Professional Documents

Culture Documents

QGTL1 Pro 07 00001 001 - 11

QGTL1 Pro 07 00001 001 - 11

Uploaded by

Muhammad Arham KhalilOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QGTL1 Pro 07 00001 001 - 11

QGTL1 Pro 07 00001 001 - 11

Uploaded by

Muhammad Arham KhalilCopyright:

Available Formats

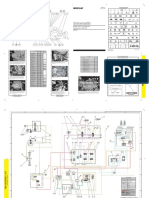

NOTES

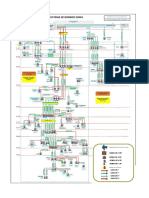

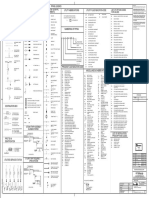

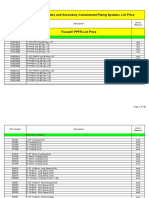

LINES FLOW LINE SERVICE PIPING ITEMS VALVES

1. REFER TO ISOLATION PHILOSOPHY FOR USE OF

SAFETY SPECTACLE BLINDS/SPACERS.

tten

REDUCER (GENERIC)

HYDRAULIC LINE 2.SEE DRAWING 00005 FOR SAMPLE TYPES.

or wri

50 Process Streams Index 50

BOUNDARY LINE 3. EXTERNAL STRAINER WITH WNRF FLANGES SHALL BE PROVIDED

th the pri

GATE VALVE AND BASIC SYMBOL.

Natural Gas NG BUTT WELD PULSATION DAMPENER UPSTREAM ALL TRAPS. STEAM TRACING TRAPS ONLY WILL BE

(PACKAGE LIMIT)

49 49

Hydrocarbon Streams P PROVIDED WITH INTERNAL STRAINER.

SOAK AWAY/GRADE

ed or wi

LPG Product LPG 4."T" TYPE STRAINER IS PROVIDED WITH DRAIN VALVE.

MAJOR PROCESS LINE FLANGED JOINT SAFETY SHOWER AND EYE WASH

48 48

GTL Fuel DP 5.ENSURE THAT ORBIT VALVES ARE INSTALLED CORRECTLY

POST INDICATOR

ACCORDING TO VENDOR SPECIFICATION AND REFER TO OPERATING

i

t was suppl

Naphtha Product NP GATE VALVE

47 MINOR PROCESS LINE RESIN TRAP 47 MANUAL SECTION 9.11.7 ORBIT VALVE INSTALLATION.

END CAP ( WELDED )

Fuel System

ch i

46 UNDERGROUND LINE Fuel Gas FG 46

BLIND FLANGE

th the term s of the agreem ent under whi

ANGLE VALVE

Oxygenates FX

45 TRACED LINE 45

Diesel Fuel FD

EXPANSION JOINT

LPG Fuel FL T STEAM TRAP

44 44

NOTE 4

LINES CROSSING CHECK VALVE

Gas Systems

43 Oxygen O2 43

VORTEX BREAKER

LP & HP Nitrogen N2

(FOR UNIT 50 ONLY) SCREWDOWN CHECK VALVE

42 LINES CONNECTED Plant Air (Utility) AU UTILITY BOX REFERENCE NUMBERS 42

Mask Air AM FLEXIBLE HOSE

41 Utility Connection 41

Instrument Air AI

n accordance wi

Box Numbers BUTTERFLY VALVE

JACKETED LINES Hydrogen H2 SEE THROUGH SIGHT GLASS

40 BUCKET FILTER / STRAINER 40

Steam Systems

1 Raw Water

DIRECTION OF FLOW

n part to others except i

39 Steam Condensate (incl. 39

SC FLAME ARRESTOR 2 Fire Water BALL VALVE

Vacuum condensed) MAX PRESS SELECTOR 3 Process Water (Treated)

38 SLOPE Superheated Steam SH 38

4 Potable Water

SLOPING LINES SILENCER

Saturated Steam SS

5 Condensate

37 MP & HP BFW BFW PARALLEL GATE VALVE 37

6 Steam

PNEUMATIC SIGNAL Steam Condensate

WA TUNDISH 7

(Inside Package B.L.)

