Professional Documents

Culture Documents

t345 Engine Update

t345 Engine Update

Uploaded by

arif adi saputra0 ratings0% found this document useful (0 votes)

21 views1 pageThis report details the results of an oil analysis test conducted on a Volvo articulated haul truck. The report includes wear metal concentrations, oil quality parameters, contaminant levels, and a graph of element trends over time. Elevated levels of iron, aluminum, silicon, and oxidation were found, indicating abnormal wear of engine components like the liner, timing gear, and valves. The report recommends checking the oil level, for leaks, the filter, and inspecting components like the rocker arms. Overall the oil quality is below ISO standards and the machine may need maintenance to address the abnormal wear found in the analysis.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis report details the results of an oil analysis test conducted on a Volvo articulated haul truck. The report includes wear metal concentrations, oil quality parameters, contaminant levels, and a graph of element trends over time. Elevated levels of iron, aluminum, silicon, and oxidation were found, indicating abnormal wear of engine components like the liner, timing gear, and valves. The report recommends checking the oil level, for leaks, the filter, and inspecting components like the rocker arms. Overall the oil quality is below ISO standards and the machine may need maintenance to address the abnormal wear found in the analysis.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

21 views1 paget345 Engine Update

t345 Engine Update

Uploaded by

arif adi saputraThis report details the results of an oil analysis test conducted on a Volvo articulated haul truck. The report includes wear metal concentrations, oil quality parameters, contaminant levels, and a graph of element trends over time. Elevated levels of iron, aluminum, silicon, and oxidation were found, indicating abnormal wear of engine components like the liner, timing gear, and valves. The report recommends checking the oil level, for leaks, the filter, and inspecting components like the rocker arms. Overall the oil quality is below ISO standards and the machine may need maintenance to address the abnormal wear found in the analysis.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

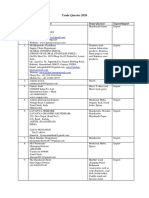

PT.

Tekenomiks Indonesia

Office : MEWS M8 Komplek PT KPC- SANGATTA - Kalimantan Timur

75611 Indonesia PROBLEM

TECHNICAL ADVANCE FOR ECONOMIC GAIN

Wear Metal Report: 00819816

Client: PT. KPC

Attention: -

Address KUTIM KUTIM 7561 KALIMANTAN TIMUR

Machine: VOLVO-ARTICULATED A35E ID No: T345

Oil Name: VOLVO ENGINE OIL VDS-3 15W40

Visc@40°C: 109 Visc@100°C: 14.5 TBN: 10.2

Compartm't: ENGINE S/N: -

Sample Date: 14/03/2023 19/04/2023 04/08/2023 29/08/2023 09/10/2023 23/10/2023

Received Date 15/03/2023 20/04/2023 05/08/2023 30/08/2023 10/10/2023 24/10/2023

Analysis Date: 15/03/2023 20/04/2023 05/08/2023 30/08/2023 10/10/2023 24/10/2023

Reported Date 15/03/2023 20/04/2023 05/08/2023 30/08/2023 10/10/2023 24/10/2023

Sample no: 00791067 00795808 00809471 00812627 00818005 00819816

SMU:(hrs) 52463 52869 53841 54203 54872 55108

Oil Hrs: 372 778 1750 2112 2781 3017

Oil Changed: No No No No No No

Component Hours - - - - - -

Wear Metal Rate 0.20 0.05 0.06 0.04 0.05 0.03

Wear Metals METHOD RESULT Caut High Comments on elevated results

lead (Pb)(mg/kg) ASTM D5185 2.5 1.5 6.2 2.1 1.6 1.7 12 20 Meningkat wear Fe Al Si dan oxidation di

atas batas normal. Kemungkinan abnormal

iron (Fe)(mg/kg) ASTM D5185 53.2 24.9 53.2 53.5 91.4 65.2 60 100 dari liner timing gear valve train main

