Professional Documents

Culture Documents

AlFattan AM Fit Gap Final v01.03

AlFattan AM Fit Gap Final v01.03

Uploaded by

marketing.alfattanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AlFattan AM Fit Gap Final v01.03

AlFattan AM Fit Gap Final v01.03

Uploaded by

marketing.alfattanCopyright:

Available Formats

SAP S/4HANA FIT-GAP Document

Asset Management

Version 01.03

Inflexion Tech FZC, PO BOX 130756, Abu Dhabi, UAE

Contents

Purpose ......................................................................................................................................................... 5

Project Details ............................................................................................................................................... 5

SAP Business FIT GAP | Solution Scope ........................................................................................................ 6

Purpose & Key Assumptions ..................................................................................................................... 6

Functional Scope Supported Business Processes or Scope items ............................................................ 6

1. Organization Structure .......................................................................................................................... 7

1.1. ALFATTAN Organizational Structure ............................................................................................. 7

1.2. Asset management Overview Diagram......................................................................................... 8

1.3. Key Elements ............................................................................................................................... 10

1.4. Key Data Structure (KDS) ............................................................................................................ 11

Technical Object type.......................................................................................................... 11

Functional Location Structure ............................................................................................. 12

Define ABC Indicators ......................................................................................................... 13

Equipment Categories ......................................................................................................... 13

Equipment Number ranges ................................................................................................. 13

Set View Profiles ................................................................................................................. 14

Assign view profile to Equipment category ........................................................................ 14

Define Notification Types.................................................................................................... 15

Define Number Ranges for Notification.............................................................................. 16

Define Order Types ............................................................................................................. 17

2. Master Data ........................................................................................................................................ 19

2.1. Purpose ....................................................................................................................................... 19

2.2. Master data elements ................................................................................................................. 19

Work center ........................................................................................................................ 19

Functional Location ............................................................................................................. 19

Equipment / Fleet ............................................................................................................... 20

Equipment Bill of Materials................................................................................................. 20

Measuring Points and counter ............................................................................................ 21

Maintenance Strategies ...................................................................................................... 21

Maintenance Task list ......................................................................................................... 21

Maintenance Plan ............................................................................................................... 21

Page 2 of 44 Asset Management - Fit-Gap Document - Confidential Version 01.03

Material Master .................................................................................................................. 21

Cost center .......................................................................................................................... 22

3. Asset Management Business Processes ............................................................................................. 22

3.1. Corrective maintenance (BH1) .................................................................................................... 22

Purpose ............................................................................................................................... 22

Key process steps ................................................................................................................ 23

Business process Diagram ................................................................................................... 25

Reports ................................................................................................................................ 26

Roles .................................................................................................................................... 26

Integration .......................................................................................................................... 26

Gap ...................................................................................................................................... 27

Others/Out-Of-Scope .......................................................................................................... 27

3.2. Preventive Maintenance (BJ2) .................................................................................................... 27

Purpose ............................................................................................................................... 27

Key Process Steps ................................................................................................................ 28

Business Process Diagram ................................................................................................... 29

Reports ................................................................................................................................ 31

Roles .................................................................................................................................... 31

Integration .......................................................................................................................... 31

Gap ...................................................................................................................................... 32

Others/Out-Of-Scope .......................................................................................................... 32

3.3. Emergency Maintenance (BH2) .................................................................................................. 32

Purpose ............................................................................................................................... 32

Key Process Steps ................................................................................................................ 32

Business Process Diagram ................................................................................................... 34

Reports ................................................................................................................................ 35

Roles .................................................................................................................................... 36

Integration .......................................................................................................................... 36

Gap ...................................................................................................................................... 36

Others/Out-Of-Scope .......................................................................................................... 36

3.4. Calibration Processing (32L)........................................................................................................ 37

Purpose ............................................................................................................................... 37

Key Process Steps ................................................................................................................ 37

Page 3 of 44 Asset Management - Fit-Gap Document - Confidential Version 01.03

Business Process Diagram ................................................................................................... 38

Reports ................................................................................................................................ 38

Roles .................................................................................................................................... 39

Integration .......................................................................................................................... 39

Gap ...................................................................................................................................... 40

Others/Out-Of-Scope .......................................................................................................... 40

3.5. Refurbishment Management ...................................................................................................... 40

Purpose ............................................................................................................................... 40

Key Process Steps ................................................................................................................ 41

Business Process Diagram ................................................................................................... 42

Reports ................................................................................................................................ 42

Roles .................................................................................................................................... 43

Integration .......................................................................................................................... 43

Gap ...................................................................................................................................... 43

Others/Out-Of-Scope .......................................................................................................... 44

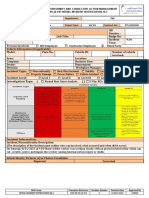

4. Document Sign-off .............................................................................................................................. 44

Page 4 of 44 Asset Management - Fit-Gap Document - Confidential Version 01.03

Purpose

This document is to capture CUSTOMER (Al Fattan Investment Holding LLC) requirements and the gap’s

discussed during Fit to Gap Sessions and for CUSTOMER Approval of Business users by a sign-off to go on

to the next Activity/phase of the SAP S/4HANA Implementation Project.

Project Details

PROJECT/PHASE IDENTIFICATION

Project Type

Project Name and Phase Project Number

(Implementation, Upgrade, other)

AlFattan & Explore Phase INFAE0056 IMPLEMENTATION

Customer Name Customer Number Date

AlFattan Investment Holding LLC 2699474 25-Nov-2022

Project Manager (Inflexion) Consultant Name (Inflexion)

Mr. Bhupesh Akkineni Mr. Dnyanesh Bhabal & Mr. Benitto A.

Project Sponsor (AlFattan) Project Manager (AlFattan)

Mr. Khaled Mohamed Rashed Al Rumaithi Mr. Firas Akram Al-Zubaidi

SAP Solution Country

SAP S/4HANA ( RISE PE) United Arab Emirates

Instance Database / Client

ASD 050

Disclaimer: All custom development and enhancement solutions mentioned in the document are subject

to technical object extensibility permitted by SAP Solution. We do not take the responsibility if this

technical feasibility is not available at the time of solution development and implementation. Suggested

Functional Solutions could have an impact based on the Future release from SAP which would then not

be our responsibility.

DOCUMENT CONTROL

Name Title Date Version

Mr. Dnyanesh Initial Draft version of SAP Asset Management Fit- 25.Nov.2022 v01.00

Bhabal Gap prepared by

Mr. Benitto A.

Page 5 of 44 Asset Management - Fit-Gap Document - Confidential Version 01.03

Mr. Benitto A Final Version of SAP Asset Management Fit-gap 10 Mar 2023 v01.01

document

Mr. Benitto A SAP Asset Management Fit-gap document 23 Mar 2023 v01.02

Mr. Bhupesh A Updated Fit-Gap 11Apr 2023 v01.03

SAP Business FIT GAP | Solution Scope

Purpose & Key Assumptions

This business FIT GAP document provides an overview of the processes and functions covered by the SAP

S4HANA Baseline Package, S4HANA solution and Best Practices.

It describes the functions and explains their business purposes. The solution design proposed in the

business FIT GAP document based on the assumption of the mutual agreement between Client and that

the SAP S4HANA, the SAP Best Practices will be positioned for this project to speed the implementation

process.

Any variations or requirements that do not match the business scenarios in reference to Client Business

Processes are recorded in gap section.

Functional Scope Supported Business Processes or Scope items

SAP Best Practices are the easiest way to set up a business solution that provides unlimited scalability,

best-of-breed functionality, complete integration, and easy collaboration for every business. With SAP

Best Practices we can reap business benefits quickly and eliminate as much risk as possible.

SAP Best Practices Baseline Package quickly turns the respective SAP software into a live system that

handles all the specific business requirements. Preconfigured business scope items help to rapidly realize

business benefits. Use it to evaluate the specific business solution. And use it to implement this solution

so that we can realize all its benefits faster, with less effort, and less expensively than ever before.

