Professional Documents

Culture Documents

0208 79 Aa00

0208 79 Aa00

Uploaded by

rezaross0 ratings0% found this document useful (0 votes)

7 views1 pageThis document provides specifications for a plate heat exchanger with one parallel unit and one series unit. It will be used as an evaporator with ethylene glycol on the gasketed side and ammonia on the welded side, exchanging a total of 1435 kW of heat. Key specifications include flow rates of 136,900 kg/h and 3,960 kg/h, operating temperatures of 0-10°C and -15°C, and design pressures of 7.5 bar and 7.5 bar. The unit has a planned number of plates of SS316L material with an EPDM gasket.

Original Description:

Original Title

0208-79-AA00

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides specifications for a plate heat exchanger with one parallel unit and one series unit. It will be used as an evaporator with ethylene glycol on the gasketed side and ammonia on the welded side, exchanging a total of 1435 kW of heat. Key specifications include flow rates of 136,900 kg/h and 3,960 kg/h, operating temperatures of 0-10°C and -15°C, and design pressures of 7.5 bar and 7.5 bar. The unit has a planned number of plates of SS316L material with an EPDM gasket.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

7 views1 page0208 79 Aa00

0208 79 Aa00

Uploaded by

rezarossThis document provides specifications for a plate heat exchanger with one parallel unit and one series unit. It will be used as an evaporator with ethylene glycol on the gasketed side and ammonia on the welded side, exchanging a total of 1435 kW of heat. Key specifications include flow rates of 136,900 kg/h and 3,960 kg/h, operating temperatures of 0-10°C and -15°C, and design pressures of 7.5 bar and 7.5 bar. The unit has a planned number of plates of SS316L material with an EPDM gasket.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

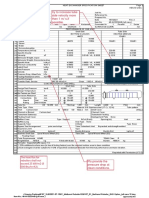

PLATE HEAT EXCHANGER

DATA SHEET Engineering Contractor

PROCESS

PO No.: DOC NO: 0208-79-AA00 PAGE 1 OF 1

Customer: Manufacturer: TAHA GHALEB TOOS

Project: Order / eng. No.: Proposal

Location: Model: HNW151-H

Item no: Serial No:

Service: Evaporator Unit No.: 1

CASE GASKETED SIDE WELDED SIDE

1 Fluid Ethylene Glycol 25% Ammonia

2 Total flow (kg/h) 136900 (38 kg/s) 3960 (1.1 kg/s)

3 Flow per PHE (kg/h) 136900 3960

4 Design Temperature (°C) 70 70

5 Minimum design metal temp. (°C) -29 -29

6 Design Pressure [bar (ga)] 7.5 7.5

7 Pressure drop allow / calc (bar) - / 0.49 - / 0.20

OPERATION DATA INLET OUTLET INLET OUTLET

8 Liquid flow (kg/h) 136900 136900 3960

9 Vapor flow (kg/h) 3960

10 Non condensable flow (kg/h)

11 Operating temperature (°C) 0.0 -10.0 -15.0 -15.0

12 Operating pressure [bar (ga)] 3 1.4

FLUID PROPERTIES

13 Density (kg/m³) 1043.0 1046.0 655.4 1.768

14 Specific heat (kJ/(kg*K)) 3.78 3.766 4.529 2.455

15 Viscosity (cP) 3.60 5.296 0.20 0.0087

16 Thermal conductivity (W/(m*K)) 0.49 0.488 0.548 0.02

17 Total heat exchanged (kW) 1435.0

18 U (W/(m²*K)) 1461.8

19 LMTD (K) 9.2

CONFIGURATION FOR EXCHENGER AND PLATE DETAILS

21 Number of PHE in parallel 1

22 Number of PHE in series 1

23 Number of passes, hot side 1

24 Number of passes, cold side 1

25 Rel. Directions of fluids countercurrent Plate chevron angle(s) H

26 Nominal plate gap (mm) Nominal plate thickness 0.60 mm

HOT SIDE COLD SIDE

27 Test pressure [bar (ga)] 10 10

28 Length/width/height (mm)

29 Mass empty/full of water (kg)

CONNECTIONS IN OUT IN OUT

30 Nozzle size (Nominal) 6" 6" 6" 6"

31 Flange rating / type 150# / R.F 150# / R.F 150# / R.F 150# / R.F

COMPONENT MATERIALS

32 PHE type Gasketed ( ) Semi–Welded ( ● ) Welded ( )

33 Plates SS316L

34 PHE gasket fixing Glued ( ) Not glued ( ● )

35 PHE gaskets hot side / cold side EPDM

36 Connection design Threaded ( ) Studded ( ● ) Flanged Nozzle ( )

Rev. NO.03 Revision Date: 1402/08/09 Prepared By: H.Shamsabadi Reviewed By: M. Sadat

