longitudinal A-A Corte Transversal B-B: Puerta DE EmergenciaPaul GmcNo ratings yet

- ARCHITECTURAL10Document1 pageARCHITECTURAL10zaccNo ratings yet

- General Notes: A B A' A B A'Document1 pageGeneral Notes: A B A' A B A'Jaycee RollanNo ratings yet

- Working Drawing: Wooden Window (W2) Wooden Ventilator (V) Wooden Window (W1)Document1 pageWorking Drawing: Wooden Window (W2) Wooden Ventilator (V) Wooden Window (W1)harishNo ratings yet

- Rapter & Conc. Box Gutter Detail: Proposed Fence and Extension PlanDocument1 pageRapter & Conc. Box Gutter Detail: Proposed Fence and Extension PlanCresdenn FuentesNo ratings yet

- TQ Cisterna y TQ Elevado EstructurasDocument1 pageTQ Cisterna y TQ Elevado EstructurasjhonelNo ratings yet

- Ashrae ChartDocument1 pageAshrae ChartHamza FayyazNo ratings yet

- Ashrae-Chart RemovedDocument1 pageAshrae-Chart RemovedSjsinssjNo ratings yet

- Psychrometric Chart - ASHRAEDocument1 pagePsychrometric Chart - ASHRAEeva.ebcedoesNo ratings yet

- Footing 03 (F3) Detail: 125Mm. Thk. Concrete SlabDocument1 pageFooting 03 (F3) Detail: 125Mm. Thk. Concrete SlabLab Dema-alaNo ratings yet

- Proposed PlansDocument1 pageProposed PlansJeremyNo ratings yet

- A-07-009 - Enlarged 1-Bedroom Units PlanDocument1 pageA-07-009 - Enlarged 1-Bedroom Units PlanzizojundiNo ratings yet

- Fachadas de La Vivienda UnifamiliarDocument1 pageFachadas de La Vivienda UnifamiliarMauricio MeloNo ratings yet

- A10-22 FARHAN KHAN (FINAL) - ModelDocument1 pageA10-22 FARHAN KHAN (FINAL) - ModelAlok VermaNo ratings yet

- Plantas Corte AmbientacionDocument1 pagePlantas Corte AmbientacionJhampool NeiraNo ratings yet

- Legend:: A. P. Garcia & AssociatesDocument1 pageLegend:: A. P. Garcia & AssociatesDominic Robiso DatuinNo ratings yet

- GF For Rcc-ModelDocument1 pageGF For Rcc-Modelharshad bahikarNo ratings yet

- Section Thru - A: Scale: 1:50MDocument1 pageSection Thru - A: Scale: 1:50MMhelvin MagdalenaNo ratings yet

- Planta Tratamiento A.residualesDocument1 pagePlanta Tratamiento A.residualesAqeel SaleemNo ratings yet

- Elevation A Elevation A: Elevation D Elevation DDocument1 pageElevation A Elevation A: Elevation D Elevation DKhushi RathodNo ratings yet

- La 6Document1 pageLa 6YASMIN ENERONo ratings yet

- Koregaon PDFDocument1 pageKoregaon PDFsskharadeNo ratings yet

- Training Center Retaining Wall PlanDocument1 pageTraining Center Retaining Wall PlanRODEL YUNTINGNo ratings yet

- Cimentación de Cisterna: Taller de Desarrollo de Proyectos I - Grupo 02Document1 pageCimentación de Cisterna: Taller de Desarrollo de Proyectos I - Grupo 02Masi Mejia SanoniNo ratings yet

- Cimentación de Cisterna: Taller de Desarrollo de Proyectos I - Grupo 02Document1 pageCimentación de Cisterna: Taller de Desarrollo de Proyectos I - Grupo 02Masi Mejia SanoniNo ratings yet

- Pl-Herbert Yu-P-2 PDFDocument1 pagePl-Herbert Yu-P-2 PDFSoy DesignoNo ratings yet

- 1 0 Denahlama (MR Afui) - ModelDocument1 page1 0 Denahlama (MR Afui) - ModelTiffany OktavianaNo ratings yet

- Primer Piso: Cuadro de ColumnasDocument1 pagePrimer Piso: Cuadro de ColumnasJonathan Valenzuela AndiaNo ratings yet