e or i

36 36

THERMAL EXPANSION DEVICE 8 Cooling Water Supply

ELECTRICAL SIGNAL GLOBE VALVE

n whol

9 Cooling Water Return

35 Water Systems 35

OPEN VENT 10

shed i

Reaction Water RXW

11 Clean Water Sewer

SOFTWARE CONNECTION Raw Water RW

l not be furni

34 34

12 Oily or Dirty Water Sewer NEEDLE VALVE

Firewater FW

13

X X X Cooling Water CW EJECTOR

33 CAPILLIARY SIGNAL 33

UV FILTRATION SYSTEM 14 Sanitary Sewer

Process Water (Treated) PW

DIAPHRAGM VALVE

on shal

15

Drinking Water (Potable) WD

32 CHANGE OF SPECIFICATION HOSE CONNECTION 16 Plant Air 32

Sea Water SW

nform ati

OR RESPONSIBILITY

17 Instrument Air

Demin Water DM

31 18 HP Nitrogen PLUG VALVE 31

s i

19 LP Nitrogen

on. Thi

30 P&ID CONNECTORS Effluent Systems FIRE FIGHTING SYSTEM LEGEND 30

20 HP Flare

Aqueous Effluent Drain DA SPACER RING ( NOTE 1 )

cati

21 LP Flare TIGHT SHUT OFF STOP CHECK VALVE

i

Sanitary Effluent SA

ntended for publ

29 CONNECTIONS WITHIN UNITS (Y PATTERN) 29

22 Flushing Oil Supply

Clean Storm Water WS INSTALLED SPADE ( NOTE 1 )

DRG. BORDER 23 Flushing Oil Return

Hydrocarbon Drain DH DELUGE VALVE

28

n Water Drain DW

24 Demi Water NOTE 5 28

P&ID No. n TIGHT SHUT-OFF VALVE

s not i

Aqueous Effluent Drain

TW PS (ORBIT)

27

n (Inside Package B.L.) OPEN SPECTACLE BLIND ( NOTE 1 ) 27

) and i

(PRESSURE SIDE)

26 n Vents and Flare

26

S.C.

Vent Gas VG

TED (Q.

CONNECTIONS TO OTHER UNITS

.

SCREWED CAP

or express approval

25 TIGHT SHUT OFF VALVE 25

Flare Gas (HP&LP) VF

SERVICE DESCRIPTION (Y-PATTERN)

MI

TS

ORYX GTL LI

24 UNIT No.

PIPING ABBREVIATIONS 24

Miscellaneous TEMPORARY STRAINER

Chemicals CH

23 ARMSTRONG "EVERLASTING" ROTATING 23

Catalyst Slurry CA

) pri

censed to

P&ID - -25- CSC CAR SEAL CLOSED

DISC ORE QUAL

Seal Oil SO

C.

SIGHT GLASS CSO CAR SEAL OPEN

S.

22 22

TED (Q.

Lubrication Oil LO FC FAIL CLOSED

i

ng to or l

3 WAY VALVE

Foam FM FL FAIL LOCKED

MI

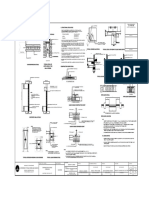

21 LINE NUMBERS Hydraulic Fluids HY

SAMPLE CONNECTION 21

res ORYX GTL LI

FMC FORCE MANUAL CLOSE

SC (X=TYPE) NOTE 2

ongi

Refrigerant RF FMO FORCE MANUAL OPEN

X

on bel

20 FOUR WAY VALVE 20

LINE NUMBER (GTL) FO FAIL OPEN

nform ati

LC LOCKED CLOSED

19 19

on thereof requi

INSULATION CODES LO LOCKED OPEN

al i

2"-NG-A1AP-30115 07-NI SP SPECIAL PIPING ITEM

MW MANWAY SPRING LOADED QUICK CLOSING VALVE

denti

18 HOT SERVICE INSULATION INTERMITTENT BLOWDOWN 18

NC NORMALLY CLOSED

XX

ns confi

NO NORMALLY OPEN

on or adaptati

17 Insulation code HC Process line Heat Conservation where 17

OV OPERATING VALVE (AT GRADE)