. مبدل فقط براي مشخصات باال به درستي عمل خواهد كرد. را به دقت مطالعه و تاييد كنيد و با شرايط واقعي موجود خود مطابقت دهيدData Sheet اطالعات اين:توجه

.در صورت نوساني بودن فشار و يا سيکلي بودن فرايند با كارشناس طراحي مبدل هماهنگ شود -

You might also like

- ZamZam Water by Dr. EmotoDocument3 pagesZamZam Water by Dr. Emotohadjeas83% (6)

- Heat Exchanger Specification SheetDocument2 pagesHeat Exchanger Specification Sheettatiana alvarezNo ratings yet

- 240-05-DTS-010 V-400 Regenaration Gas SeperatorDocument20 pages240-05-DTS-010 V-400 Regenaration Gas SeperatorEmran NazirNo ratings yet

- 240-05-DTS-009 V-501 Air ReceiverDocument20 pages240-05-DTS-009 V-501 Air ReceiverEmran NazirNo ratings yet

- T4638 DatasheetDocument12 pagesT4638 DatasheetMUHAMMAD ABHAR AMZAR BIN ZAMZURINo ratings yet

- Heat Exchanger Specification SheetDocument2 pagesHeat Exchanger Specification Sheettatiana alvarezNo ratings yet

- Heat Exchanger Sizing E-3010A #1Document2 pagesHeat Exchanger Sizing E-3010A #1Luis Enrique Leyva Ovalle100% (1)

- 2400-05-DTS-005cooling TowerDocument19 pages2400-05-DTS-005cooling TowerEmran NazirNo ratings yet

- 240-05-DTS-XXX Flare StackDocument18 pages240-05-DTS-XXX Flare StackEmran NazirNo ratings yet

- 240-05-DTS-000 Fire Water PumpDocument19 pages240-05-DTS-000 Fire Water PumpEmran NazirNo ratings yet

- Data Sheet Gas Scrubber 42 InchDocument32 pagesData Sheet Gas Scrubber 42 InchWijayantoNo ratings yet

- Heat Exchanger Sizing E-5000 #1Document2 pagesHeat Exchanger Sizing E-5000 #1Luis Enrique Leyva OvalleNo ratings yet

- SE230701184 - Heater & Panel DatasheetsDocument18 pagesSE230701184 - Heater & Panel DatasheetsVivek SavaliyaNo ratings yet

- Ea 101Document2 pagesEa 101Najmul SaqibNo ratings yet

- Output - ITEM NO. 113486 - 24 Inch at 10000 KGHRDocument1 pageOutput - ITEM NO. 113486 - 24 Inch at 10000 KGHRyadav yadavNo ratings yet

- SQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21-CmtdDocument4 pagesSQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21-CmtdSRINo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V11Document1 pageAspen Exchanger Design and Rating Shell & Tube V11Ginna RodriguezNo ratings yet

- CrudoDocument2 pagesCrudoAndrés Felipe TáutivaNo ratings yet

- Ea 102Document2 pagesEa 102Najmul SaqibNo ratings yet

- TEMA Sheet CorregidoDocument1 pageTEMA Sheet Corregidosaragineth.saNo ratings yet

- ShellTubeHE Hot PT Konigs E-202 ColdDocument1 pageShellTubeHE Hot PT Konigs E-202 Coldeka prasetiaNo ratings yet

- CH-RA3 Page 1Document1 pageCH-RA3 Page 1Sonya LoveraNo ratings yet

- DJM MBA PCS CA 007 Deethanizer Reboiler E 1401 Rev BDocument37 pagesDJM MBA PCS CA 007 Deethanizer Reboiler E 1401 Rev BDIANTORONo ratings yet

- L-R Intercambiador Coraza y Tubos PDFDocument1 pageL-R Intercambiador Coraza y Tubos PDFAlejandro OsorioNo ratings yet

- Output - ITEM NO. 106773 - 20 Inch at 10000 KG Per HRDocument1 pageOutput - ITEM NO. 106773 - 20 Inch at 10000 KG Per HRyadav yadavNo ratings yet

- SQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21Document4 pagesSQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21SRINo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: File: E-501-A - 1.edr Printed: 22/03/2019 at 05:07:09 A. M. TEMA SheetDocument2 pagesAspen Exchanger Design and Rating Shell & Tube V10: File: E-501-A - 1.edr Printed: 22/03/2019 at 05:07:09 A. M. TEMA SheetLandaNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V11Document1 pageAspen Exchanger Design and Rating Shell & Tube V11Luis NewballNo ratings yet