aluminium (Al)(mg/kg) ASTM D5185 11.6 7.1 11.2 11.8 20.3 18.8 6 10 bearing rod bearing rocker arm bracket dan

copper (Cu)(mg/kg) ASTM D5185 4.1 1.2 21.8 7.0 5.7 4.1 9 15 debu/kotoran. Mohon di check oil level

check kondisi oil check kebocoran oil check

chromium (Cr)(mg/kg) ASTM D5185 0.9 0.6 3.6 3.2 5.6 4.9 6 10 filter cut check noise inspeski rocker arm

tin (Sn)(mg/kg) ASTM D5185 0.9 0.3 4.2 1.7 1.3 1.2 6 10 check mechanisme valve dan check oil

nickel (Ni)(mg/kg) ASTM D5185

press system. Visco 40c @27% dan 100c

0.9 0.4 2.3 1.7 2.0 1.8 6 10

@18% di bawah standar iso code. teo-

Contaminants sangattalab

silicon (Si)(mg/kg) ASTM D5185 25.5 10.1 45.4 31.5 53.8 52.6 12 20

sodium (Na)(mg/kg) ASTM D5185 6.8 3.5 13.7 4.8 4.0 2.6 11 28

Oil Additives

magnesium (Mg)(mg/kg) ASTM D5185 14 100 13 14 12 13 0 0

zinc (Zn)(mg/kg) ASTM D5185 1002 947 872 1339 774 895 0 0

molybdenum (Mo)(mg/kg) ASTM D5185 44 47 40 47 34 39 0 0

calcium (Ca)(mg/kg) ASTM D5185 3388 3674 3124 3815 3100 3994 0 0

phosphorous (P)(mg/kg) ASTM D5185 1023 1024 891 1152 854 956 0 0 Approved by : Erna ( Manager Area )

boron (B)(mg/kg) ASTM D5185 274 323 252 344 260 341 0 0

Infra Red

TBN(mgKOH/g) ASTM D4739 8.10 8.21 6.48 6.97 6.30 6.96 -25% -50%

TAN(mgKOH/g) ASTM D974 n/a n/a n/a n/a n/a n/a 0 0

soot(Abs/cm) ASTM E2412 16 18 29 24 44 11 35 70

glycol(% vol) ASTM E2412 0 0 0 0 0 0 18 30

oxidation((x.100)abs/0.1mm) ASTM E2412 13 14 89 62 106 65 60 100

nitration((x.100)abs/0.1mm) ASTM E2412 5 6 4 3 7 5 60 100

sulphation((x.100)abs/0.1mm) ASTM E2412 9 11 19 14 25 11 60 100

Physical Tests Particle Cleanliness Analysis

water(ppm) ASTM D6304 0.0 0.0 0.0 0.0 0.0 0.0 0 0 ISO 4406 - 04 | -

fuel dilution(% vol) ASTM D3828 0.00 0.00 1.00 0.00 1.00 0.00 1 2 ISO 4406 - 06 | -

water(%) ASTM E2412 0.11 0.12 0.12 0.12 0.12 0.13 0.15 0.2 ISO 4406 - 14 | -

F.debris() Midas 21 7 10 11 9 10 16 26 Count 1ml | -

visc @ 100oC(mm2/s) ASTM D445 12.98 13.15 10.54 11.53 10.72 11.94 +-10 +-30

visc @ 40oC(mm2/s) ASTM D445 94.84 96.50 70.38 77.32 67.21 79.43 +-10 +-30

Iso Code (Part/mL)() ISO 4406 -/-/- -/-/- -/-/- -/-/- -/-/- -/-/- 0 0

Element Trends Graph

For enquiries,Tekenomiks Sangata, email : labsgt@techenomics.com, mobile/wa : 08115817837

This wear analysis and oil condition report should be used in conjunction with normal maintenance and evaluated from sample to sample. Every care will be taken in processing samples but no express or implied guarantee is furnished in

regard to the continuing operation or condition of this machinery or any part thereof.

The Result of Analysis is only related to the sample analyzed.