normal operating temperature exceed

ng contai

Sequential number PO PILOT OPERATED

93C 'Y' TYPE STRAINER

16 HAND 3 WAY VALVE 16

P&ID Number Heat conservation for Steam and PP PRESSURE POINT

HS

s drawi

), and any reproducti

condensate lines RS REMOVABLE SPOOL

Piping Material Class

15 Process Stabilisation to assist in 15

PS TSO TIGHT SHUT OFF

ghts reserved. Thi

Service Index process control EXHAUST HEAD NNF NORMALLY NO FLOW

14 Size 14

ST Steam Traced FS FLASHING SERVICE

ST1 Steam Traced (SS lines) FIP FAIL IN PLACE

C.

13 SIX WAY VALVE 13

S.

al property ri

SS Steam traced with Spacers

TED (Q.

BIRD SCREEN

12 SC Steam traced with heat transfer 12 11 21/11/16 AS BUILT (WO-02) AH RG RRR

MI

Cement

s owned by ORYX GTL LI

10 15.05.2016 AS BUILT AS PER MOC 963 MCS PP RT

ndustri

11 SC1 Steam traced with heat transfer 11

09 02/06/15 AS BUILT(MOC-577) SGB AG THG/BGS

LINE NUMBER Cement (SS lines)

UNIT NUMBERS

l other i

FOR UNIT 89 (JETTY BERTH 2A) TIE IN POINT 08 05/03/13 AS BUILT(MOC-128) SGB JRT NSK/BGS

10 ET Electrically Traced 10

ght, patents, and al

07 30/04/07 AS BUILT CARINCI LIPPI CORSI/BULLETTI

9

SJ Steam Jacketed UNIT ABBREVIATIONS 9

NUMBER DESCRIPTION 05,06 NOT ISSUED

2"-DP-U-89-02-001-A1AP-NI

ng i

PP Personnel Protection

s drawi

04 31/01/05 REVISED AS SHOWN

10 Air Separation CAPOZZA LIPPI DI CINTIO/GRANO

8 PG Personnel protection with stand-off 8

"T" TYPE STRAINER 6" 20 Synthesis Gas AG ABOVE GROUND REV. DATE DESCRIPTION PREPARED CHECKED APPR/AUTH

metal Guard

n thi

NOTE 4 30 F-T Synthesis UG UNDER GROUND

censor. Copyri

FP Fire hazard Protection

7 7

ght i

Insulation code 35 Heavy Ends Recovery (V) VENT

A Acoustic protection at various level

l be returned upon request. The copyri

of requirement 40 Water Treatment (D) DRAIN

Piping material class B

6 6

C 45 Wax Treatment (C) CONTRACTOR

S Li

STATIC MIXER

Sequential number

50 Product Work-Up (S) SUPPLIER

) (ORYX) or ORYX'

NI Not Insulated

5 5

System munber 60 Hydrogen Production DEC DESIGN ENGINEERING CONTRACTOR

71 Raw Water Treatment HER HEAVY ENDS RECOVERY

Unit number

4 COLD SERVICE INSULATION DIAPHRAM SEAL 4

72 HP Steam RTD RESISTANCE THERMOMETER DETECTOR

Project code

73 MP Steam and Power Generation TC THERMO-COUPLE

CC Prevention of heat gain in process

ORYX GTL PROJECT

C.

3 Service Index 3

S.

lines where normal operating VORTEX BREAK MFR MANUFACTURER

74 Cooling Water

TED (Q.

temperatures are below 35C TP TPIT

Size 75 Plant/Instrument Air and Nitrogen Systems RAS LAFFAN INDUSTRIAL CITY-QATAR

2 2

) and shal

HHLL HIGH HIGH LIQUID LEVEL

MI

CP Personnel Protection with stand-off 77 Effluent Treatment

s the property of ORYX GTL LI

metal guards 78 Fuel System HLL HIGH LIQUID LEVEL

1 AIR SUCTION STRAINER 1

Acoustic protection at various level 81 Flare System NLL NORMAL LIQUID LEVEL

C.