- Heat Exchanger Sizing E-7010 #1Document2 pagesHeat Exchanger Sizing E-7010 #1Luis Enrique Leyva OvalleNo ratings yet

- 100-Mc-417-Ra3-Hx-Ra3 - HDC Condensador Reactor PDFDocument2 pages100-Mc-417-Ra3-Hx-Ra3 - HDC Condensador Reactor PDFSonya LoveraNo ratings yet

- Intercambiador de Calor: Heat Exchanger Data SheetDocument6 pagesIntercambiador de Calor: Heat Exchanger Data SheetBRENDA VIVIANA ARANDA JURADONo ratings yet

- SQ8167 - 02 - Column Feed Bottoms Exchanger Process DS Rev B (Alt Case 10 Deg Approach) - HTRI 6th Aug 21Document3 pagesSQ8167 - 02 - Column Feed Bottoms Exchanger Process DS Rev B (Alt Case 10 Deg Approach) - HTRI 6th Aug 21SRINo ratings yet

- Precision Equipments (Chennai) Pvt. LTD.: Design Data Tema TypeDocument2 pagesPrecision Equipments (Chennai) Pvt. LTD.: Design Data Tema TypeAnonymous AyDvqgNo ratings yet

- Output PDFDocument1 pageOutput PDFAlex AgualemaNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: File: B1 - 26.edr Printed: 7/1/2019 at 11:00:15 PMDocument1 pageAspen Exchanger Design and Rating Shell & Tube V10: File: B1 - 26.edr Printed: 7/1/2019 at 11:00:15 PMAlex AgualemaNo ratings yet

- Mtu Engine Model12V4000G63 A. LT CIRCUIT (260 KW at 29 M /HR) Heat Exchanger: Gl-13Lx24 Duty RequirementsDocument4 pagesMtu Engine Model12V4000G63 A. LT CIRCUIT (260 KW at 29 M /HR) Heat Exchanger: Gl-13Lx24 Duty RequirementsbaljeetjatNo ratings yet

- Exchanger Tube Min ThicknessDocument2 pagesExchanger Tube Min ThicknessMohamed ElshehnyNo ratings yet

- TEMA Sheed L-R ExchangerDocument1 pageTEMA Sheed L-R ExchangerAlejandra BuenoNo ratings yet

- Steam HXDocument1 pageSteam HXrajachemNo ratings yet

- Mtu Engine Model 12V4000G23 A. LT CIRCUIT (200 KW at 29 M /HR) Heat Exchanger: Gl-13Lx22 Duty RequirementsDocument4 pagesMtu Engine Model 12V4000G23 A. LT CIRCUIT (200 KW at 29 M /HR) Heat Exchanger: Gl-13Lx22 Duty RequirementsbaljeetjatNo ratings yet

- 80 KW Water-Cooler ratavljiviDS (6364)Document1 page80 KW Water-Cooler ratavljiviDS (6364)Jelena VuleticNo ratings yet

- API Heat Exchanger Spec RequiremenDocument11 pagesAPI Heat Exchanger Spec RequiremenElias EliasNo ratings yet

- Mtu Engine Model 20V4000G63L A. LT CIRCUIT (410 KW@ 30 M /HR) Heat Exchanger: Gl-13Lx36 Duty RequirementsDocument4 pagesMtu Engine Model 20V4000G63L A. LT CIRCUIT (410 KW@ 30 M /HR) Heat Exchanger: Gl-13Lx36 Duty RequirementsbaljeetjatNo ratings yet

- Htri 105 PDFDocument1 pageHtri 105 PDFhirenpatel_62No ratings yet

- 100-Mc-417-Ra3-Hx-Ra3 - HDB Condensador ReactorDocument1 page100-Mc-417-Ra3-Hx-Ra3 - HDB Condensador ReactorSonya LoveraNo ratings yet

- AQ10T-BFM, 363PL 2335kWDocument2 pagesAQ10T-BFM, 363PL 2335kWLiviu ConstantinNo ratings yet

- Heat Exchanger Rev - 02Document1 pageHeat Exchanger Rev - 02TKT ConsultantNo ratings yet

- Техническая спецификация S21-IG10-33-TK-SteamDocument1 pageТехническая спецификация S21-IG10-33-TK-SteamArtur AsaturyanNo ratings yet

- LUBRIZOL 2320 - 0.75 sch40 PDFDocument4 pagesLUBRIZOL 2320 - 0.75 sch40 PDFNILTON BERNALNo ratings yet