Page 6 of 44 Asset Management - Fit-Gap Document - Confidential Version 01.03

1. Organization Structure

1.1. ALFATTAN Organizational Structure

Page 7 of 44 Asset Management - Fit-Gap Document - Confidential Version 01.03

1.2. Asset management Overview Diagram

Asset management follows the Organization structure defined by other Business functions. The

following Organization units are followed in Asset management.

Maintenance Plants:

Company Plant Planning Maintenance Description

Code Plant Plant

1100 1100 1100 1100 Al Fattan Holding Investment LLC

1200 1200 1200 1200 Al Fattan Ship Industry

1300 1300 1300 1300 Al Fattan Marine Services

1400 1400 1400 1400 Al Fattan Contracting & Properties

Management

1500 1500 1500 1500 Al Fattan Defense System LLC

Page 8 of 44 Asset Management - Fit-Gap Document - Confidential Version 01.03

Plant Sections:

Maintenance Plant Plant Section Description

1100 01 Section 1

02 Section 2

03 Section 3

1200 01 Aluminium Workshop

02 Fabrication Section

03 AFMS

04 Carpentry

05 70M Workshop

06 Piping Workshop

07 Lamination Workshop

08 Marine Fiber Workshop

09 Fiber Workshop

10 New Electrical Workshop

11 Machine Workshop

1300 01 Sites

02 Fabrication (Al Fattan Yard)

03 Dock Area

04 Shipyard

1400 01 Sites

02 Fabrication (Al Fattan Yard)

03 Dock Area

1500 01 Section 1

02 Section 2

03 Section 3

Page 9 of 44 Asset Management - Fit-Gap Document - Confidential Version 01.03

Planner Group:

Maintenance Planning Plant Planner Group Description

1100 110 Maintenance

170 IT

1200 210 Utilities

220 Manufacturing

230 Instrumentation

240 Civil

250 Project

260 Quality

271 IT1

272 IT2

273 IT3

1300 310 Maintenance

320 IT

1400 410 Maintenance

420 IT

1500 510 Maintenance

520 IT

1.3. Key Elements

Maintenance Planning Plant - The Maintenance Planning Plant for technical objects is the plant in

which the maintenance tasks for the object are planned and prepared. ALFATTAN will have De-

centralized Planning, which means all maintenance plant will have their independent Planning plants.

Maintenance Plant - The maintenance plant of a technical object is the plant at which it is installed.

Work center - The main work center usually represents one person or a department, responsible for

ensuring that the maintenance work in an order is executed by the work centers performing the

individual operations.

Maintenance Planner group - Maintenance Planner group must be defined separately for each

Maintenance Planning Plant.

Plant Section - The plant section enables you to subdivide the maintenance plant from the point of

view of production responsibility. The person responsible for the plant section is the contact for

Page 10 of 44 Asset Management - Fit-Gap Document - Confidential Version 01.03

coordination between production and plant maintenance. The plant section can be used for

evaluation purposes.

1.4. Key Data Structure (KDS)

Technical Object type

Define different types of technical objects to categorize the Assets. You can assign each piece of

equipment and each functional location to a technical object type. This allows pieces of equipment that

have the same use, for example, to be combined into groups. You can use this grouping for evaluating

your master data or maintenance data. Below is the finalized list agreed by ALFATTAN.

Object Description

type

1000 Chillers

1010 Boilers

1020 Pumps

1030 Test Equipment

1040 Weighing

1050 Compressors

1060 Motors

1070 Quality Control Equipment

1080 HVAC

1090 Exhaust Fans

1100 Sensor

1110 Miscellaneous

1120 R&D Equipment

1130 QA Equipment

4000 Car

4010 Pickup

4020 Van

4030 Bus

4040 Trucks

4050 Heavy Machinery

4060 Spare 1

4070 Spare 2

Page 11 of 44 Asset Management - Fit-Gap Document - Confidential Version 01.03

6000 Server

6010 Computers

6020 Storage

6030 Accessories

6040 Media

6050 NVR

6060 Cameras

6070 Network Appliance

6080 Access Point

6090 Access Control

6100 Telephone

6110 IT 1

6120 IT 2

6130 IT 3

Note: Final confirmation is required from Al Fattan Business team on the preferred Object types

Functional Location Structure

It determines the generic structure of the functional location label. In this step, we can define the site

structure indicators for functional locations. The structure indicator determines the number of the

hierarchy levels when we create functional location structures.

Structure Indicator Structure

Engineering Mask ID: XX-NN-XXXXX-XXX-XXX

Hierarchy Level: 1 2 3 4 5

IT XX-NN-XXXXX-XXX-XXX

Vehicle XXXX-XXX-XXX-XXXXXXXXX

Example: “PR-01-HG001” will denote Production department’s 1st room in Hanger number 1 where

machine is located.

Where,

First 2 characters denote: Department Code (PR= Production, WH=Warehouse)

3rd & 4th Character denote: Section/Room number (00= Ground floor, 01= First floor or 01= Room

number 1 within Production)

5th to 9th Character denote: Sub Section (as per existing practice eg: Hanger location)

Page 12 of 44 Asset Management - Fit-Gap Document - Confidential Version 01.03

Note: Final confirmation is required from Al Fattan Business team on the preferred Coding Mask

Define ABC Indicators

ABC indicators to describe criticality of the Asset. Example is shown in the below. These will be available

as an additional categorization criterion which can be used at a later instance by ALFATTAN if required.

We should not confuse the ABC indicators with ‘Priority’ function used in Maintenance Order.

ABC Ind. ABC Indicator text

A Critical

B Medium

C Low

Equipment Categories

We must allocate an equipment category to every equipment master record that we create. The Category

determine the features of an equipment master by its equipment category. Example is shown in the

below. The below Categories are recommended by Inflexion as there is no input from Al-Fattan Business

Users.

Categories Equipment Category Description

M Engineering Equipment

Q Test/ Measurement Equipment

V Vehicle

I IT Equipment

Equipment Number ranges

Number assignment is for each Equipment category. We must allocate a unique number for each

equipment master record. It will be an internal number range, meaning the System will generate the

sequential number for each equipment based on the category. The existing machine ID’s can be assigned

to the system generated SAP equipment ID for ease of reporting and analysis.

Categories From Number To Number External

M 10000000 19999999

I 20000000 29999999

Page 13 of 44 Asset Management - Fit-Gap Document - Confidential Version 01.03

Q 30000000 39999999

V 40000000 49999999

Set View Profiles

This Customizing activity allows to create individual screens for technical objects. Each view profile

enables to assign pre-grouped and accompanying data fields to individual screen templates.

Profile Layout Description

EN000001 Engineering Machines

EN000002 Test Equipment View

IT000001 IT Equipment View

FLEET01 Vehicle View

Assign view profile to Equipment category

In this activity, we define applicable View Profile for each Equipment category. SAP gives flexibility to

assign different Fleet Object types to different Screen views if required. However, we will not have

different screen layouts for different Vehicle types in ALFATTAN as there is no such business requirement

presently.

Equipment cat. Profile

M EN000001

Q EN000002

V FLEET01

I IT000001

Page 14 of 44 Asset Management - Fit-Gap Document - Confidential Version 01.03

Define Notification Types

Each notification type references a notification category and an origin. The origin requires a suitable

screen control in the notification transactions.