You might also like

- FS Kakanin Feasibility Study Ana Adona 2018Document112 pagesFS Kakanin Feasibility Study Ana Adona 2018Dang Bi100% (4)

- Agriculture Statistics Balochistan 2019 20Document220 pagesAgriculture Statistics Balochistan 2019 20Muhamamd Zahid Ullah Khan50% (2)

- DT1342 EngineDocument1 pageDT1342 EnginedayatNo ratings yet

- Oil Sample S315Document1 pageOil Sample S315yudhaperkasa92No ratings yet

- Batch 124232 Pt. Kerta Bumi Teknindo - PLTD TinaboganDocument5 pagesBatch 124232 Pt. Kerta Bumi Teknindo - PLTD Tinaboganamin ghozaliNo ratings yet

- HDTL 025Document1 pageHDTL 025Angga 99No ratings yet

- DT2872 Final Drive Center RHDocument1 pageDT2872 Final Drive Center RHdayatNo ratings yet

- Pap S315 11may21Document1 pagePap S315 11may21yudhaperkasa92No ratings yet

- DT2407 DifferentialDocument1 pageDT2407 DifferentialdayatNo ratings yet

- HGR3098 Engine 23augDocument1 pageHGR3098 Engine 23augIndo BemlNo ratings yet

- Pdf24 MergedDocument9 pagesPdf24 MergedauliaadyaksaNo ratings yet

- PT Petrolab Services: Test DetailDocument1 pagePT Petrolab Services: Test DetailDiat NorNo ratings yet

- PC390LC-8M0 AnalisisDocument30 pagesPC390LC-8M0 AnalisisBecker Johang Dominguez LindoNo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsAlex gonNo ratings yet

- TM GDR-413Document2 pagesTM GDR-413Ahmat RamadaniNo ratings yet

- HGR3100 Engine 23augDocument1 pageHGR3100 Engine 23augIndo BemlNo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsAlex gonNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesDocument10 pagesWelding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesAhmad KamilNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesDocument10 pagesWelding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement Consumableskeymal9195No ratings yet

- PT. Tekenomiks IndonesiaDocument4 pagesPT. Tekenomiks IndonesiaAhmat RamadaniNo ratings yet

- GM 10 20072020Document2 pagesGM 10 20072020Enrique CallesNo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsAlex gonNo ratings yet

- WCC.10002MG (Tanjung Bin)Document10 pagesWCC.10002MG (Tanjung Bin)keymal9195No ratings yet

- Adt-03 Engine 1001 Ob2000450Document1 pageAdt-03 Engine 1001 Ob2000450abdul rahmatNo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsAlex gonNo ratings yet

- Mycom #1Document1 pageMycom #1Rifky Windya NNo ratings yet

- Test Certificate: (, Phone: 26751763 MillDocument1 pageTest Certificate: (, Phone: 26751763 MillQc QatarNo ratings yet

- Preliminary 00122.00023 Pt. Semesta Alam BaritoDocument2 pagesPreliminary 00122.00023 Pt. Semesta Alam BaritoBayu Araruna NangasNo ratings yet

- DTHW 005Document1 pageDTHW 005Angga 99No ratings yet

- Welding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesDocument10 pagesWelding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesAhmad KamilNo ratings yet

- Engine Experiment FormatDocument1 pageEngine Experiment FormatMD Ashfakul Karim KausikNo ratings yet

- George Taylor & Co Lifting Gear (Midlands) LTD: Grade 8 Clevis Shortening ClutchesDocument1 pageGeorge Taylor & Co Lifting Gear (Midlands) LTD: Grade 8 Clevis Shortening ClutchesEduardo SolanoNo ratings yet

- Cement Mill Test - Fairborn Cement Company Type-IA - Jan2022Document2 pagesCement Mill Test - Fairborn Cement Company Type-IA - Jan2022mohamed ElsayedNo ratings yet

- API Test Data For Distribution 1 1Document6 pagesAPI Test Data For Distribution 1 1Avyan KelanNo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsAhmad HisyamNo ratings yet