A

PIPING AND INSTRUMENT DIAGRAM

S.

B of requirement LLL LOW LIQUID LEVEL

TED (Q.

82 Fire Systems

C Intermediate Tankage LLLL LOW LOW LIQUID LEVEL

83 P&ID SYMBOLOGY

MI

F Fire Protection in addition to 84 Product Tankage DS DIAPHRAGM SEAL

consent of ORYX GTL LI

prevention of heat gain LINES & EQUIPMENT

87 LPG Clean up Facility

TECHNIP DRAWING NO. SHEET NO. REV.

NI Not Insulated CALIBRATION POT 89 Jetty Berth 2A

ng i

99 Site Interfaces 2158-00-PID-0021-001

s drawi

ORYX DRAWING NO.

001 of 002 11

Thi

QGTL1-PRO-07-00001

QGTL1-PRO-07-00001-001_11

TECHNIP ITALY S.p.A. - 00148 ROMA - Viale Castello della Magliana, 68

You might also like

- Doosan DX300LCDocument1 pageDoosan DX300LCjames jbjuryhotmail.comNo ratings yet

- Case Ih Schematic Electrical 6-12750 Mx210 Mx230 Mx255 Mx285Document4 pagesCase Ih Schematic Electrical 6-12750 Mx210 Mx230 Mx255 Mx285gregfortkamp0% (4)

- Sullair 900 1150 Parts ManualDocument136 pagesSullair 900 1150 Parts ManualHans Kaempffer Balague100% (4)

- Fans and Blowers Part I ModuleDocument26 pagesFans and Blowers Part I ModuleCharlyn Flores67% (3)

- MX335 Elec SchematicsDocument5 pagesMX335 Elec SchematicsЕвгений ТкачNo ratings yet

- 966M and 972M Wheel Loader 966mDocument2 pages966M and 972M Wheel Loader 966mF Labio AlexNo ratings yet

- UTILITIES Quiz 3Document3 pagesUTILITIES Quiz 3Amiel TayagNo ratings yet

- Hidraulico D9T PDFDocument2 pagesHidraulico D9T PDFOswaldo Andrade100% (2)

- MAGNUM 225, 250, 280, 310 SERIES TRACTORS Euro Electrical Schematic 87389709Document4 pagesMAGNUM 225, 250, 280, 310 SERIES TRACTORS Euro Electrical Schematic 87389709Fábio CostaNo ratings yet

- CatalogoPGT25 PDFDocument4 pagesCatalogoPGT25 PDFshihabjamaan100% (5)

- Stainless Steel Pipe Dimensions and Weight ChartDocument5 pagesStainless Steel Pipe Dimensions and Weight ChartArun Chopra33% (3)

- G+3 ArchitectureDocument1 pageG+3 ArchitectureMANNANo ratings yet

- Irrigation Main Line LayoutDocument4 pagesIrrigation Main Line Layoutalivesince1091No ratings yet

- Implement Control Valve and Cylinder Circuit: Hydraulic System 16M Motor GraderDocument4 pagesImplement Control Valve and Cylinder Circuit: Hydraulic System 16M Motor GraderFabricio Soria0% (1)

- Sample Plan 1Document3 pagesSample Plan 1skylines1580No ratings yet

- 245 Ebd 9002 - 0Document1 page245 Ebd 9002 - 0sareluis2727No ratings yet

- Vie Pc01 STN DWG MP Sub 01151 0Document1 pageVie Pc01 STN DWG MP Sub 01151 0Ashish BhartiNo ratings yet

- General-Plan-Basement Floor: Mohammed Tamimi VILLA, Duabi, UAEDocument1 pageGeneral-Plan-Basement Floor: Mohammed Tamimi VILLA, Duabi, UAErollyNo ratings yet

- P02-Abd-U06-Nu3-Ch-Acc-6205 Abd1-P02-Abd-U06-Nu3-Ch-Acc-6205Document1 pageP02-Abd-U06-Nu3-Ch-Acc-6205 Abd1-P02-Abd-U06-Nu3-Ch-Acc-6205mohammadNo ratings yet