- OLOA 55531 - 0.75 sch40Document4 pagesOLOA 55531 - 0.75 sch40NILTON BERNALNo ratings yet

- Tema SheetDocument1 pageTema SheetMayank AgrawalNo ratings yet

- MSS SP 58Document1 pageMSS SP 58octa aldyNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 1/31/2023 at 3:41:24 PM TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 1/31/2023 at 3:41:24 PM TEMA Sheetvaratharajan g rNo ratings yet

- Gas-Gas Exchanger DatasheetDocument3 pagesGas-Gas Exchanger DatasheetidilfitriNo ratings yet

- Reactor Data Sheet: Sketch (Bundle / Nozzle Orientation) GeneralDocument1 pageReactor Data Sheet: Sketch (Bundle / Nozzle Orientation) GeneralAndrés SepúlvedaNo ratings yet

- 8670 HAP3135 - HDS - REV 1 (250NB #2500 U Stamp)Document3 pages8670 HAP3135 - HDS - REV 1 (250NB #2500 U Stamp)SonNguyenNo ratings yet

- $TEMA Sheet Gas Chiller Rev 2Document1 page$TEMA Sheet Gas Chiller Rev 2HudaFiHayyatNo ratings yet

- Shell&TubeResults 215E009Document5 pagesShell&TubeResults 215E009ganis supriadiNo ratings yet

- By Todd Harvey at 10:31 Am, Sep 30, 2013: API 661 Air-Cooled Heat Exchanger - Specification SheetDocument12 pagesBy Todd Harvey at 10:31 Am, Sep 30, 2013: API 661 Air-Cooled Heat Exchanger - Specification SheetPackage RotaryNo ratings yet

- 172 Primary SludgeDocument1 page172 Primary SludgerezarossNo ratings yet

- UWDocument1 pageUWrezarossNo ratings yet

- مقایسه مبدل های قدیم و جدیدDocument10 pagesمقایسه مبدل های قدیم و جدیدrezarossNo ratings yet

- 1-s2.0-S0149197016300816-Mingjun Wang Ammonia-Water Mixture 2016Document23 pages1-s2.0-S0149197016300816-Mingjun Wang Ammonia-Water Mixture 2016rezarossNo ratings yet

- 090 Performance CurveDocument1 page090 Performance CurverezarossNo ratings yet

- Coek - Info - Determination of The Ejector Dimensions of A Bus ADocument10 pagesCoek - Info - Determination of The Ejector Dimensions of A Bus ArezarossNo ratings yet

- "Best Stuff I Ever Used": We Hear It All The Time - .Document2 pages"Best Stuff I Ever Used": We Hear It All The Time - .rezarossNo ratings yet

- A Review On Novel Air Conditioning System Using Alternative RefrigerantsDocument5 pagesA Review On Novel Air Conditioning System Using Alternative RefrigerantsrezarossNo ratings yet

- Numerical Simulation of R1234ze Ejector-ExpansionDocument13 pagesNumerical Simulation of R1234ze Ejector-ExpansionrezarossNo ratings yet

- Mazda Limited: Terms and ConditionsDocument3 pagesMazda Limited: Terms and ConditionsrezarossNo ratings yet

- EnergyDocument9 pagesEnergyrezarossNo ratings yet

- Air-Cooled Solar Absorption Air ConditioningDocument230 pagesAir-Cooled Solar Absorption Air ConditioningrezarossNo ratings yet

- High-Pressure Screw Compressors For Fuel Gas BoostingDocument8 pagesHigh-Pressure Screw Compressors For Fuel Gas BoostingrezarossNo ratings yet

- Paper Waterjetairpump EditedDocument61 pagesPaper Waterjetairpump EditedrezarossNo ratings yet

- High-Pressure 100 Barg Oil-Flooded Screw Compressor: Yasushi AmanoDocument5 pagesHigh-Pressure 100 Barg Oil-Flooded Screw Compressor: Yasushi AmanorezarossNo ratings yet

- Gas Compression With The Liquid Jet PumpDocument13 pagesGas Compression With The Liquid Jet PumprezarossNo ratings yet

- Ejectors and Jet Pumps - Design and Perfo 2Document101 pagesEjectors and Jet Pumps - Design and Perfo 2rezarossNo ratings yet

- Ray OpticsDocument6 pagesRay OpticsshardaviharphysicsNo ratings yet

- ECEF341 Lecture 26 Mar 27 RC Phase Shift Oscillator, IC 555 - Timer IC Working and Its Monostable OperationDocument29 pagesECEF341 Lecture 26 Mar 27 RC Phase Shift Oscillator, IC 555 - Timer IC Working and Its Monostable OperationVikranth VikiNo ratings yet