Plant Notification Notification origin To be Used by

Type

1100 1A Engg- General Maintenance Engineering Team

1B Engg- Breakdown Maintenance

1C Engg- Preventive Maintenance

1X IT- General Maintenance IT Team

1Y IT- Breakdown Maintenance

1Z IT- Preventive Maintenance

1V Veh- General Maintenance Vehicle maintenance team

1U Veh- Breakdown Maintenance

1T Veh- Preventive Maintenance

1200 2A Engg- General Maintenance Engineering Team

2B Engg- Breakdown Maintenance

2C Engg- Preventive Maintenance

2X IT- General Maintenance IT Team

2Y IT- Breakdown Maintenance

2Z IT- Preventive Maintenance

2V Veh- General Maintenance Vehicle maintenance team

2U Veh- Breakdown Maintenance

2T Veh- Preventive Maintenance

1300 3A Engg- General Maintenance Engineering Team

3B Engg- Breakdown Maintenance

3C Engg- Preventive Maintenance

3X IT- General Maintenance IT Team

3Y IT- Breakdown Maintenance

3Z IT- Preventive Maintenance

3V Veh- General Maintenance Vehicle maintenance team

3U Veh- Breakdown Maintenance

3T Veh- Preventive Maintenance

1400 4A Engg- General Maintenance Engineering Team

4B Engg- Breakdown Maintenance

4C Engg- Preventive Maintenance

4X IT- General Maintenance IT Team

Page 15 of 44 Asset Management - Fit-Gap Document - Confidential Version 01.03

4Y IT- Breakdown Maintenance

4Z IT- Preventive Maintenance

4V Veh- General Maintenance Vehicle maintenance team

4U Veh- Breakdown Maintenance

4T Veh- Preventive Maintenance

Plant Notification Notification origin To be Used by

Type

1500 DA Engg- General Maintenance Engineering Team

DB Engg- Breakdown Maintenance

DC Engg- Preventive Maintenance

DX IT- General Maintenance IT Team

DY IT- Breakdown Maintenance

DZ IT- Preventive Maintenance

DV Veh- General Maintenance Vehicle maintenance team

DU Veh- Breakdown Maintenance

DT Veh- Preventive Maintenance

Define Number Ranges for Notification

We define the accompanying number range interval for each notification type. We can define a number

range interval for each notification type, whereby we can choose between internal and external number

assignment. For ALFATTAN, we will have Internal number range for the notifications. Below is the agreed

number range for Engineering, IT and Vehicle related Notifications respectively.

Notification type From No To Number

1A, 1B & 1C 11000000 11999999

1X, 1Y & 1Z 12000000 12999999

1V, 1U & 1T 13000000 13999999

2A, 2B & 2C 21000000 21999999

2X, 2Y & 2Z 22000000 22999999

2V, 2U & 2T 23000000 23999999

3A, 3B & 3C 31000000 31999999

3X, 3Y & 3Z 32000000 32999999

3V, 3U & 3T 33000000 33999999

4A, 4B & 4C 41000000 41999999

4X, 4Y & 4Z 42000000 42999999

4V, 4U & 4T 43000000 43999999

Page 16 of 44 Asset Management - Fit-Gap Document - Confidential Version 01.03

DA, DB & DC 51000000 51999999

DX, DY & DZ 52000000 52999999

DV, DU & DT 53000000 53999999

Define Order Types

In addition to the business reasons for configuring several order types, there are also technical controls

which depend on the order type. Depending on the order type Number ranges, Settlement proposal,

control key and maintenance activity, permitted type for each of the maintenance planning plant are

defined.

Main. Order Description Used By Team Number range

Plant type

1100 Z1A1 Corrective Maintenance Engineering 110000 - 119999

Z1B1 Breakdown Maintenance

Z1P1 Preventive Maintenance

Z1R1 Refurbishment Order

Z1C1 Calibration Order

Z1X1 Corrective Maintenance- IT IT 120000-129999

Z1Y1 Breakdown Maintenance- IT

Z1Z1 Preventive Maintenance- IT

Z1I1 Refurbishment Order-IT

Z1V1 Vehicle- Corrective Maintenance Vehicle 130000-139999

Z1U1 Vehicle- Breakdown Maintenance Maintenance

Z1T1 Vehicle- Preventive Maintenance

1200 Z2A1 Corrective Maintenance Engineering 210000 - 219999

Z2B1 Breakdown Maintenance

Z2P1 Preventive Maintenance

Z2R1 Refurbishment Order

Z2C1 Calibration Order

Z2X1 Corrective Maintenance- IT IT 220000-229999

Z2Y1 Breakdown Maintenance- IT

Z2Z1 Preventive Maintenance- IT

Z2I1 Refurbishment Order-IT

Z2V1 Vehicle- Corrective Maintenance Vehicle 230000-239999

Z2U1 Vehicle- Breakdown Maintenance Maintenance

Z2T1 Vehicle- Preventive Maintenance

1300 Z3A1 Corrective Maintenance Engineering 310000 - 319999

Z3B1 Breakdown Maintenance

Z3P1 Preventive Maintenance

Z3R1 Refurbishment Order

Z3C1 Calibration Order

Z3X1 Corrective Maintenance- IT IT 320000-329999

Z3Y1 Breakdown Maintenance- IT

Z3Z1 Preventive Maintenance- IT

Page 17 of 44 Asset Management - Fit-Gap Document - Confidential Version 01.03

Z3I1 Refurbishment Order-IT

Z3V1 Vehicle- Corrective Maintenance Vehicle 330000-339999

Z3U1 Vehicle- Breakdown Maintenance Maintenance

Z3T1 Vehicle- Preventive Maintenance

Main. Order Description Used By Team Number range

Plant type

1400 Z4A1 Corrective Maintenance Engineering 410000 - 419999

Z4B1 Breakdown Maintenance

Z4P1 Preventive Maintenance

Z4R1 Refurbishment Order

Z4C1 Calibration Order

Z4X1 Corrective Maintenance- IT IT 420000-429999

Z4Y1 Breakdown Maintenance- IT

Z4Z1 Preventive Maintenance- IT

Z4I1 Refurbishment Order-IT

Z4V1 Vehicle- Corrective Maintenance Vehicle 430000-439999

Z4U1 Vehicle- Breakdown Maintenance Maintenance

Z4T1 Vehicle- Preventive Maintenance

1500 ZDA1 Corrective Maintenance Engineering 510000 - 519999

ZDB1 Breakdown Maintenance

ZDP1 Preventive Maintenance

ZDR1 Refurbishment Order

ZDC1 Calibration Order

ZDX1 Corrective Maintenance- IT IT 520000-529999

ZDY1 Breakdown Maintenance- IT

ZDZ1 Preventive Maintenance- IT

ZDI1 Refurbishment Order-IT

ZDV1 Vehicle- Corrective Maintenance Vehicle 530000-539999

ZDU1 Vehicle- Breakdown Maintenance Maintenance

ZDT1 Vehicle- Preventive Maintenance

Page 18 of 44 Asset Management - Fit-Gap Document - Confidential Version 01.03

2. Master Data

2.1. Purpose

The following master data are required for ALFATTAN, which are the core data of an enterprise that exists

independently of specific business transactions and is referenced in business transactions. It builds the

foundation for the smooth execution of business processes and well-informed business decisions.

2.2. Master data elements

Work center

The main work center usually represents one person or a department, responsible for ensuring that the

maintenance work in an order is executed by the work centers performing the individual operations. The

work center Category is 0005 for Plant Maintenance.

Following Work Centers will be created based on the Fit-Gap session discussions.

Maintenance Work center Description Category Applicable to

Plant

Civil Technician Person Engineering

Electro-Mech Tech Person

Senior Engineer Person

1100 To 1500

Fleet Mechanics Person Vehicle/ Transport

IT1 Person IT

IT2 Person

Quality Maintenance Person Quality

Note: Work centers are part of Master data and therefore can be Created/ changed/ Modified at a later

stage by Business User with relevant authorization.

Functional Location

Functional locations are elements of a technical structure (for example, functional units within a system).

We create functional locations hierarchically, and can also structure them based on the following criteria:

• Functional

• Process-related

• Spatial

Page 19 of 44 Asset Management - Fit-Gap Document - Confidential Version 01.03

Each functional location is managed independently in the system, so that we can:

• Manage individual data from a maintenance perspective for the object

• Perform individual maintenance tasks for the object

• Keep a record of the maintenance tasks performed for the object

• Collect and evaluate data over a long period of time for the object

Example: PR-01-HG001 will have individual Machines/Equipment installed to it and hence the

maintenance details can be aggregated to this Functional location. Moreover, reporting can also be

generated for Higher level objects i.e., at PR-01 or PR functional location respectively because of the

hierarchical structure creation.