- Boeing 787-9 VistaraDocument7 pagesBoeing 787-9 VistaraKaran ZillaNo ratings yet

- Edoc - Pub 938giihydraulicsystemDocument2 pagesEdoc - Pub 938giihydraulicsystemGeobel HernandezNo ratings yet

- Elect SchematicDocument4 pagesElect SchematicDenis HernandezNo ratings yet

- Khea Concept - P 1Document1 pageKhea Concept - P 1Zen Marl GaorNo ratings yet

- Fire Protection PlanDocument4 pagesFire Protection PlanBlueEliteVortexNo ratings yet

- Tray DrawingDocument1 pageTray DrawingFareethAbdullahNo ratings yet

- FP-02 Site Dev't PlanDocument1 pageFP-02 Site Dev't PlanBerlin Andrew SionNo ratings yet

- SCR 003789Document1 pageSCR 003789jeplgpbmcNo ratings yet

- Diag. Unifilar Del Sistema de Bombeo - Simsa ActualizarDocument1 pageDiag. Unifilar Del Sistema de Bombeo - Simsa ActualizarJEAN CARLONo ratings yet

- Construction Drawing: Boundary Line Boundary Line Boundary LineDocument1 pageConstruction Drawing: Boundary Line Boundary Line Boundary LinerajavelNo ratings yet

- B787-9 VistaraDocument8 pagesB787-9 VistaraSandmanNo ratings yet

- 825H Soil Compactor Hydraulic SystemDocument2 pages825H Soil Compactor Hydraulic SystemTom SouzaNo ratings yet

- 18.detail Standard Fire FightingDocument1 page18.detail Standard Fire FightingMuhammad ArifNo ratings yet

- Irrigation Control Cable LayoutDocument4 pagesIrrigation Control Cable Layoutalivesince1091No ratings yet

- Notes:: Water Line Gate Valve DetailDocument1 pageNotes:: Water Line Gate Valve DetailDJNo ratings yet

- MARK UP Column L1 TO L2Document1 pageMARK UP Column L1 TO L2Emon SahNo ratings yet

- Workshop 5Document1 pageWorkshop 5Thamarai kannan SrinivasanNo ratings yet

- Dimensi Panel Cad 2010 Mit Rev 04 SD Mit Fabs Ccep El Hvac 007Document1 pageDimensi Panel Cad 2010 Mit Rev 04 SD Mit Fabs Ccep El Hvac 007Wijaya GultomNo ratings yet

- Plumbing SignedcombinedDocument10 pagesPlumbing SignedcombinedAsg DeraNo ratings yet

- Produced by An Autodesk Student Version: Open HR Coil StorageDocument1 pageProduced by An Autodesk Student Version: Open HR Coil StorageIT MalurNo ratings yet

- Workshop 4Document1 pageWorkshop 4Thamarai kannan SrinivasanNo ratings yet

- Ec3-04 Accesss Control Single Line DiagramDocument1 pageEc3-04 Accesss Control Single Line DiagramSEDFREY DELA CRUZNo ratings yet

- Sae As 33649a 2005-08Document4 pagesSae As 33649a 2005-08Andr EkmeNo ratings yet

- PlumbingDocument14 pagesPlumbingRaizen TanNo ratings yet

- 2.symbol and AbbreviationsDocument1 page2.symbol and Abbreviationshambi1986No ratings yet

- Detail of Floor Drain Detail of Water Meter: General Notes Septic Tank ComputationDocument1 pageDetail of Floor Drain Detail of Water Meter: General Notes Septic Tank ComputationCamille ArielNo ratings yet

- Legend:: All 3 Compressors Typical For All 3 Compressors Typical ForDocument1 pageLegend:: All 3 Compressors Typical For All 3 Compressors Typical Forsiva anandNo ratings yet

- S2 Structural NotesDocument1 pageS2 Structural NotesRaynz PatronNo ratings yet

- Doosan DX225LCA Electric Circuit 110705 PDFDocument1 pageDoosan DX225LCA Electric Circuit 110705 PDFDaniel Ardila100% (1)

