Professional Documents

Culture Documents

Series 1500 Engineering

Series 1500 Engineering

Uploaded by

roychabCopyright:

Available Formats

You might also like

- PDF New Perspectives On The Internet Comprehensive Loose Leaf Version 10Th Edition Jessica Evans Ebook Full ChapterDocument53 pagesPDF New Perspectives On The Internet Comprehensive Loose Leaf Version 10Th Edition Jessica Evans Ebook Full Chapterlorna.rayfield998100% (3)

- Geriatric Consideration in NursingDocument31 pagesGeriatric Consideration in NursingBabita Dhruw100% (5)

- All Sizes and TorquesDocument13 pagesAll Sizes and TorquesMohammad Rizwan100% (1)

- Catalog - e - LorünserDocument99 pagesCatalog - e - Lorünserbrayan colorado tobonNo ratings yet

- Example (Pty) LTD: Asset Set-UpDocument25 pagesExample (Pty) LTD: Asset Set-UpMichaelszAndreyNo ratings yet

- Wisdom From TD Jakes FREEDocument224 pagesWisdom From TD Jakes FREEayodeji78100% (3)

- Senior High School: Emilio Aguinaldo College City of Dasmariñas, CaviteDocument7 pagesSenior High School: Emilio Aguinaldo College City of Dasmariñas, CaviteNicole De AsisNo ratings yet

- Guia Parafusos, Arruelas E Porcas 1Document156 pagesGuia Parafusos, Arruelas E Porcas 1Adrian VerattiNo ratings yet

- API Drill Pipe DataDocument2 pagesAPI Drill Pipe DataJohn100% (1)

- STRG CapacitiesDocument1 pageSTRG Capacitiesislam atifNo ratings yet

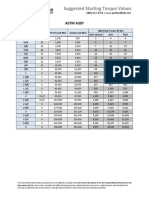

- Suggested Starting Torque Values: ASTM A307Document5 pagesSuggested Starting Torque Values: ASTM A307mostapha soubraNo ratings yet

- Ch165a 25120 01Document8 pagesCh165a 25120 01surya jaya bearingNo ratings yet

- Torque - and - Makeup - Loss - Metric 4Document4 pagesTorque - and - Makeup - Loss - Metric 4CRISTIANONo ratings yet

- Gunnebo Industries - Alloy Steel Rigging Screw No. 801, 802 & 804Document2 pagesGunnebo Industries - Alloy Steel Rigging Screw No. 801, 802 & 804REDDYNo ratings yet

- ASTM A307: Diámetro Paso Carga de Prueba (LBS) Fuerza de Apriete (LBS) Torque (FT LBS) Lubricado Galv NegroDocument1 pageASTM A307: Diámetro Paso Carga de Prueba (LBS) Fuerza de Apriete (LBS) Torque (FT LBS) Lubricado Galv NegroGutierrez FerchoNo ratings yet

- Make Up TorqueDocument1 pageMake Up TorqueNicasio AlonzoNo ratings yet

- SUNITRAC OTR Tyre CatalogDocument12 pagesSUNITRAC OTR Tyre CatalogCarlos Alberto Reque BardalesNo ratings yet

- Ca3000b 358Document1 pageCa3000b 358cfloresahumadaNo ratings yet

- 12-Volt Intimidator® - Agm - Valve Regulated: Effective July 1, 2020Document4 pages12-Volt Intimidator® - Agm - Valve Regulated: Effective July 1, 2020ragachemi ragaNo ratings yet

- API - Iadc Recommended Drill String Make-Up TorqueDocument2 pagesAPI - Iadc Recommended Drill String Make-Up TorqueQuality controller100% (6)

- даукониDocument21 pagesдаукониLeonid YurchenkofNo ratings yet

- DW1020 - Capscrew Torque Chart & InstructionsDocument4 pagesDW1020 - Capscrew Torque Chart & InstructionsAlex RamirezNo ratings yet

- Boat WiringDocument4 pagesBoat WiringRenganathanPadmanabhanNo ratings yet

- Piezas Bridadas HD Awwa C110Document12 pagesPiezas Bridadas HD Awwa C110Francisco Javier Espinoza GilNo ratings yet

- AP EngDocument34 pagesAP EngNail KayaNo ratings yet

- Tabla de Bridas y Esparragos PDFDocument1 pageTabla de Bridas y Esparragos PDFjairo ardila100% (1)

- 10 1008 PDFDocument1 page10 1008 PDFtuzarraNo ratings yet

- 10 1008 PDFDocument1 page10 1008 PDFPrasadNo ratings yet

- Bolt Torque ChartDocument7 pagesBolt Torque ChartVìctor ChicaìzaNo ratings yet

- Programs OvershotsDocument18 pagesPrograms OvershotsDon BraithwaiteNo ratings yet

- Drill Pipe Spec SheetDocument2 pagesDrill Pipe Spec SheetVijay KotiNo ratings yet

- Bodytobonnet Torque Values For Fluorocarboncoated FastenersDocument8 pagesBodytobonnet Torque Values For Fluorocarboncoated FastenersJoão Mendonça SantosNo ratings yet