Equipment / Fleet

The business object "Equipment/Fleet" is an individual, physical object that is to be maintained

independently. It can be installed in a technical system or part of a technical system.

We can manage all types of devices as pieces of equipment (for example, production utilities, Machines,

Fleet, test equipment, production resources/tools, spares, PCs, Laptops, projectors, etc.).

We define and manage each piece of equipment in the Plant Maintenance (PM) System in a separate

master record and can set up an individual maintenance history for each one.

Equipment Bill of Materials

A maintenance bill of material (BOM) is a complete, formally structured list of the components making up

a technical object or an assembly. The list contains the individual components together with their quantity

and unit of measure. The components can be stock (L) or non-stock spares (N), which in turn can be

described using maintenance BOMs.

Maintenance BOMs are primarily used for the following purposes:

• Structure description

• Assignment of spare parts

This is an optional master data that can be maintained by ALFATTAN Maintenance team to facilitate quick

retrieval of applicable part list for maintenance Processing.

Page 20 of 44 Asset Management - Fit-Gap Document - Confidential Version 01.03

Measuring Points and counter

A system object representing a physical device that measures a parameter for an object, such as a machine

or a piece of equipment. Values measured by the measuring point can increase or decrease at any point

in time, whereas values shown on a counter run either forwards or backwards.

Measuring points are located on technical objects, in other words, on pieces of equipment or functional

locations.

Example: Odometer reading, Pressure Gauge, Temperature Gauge.

Maintenance Strategies

A maintenance strategy defines the rules for the sequence of planned maintenance work.

A maintenance strategy contains maintenance packages in which the following information is defined:

The cycle in which the individual work should be performed (for example, every two months, 6 Month).

Maintenance Task list

Maintenance task lists describe a sequence of individual maintenance activities which must be repeatedly

performed within a company.

There are three types of task lists that can be distinguished from one another using indicators:

• General Maintenance Task list

• Equipment Task list

• Functional Location Task list

Maintenance Plan

We create a strategy plan and assign a maintenance strategy in which we have defined the maintenance

cycles (in the strategy maintenance packages). A maintenance strategy contains general scheduling

information and can therefore be assigned to as many maintenance plans and maintenance task lists as

required.

For example, it makes sense to use a strategy plan if different maintenance tasks for a car are due in

different cycles: oil check every 1,200 KM, oil change every 6,000 KM.

Material Master

The "Material Master", comprising all the individual material master records stored in the system contains

descriptions of all materials that an enterprise procures, produces, and keeps in stock. It is the central

Page 21 of 44 Asset Management - Fit-Gap Document - Confidential Version 01.03

repository of information on materials. Asset Management module will use the Material and Service

master defined in the SAP system for its Order Processing.

Cost center

It is an organizational unit within a controlling area that represents a defined location of cost incurrence.

The definition can be based on:

• Functional requirements

• Allocation criteria

• Physical location

• Responsibility for costs

3. Asset Management Business Processes

This component contains the functions for Maintenance. Maintenance comprises the following activities:

• Inspection

All measures which establish the actual condition of a technical system

• Preventive maintenance

All measures which maintain the ideal condition of a technical system

• Repair

All measures which restore the ideal condition of a technical system

• Other measures taken using the maintenance organization

3.1. Corrective maintenance (BH1)

Purpose

SAP System supports the entire maintenance department in planning, Processing, and settling

maintenance task. This scope item allows you to perform the corrective maintenance of technical objects

whenever a breakdown or failure occurs. The plant maintenance component provides a comprehensive

notification and order system to facilitate this process. You process a repair using several planning stages,

such as preliminary costing, work scheduling, material provision and resource planning. You also react

immediately to issues that may lead to the shutdown of production facilities. When this becomes

necessary, you create the required maintenance work orders and shop papers with a minimum of entries

in the shortest possible time.

Page 22 of 44 Asset Management - Fit-Gap Document - Confidential Version 01.03

Key process steps

Process Step Business Role App Expected Result

Request Maintenance Employee Request Maintenance Maintenance Notification

gets created

Monitor Maintenance Employee Monitor Maintenance Notification List displays

Requests Requests

Optional - Create Maintenance Create Maintenance Maintenance Notification

Maintenance Technician Notification gets created

Notification

Create Maintenance Maintenance Manage Orders and Maintenance order gets

Order Planner Notifications in created

Information Center

Plan Spare parts Maintenance Manage Orders and Reservation gets created

required if any Planner Notifications in for Spare parts

Information Center

Release Maintenance Maintenance Manage Orders and Maintenance order status

Order Planner Notifications in changed to ‘REL’

Information Center

Goods Issue from the Inventory Clerk Post Goods Movement Spare part gets issued to

Store Order

Create Purchase Maintenance Manage Orders and Purchase requisition gets

requisition or Service Planner Notifications in created for Service or

request as required Information Center Spare part

Convert Purchase Purchaser Purchase Requisition Purchase order gets

Requisitions if any to Processing created

Purchase Orders

Post Goods Receipt for Warehouse Clerk Post Goods Movement Material receipt & stock

Purchase Order for gets updated in the

Spare parts warehouse

Maintain Service Entry Purchaser Maintain Service Entry Service Entry sheet gets

Sheet for External Sheet created for external

Services service

Approve Service Entry Maintenance Approve Service Entry Confirmation for the

Sheet Manager Sheet completion of external

service

Create Supplier Invoice Accounts Payable Create Supplier Invoice Supplier Invoice gets

with PO/GR relation Accountant created

Show Costs on Maintenance Manage Orders and Costs get updated in the

Maintenance Order Planner Notifications in maintenance order

Information Center

Page 23 of 44 Asset Management - Fit-Gap Document - Confidential Version 01.03

Technically Complete Maintenance Manage Orders and Maintenance order status

Maintenance Order Planner Notifications in changed to ‘TECO’

Information Center

Cost Settlement of Finance Create Settlement All the Cost gets settled

Maintenance order

Business closure of Finance Change Service order Maintenance order gets

Maintenance order closed completely

Page 24 of 44 Asset Management - Fit-Gap Document - Confidential Version 01.03

Business process Diagram

Page 25 of 44 Asset Management - Fit-Gap Document - Confidential Version 01.03

Reports

These are some of the important SAP Reports which can be used in the daily business operations.

S.No Report Name Fiori/Transaction App

1 Notification List - Change Transaction App – IW28

2 Notification List - Display Transaction App – IW29

3 Monitor Maintenance Requests Fiori App

4 Order List - Change Transaction App – IW38

5 Order List - Display Transaction App – IW39

6 Order list with Operation Transaction App – IW37N

7 Order list with Operation Transaction App – IW40N

8 Manage orders and Notifications Fiori App

9 Find Maintenance Orders and Fiori App

Operations

10 Technical Object Breakdowns Fiori App

11 Display Master data Information center Fiori App

12 Manage Orders and Notifications in Fiori App

Information Center

13 Find Maintenance Order Confirmation Fiori App

14 Display Job list Fiori App

Roles

Role Description App Role

Maintenance Technician SAP_BR_MAINTENANCE_TECHNICIAN

Maintenance Planner SAP_BR_MAINTENANCE_PLANNER

Employee – Maintenance Info SAP_BR_EMPLOYEE_MAINTENANCE

Integration

The below mentioned matrix and points refers to the integration between Asset Management and all

other modules which will be applicable for this specific process.

Module Description

Asset Integration –

Finance Asset no. is to be given by Finance dept. The equipment is linked

with the Asset Master.

Inventory & Procurement Spares planning:

Master data for spares is maintained, Purchase requisition,

Purchase order

Inventory & Warehouse Material Receipt & Issue:

Receipt of Spares, Refurbished items from Vendors and damaged

parts from Maintenance department.