- Planta 1 Esc 1:50: Los SaucesDocument1 pagePlanta 1 Esc 1:50: Los SaucesBoris Martin Barrios LoayzaNo ratings yet

- Truss 01: Mr. & Mrs. Sire Henrik Andersson A Proposed Penthouse ExtensionDocument1 pageTruss 01: Mr. & Mrs. Sire Henrik Andersson A Proposed Penthouse ExtensionChrysler DuasoNo ratings yet

- TV ATC DysonDocument1 pageTV ATC DysonJean Lindley JosonNo ratings yet

- ASHRAE Psychrometric ChartDocument1 pageASHRAE Psychrometric ChartKenneth Dale San JuanNo ratings yet

- Ashrae Psychrometric Chart No 1 Normal TDocument1 pageAshrae Psychrometric Chart No 1 Normal TFelipe ProcopioNo ratings yet

- FCS PDFDocument1 pageFCS PDFJose Daniel Andrades del ÁguilaNo ratings yet

- PSYCHROMETRIC - CHART-Condiciones de ProyectoDocument1 pagePSYCHROMETRIC - CHART-Condiciones de Proyectoalvarellos92No ratings yet

- 11-01-2024 Grill Detail 2Document1 page11-01-2024 Grill Detail 2ABDUL SAMADNo ratings yet

- Structural 1Document1 pageStructural 1Ryan LimboNo ratings yet

- Bosa Cra 82c V1-ModelDocument1 pageBosa Cra 82c V1-ModelAlvaroSartoNo ratings yet

- Plan of Samrat ChowkDocument1 pagePlan of Samrat Chowkshivshankar kushwahaNo ratings yet

- Tempfacil Loctob Spring LobocDocument5 pagesTempfacil Loctob Spring LobocRichli HarleyNo ratings yet

- Construction Estimate 2Document1 pageConstruction Estimate 2Christopher Narvato PostigoNo ratings yet

- Roof Plan: Two-Storey Residential House Oliver B. Patupat Oliver B. PatupatDocument1 pageRoof Plan: Two-Storey Residential House Oliver B. Patupat Oliver B. Patupatbenj panganibanNo ratings yet

- Lámina A1Document1 pageLámina A1Arq Marcelo CardenasNo ratings yet

- PlanoDocument1 pagePlanojotaNo ratings yet

- 1 Storey Archl Model 1Document1 page1 Storey Archl Model 1Joenifer Jr MontebonNo ratings yet

- Typical Single Slab CulvertDocument1 pageTypical Single Slab CulvertAshok DhakalNo ratings yet

- Rchitects: V e R G A Ra V e R G A Ra V e R G A RaDocument1 pageRchitects: V e R G A Ra V e R G A Ra V e R G A RaMay Ann DuronNo ratings yet

- Drainage Details: National Housing Authority Salcedo Housing Project Variation No. 1Document1 pageDrainage Details: National Housing Authority Salcedo Housing Project Variation No. 1Jayson DaiganNo ratings yet

- Sitio Y Techos: UbicacionDocument1 pageSitio Y Techos: UbicacionJose Carlos ChuraNo ratings yet

- LO AD 2 LOWW 9-4-1 enDocument8 pagesLO AD 2 LOWW 9-4-1 enjoseph.mangan1892No ratings yet

- D C B A 1 3 2: Longitudinal Secttion Cross Section Window Grills DetailDocument1 pageD C B A 1 3 2: Longitudinal Secttion Cross Section Window Grills DetailImel Aguado TalagNo ratings yet

- Plan Armare Radier - 3Document1 pagePlan Armare Radier - 3Vlad JoldesNo ratings yet

- Proposed 4-Storey Apartment: Schedule of Doors & WindowDocument1 pageProposed 4-Storey Apartment: Schedule of Doors & WindowArch. John Bernard AbadNo ratings yet

- Comedores: Corte Transvesal C - C'Document1 pageComedores: Corte Transvesal C - C'WILDER LEQQUE QUISPENo ratings yet

- Https SLPRB - Ap.gov - in UI SIResultsDocument1 pageHttps SLPRB - Ap.gov - in UI SIResultsRaamNo ratings yet

- Ap 10220220032147Document1 pageAp 10220220032147RaamNo ratings yet

- R6.8.1 Roof Slab Water ProofingDocument88 pagesR6.8.1 Roof Slab Water ProofingRaamNo ratings yet