- Suggested Starting Torque Values: ASTM A307Document6 pagesSuggested Starting Torque Values: ASTM A307marioNo ratings yet

- Tabel Konversi Tekanan Angin, LoadDocument4 pagesTabel Konversi Tekanan Angin, Loadtaufiqhuda8No ratings yet

- Selection Guide - Mosfet ProductDocument6 pagesSelection Guide - Mosfet ProductlapiamaNo ratings yet

- Giddings & Lewis Zappendix ADocument9 pagesGiddings & Lewis Zappendix AAngel AdautaNo ratings yet

- CM20180409 17540 55148Document7 pagesCM20180409 17540 55148fathi226No ratings yet

- 9010 Seamless TubingDocument1 page9010 Seamless Tubingbingb39No ratings yet

- Drill Pipe Data BookDocument2 pagesDrill Pipe Data BookemadabdelsattarNo ratings yet

- Keppel Piping Hand BookDocument21 pagesKeppel Piping Hand BooktinzarmoeNo ratings yet

- Torque de Trepanos Smith (PDC - Tricono) PDFDocument1 pageTorque de Trepanos Smith (PDC - Tricono) PDFPither ZuritaNo ratings yet

- MOTOR SIZING OF BREAKER,CONTACTOR AND OVERLOADDocument2 pagesMOTOR SIZING OF BREAKER,CONTACTOR AND OVERLOADengr.mjadetabotaboNo ratings yet

- Portland Bolt Bolt Torque ChartDocument5 pagesPortland Bolt Bolt Torque ChartRamadanNo ratings yet

- Portland-Bolt-Bolt-Torque-Chart - A325 - A307 - A449 - A490 - A193 - A354Document5 pagesPortland-Bolt-Bolt-Torque-Chart - A325 - A307 - A449 - A490 - A193 - A354João Mendonça Santos100% (1)

- Portland Bolt Bolt Torque Chart For DTI'sDocument5 pagesPortland Bolt Bolt Torque Chart For DTI'sTaylor ButlerNo ratings yet

- Valvula Sismica Vertical Entrada Inferiori Bridada Mod VB319FDocument2 pagesValvula Sismica Vertical Entrada Inferiori Bridada Mod VB319FGrecia Paola Garza RodriguezNo ratings yet

- Tabla de ConsumosDocument10 pagesTabla de ConsumosJuan Jo RamirezNo ratings yet

- Balmoral RWH HH Direct ManualDocument2 pagesBalmoral RWH HH Direct ManualAlberto DiazNo ratings yet

- R410a Fixed Speed RotaryDocument2 pagesR410a Fixed Speed RotaryashokindeedNo ratings yet

- Aksa Master Pricelist 2014Document1 pageAksa Master Pricelist 2014Wissam JarmakNo ratings yet

- zpk5 Service Compressor Kits 17 18 en Us 5082464Document12 pageszpk5 Service Compressor Kits 17 18 en Us 5082464fjeroNo ratings yet

- Common Bolt Markings Torques Tech Bulletin AERA Melling Engine PartsDocument1 pageCommon Bolt Markings Torques Tech Bulletin AERA Melling Engine PartsNazar AlrodainyNo ratings yet

- UPN Profile DataDocument2 pagesUPN Profile DataManas80No ratings yet

- Axial Flow FansDocument3 pagesAxial Flow FansABCDNo ratings yet

- Bolt Torque SpecsDocument5 pagesBolt Torque SpecsSilvia ErazoNo ratings yet

- Cortland SlingsDocument12 pagesCortland SlingsafafaNo ratings yet

- Midea KFR26 GDocument40 pagesMidea KFR26 Gmr.aikidoNo ratings yet

- Ha Quad Assemblies OsDocument2 pagesHa Quad Assemblies OsjpriceNo ratings yet

- Butterfly Valve B7GDocument3 pagesButterfly Valve B7GJorgeCabreraCoronelNo ratings yet

- Tee PeDocument1 pageTee PeMishelle SolorzanoNo ratings yet

- LEADHOSE (1)Document4 pagesLEADHOSE (1)BurhanudinUrcNo ratings yet

- Reliable Performance All Year RoundDocument4 pagesReliable Performance All Year RounddavidNo ratings yet

- Padeye Design: Allseas LogoDocument12 pagesPadeye Design: Allseas LogoHemam PrasantaNo ratings yet

- VP3401 As04Document2 pagesVP3401 As04shivamtyagi68637No ratings yet

- Chroma Bidirectional DC Power Supply Model 62000D SeriesDocument12 pagesChroma Bidirectional DC Power Supply Model 62000D SeriesaboofazilNo ratings yet

- Approach To Floppy InfantDocument44 pagesApproach To Floppy InfantNavya Hegde100% (2)

- Drug Dosage and IV Rates Calculations PDFDocument6 pagesDrug Dosage and IV Rates Calculations PDFvarmaNo ratings yet

- Application of Buoyancy-Power Generator For Compressed Air Energy Storage Using A Fluid-Air Displacement System - ScienceDirectDocument7 pagesApplication of Buoyancy-Power Generator For Compressed Air Energy Storage Using A Fluid-Air Displacement System - ScienceDirectJoel Stanley TylerNo ratings yet