Page 26 of 44 Asset Management - Fit-Gap Document - Confidential Version 01.03

Issue of material against maintenance order

Procurement External services:

Maintenance of service master data

Service Entry Sheet

HR Assignment of personnel to Work centers for activity allocation.

Settlement of maintenance expenses

Controlling

Gap

User Story ID User Story Title User Story Short Description Product Status

(PO) (PO) Owner (PO)

Others/Out-Of-Scope

• Business Solutions other than mentioned in the scope

• Data Sources for Conversion from legacy to sap

3.2. Preventive Maintenance (BJ2)

Purpose

This scope item covers the processes you perform to prevent system breakdowns or breakdowns of other

objects that have high repair costs. Such breakdowns result in greater costs due to production downtime.

Preventive maintenance support processes to plan the scope and time of maintenance work for

inspections, maintenance, and repairs, in advance. The quality of products manufactured is substantially

affected by the operational condition of the production plant. There is a requirement for quality assurance

to be more cost effective to maintain objects regularly, and in return avoid a more expensive breakdown.

You determine the data required for preventive maintenance by using previous data supplied by the

system.

SAP System supports the entire maintenance department in planning, processing, and settling

maintenance task.

Business Benefits:

• Plan better by changing from reactive to proactive maintenance

• Ensure high availability of equipment and therefore better performance and utilization of assets

• Reduce total maintenance costs by reducing breakdowns

• Support external requirements, such as manufacturer recommendations, and legal and

environmental requirements

Page 27 of 44 Asset Management - Fit-Gap Document - Confidential Version 01.03

Key Process Steps

The scope item Preventive Maintenance consists of several process steps provided in the table below.

Process Step SAP/Manual Business Transaction/App Expected

Role Result

Maintain Maintenance SAP Maintenance Maintenance Maintenance

Strategies Planner Strategies. Strategy got

created

Create General Task List SAP Maintenance Create Task List. General Task

Planner list got

created

Create Maintenance Plan SAP Maintenance Create Maintenance

Planner Maintenance Plan got

Plan. created

Enter the Counter reading for SAP Maintenance Transaction App Counter

Activity based Preventive Planner (IK11) reading gets

Maintenance updated

Schedule Maintenance Plan SAP Maintenance Schedule Maintenance

Planner Maintenance order gets

Plan. created

Release Preventive Maintenance SAP Maintenance Manage Orders Maintenance

Order Planner and Notifications order gets

in Information updated

Center. with status

‘REL’

Show Costs on Preventive SAP Maintenance Manage Orders Costs

Maintenance Order Planner and Notifications displayed in

in Information the order

Center.

Technically Complete Preventive SAP Maintenance Manage Orders Order status

Maintenance Order Planner and Notifications changes to

in Information ‘TECO’

Center.

Cost Settlement of Preventive SAP Finance Order Settle Cost settled

order

Business closure of Preventive SAP Finance Order Closure Maintenance

order order closed

Page 28 of 44 Asset Management - Fit-Gap Document - Confidential Version 01.03

Business Process Diagram

Time Based Maintenance Plan:

Page 29 of 44 Asset Management - Fit-Gap Document - Confidential Version 01.03

Performance Based Maintenance Plan:

Page 30 of 44 Asset Management - Fit-Gap Document - Confidential Version 01.03

Reports

Sr.No Report Name Fiori/Transaction App

1 Find Maintenance Task List Fiori App

2 Find Maintenance Task List and Fiori App

Operation

3 Order List - Change Transaction App – IW38

4 Order List - Display Transaction App – IW39

5 Order list with Operation Transaction App – IW37N

6 Manage orders and Notifications Fiori App

7 Find Maintenance Orders and Fiori App

Operations

8 Scheduling Overview Fiori App

9 Display Master data Information center Fiori App

10 Manage Orders and Notifications in Fiori App

Information Center

11 Find Maintenance Order Confirmation Fiori App

12 Display Job list Fiori App

13 Manage Maintenance Plan and Item list Fiori App

14 Measuring Document list - Change Transaction App – IK18

15 Measuring Document list - Display Transaction App – IK17

16 Measuring Point list – Change Transaction App – IK08

17 Measuring Point list – Display Transaction App – IK09

Roles

Role Description App Role

Maintenance Technician SAP_BR_MAINTENANCE_TECHNICIAN

Maintenance Planner SAP_BR_MAINTENANCE_PLANNER

Employee – Maintenance Info SAP_BR_EMPLOYEE_MAINTENANCE

Integration

The below mentioned matrix and points refers to the integration between PM and all other modules

which will be applicable for this specific process.

Module Description

Material Spares planning:

Management Master data for spares is maintained, Purchase requisition, Purchase

order

Material Receipt & Issue:

Receipt of Spares, Refurbished items from Vendors and damaged parts

from Maintenance department.

Page 31 of 44 Asset Management - Fit-Gap Document - Confidential Version 01.03

Issue of material against maintenance order

External services:

Maintenance of service master data

Service Entry Sheet

Activity types would be created to calculate cost of maintenance order

Controlling Settlement of maintenance expenses

Gap

User Story ID User Story Title User Story Short Product Owner Status

(PO) Description (PO)

(PO)

Others/Out-Of-Scope

• Business Solutions other than mentioned in the scope

• Data Sources for Conversion from legacy to sap

3.3. Emergency Maintenance (BH2)

Purpose

This scope item uses order recording after an event to log unforeseen and urgent maintenance work by

creating and confirming an order in the same operation. The technician can identify an issue affecting a

piece of equipment, immediately fix the issue, and later report the time spent and the material consumed.

The technician can enter required data quickly. It can then be used for planning objects (such as

maintenance orders) and for actual recording (order confirmation, notification data, and goods

movements). Planned data does not differ from the actual data, which is the work recorded on an

operation corresponding to the confirmed actual work. The order is created, released, and if required,

technically completed. In addition, you can install, dismantle, or replace pieces of equipment.

SAP System supports the entire maintenance department in planning, processing, and settling

maintenance task.

Key Process Steps

3.3.2.1 Asset Emergency Maintenance

The scope item Emergency Maintenance consists of several process steps provided in the table below.

Page 32 of 44 Asset Management - Fit-Gap Document - Confidential Version 01.03

Process Step Business Role Transaction/App Expected Result

Report Malfunction Maintenance Report Malfunction Maintenance

Planner/Employee (F2023) Notification gets

created

Repair Malfunction Maintenance Repair Malfunction Unplanned Job is

Technician completed

Post Goods Issue Warehouse Clerk Post Goods Movement Spare parts if any are

(MIGO) issued

Complete Malfunction Maintenance Manage Malfunction Malfunction

Report Technician Reports (F2023) notification list got

displayed

Review Asset Maintenance Display Equipment – Equipment master

Maintenance Object Planner Transaction App record is displayed

3.3.2.2 Fleet (Vehicle) Emergency Maintenance

The scope item Fleet Emergency Maintenance consists of several process steps provided in the table

below.

Process Step Business Role Transaction/App Expected Result

Report Vehicle Maintenance Report Malfunction Maintenance

Malfunction technician/Driver (F2023) Notification gets

created

Inform Vendor to Pick Manual

the Vehicle

Vehicle repair Post Goods Movement Spare parts if any are

completion by Vendor (MIGO) issued

Maintain Service entry Purchaser Maintain Service Entry Service Entry sheet gets

sheet sheet created

Approve Service entry Maintenance Approve service entry Work completion by

sheet Planner sheet Vendor is approved

Complete Maintenance

Order & Notification

Page 33 of 44 Asset Management - Fit-Gap Document - Confidential Version 01.03

Business Process Diagram

3.3.3.1. Asset Emergency Maintenance

Page 34 of 44 Asset Management - Fit-Gap Document - Confidential Version 01.03

3.3.3.2. Fleet Emergency Maintenance

Reports

S.No Report Name Fiori/Transaction App

1 Notification List - Change Transaction App – IW28

2 Notification List - Display Transaction App – IW29

3 Manage Malfunction Reports Fiori App

4 Repair Malfunctions – My Job list Fiori App

Page 35 of 44 Asset Management - Fit-Gap Document - Confidential Version 01.03

Roles

Role Description App Role

Maintenance Technician SAP_BR_MAINTENANCE_TECHNICIAN

Maintenance Planner SAP_BR_MAINTENANCE_PLANNER

Employee – Maintenance Info SAP_BR_EMPLOYEE_MAINTENANCE

Integration

The below mentioned matrix and points refers to the integration between PM and all other

modules which will be applicable for this specific process

Module Description

Material Spares planning:

Management Master data for spares is maintained, Purchase requisition, Purchase order

Material Receipt & Issue:

Receipt of Spares, Refurbished items from Vendors and damaged parts from

Maintenance department.