- P011-0002, Symbols & Legends (2,3)Document1 pageP011-0002, Symbols & Legends (2,3)Mubashir fareedNo ratings yet

- Master PlanDocument1 pageMaster PlanArchitect WaqarNo ratings yet

- 01pantry LayoutDocument4 pages01pantry LayoutrollyNo ratings yet

- Progress Report (16-12-23)Document1 pageProgress Report (16-12-23)Wijaya GultomNo ratings yet

- Ec3-01 Tel. - Data Single Line DiagramDocument1 pageEc3-01 Tel. - Data Single Line DiagramSEDFREY DELA CRUZNo ratings yet

- 2nd Floor & 3rd FloorDocument1 page2nd Floor & 3rd FloorRekha TanpureNo ratings yet

- Group 2 Electrical Circuit: 35D7EEL02Document10 pagesGroup 2 Electrical Circuit: 35D7EEL02André TarginoNo ratings yet

- Hydraulic Schematic IT38G Series II Wheel LoaderDocument2 pagesHydraulic Schematic IT38G Series II Wheel LoaderDennis OlayaNo ratings yet

- 2301 - A5 Shop Drawing For Infrastructure Works (Sales Gallery)Document2 pages2301 - A5 Shop Drawing For Infrastructure Works (Sales Gallery)rizwan hamidNo ratings yet

- Sewerage Drainage Floor Plans Shopdrawing02-03-Dr-102bDocument1 pageSewerage Drainage Floor Plans Shopdrawing02-03-Dr-102ba.azeemNo ratings yet

- Legend:: 09 01 2020 Electrical System Design of A Commercial BuildingDocument1 pageLegend:: 09 01 2020 Electrical System Design of A Commercial BuildingMarkLloydValleNo ratings yet

- Blurb 53 File 286 RiskManagementSystemDocument1 pageBlurb 53 File 286 RiskManagementSystemCharilyn EcheverreNo ratings yet

- Zamboanga Pet Line 110419Document1 pageZamboanga Pet Line 110419PAul JoHn MeNdozaNo ratings yet

- Construction Drawing: Boundary Line Boundary Line Boundary LineDocument1 pageConstruction Drawing: Boundary Line Boundary Line Boundary LinerajavelNo ratings yet

- Instant Assessments for Data Tracking, Grade 1: Language ArtsFrom EverandInstant Assessments for Data Tracking, Grade 1: Language ArtsNo ratings yet

- QGTL1 Pro 07 00007 001 - 08Document1 pageQGTL1 Pro 07 00007 001 - 08Muhammad Arham KhalilNo ratings yet

- QGTL1 Pro 07 00004 001 - 09Document1 pageQGTL1 Pro 07 00004 001 - 09Muhammad Arham KhalilNo ratings yet

- QGTL1 Pro 07 00003 001 - 09Document1 pageQGTL1 Pro 07 00003 001 - 09Muhammad Arham KhalilNo ratings yet

- 30 99 09 0203-PressureVesselsDocument12 pages30 99 09 0203-PressureVesselsMuhammad Arham KhalilNo ratings yet

- 30.99.09.0205-Secondary ContainmentDocument10 pages30.99.09.0205-Secondary ContainmentMuhammad Arham KhalilNo ratings yet

- 30.99.09.0204-Passive Fire ExplosionDocument9 pages30.99.09.0204-Passive Fire ExplosionMuhammad Arham KhalilNo ratings yet

- Spare Parts List STORM 15 20180000 XDocument4 pagesSpare Parts List STORM 15 20180000 XFati ZoraNo ratings yet

- Flow Over Bodies: Drag and Lift: Solutions Manual For Fluid Mechanics: Fundamentals and Applications by Çengel & CimbalaDocument65 pagesFlow Over Bodies: Drag and Lift: Solutions Manual For Fluid Mechanics: Fundamentals and Applications by Çengel & Cimbalaapi-19800460100% (8)

- Gas Turbines and Associated Auxiliary Systems in Oil and Gas ApplicationsDocument27 pagesGas Turbines and Associated Auxiliary Systems in Oil and Gas ApplicationsGhazaleh GhazanfariNo ratings yet