- Class VI Science Chap - 3 TP Solution (Date 19-07-2019)Document3 pagesClass VI Science Chap - 3 TP Solution (Date 19-07-2019)Gopal ShuklaNo ratings yet

- Physics For Scientists and Engineers 3rd Edition Knight Test BankDocument35 pagesPhysics For Scientists and Engineers 3rd Edition Knight Test Bankberthahendersonp3oez100% (26)

- Agribusiness: ExamplesDocument4 pagesAgribusiness: ExamplesAngelo AristizabalNo ratings yet

- Grade 10-EnglishDocument11 pagesGrade 10-EnglishlaiwelynNo ratings yet

- First Homework For Reservoir Rock and Fluid Properties LabDocument7 pagesFirst Homework For Reservoir Rock and Fluid Properties Labعامر ابراهيم0% (1)

- Computational Methods: Test Program For Chasing Method Developed in MatlabDocument6 pagesComputational Methods: Test Program For Chasing Method Developed in MatlabMujtaba MujahidNo ratings yet

- Equivalent Length Calculator - RevADocument10 pagesEquivalent Length Calculator - RevArkrajan1502No ratings yet

- MH370 (MAS370) Malaysia Airlines Flight Tracking and History 11-Mar-2014 (KUL - WMKK-PEK - ZBAA) - FlightAwareDocument2 pagesMH370 (MAS370) Malaysia Airlines Flight Tracking and History 11-Mar-2014 (KUL - WMKK-PEK - ZBAA) - FlightAware陳佩No ratings yet

- 03 2018 CHT Scheme & Syllabus VTUDocument57 pages03 2018 CHT Scheme & Syllabus VTUtejNo ratings yet

- What Hartmann'S Solution Is and What It Is Used For?Document4 pagesWhat Hartmann'S Solution Is and What It Is Used For?YudhaNo ratings yet

- A Review On Rasamanjari: It's Contribution in Pharmaceutical ScienceDocument3 pagesA Review On Rasamanjari: It's Contribution in Pharmaceutical ScienceEditor IJTSRDNo ratings yet

- Ce Board ObjectivesDocument2 pagesCe Board ObjectivesAnonymous kTompoaNo ratings yet

- Volumetric Rotary Piston Meter Asm LXH SA1508 15mm, 20mm & 25mmDocument19 pagesVolumetric Rotary Piston Meter Asm LXH SA1508 15mm, 20mm & 25mmGreen FarmersNo ratings yet

- Application of MPC To Cts2-CorrecetdDocument150 pagesApplication of MPC To Cts2-CorrecetdhbuddyNo ratings yet

- Modbus Communications Reference Guide: SMD Series DrivesDocument32 pagesModbus Communications Reference Guide: SMD Series DrivesTsietsi SeralaNo ratings yet

- Callistephus Chinensis GalaDocument4 pagesCallistephus Chinensis GalaBacic SanjaNo ratings yet

- Logg 4000Document7 pagesLogg 4000Stjepan FrljicNo ratings yet

- 0 - Ar - RavindraBhan LaDocument11 pages0 - Ar - RavindraBhan LaSuryNo ratings yet

- PROPOSALDocument62 pagesPROPOSALJam Dela CruzNo ratings yet

- pBrain-HexEngine Configuration Guide v1.2Document35 pagespBrain-HexEngine Configuration Guide v1.2lazer155No ratings yet

- Cooper Ls Brochure Industrial Led Lighting Product CatalogueDocument68 pagesCooper Ls Brochure Industrial Led Lighting Product CataloguecarlosmandopintoNo ratings yet

- Excavation of A Shop-House Garden at PompeiiDocument12 pagesExcavation of A Shop-House Garden at PompeiiJuan Francisco Martos MontielNo ratings yet

- Biochemical Aspects of CellDocument39 pagesBiochemical Aspects of CellHaroon BadarNo ratings yet

- Specifications Battery Chargers For Rail VehiclesDocument2 pagesSpecifications Battery Chargers For Rail VehiclesPirata ScribNo ratings yet

- Måttblad Bauer BK P7112BGM CatalogueB2010 0312 en A4 Chapter12Document54 pagesMåttblad Bauer BK P7112BGM CatalogueB2010 0312 en A4 Chapter12earrNo ratings yet

- CKD 2 Way Valve ADK11/12Document10 pagesCKD 2 Way Valve ADK11/12mon012No ratings yet

- MATH 5 Q4 Module 2 Vizualizing Volume of Cube and Rectangular PrismDocument21 pagesMATH 5 Q4 Module 2 Vizualizing Volume of Cube and Rectangular PrismAnj De Guzman75% (4)