Issue of material against maintenance order

External services:

Maintenance of service master data

Service Entry Sheet

Activity types would be created to calculate cost of maintenance order

Controlling Settlement of maintenance expenses

Gap

User Story ID User Story Title User Story Short Product Owner (PO) Status

(PO) Description

(PO)

Others/Out-Of-Scope

• Business Solutions other than mentioned in the scope

• Data Sources for Conversion from legacy to sap

Page 36 of 44 Asset Management - Fit-Gap Document - Confidential Version 01.03

3.4. Calibration Processing (32L)

Purpose

Calibration defines the accuracy and quality of measurements recorded using a piece of equipment. Over

the period, accuracy of measuring equipment drifts and measured value may not be correct. To get the

accurate and reliable measurements, service and calibration need to be carried out after a certain interval.

The goal of calibration is to minimize any measurement uncertainty by ensuring the accuracy of test

equipment. A calibration inspection provides you with an enhanced measured value function for

inspection results, with which you can monitor test equipment defined as pieces of equipment. This is

advisable if you:

• Maintain equipment for which entries for measured values are important

• Want to monitor the accuracy calibration devices (for example, if you want to check the

accuracy of measurements by a measuring device)

Key Process Steps

The scope item Calibration Processing consists of several process steps provided in the table below.

Process Step Business Role Transaction/App Expected Result

Create Master Maintenance planner Create Master Master Inspection

Inspection Inspection Characteristic is

Characteristic Characteristic created successfully.

Create Inspection Task Maintenance planner Create General Task Inspection Task List

List List created successfully

Create Calibration Plan Maintenance planner Create Maintenance Calibration Plan has

Plan been Created

Scheduling Calibration Maintenance planner Schedule Calibration Plan has

Plan Maintenance Plan been scheduled

Check Calibration Maintenance planner Schedule Check Order with

Order Created with maintenance Plan Inspection Lot is

Inspection Lot created

Result Recording Maintenance Record Inspection Result is recorded

against Inspection Lot Technician Results against the values

defined in MIC

Usage Decision for Maintenance planner Record Usage Usage Decision of the

Inspection Lot Decision Inspection Lot is taken

as per the Result

recorded

Page 37 of 44 Asset Management - Fit-Gap Document - Confidential Version 01.03

Business Process Diagram

Reports

S.No Report Name Fiori/Transaction App

1 Find Maintenance Task List Fiori App

2 Find Maintenance Task List and Fiori App

Operation

3 Order List - Change Transaction App – IW38

4 Order List - Display Transaction App – IW39

Page 38 of 44 Asset Management - Fit-Gap Document - Confidential Version 01.03

5 Order list with Operation Transaction App – IW37N

6 Manage orders and Notifications Fiori App

7 Find Maintenance Orders and Fiori App

Operations

8 Scheduling Overview Fiori App

9 Display Master data Information center Fiori App

10 Manage Orders and Notifications in Fiori App

Information Center

11 Find Maintenance Order Confirmation Fiori App

12 Display Job list Fiori App

13 Manage Maintenance Plan and Item list Fiori App

14 Measuring Document list - Change Transaction App – IK18

15 Measuring Document list - Display Transaction App – IK17

16 Measuring Point list – Change Transaction App – IK08

17 Measuring Point list – Display Transaction App – IK09

Roles

Role Description App Role

Maintenance Technician SAP_BR_MAINTENANCE_TECHNICIAN

SAP_BR_QUALITY_ TECHNICIAN

Maintenance Planner SAP_BR_MAINTENANCE_PLANNER

SAP_BR_QUALITY_ENGINEER

SAP_BR_QUALITY_PLANNER

Integration

The below mentioned matrix and points refers to the integration between PM and all other

modules which will be applicable for this specific process

Module Description

Material Spares planning:

Management Master data for spares is maintained, Purchase requisition, Purchase order

Material Receipt & Issue:

Receipt of Spares, Refurbished items from Vendors and damaged parts from

Maintenance department.

Issue of material against maintenance order

External services:

Maintenance of service master data

Service Entry Sheet

Quality Creation of Inspection Lot & Quality Notification (Optional)

management

Page 39 of 44 Asset Management - Fit-Gap Document - Confidential Version 01.03

Activity types would be created to calculate cost of maintenance order Settlement

Controlling of maintenance expenses

Gap

User Story ID User Story Title User Story Short Product Owner (PO) Status

(PO) Description

(PO)

Others/Out-Of-Scope

• Business Solutions other than mentioned in the scope

• Data Sources for Conversion from legacy to sap

3.5. Refurbishment Management

Purpose

The refurbishment of high value faulty repairable spares is of considerable economic importance for

companies and is a core process in Maintenance Processing. Refurbishment is much more cost-effective

than a new purchase. In this scope item, the spare part has different valuation types to represent different

values. Because it is also a high value spare part or critical part, this spare part is serial-number managed.

In this scope item, a spare part is procured and installed in the functional location as equipment. Serial

numbers can be assigned to the procured material. These repairable spare parts can be identified with

different valuation types with corresponding cost assignments, such as:

• New (C1)

• Refurbished (C2)

• Damaged (C3)

If the installed equipment malfunctions, it is dismantled from the functional location and a spare part /

equipment is withdrawn and installed at the functional location. The defective equipment is returned as

damaged item to the warehouse (Valuation type C3). The stock in the warehouse is automatically updated

(Valuation types) with the corresponding cost.

The maintenance planner creates a refurbishment order. These defective repairable spares (Valuation

class C3) are withdrawn from the warehouse and repaired. When the refurbishment is finished, the

equipment is returned to warehouse as repaired material (Valuation type C2) and the cost is updated

accordingly in the material master.

Page 40 of 44 Asset Management - Fit-Gap Document - Confidential Version 01.03

After the settlement of the refurbishment order, the maintenance expense is settled to the specific

material, and then the moving average price of this spare is updated in the material master. The moving

average price of this spare varies during the different phases of refurbishment.

Key Process Steps

The scope item Calibration Processing consists of several process steps provided in the table below.

Process Step Business Role Transaction/App Expected Result

Create Standard Maintenance Planner Create maintenance Standard maintenance

Maintenance Order Order order has been

created.

Remove Defective Part Maintenance Planner Change Material Assign Equipment

Serial Number Number to Material

Return Defective Part Warehouse Clerk Post Goods The defective

to Warehouse Movement equipment is returned

to warehouse

Goods Issue with New Warehouse Clerk Post Goods Parts have been issued

Part with Serial Movement to maintenance order

Number

Activating Equipment Maintenance Planner Change Material Set up new equipment

View for New Part and Serial Number to related function

Install location

Creating Maintenance Planner Create Refurbishment Refurbishment order

Refurbishment Order Order for defective

equipment

Material Withdrawal Warehouse Clerk Post Goods The defective part has

for Refurbishment Movement been issued to

refurbishment order

Time Confirmation Maintenance Enter PM Order Confirm refurbishment

Technician Confirmation order

G/R for Refurbishment Maintenance Planner Goods Receipt Serial Goods receipt for

order Number for refurbishment order

Refurbishment Order

Check Material Stock Inventory Manager Display Stock Check material stock

Overview

Display Material Master Data Display Material Display Material

Specialist - Product

Data

Technically Completing Maintenance Change Order Refurbishment order

Order Technician was technically

completed.