- GE - Frame - 9E - LUBE - OIL - FILTER - LOF11Document14 pagesGE - Frame - 9E - LUBE - OIL - FILTER - LOF11Abbas AkbarNo ratings yet

- Solenoid and Pressure Operated Valve Technology: Function, Terminology and Construction TypesDocument4 pagesSolenoid and Pressure Operated Valve Technology: Function, Terminology and Construction TypesfragercitoNo ratings yet

- GE 9FA Water Wash PROCEDURE FinalDocument43 pagesGE 9FA Water Wash PROCEDURE FinalAbdelaziz Eldeeb100% (2)

- BOP Chamber Volume & Dimensions: No Equipment Size & Rating Manufacture TypeDocument14 pagesBOP Chamber Volume & Dimensions: No Equipment Size & Rating Manufacture TypeBoedi SyafiqNo ratings yet

- Aversa DP Cat RO EN PDFDocument16 pagesAversa DP Cat RO EN PDFmatache temelieNo ratings yet

- Bernoulli's EquationDocument21 pagesBernoulli's Equationananthu.uNo ratings yet

- The Basic Principles of HydraulicsDocument8 pagesThe Basic Principles of Hydraulicsyakarim100% (3)

- Fundamentals of Compressible Flow: Measurement Diagnostics and Experimental Facilities For Compressible FlowDocument6 pagesFundamentals of Compressible Flow: Measurement Diagnostics and Experimental Facilities For Compressible Flowkushal bosuNo ratings yet

- BITZER Company Presentation 2011 - EN - FINxDocument30 pagesBITZER Company Presentation 2011 - EN - FINxAndr_Guerra_3324No ratings yet

- MAN B&W Fuel Pump Components PDFDocument18 pagesMAN B&W Fuel Pump Components PDFAnonymous dMpyrukeJ100% (2)

- Hazen-Williams Pipe Flow Calculations SI UnitsDocument25 pagesHazen-Williams Pipe Flow Calculations SI UnitsJorge CottonNo ratings yet

- Waste Piping Systems and Secondary Containment Piping Systems List PriceDocument146 pagesWaste Piping Systems and Secondary Containment Piping Systems List PriceAaron Marius JuliusNo ratings yet

- Sadara Business Complex: Sports CentreDocument4 pagesSadara Business Complex: Sports CentreraziNo ratings yet

- Operation Manual: Hydraulic Slow-Closing Check Butterfly ValveDocument41 pagesOperation Manual: Hydraulic Slow-Closing Check Butterfly ValveAnton HidayatNo ratings yet

- Gem Pump InstructionsDocument2 pagesGem Pump InstructionsRoberto BrunoNo ratings yet

- Experiment 4 Centrifugal PumpDocument9 pagesExperiment 4 Centrifugal PumpSaranya Devi RagupathyNo ratings yet

- Rheem Classic RrnaDocument44 pagesRheem Classic RrnaRedmanJackieNo ratings yet

- Erosion Velocity CalculationsDocument9 pagesErosion Velocity CalculationsMANISH GUPTANo ratings yet

- Liquid Unloading in A Big Bore Completion - Comparison Gas Lift & Velocity stringSPE-88523-MSDocument14 pagesLiquid Unloading in A Big Bore Completion - Comparison Gas Lift & Velocity stringSPE-88523-MSQaiser HafeezNo ratings yet

- Design and Modeling of Fluid Power Systems: ME 597/ABE 591 - Lecture 6Document30 pagesDesign and Modeling of Fluid Power Systems: ME 597/ABE 591 - Lecture 6Elias80No ratings yet

- Oil Pump Type Ale Gear Sizes 35-55: ALE Oil Pump Incorporates A Blocking Solenoid Valve Fitted With A Built-InDocument2 pagesOil Pump Type Ale Gear Sizes 35-55: ALE Oil Pump Incorporates A Blocking Solenoid Valve Fitted With A Built-Inmochammad RezaNo ratings yet

- Summer 2020 Dr. Hidir Maral Department of Mechanical EngineeringDocument36 pagesSummer 2020 Dr. Hidir Maral Department of Mechanical EngineeringRıza ÜnalNo ratings yet