- Kohlberg's Stages of Moral DevelopmentDocument14 pagesKohlberg's Stages of Moral DevelopmentMarvelyn De StoTomas IgnacioNo ratings yet

- MC&OB Unit 4Document17 pagesMC&OB Unit 4Tanya MalviyaNo ratings yet

- HUAWEI - SUN2000-20-40KTL-M3-UserManual GCADocument102 pagesHUAWEI - SUN2000-20-40KTL-M3-UserManual GCAReardon MetalsNo ratings yet

- DAPA Teams Spider DiagramDocument2 pagesDAPA Teams Spider DiagramEduardoJaimeNo ratings yet

- Miller PreviewDocument252 pagesMiller PreviewcqpresscustomNo ratings yet

- Academic Journal Guide 2021-MethodologyDocument22 pagesAcademic Journal Guide 2021-MethodologySyedNo ratings yet

- Occupational Safety and Health Aspects of Voice and Speech ProfessionsDocument34 pagesOccupational Safety and Health Aspects of Voice and Speech ProfessionskaaanyuNo ratings yet

- HVLDocument44 pagesHVLlogofwood6858100% (2)

- Relatorio Mano JulioDocument7 pagesRelatorio Mano JulioProGeo Projetos AmbientaisNo ratings yet

- Lec 1 Introduction Slides 1 20 MergedDocument153 pagesLec 1 Introduction Slides 1 20 MergedNeeraj VarmaNo ratings yet

- Tle 7-1st Periodic TestDocument2 pagesTle 7-1st Periodic TestReymart TumanguilNo ratings yet

- Digital Banking A Case Study of India: Solid State Technology December 2020Document10 pagesDigital Banking A Case Study of India: Solid State Technology December 2020Mohit PacharNo ratings yet

- Software Engineering. Specification, Implementation, VerificationDocument186 pagesSoftware Engineering. Specification, Implementation, Verificationazariel.rodrigo100% (1)

- Beira International School: End of Year ExaminationDocument7 pagesBeira International School: End of Year ExaminationnothandoNo ratings yet

- Tuyển Sinh 10 - đề 1 -KeyDocument5 pagesTuyển Sinh 10 - đề 1 -Keynguyenhoang17042004No ratings yet

- 3M CorporationDocument3 pages3M CorporationIndoxfeeds GramNo ratings yet

- Yamabe Flow On Nilpotent Lie GroupsDocument20 pagesYamabe Flow On Nilpotent Lie GroupsEnzo RicNo ratings yet

- StatementOfAccount 6316692309 21072023 222045Document17 pagesStatementOfAccount 6316692309 21072023 222045Asekar AlagarsamyNo ratings yet

- A 182Document20 pagesA 182Thomas100% (1)

- Ovarian Cancer ThesisDocument8 pagesOvarian Cancer ThesisDon Dooley100% (1)

- Company Profile For ICB TechnimontDocument4 pagesCompany Profile For ICB TechnimontShankarMukherjeeNo ratings yet

Series 1500 Engineering

Series 1500 Engineering

Uploaded by

roychabOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Series 1500 Engineering

Series 1500 Engineering

Uploaded by

roychabCopyright:

Available Formats

Series 1500 Cooling Towers

Engineering Data

Engineering Data

Single/Multi-Cell Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Dimensional Reference Drawings . . . . . . . . . . . . . . . . . . . . . . . . . .2

Structural Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Structural Support Alternatives . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Engineering Data

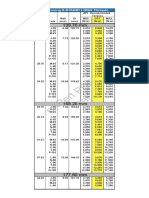

Single Cell Unit

Weights (lbs) Dimensions

Ind. Fan

Model Nominal Motor Fan Heaviest Inlet

Series 1500 Engineering Data

Number Tonnage9 Motor HP Option (CFM) Operating1 Shipping Section L H A C D Conn.2

15146 146 7.5 N/A 40,320 7,920 3,940 3,940

15160 160 10 N/A 44,190 7,940 3,960 3,960 8’ 5-3/4” 10’ 2-7/8” N/A 9’ 8-5/8” 4’ 2-7/8” 6”

15176 176 15 N/A 48,160 7,990 4,010 4,010

15162 162 7.5 N/A 43,080 8,610 4,200 4,200

15177 177 10 N/A 47,070 8,630 4,220 4,220 8’ 5-3/4” 11’ 6-7/8” N/A 11’ 0-5/8” 6”

4’ 2-7/8”

15201 201 15 N/A 53,540 8,690 4,280 4,280

15219 219 20 N/A 58,240 8,710 4,300 4,300

15200 200 10 N/A 52,320 11,430 5,350 2,770

15227 227 15 N/A 59,380 11,490 5,410 2,780 8’ 5-3/4” 14’ 3-3/8” 7’ 4-3/4” 13’ 9-1/4” 4’ 2-7/8” 6”

15250 250 20 N/A 65,400 11,510 5,430 2,800

15214 214 10 N/A 56,610 12,450 5,640 2,920

15245 245 15 N/A 64,810 12,510 5,700 2,920 8’ 5-3/4” 15’ 7-3/8” 8’ 8-3/4” 15’ 1-1/4” 6”