Settling Order Maintenance Planner Actual Settlement Settled the

refurbishment order

Closing Order Maintenance Planner Change Order Business Close of Order

(Optional)

Page 41 of 44 Asset Management - Fit-Gap Document - Confidential Version 01.03

Business Process Diagram

Reports

S.No Report Name Fiori/Transaction App

1 Order List - Change Transaction App – IW38

2 Order List - Display Transaction App – IW39

3 Order list with Operation Transaction App – IW37N

4 Order list with Operation Transaction App – IW40N

5 Manage orders and Notifications Fiori App

6 Find Maintenance Orders and Fiori App

Operations

7 Technical Object Breakdowns Fiori App

Page 42 of 44 Asset Management - Fit-Gap Document - Confidential Version 01.03

8 Display Master data Information center Fiori App

9 Manage Orders and Notifications in Fiori App

Information Center

10 Find Maintenance Order Confirmation Fiori App

11 Display Job list Fiori App

12 Display Stock Overview Fiori App

Roles

Role Description App Role

Maintenance Planner SAP_BR_MAINTENANCE_PLANNER

Maintenance Technician SAP_BR_MAINTENANCE_TECHNICIAN

Warehouse Clerk SAP_BR_WAREHOUSE_CLERK

Inventory Manager SAP_BR_INVENTORY_MANAGER

Master Data Specialist - Product Data SAP_BR_PRODMASTER_SPECIALIST

Integration

The below mentioned matrix and points refers to the integration between PM and all other modules

which will be applicable for this specific process

Module Description

Material Spares planning:

Management Master data for spares is maintained, Purchase requisition, Purchase order

Material Receipt & Issue:

Receipt of Spares, Refurbished items from Vendors and damaged parts from

Maintenance department.

Issue of material against maintenance order

External services:

Maintenance of service master data

Service Entry Sheet

Quality Creation of Inspection Lot & Quality Notification (Optional)

management

Activity types would be created to calculate cost of maintenance order

Controlling Settlement of maintenance expenses

Gap

User Story ID User Story Title User Story Short Product Owner (PO) Status

(PO) Description

(PO)

Page 43 of 44 Asset Management - Fit-Gap Document - Confidential Version 01.03

Others/Out-Of-Scope

• Business Solutions other than mentioned in the scope

• Data Sources for Conversion from legacy to sap

4. Document Sign-off

REVIEW AND APPROVAL: Below Authorized representative(s) have agreed for all above sections of this

Fit-Gap document and provide their consent of Approval.

NAME DESIGNATION DATE SIGNATURE

Page 44 of 44 Asset Management - Fit-Gap Document - Confidential Version 01.03

You might also like

- D365 BC - Finance Essentials PDFDocument99 pagesD365 BC - Finance Essentials PDFJames Sanabria100% (1)

- Project Report ON Comparative Analysis of Financial Performance of Zomato: A Ratio Analysis ApproachDocument49 pagesProject Report ON Comparative Analysis of Financial Performance of Zomato: A Ratio Analysis Approachsudhanshu jeevtani100% (5)

- SAP ERP Financials Configure and Design PDFDocument35 pagesSAP ERP Financials Configure and Design PDFAbdur RahmanNo ratings yet

- DQL Reference Manual 6.5Document458 pagesDQL Reference Manual 6.5jazarja100% (9)

- Aam HelpDocument503 pagesAam Helpanupamb82No ratings yet

- CreditLens Business Process and Collaboration Tool Configuration GuideDocument140 pagesCreditLens Business Process and Collaboration Tool Configuration GuideLinaCAlzateNo ratings yet

- Simplicity Technical Writeup - SBG Industry PLCDocument57 pagesSimplicity Technical Writeup - SBG Industry PLCMesay EmishawNo ratings yet

- Zen CM Deployment BPDocument198 pagesZen CM Deployment BPOmar MartinezNo ratings yet

- EMC Documentum Business Process Suite: Best Practices Guide P/N 300-009-005 A01Document118 pagesEMC Documentum Business Process Suite: Best Practices Guide P/N 300-009-005 A01jjjjjjjhjjjhjjjjjjjjjNo ratings yet

- SOP CommentedDocument59 pagesSOP CommentedBesufikad solomonNo ratings yet

- Tutorial Engineering Allplan BIM 2008 PDFDocument334 pagesTutorial Engineering Allplan BIM 2008 PDFdomagoj999No ratings yet

- Idmc Iics 101 Labs v10Document120 pagesIdmc Iics 101 Labs v10ericaldiNo ratings yet

- Bus Ticket Reservation SystemDocument60 pagesBus Ticket Reservation SystemSunitha Vadaga100% (1)

- QCStandardProcesses LatestDocument63 pagesQCStandardProcesses Latestminoo61No ratings yet

- Master Data Management: An Oracle White Paper June 2010Document61 pagesMaster Data Management: An Oracle White Paper June 2010Nguyễn Mạnh TrungNo ratings yet

- De Beers 'Project Plus' Management SystemDocument31 pagesDe Beers 'Project Plus' Management Systemkhonzaphi dubeNo ratings yet

- S4SCSD 20 enDocument256 pagesS4SCSD 20 enDebanjan PramanikNo ratings yet

- SRCE 2.0 User Manual R2Document117 pagesSRCE 2.0 User Manual R2Shalaho D DevyNo ratings yet

- Experi AnDocument58 pagesExperi AnPriya DasNo ratings yet

- GMAT User Guide PDFDocument188 pagesGMAT User Guide PDFpchirnNo ratings yet

- Last FinalDocument55 pagesLast Finalashikipe16No ratings yet

- 2015-04-16 PMO Operations GuideDocument27 pages2015-04-16 PMO Operations GuideHammad MasoodNo ratings yet

- M02 InitialSetup - TG - v2016EEDocument85 pagesM02 InitialSetup - TG - v2016EEfkjh ijwrNo ratings yet

- Configuration Document SAP PP PI mySAP E PDFDocument75 pagesConfiguration Document SAP PP PI mySAP E PDFibrahimNo ratings yet

- Workflow and Worklets PC - 1040 - WorkflowBasicsGuide - enDocument262 pagesWorkflow and Worklets PC - 1040 - WorkflowBasicsGuide - enVivek PrasadNo ratings yet

- Dlv03.01-Functional Requirements OverviewDocument70 pagesDlv03.01-Functional Requirements OverviewJán MičíkNo ratings yet

- Project On Financial PlaningDocument262 pagesProject On Financial Planingvinay66No ratings yet

- Engineering Systems HandbookDocument164 pagesEngineering Systems Handbookgaipat100% (1)

- Ongoing Building Commissioning Best PracticesDocument46 pagesOngoing Building Commissioning Best PracticesEyad OsNo ratings yet

- Click Script Demo Env. - Production Operation Excellence For AandD - HE - IM Supply - OpCenter Execution Discrete 2307Document182 pagesClick Script Demo Env. - Production Operation Excellence For AandD - HE - IM Supply - OpCenter Execution Discrete 2307frank0213No ratings yet

- Workshop Introduction: All Rights Reserved, Juran Institute, IncDocument10 pagesWorkshop Introduction: All Rights Reserved, Juran Institute, IncRahulRahuNo ratings yet

- MFG - PRO Quick Start TRAINING GUIDEDocument402 pagesMFG - PRO Quick Start TRAINING GUIDEhaotuzi10260428No ratings yet

- Operations Guide For SAP Global Trade Services 11.0Document34 pagesOperations Guide For SAP Global Trade Services 11.0ramesh410No ratings yet

- Performance & Goals Management With Integration To Development PlanningDocument98 pagesPerformance & Goals Management With Integration To Development PlanningRaviNo ratings yet

- Sap Fi Aa BBP DocumentDocument86 pagesSap Fi Aa BBP Documentsanjusivan100% (1)