- HUME PIPE Mar 2018 SCHEDULEDocument11 pagesHUME PIPE Mar 2018 SCHEDULERaamNo ratings yet

- Temporary PassDocument1 pageTemporary PassRaamNo ratings yet

- Concrete Mix Design - ExcelDocument1 pageConcrete Mix Design - ExcelTijani MohammedNo ratings yet

- ACI 304R-00 Guide For Measuring, Mixing, Transporting, and Placing Concrete - MyCivil - IrDocument41 pagesACI 304R-00 Guide For Measuring, Mixing, Transporting, and Placing Concrete - MyCivil - IrAyman ZakariaNo ratings yet

- Septic Tank Estimate Copy: S.No (In Feet) (In Feet) (In Feet)Document1 pageSeptic Tank Estimate Copy: S.No (In Feet) (In Feet) (In Feet)manojNo ratings yet

- MS For Raft Concrete Works (3 Files Merged)Document13 pagesMS For Raft Concrete Works (3 Files Merged)Himanshu KumarNo ratings yet

- Precast Mix Design 2020Document2 pagesPrecast Mix Design 2020Dilhara WickramaarachchiNo ratings yet

- 1 1 High: Amendment NO. 1 June 2001 TO IS 456:2000 Plain and Reinforced Concrete - Code of Practice (FourthDocument10 pages1 1 High: Amendment NO. 1 June 2001 TO IS 456:2000 Plain and Reinforced Concrete - Code of Practice (FourthPankaj Garg100% (1)

- Book 9Document1 pageBook 9Anal BiswasNo ratings yet

- Shotcrete 3 PDFDocument18 pagesShotcrete 3 PDFCarlos GuerraNo ratings yet

- ms1314-2004 - Compress 2Document28 pagesms1314-2004 - Compress 2Robbie LimbiNo ratings yet

- Palomar Ojt - Bom FootingDocument1 pagePalomar Ojt - Bom FootingJayjay PalomarNo ratings yet

- 010 Frank Stremaform BRDocument32 pages010 Frank Stremaform BRdiogesodreNo ratings yet

- Utilization of Geopolymer Fly Ash As Concrete BinderDocument50 pagesUtilization of Geopolymer Fly Ash As Concrete BinderRonald PanaliganNo ratings yet

- Concreting Operations: OutlineDocument12 pagesConcreting Operations: OutlineanjalidilipthoraveNo ratings yet

- Review of Related Literature and Studies: Default - AspxDocument2 pagesReview of Related Literature and Studies: Default - AspxHallel John G. TangonanNo ratings yet

- Ready Mix ConcreteDocument17 pagesReady Mix ConcreteAbhishek KoulNo ratings yet

- Effect of Nano Silica On The Compressive Strength of ConcreteDocument4 pagesEffect of Nano Silica On The Compressive Strength of ConcreteEditor IJTSRDNo ratings yet

- Permissible Limit For SolidsDocument3 pagesPermissible Limit For SolidssabishanuNo ratings yet

- Supplementary Cementing MaterialsDocument23 pagesSupplementary Cementing MaterialsMIL RABNo ratings yet

- CIVIL-Concrete-Defects & Quality ControlDocument11 pagesCIVIL-Concrete-Defects & Quality ControlNeeraj VermaNo ratings yet

- A Review in High Early Strength Concrete and Local PDFDocument10 pagesA Review in High Early Strength Concrete and Local PDFAgikx ChabeNo ratings yet

- Effect of Starch Admixtures On Fresh and Hardened Properties of ConcreteDocument4 pagesEffect of Starch Admixtures On Fresh and Hardened Properties of ConcreteRockstar SantyNo ratings yet

- Master Drain Drawing From 406 To 512 (Yet To Submit)Document1 pageMaster Drain Drawing From 406 To 512 (Yet To Submit)Anal BiswasNo ratings yet

- Gambella University: Department of Civil Engineering Construction Material Chapter Three (B) - ConcreteDocument117 pagesGambella University: Department of Civil Engineering Construction Material Chapter Three (B) - ConcreteGetahun TadesseNo ratings yet

- Sector Group Sub - GroupDocument5 pagesSector Group Sub - GroupRakesh GoitNo ratings yet

- 7.RC Ditch PDFDocument2 pages7.RC Ditch PDFMuhammad IrfanNo ratings yet