4’ 2-7/8”

15270 270 20 N/A 71,420 12,530 5,720 2,920

15282 282 25 N/A 74,600 12,610 5,800 2,920

15296 296 15 (2) 7.5 77,440 15,540 6,750 3,540

15325 325 20 (2) 10 85,030 15,590 6,800 3,590 12’ 1-1/4” 14’ 3-3/8” 7’ 4-3/4” 13’ 9-1/4” 8”

6’ 0-5/8”

15350 350 25 (2) 15 91,560 15,640 6,850 3,640

15368 368 30 (2) 15 96,280 15,660 6,870 3,660

15310 310 15 (2) 7.5 82,000 17,050 7,070 3,540

15340 340 20 (2) 10 89,940 17,100 7,120 3,590

15365 365 25 (2) 15 96,550 17,150 7,170 3,640 12’ 1-1/4” 15’ 7-3/8” 8’ 8-3/4” 15’ 1-1/4” 6’ 0-5/8” 8”

15385 387 30 (2) 15 101,840 17,180 7,200 3,670

15425 428 40 (2) 20 112,340 17,450 7,470 3,940

Multi-Cell Units

15146-2 292 (2) 7.5 N/A 80,640 15,840 7,880 3,940

15160-2 320 (2) 10 N/A 88,380 15,880 7,920 3,960 17’ 2” 10’ 2-7/8” N/A 9’ 8-5/8” 4’ 2-7/8” (2) 6”

15176-2 352 (2) 15 N/A 96,320 15,890 8,020 4,010

15162-2 324 (2) 7.5 N/A 86,160 17,220 8,400 4,200

15177-2 354 (2) 10 N/A 94,140 17,260 8,440 4,220

17’ 2” 11’ 6-7/8” N/A 11’ 0-5/8” 4’ 2-7/8” (2) 6”

15201-2 402 (2) 15 N/A 106,900 17,380 8,560 4,280

15219-2 438 (2) 20 N/A 116,480 17,420 8,600 4,300

15200-2 400 (2) 10 N/A 104,640 22,860 10,700 2,770

15227-2 454 (2) 15 N/A 118,760 22,980 10,820 2,780 17’ 2” 14’ 3-3/8” 7’ 4-3/4” 13’ 9-1/4” 4’ 2-7/8” (2) 6”

15250-2 500 (2) 20 N/A 130,800 23,020 10,860 2,800

15214-2 428 (2) 10 N/A 113,220 24,900 11,280 2,920

15245-2 490 (2) 15 N/A 129,620 25,020 11,400 2,920

17’ 2” 15’ 7-3/8” 8’ 8-3/4” 15’ 1-1/4” 4’ 2-7/8” (2) 6”

15270-2 540 (2) 20 N/A 142,840 25,060 11,440 2,920

15282-2 564 (2) 25 N/A 149,200 25,220 11,600 2,920

15296-2 592 (2) 15 (4) 7.5 154,880 31,080 13,500 3,540

15325-2 650 (2) 20 (4) 10 170,060 31,180 13,600 3,590

24’ 5” 14’ 3-3/8” 7’ 4-3/4” 13’ 9-1/4” 6’ 0-5/8” (2) 8”

15350-2 700 (2) 25 (4) 15 183,120 31,280 13,700 3,640

15368-2 736 (2) 30 (4) 15 192,560 31,320 13,740 3,660

15310-2 620 (2) 15 (4) 7.5 164,000 34,100 14,140 3,540

15340-2 680 (2) 20 (4) 10 179,880 34,200 14,240 3,590

15365-2 730 (2) 25 (4) 15 193,100 34,300 14,340 3,640 24’ 5” 15’ 7-3/8” 8’ 8-3/4” 15’ 1-1/4” 6’ 0-5/8” (2) 8”

15385-2 774 (2) 30 (4) 15 203,680 34,360 14,400 3,670

15425-2 856 (2) 40 (4) 20 224,680 34,900 14,940 3,940

Do not use for construction. Refer to factory certified dimensions.

1 Baltimore Aircoil Company

Copyright Baltimore Aircoil Company 2009

Dimensional Reference Drawings

AIR OUT

5 1/8"

Series 1500 Engineering Data

AIR IN

H

AIR IN

A

8" WATER OUTLET

ACCESS DOOR 7 1/4"

3"

6

7"

11 1/2"

1'-5 1/2"

2" DRAIN

3" OVERFLOW 2'-7 1/8"

11'-10"

END ELEVATION

WATER INLET WA

WATER

T R

E INLET

INLE

T

D D

(TYP

(TYP)

)

C

C

2'-7 1/2"

8

1 1/2" MAKE UP

2'-7 1/2"

8

1 1/2" MAKE UP

6"

6"

2 1/2"

5 5

1/4" L 1/4

1/4"

"

1/4" L

SIDE ELEVATION

Notes:

1. Operating weight is for tower with water level in the cold water 4. The heaviest section for all models except 15214 through 15282

basin at overflow. If a lower operating weight is needed to meet is the upper section. Models 15146 to 15219 ship in one piece.

design requirements, your local BAC Representative can provide 5. Models 15296 through 15425 – 2 1/8”

additional assistance.