- RD 215 - Engine - 3110 - Ob2226661 - NDocument1 pageRD 215 - Engine - 3110 - Ob2226661 - Nopen hartigNo ratings yet

- Pt. Riodi Jaya Medan Oj02944 Uo 24 QRDocument1 pagePt. Riodi Jaya Medan Oj02944 Uo 24 QRdotaaja222No ratings yet

- Welding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement ConsumablesDocument8 pagesWelding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement Consumableskeymal9195No ratings yet

- Sterntube - Man. AstaDocument1 pageSterntube - Man. AstacahyoNo ratings yet

- 3-Cement Test ReportDocument2 pages3-Cement Test ReportAhsan Farid100% (1)

- E10018d2-Eng LINCOLNDocument1 pageE10018d2-Eng LINCOLNBenfil ViernezNo ratings yet

- Oil Analysis Report: PT Petrolab ServicesDocument1 pageOil Analysis Report: PT Petrolab ServicesJon HermanNo ratings yet

- Optigear 1100 RangeDocument3 pagesOptigear 1100 RangeResistenciaDisidenteNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement ConsumablesDocument10 pagesWelding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement Consumableskeymal9195No ratings yet

- Sub-Base Material Tests, June. 2019Document2 pagesSub-Base Material Tests, June. 2019mulNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesDocument10 pagesWelding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesAhmad KamilNo ratings yet

- LSK-0278-15 Prov. MNS-002-15 42Document1 pageLSK-0278-15 Prov. MNS-002-15 42Muhammad Hasan Anees Muhammad AneesNo ratings yet

- CLC 17-13-5LN: A 317LN Modified Mo 4% Austenitic Stainless Steel (317LNM)Document4 pagesCLC 17-13-5LN: A 317LN Modified Mo 4% Austenitic Stainless Steel (317LNM)PeterWayNo ratings yet

- Dewpoint Copper DPC-0521-DDocument4 pagesDewpoint Copper DPC-0521-DTengku MunzirNo ratings yet

- Techalloy 625: Conformances Key FeaturesDocument2 pagesTechalloy 625: Conformances Key FeaturesJulian AdaraqueNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesDocument10 pagesWelding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement Consumableskeymal9195No ratings yet

- DZ1610Document1 pageDZ1610Dany LeaNo ratings yet

- Oil Analysis Report: Test DetailsDocument1 pageOil Analysis Report: Test DetailsAlex gonNo ratings yet

- NKL-967 (0126 - Hpu-Mca) - Hydraulic - 2111 - Ob2324031 - BDocument2 pagesNKL-967 (0126 - Hpu-Mca) - Hydraulic - 2111 - Ob2324031 - BMUHAMMAD LUTHFINo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesDocument10 pagesWelding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement Consumableskeymal9195No ratings yet

- Lincoln, TECHALLOY® 606 (c14107)Document2 pagesLincoln, TECHALLOY® 606 (c14107)RodrigoNo ratings yet

- SKL-1155 (0132 - Hpu-Mca) - Hydraulic - 2111 - Ob2324030 - BDocument2 pagesSKL-1155 (0132 - Hpu-Mca) - Hydraulic - 2111 - Ob2324030 - BMUHAMMAD LUTHFINo ratings yet

- Batch 127232 Hexindo BalikpapanDocument2 pagesBatch 127232 Hexindo BalikpapanlilikNo ratings yet

- BF20112602 English MTC PDFDocument2 pagesBF20112602 English MTC PDFSvetlana VujovićNo ratings yet

- 120210lub - El350 Sae 40Document1 page120210lub - El350 Sae 40JorgeLuisRodriguezAguilarNo ratings yet

- DiagnosisDocument3 pagesDiagnosispalashNo ratings yet

- Vitamin-A Prophylaxis Programme 0rDocument38 pagesVitamin-A Prophylaxis Programme 0rShubhendu ChattopadhyayNo ratings yet