- MFG - Pro Quick Start Training GuideDocument385 pagesMFG - Pro Quick Start Training Guidehaotuzi10260428No ratings yet

- Incentive Management Admin Design Guide: User Guide - PUBLIC Document Version: PROD - 2024-02-23Document482 pagesIncentive Management Admin Design Guide: User Guide - PUBLIC Document Version: PROD - 2024-02-23ishtiaqalamNo ratings yet

- BPMN by Example An Introduction To BPMN PDFDocument59 pagesBPMN by Example An Introduction To BPMN PDFsangameshwar KadoleNo ratings yet

- Silo - Tips - Project Management Plan For The Vdi Data Center Project PDFDocument51 pagesSilo - Tips - Project Management Plan For The Vdi Data Center Project PDFbalamurali_aNo ratings yet

- The International Attribute Tracking Standard v1.0Document66 pagesThe International Attribute Tracking Standard v1.0Muhammad Umer KamalNo ratings yet

- Documents For AssignmentDocument71 pagesDocuments For AssignmentAbhishek BharteNo ratings yet

- OM Notes SajinJDocument43 pagesOM Notes SajinJAcc1234No ratings yet

- SFHCM Config Guide Getting Started TimeOff and Leave of Absence EN XXDocument58 pagesSFHCM Config Guide Getting Started TimeOff and Leave of Absence EN XXgumnani.rewachandNo ratings yet

- Ntroduction To Roject: Project Management IM-419, IMD Page 1 of 34Document34 pagesNtroduction To Roject: Project Management IM-419, IMD Page 1 of 34ahsan khurNo ratings yet

- Emia 3 50 Software Operations ManualDocument145 pagesEmia 3 50 Software Operations ManualAz RaNo ratings yet

- Edible Oil Business Plan - Draft ReportDocument80 pagesEdible Oil Business Plan - Draft ReportYoseph MelesseNo ratings yet

- TOGAF Business ScenariosDocument51 pagesTOGAF Business ScenariosНиколай ТроханNo ratings yet

- TIB Bstudio-Bpm TutorialsDocument342 pagesTIB Bstudio-Bpm TutorialsjovellloyNo ratings yet

- TOGAF Series Guide - Business ScenariosDocument51 pagesTOGAF Series Guide - Business ScenarioshananNo ratings yet

- Developing Qualified NDT Procedures & The Technical Justification Process - SampleDocument28 pagesDeveloping Qualified NDT Procedures & The Technical Justification Process - SampleDouglas VieiraNo ratings yet

- AspenIcarusProcMgr2006 5-Usr PDFDocument281 pagesAspenIcarusProcMgr2006 5-Usr PDFSanthosh KumarNo ratings yet

- Scope Project (NAPHDA)Document159 pagesScope Project (NAPHDA)iffat zaheerNo ratings yet

- Database Project Group ReportDocument70 pagesDatabase Project Group ReportSaad Kabir ProttoyNo ratings yet

- Mastercard Rewards Systems Product Guide: 30 July 2020Document99 pagesMastercard Rewards Systems Product Guide: 30 July 2020LENINNo ratings yet

- WRU Project Guideline For StudentsDocument40 pagesWRU Project Guideline For StudentsAdugna BayisaNo ratings yet

- Oracle Retail Reference Model: User Guide Release 14.1.1 June 2015Document54 pagesOracle Retail Reference Model: User Guide Release 14.1.1 June 2015kuullaurNo ratings yet

- Corporate Management, Corporate Social Responsibility and Customers: An Empirical InvestigationFrom EverandCorporate Management, Corporate Social Responsibility and Customers: An Empirical InvestigationNo ratings yet

- Ohs-Pr-09-26-F01 Initial Incident Notification 26.1 (2022)Document2 pagesOhs-Pr-09-26-F01 Initial Incident Notification 26.1 (2022)Shafie ZubierNo ratings yet

- Eugen Ritter Von Böhm-BawerkDocument6 pagesEugen Ritter Von Böhm-BawerkPat ONo ratings yet

- International Business Law and Its Environment 9th Edition Schaffer Solutions Manual DownloadDocument8 pagesInternational Business Law and Its Environment 9th Edition Schaffer Solutions Manual DownloadJohn Stewart100% (17)

- Case Study RubricDocument4 pagesCase Study RubricBrijendra SinghNo ratings yet

- Trends in Data ArchitectureDocument25 pagesTrends in Data ArchitectureJohnNo ratings yet

- Thiruvananthapuram (TRV) Kolkata (CCU) : 09:40 PM 11:05 PMDocument3 pagesThiruvananthapuram (TRV) Kolkata (CCU) : 09:40 PM 11:05 PMAnu sNo ratings yet

- Universiti Teknologi Mara (Uitm) : Living Address: Kampung Tok Elong, 14000 Bukit Mertajam, Pulau PinangDocument1 pageUniversiti Teknologi Mara (Uitm) : Living Address: Kampung Tok Elong, 14000 Bukit Mertajam, Pulau PinanghamkaNo ratings yet

- Part I - Unit IV Copra 2019Document15 pagesPart I - Unit IV Copra 2019shilpakr555No ratings yet

- Ent530bp Guideline and Template Oct2022Document15 pagesEnt530bp Guideline and Template Oct2022MOHD NOOR TAUFIQ JALALUDINNo ratings yet

- Proposal On Performance Appraisal of Dashen Bank of EthiopiaDocument3 pagesProposal On Performance Appraisal of Dashen Bank of Ethiopiaheluta934No ratings yet

- Contract Lecture 10 (Mistake)Document12 pagesContract Lecture 10 (Mistake)Jabachi NwaoguNo ratings yet

- BEC Vantage PG 8Document1 pageBEC Vantage PG 8juanNo ratings yet

- Management AccountingDocument2 pagesManagement AccountingMateen PathanNo ratings yet

- Reveiw For MondayDocument8 pagesReveiw For MondayRehab ElsamnyNo ratings yet

- Global 04 Political & Legal Environment-1Document35 pagesGlobal 04 Political & Legal Environment-1pritesh1983No ratings yet

- Popular - Telex & Other DocumentsDocument12 pagesPopular - Telex & Other DocumentsnajmithagoshiNo ratings yet

- SEO and Its Importance For BusinessDocument3 pagesSEO and Its Importance For Businessenjeela subediNo ratings yet

- Copy - Volume Spurt, Technical Analysis ScannerDocument2 pagesCopy - Volume Spurt, Technical Analysis ScannerVimalahar rajagopalNo ratings yet

- Economics - Textile Industry of PakistanDocument18 pagesEconomics - Textile Industry of PakistanQuratulain QureshiNo ratings yet

- ICAB Advance Level Strategic Business Management Compilation of Chapterwise Theory For Exam May June 2020Document459 pagesICAB Advance Level Strategic Business Management Compilation of Chapterwise Theory For Exam May June 2020Optimal Management Solution100% (1)

- Solved The Outstanding Stock in Red Blue and Green Corporations EachDocument1 pageSolved The Outstanding Stock in Red Blue and Green Corporations EachAnbu jaromiaNo ratings yet

- Dethi Unica De2 3 DraftDocument26 pagesDethi Unica De2 3 Draftallo helloNo ratings yet

- Chapter 6 LearningDocument28 pagesChapter 6 Learningفيصل ابراهيمNo ratings yet

- Define Negotiation. and Discuss Various Tactics Adopted in NegotiationDocument7 pagesDefine Negotiation. and Discuss Various Tactics Adopted in NegotiationRicha UpadhyayNo ratings yet

- 11 - Chapter 4 The Valuation of Long-Term SecuritiesDocument53 pages11 - Chapter 4 The Valuation of Long-Term SecuritiesIni Ichiii100% (1)

- The Grat DreprestionDocument29 pagesThe Grat DreprestionAwura KwayowaaNo ratings yet

- Financial Analysis Sample 5Document10 pagesFinancial Analysis Sample 5throwawayyyNo ratings yet

- Operations ManagementDocument10 pagesOperations ManagementBonface Nabuko100% (1)