6. Models 15296 through 15425 – 8”

2. The specific size of the inlet and outlet connection may vary with the

7. Models 15146 through 15219 and 15296 through

cooling water design flow rate. Consult unit print for dimensions.

15425 – 2 3/4”

3. Unless otherwise indicated, all connections 3" and smaller are MPT.

8. Models 15296 through 15425 – 1 1/2”

Connections 4" and larger are beveled for welding and mechanically

grooved. 9. Nominal tons of cooling represents 3 GPM of water cooled

from 95ºF to 85ºF at a 78ºF entering wet-bulb temperature.

2 Baltimore Aircoil Company

Copyright Baltimore Aircoil Company 2009

Structural Support

The recommended support arrangement for the Series 1500 Cooling Tower consists of parallel I-beams

positioned as shown in the following drawings. Besides providing adequate support, the steel also serves to

raise the unit above any solid foundation to ensure access to the bottom of the tower. The Series 1500 may

also be supported on columns at the anchor bolt locations shown in Plan A/C or Plan B. A minimum 12”x12”

(304.8mm x 304.8mm) bearing surface must be provided under each of the concentrated load points (See

Series 1500 Engineering Data

Note 5). To support a Series 1500 Cooling Tower on columns or in an alternate steel support arrangement,

consult your local BAC Representative.

7/8" DIA. MOUNTING HOLES

Plan A/C

7/8" DIA. MOUNTING HOLES

Plan B

1 1/8"

10"

(4 REQUIRED PER CELL) (4 REQUIRED)

UNIT OUTLINE

AIR

C BOLT

SIDE ELEVATION

AIR

1'-10 1/2"

L1

C BOLT

A

L

L

INLET

2 1/2"

UNIT OUTLINE INLET

L

L

1 1/8"

AIR

C BOLT

L1

INLET C BOLT

L

L

3" 11'-4" 3"

UNIT OVERALL

C BOLT 11'-10"

L

10"

1 1/8" 11'-7 3/4" 1 1/8"

PLAN VIEW

UNIT OVERALL

11'-10"

PLAN VIEW

END ELEVATION

Plan A/C: Single-Cell and Multi-Cell Units

Model Number A L1 L

15146 to 15282 6’ 9-3/4” 8’ 5-3/4” -

15296 to 15425 10’ 5-1/4” 12’ 1-1/4” -

15146-2 to 15282-2 6’ 9-3/4” 8’ 5-3/4” 17’ 2”

15296-2 to 15425-2 10’ 5-1/4” 12’ 1-1/4” 24’ 5”

Plan B: Single-Cell Units Only

Model Number A L

15146 to 15282 8’ 3-1/2” 8’ 5-3/4”

15296 to 15425 11’ 11” 12’ 1-1/4”

Notes:

1. Support beams and anchor bolts are to be selected and installed for units on support Plan A/C. When determining the length of

by others. steel beams, allow for the length of vibration isolation rails, as they

may be longer than the tower length shown above.

2. All supporting steel must be level at the top.

5. If point vibration isolation is used with multi-cell towers, the

3. Beams must be selected in accordance with accepted structural

isolators must be located under the supporting steel, not between

practice. Maximum deflection of beam under unit to be 1/360 of

the support steel and the cooling towers.

span, not to exceed 1/2 inch.

6. When using Alternative Plan A support arrangements with optional

4. All units can be furnished with an optional vibration isolation

bottom water outlet, size and location restrictions will apply to

package, if required, to be installed between the tower and

water outlet piping. Consider the Cantilevered Plan A support

supporting steel. The BAC vibration isolation package is designed

arrangement or consult your local BAC Representative for details.

3 Baltimore Aircoil Company

Copyright Baltimore Aircoil Company 2009

Structural Support Alternatives

For replacement installations, the Series 1500 Cooling Tower has been designed to match the supporting

steel of most existing counterflow and crossflow cooling towers without modifications. Shown below are the

most common steel support arrangements which can be accommodated by the Series 1500. If individual

point support is required, or if steel arrangement is not as shown below, consult your local BAC

Series 1500 Engineering Data

Representative for assistance.

Alternative Plan A UNIT OUTLINE

Cantilevered Plan A UNIT OUTLINE

1 1/8"

1 1/8"

7/8" DIA. MOUNTING HOLES

7/8" DIA. MOUNTING HOLES

10"

(4 REQUIRED PER CELL)

AIR

C BOLT

AIR

CL BOLT

L1

CL BOLT

C

1'-10 1/2"

C1

C2

L1

2 1/2"

4 3/4"

2 1/2"

INLET

L

INLET

4 3/4"

C BOLT

AIR

AIR

L1

CL BOLT

CL BOLT

C

C1

C2

L1

L

INLET

INLET

C BOLT C BOLT

L L

1 1/8"

10"

1 1/8"

B A B

B A 1 1/8"

UNIT OVERALL

UNIT OVERALL

11'-10"

11'-10"