- General PediatricsDocument21 pagesGeneral PediatricsShanmugam Balasubramaniam100% (2)

- Trade Queries 2020: S No. Company Particular Items Queried Export/ImportDocument16 pagesTrade Queries 2020: S No. Company Particular Items Queried Export/ImportINFO CEMARKINGNo ratings yet

- Nodel Demand Calculation of Zone 01 (Diet College Elsr) : 0.0017 3.0 (As Per CPHEEO Manual Population Below 50000)Document6 pagesNodel Demand Calculation of Zone 01 (Diet College Elsr) : 0.0017 3.0 (As Per CPHEEO Manual Population Below 50000)rajsedasariNo ratings yet

- Coastal Assignment EDITED 4Document24 pagesCoastal Assignment EDITED 4mohamadfaiz0% (1)

- Lesson1. TriangulationDocument21 pagesLesson1. TriangulationTristania Leighan DeypuyartNo ratings yet

- Hazard ManagementDocument18 pagesHazard Managementsthiyagu0% (1)

- Ilovepdf MergedDocument95 pagesIlovepdf MergedYoussef El bahiNo ratings yet

- Veronica Without ArmsDocument2 pagesVeronica Without Armsfat26No ratings yet

- Michael's On East Lunch MenuDocument2 pagesMichael's On East Lunch Menusupport_local_flavorNo ratings yet

- Continental CarrierDocument10 pagesContinental CarrierYetunde James100% (1)

- IPCO IP Release-Agent-spraying-system ProSpray 03 2020 v1.0 LO-RESDocument2 pagesIPCO IP Release-Agent-spraying-system ProSpray 03 2020 v1.0 LO-RESborodichNo ratings yet

- DBQ EcologyDocument11 pagesDBQ Ecologydafer krishiNo ratings yet

- Humms 11 Pasay Diass s2 q1 w2Document20 pagesHumms 11 Pasay Diass s2 q1 w2Victoria De Los SantosNo ratings yet

- Menu Template - 02Document5 pagesMenu Template - 02Prashanna SapkotaNo ratings yet

- Soal UNBK Bahasa Inggris SMPDocument13 pagesSoal UNBK Bahasa Inggris SMPfendiwaloyosugiartoNo ratings yet

- Antibiotic Resistance in Pseudomonas Aeruginosa - MechanismsDocument22 pagesAntibiotic Resistance in Pseudomonas Aeruginosa - MechanismsValentina RondonNo ratings yet

- D5462 PDFDocument6 pagesD5462 PDFZamir Danilo Morera ForeroNo ratings yet

- NABL Certificate & NABL ScopeDocument10 pagesNABL Certificate & NABL ScopeAruneshNo ratings yet

- GRE CatelogueDocument16 pagesGRE CatelogueRam Shankar PrasadNo ratings yet

- Ids-3319 DS (010220)Document2 pagesIds-3319 DS (010220)Arif MahmudiNo ratings yet

- SF20 - OKL04 Risk Assessment WeldingDocument2 pagesSF20 - OKL04 Risk Assessment WeldingMike BoyesNo ratings yet

- BiologyDocument23 pagesBiologyDevendra AryaNo ratings yet

- Pemerintah Kabupaten Klungkung Dinas Kesehatan: Jalan Gajah Mada No. 55 Semarapura Telp. (0366) 21150Document4 pagesPemerintah Kabupaten Klungkung Dinas Kesehatan: Jalan Gajah Mada No. 55 Semarapura Telp. (0366) 21150anggaNo ratings yet

- The Utility of COMPASS 31 Questionnaire To Predict.98958Document5 pagesThe Utility of COMPASS 31 Questionnaire To Predict.98958TEOFILO PALSIMON JR.No ratings yet

- Analytical Research PapersDocument4 pagesAnalytical Research PapersabimubNo ratings yet

- Home Care CompetencyDocument54 pagesHome Care Competencyapi-3002188600% (1)

- File Download AjaDocument3 pagesFile Download AjaIdaNurNo ratings yet