PLAN VIEW

END ELEVATION

END ELEVATION

Alternative Plan A: Typical Dimensions for Single-Cell and Multi-Cell Units

Model Number Unit Replaced A B C L1

15146 to 15282 VLT/VST 8’ 9-1/8” 1’ 6-7/16” 8’ 3-1/2” 8’ 5-3/4”

VLT/VST/VXT 8’ 11-1/4” 1’ 5-3/8” 11’ 11” 12’ 1-1/4”

15296 to 15425 VXT/VXMT 9’ 7-1/2” 1’ 1-1/4” 11’ 11” 12’ 1-1/4”

CFT 8’ 0” 1’ 11” 8’ 3-1/2” 8’ 5-3/4”

15146 to 15282 Series 3000 8’ 3-1/4” 1’ 9-3/8” 8’ 3-1/2” 8’ 5-3/4”

CFT 8’ 0” 1’ 11” 11’ 11” 12’ 1-1/4”

15296 to 15425 Series 3000 9’ 6” 1’ 2” 11’ 11” 12’ 1-1/4”

Cantilevered Plan A: Typical Dimensions for Single-Cell and Multi-Cell Units

Model Number Unit Replaced A B C1 C2 L1

15146 to 15282 VLT/VST 8’ 9-1/8” 2’ 11-3/4” 8’ 3-1/2” 6’ 9-3/4” 8’ 5-3/4”

VLT/VST/VXT 8’ 11-1/4” 2’ 9-5/8” 11’ 11” 10’ 5-1/4” 12’ 1-1/4”

15296 to 15425

VXT/VXMT 9’ 7-1/2” 2’ 1-3/8” 11’ 11” 10’ 5-1/4” 12’ 1-1/4”

CFT 8’ 0” 3’ 8-7/8” 8’ 3-1/2” 6’ 9-3/4” 8’ 5-3/4”

15146 to 15282

Series 3000 8’ 3-1/4” 3’ 5-5/8” 8’ 3-1/2” 6’ 9-3/4” 8’ 5-3/4”

CFT 8’ 0” 3’ 8-7/8” 11’ 11” 10’ 5-1/4” 12’ 1-1/4”

15296 to 15425

Series 3000 9’ 6” 2’ 2-7/8” 11’ 11” 10’ 5-1/4” 12’ 1-1/4”

See Notes on previous page.

4 Baltimore Aircoil Company

Copyright Baltimore Aircoil Company 2009

You might also like

- PDF New Perspectives On The Internet Comprehensive Loose Leaf Version 10Th Edition Jessica Evans Ebook Full ChapterDocument53 pagesPDF New Perspectives On The Internet Comprehensive Loose Leaf Version 10Th Edition Jessica Evans Ebook Full Chapterlorna.rayfield998100% (3)

- Geriatric Consideration in NursingDocument31 pagesGeriatric Consideration in NursingBabita Dhruw100% (5)

- All Sizes and TorquesDocument13 pagesAll Sizes and TorquesMohammad Rizwan100% (1)

- Catalog - e - LorünserDocument99 pagesCatalog - e - Lorünserbrayan colorado tobonNo ratings yet

- Example (Pty) LTD: Asset Set-UpDocument25 pagesExample (Pty) LTD: Asset Set-UpMichaelszAndreyNo ratings yet

- Wisdom From TD Jakes FREEDocument224 pagesWisdom From TD Jakes FREEayodeji78100% (3)

- Senior High School: Emilio Aguinaldo College City of Dasmariñas, CaviteDocument7 pagesSenior High School: Emilio Aguinaldo College City of Dasmariñas, CaviteNicole De AsisNo ratings yet

- Guia Parafusos, Arruelas E Porcas 1Document156 pagesGuia Parafusos, Arruelas E Porcas 1Adrian VerattiNo ratings yet

- API Drill Pipe DataDocument2 pagesAPI Drill Pipe DataJohn100% (1)

- STRG CapacitiesDocument1 pageSTRG Capacitiesislam atifNo ratings yet

- Suggested Starting Torque Values: ASTM A307Document5 pagesSuggested Starting Torque Values: ASTM A307mostapha soubraNo ratings yet

- Ch165a 25120 01Document8 pagesCh165a 25120 01surya jaya bearingNo ratings yet

- Torque - and - Makeup - Loss - Metric 4Document4 pagesTorque - and - Makeup - Loss - Metric 4CRISTIANONo ratings yet

- Gunnebo Industries - Alloy Steel Rigging Screw No. 801, 802 & 804Document2 pagesGunnebo Industries - Alloy Steel Rigging Screw No. 801, 802 & 804REDDYNo ratings yet

- ASTM A307: Diámetro Paso Carga de Prueba (LBS) Fuerza de Apriete (LBS) Torque (FT LBS) Lubricado Galv NegroDocument1 pageASTM A307: Diámetro Paso Carga de Prueba (LBS) Fuerza de Apriete (LBS) Torque (FT LBS) Lubricado Galv NegroGutierrez FerchoNo ratings yet

- Make Up TorqueDocument1 pageMake Up TorqueNicasio AlonzoNo ratings yet

- SUNITRAC OTR Tyre CatalogDocument12 pagesSUNITRAC OTR Tyre CatalogCarlos Alberto Reque BardalesNo ratings yet

- Ca3000b 358Document1 pageCa3000b 358cfloresahumadaNo ratings yet

- 12-Volt Intimidator® - Agm - Valve Regulated: Effective July 1, 2020Document4 pages12-Volt Intimidator® - Agm - Valve Regulated: Effective July 1, 2020ragachemi ragaNo ratings yet

- API - Iadc Recommended Drill String Make-Up TorqueDocument2 pagesAPI - Iadc Recommended Drill String Make-Up TorqueQuality controller100% (6)

- даукониDocument21 pagesдаукониLeonid YurchenkofNo ratings yet

- DW1020 - Capscrew Torque Chart & InstructionsDocument4 pagesDW1020 - Capscrew Torque Chart & InstructionsAlex RamirezNo ratings yet

- Boat WiringDocument4 pagesBoat WiringRenganathanPadmanabhanNo ratings yet

- Piezas Bridadas HD Awwa C110Document12 pagesPiezas Bridadas HD Awwa C110Francisco Javier Espinoza GilNo ratings yet

- AP EngDocument34 pagesAP EngNail KayaNo ratings yet

- Tabla de Bridas y Esparragos PDFDocument1 pageTabla de Bridas y Esparragos PDFjairo ardila100% (1)

- 10 1008 PDFDocument1 page10 1008 PDFtuzarraNo ratings yet

- 10 1008 PDFDocument1 page10 1008 PDFPrasadNo ratings yet

- Bolt Torque ChartDocument7 pagesBolt Torque ChartVìctor ChicaìzaNo ratings yet

- Programs OvershotsDocument18 pagesPrograms OvershotsDon BraithwaiteNo ratings yet

- Drill Pipe Spec SheetDocument2 pagesDrill Pipe Spec SheetVijay KotiNo ratings yet

- Bodytobonnet Torque Values For Fluorocarboncoated FastenersDocument8 pagesBodytobonnet Torque Values For Fluorocarboncoated FastenersJoão Mendonça SantosNo ratings yet

- Suggested Starting Torque Values: ASTM A307Document6 pagesSuggested Starting Torque Values: ASTM A307marioNo ratings yet

- Tabel Konversi Tekanan Angin, LoadDocument4 pagesTabel Konversi Tekanan Angin, Loadtaufiqhuda8No ratings yet

- Selection Guide - Mosfet ProductDocument6 pagesSelection Guide - Mosfet ProductlapiamaNo ratings yet

- Giddings & Lewis Zappendix ADocument9 pagesGiddings & Lewis Zappendix AAngel AdautaNo ratings yet

- CM20180409 17540 55148Document7 pagesCM20180409 17540 55148fathi226No ratings yet

- 9010 Seamless TubingDocument1 page9010 Seamless Tubingbingb39No ratings yet

- Drill Pipe Data BookDocument2 pagesDrill Pipe Data BookemadabdelsattarNo ratings yet

- Keppel Piping Hand BookDocument21 pagesKeppel Piping Hand BooktinzarmoeNo ratings yet

- Torque de Trepanos Smith (PDC - Tricono) PDFDocument1 pageTorque de Trepanos Smith (PDC - Tricono) PDFPither ZuritaNo ratings yet

- MOTOR SIZING OF BREAKER,CONTACTOR AND OVERLOADDocument2 pagesMOTOR SIZING OF BREAKER,CONTACTOR AND OVERLOADengr.mjadetabotaboNo ratings yet

- Portland Bolt Bolt Torque ChartDocument5 pagesPortland Bolt Bolt Torque ChartRamadanNo ratings yet

- Portland-Bolt-Bolt-Torque-Chart - A325 - A307 - A449 - A490 - A193 - A354Document5 pagesPortland-Bolt-Bolt-Torque-Chart - A325 - A307 - A449 - A490 - A193 - A354João Mendonça Santos100% (1)

- Portland Bolt Bolt Torque Chart For DTI'sDocument5 pagesPortland Bolt Bolt Torque Chart For DTI'sTaylor ButlerNo ratings yet

- Valvula Sismica Vertical Entrada Inferiori Bridada Mod VB319FDocument2 pagesValvula Sismica Vertical Entrada Inferiori Bridada Mod VB319FGrecia Paola Garza RodriguezNo ratings yet

- Tabla de ConsumosDocument10 pagesTabla de ConsumosJuan Jo RamirezNo ratings yet

- Balmoral RWH HH Direct ManualDocument2 pagesBalmoral RWH HH Direct ManualAlberto DiazNo ratings yet

- R410a Fixed Speed RotaryDocument2 pagesR410a Fixed Speed RotaryashokindeedNo ratings yet

- Aksa Master Pricelist 2014Document1 pageAksa Master Pricelist 2014Wissam JarmakNo ratings yet

- zpk5 Service Compressor Kits 17 18 en Us 5082464Document12 pageszpk5 Service Compressor Kits 17 18 en Us 5082464fjeroNo ratings yet

- Common Bolt Markings Torques Tech Bulletin AERA Melling Engine PartsDocument1 pageCommon Bolt Markings Torques Tech Bulletin AERA Melling Engine PartsNazar AlrodainyNo ratings yet

- UPN Profile DataDocument2 pagesUPN Profile DataManas80No ratings yet

- Axial Flow FansDocument3 pagesAxial Flow FansABCDNo ratings yet

- Bolt Torque SpecsDocument5 pagesBolt Torque SpecsSilvia ErazoNo ratings yet

- Cortland SlingsDocument12 pagesCortland SlingsafafaNo ratings yet

- Midea KFR26 GDocument40 pagesMidea KFR26 Gmr.aikidoNo ratings yet

- Ha Quad Assemblies OsDocument2 pagesHa Quad Assemblies OsjpriceNo ratings yet

- Butterfly Valve B7GDocument3 pagesButterfly Valve B7GJorgeCabreraCoronelNo ratings yet

- Tee PeDocument1 pageTee PeMishelle SolorzanoNo ratings yet

- LEADHOSE (1)Document4 pagesLEADHOSE (1)BurhanudinUrcNo ratings yet

- Reliable Performance All Year RoundDocument4 pagesReliable Performance All Year RounddavidNo ratings yet

- Padeye Design: Allseas LogoDocument12 pagesPadeye Design: Allseas LogoHemam PrasantaNo ratings yet

- VP3401 As04Document2 pagesVP3401 As04shivamtyagi68637No ratings yet

- Chroma Bidirectional DC Power Supply Model 62000D SeriesDocument12 pagesChroma Bidirectional DC Power Supply Model 62000D SeriesaboofazilNo ratings yet

- Approach To Floppy InfantDocument44 pagesApproach To Floppy InfantNavya Hegde100% (2)

- Drug Dosage and IV Rates Calculations PDFDocument6 pagesDrug Dosage and IV Rates Calculations PDFvarmaNo ratings yet

- Application of Buoyancy-Power Generator For Compressed Air Energy Storage Using A Fluid-Air Displacement System - ScienceDirectDocument7 pagesApplication of Buoyancy-Power Generator For Compressed Air Energy Storage Using A Fluid-Air Displacement System - ScienceDirectJoel Stanley TylerNo ratings yet

- Kohlberg's Stages of Moral DevelopmentDocument14 pagesKohlberg's Stages of Moral DevelopmentMarvelyn De StoTomas IgnacioNo ratings yet

- MC&OB Unit 4Document17 pagesMC&OB Unit 4Tanya MalviyaNo ratings yet

- HUAWEI - SUN2000-20-40KTL-M3-UserManual GCADocument102 pagesHUAWEI - SUN2000-20-40KTL-M3-UserManual GCAReardon MetalsNo ratings yet

- DAPA Teams Spider DiagramDocument2 pagesDAPA Teams Spider DiagramEduardoJaimeNo ratings yet

- Miller PreviewDocument252 pagesMiller PreviewcqpresscustomNo ratings yet

- Academic Journal Guide 2021-MethodologyDocument22 pagesAcademic Journal Guide 2021-MethodologySyedNo ratings yet

- Occupational Safety and Health Aspects of Voice and Speech ProfessionsDocument34 pagesOccupational Safety and Health Aspects of Voice and Speech ProfessionskaaanyuNo ratings yet

- HVLDocument44 pagesHVLlogofwood6858100% (2)

- Relatorio Mano JulioDocument7 pagesRelatorio Mano JulioProGeo Projetos AmbientaisNo ratings yet

- Lec 1 Introduction Slides 1 20 MergedDocument153 pagesLec 1 Introduction Slides 1 20 MergedNeeraj VarmaNo ratings yet

- Tle 7-1st Periodic TestDocument2 pagesTle 7-1st Periodic TestReymart TumanguilNo ratings yet

- Digital Banking A Case Study of India: Solid State Technology December 2020Document10 pagesDigital Banking A Case Study of India: Solid State Technology December 2020Mohit PacharNo ratings yet

- Software Engineering. Specification, Implementation, VerificationDocument186 pagesSoftware Engineering. Specification, Implementation, Verificationazariel.rodrigo100% (1)

- Beira International School: End of Year ExaminationDocument7 pagesBeira International School: End of Year ExaminationnothandoNo ratings yet

- Tuyển Sinh 10 - đề 1 -KeyDocument5 pagesTuyển Sinh 10 - đề 1 -Keynguyenhoang17042004No ratings yet

- 3M CorporationDocument3 pages3M CorporationIndoxfeeds GramNo ratings yet

- Yamabe Flow On Nilpotent Lie GroupsDocument20 pagesYamabe Flow On Nilpotent Lie GroupsEnzo RicNo ratings yet

- StatementOfAccount 6316692309 21072023 222045Document17 pagesStatementOfAccount 6316692309 21072023 222045Asekar AlagarsamyNo ratings yet

- A 182Document20 pagesA 182Thomas100% (1)

- Ovarian Cancer ThesisDocument8 pagesOvarian Cancer ThesisDon Dooley100% (1)

- Company Profile For ICB TechnimontDocument4 pagesCompany Profile For ICB TechnimontShankarMukherjeeNo ratings yet