Professional Documents

Culture Documents

Benzola 1311

Benzola 1311

Uploaded by

vanduongCopyright:

Available Formats

You might also like

- Denso Protal 7200 Brush Application SpecDocument2 pagesDenso Protal 7200 Brush Application SpecTino VelázquezNo ratings yet

- Belzona 1151: Instructions For UseDocument2 pagesBelzona 1151: Instructions For UseIrvansyah RazadinNo ratings yet

- Belzona 1311: Instructions For UseDocument2 pagesBelzona 1311: Instructions For UserobertomaleoNo ratings yet

- Belzona 1321Document2 pagesBelzona 1321GabrielNo ratings yet

- UK1111if 10132 PDFDocument2 pagesUK1111if 10132 PDFAdeImanudinNo ratings yet

- 1111 IfDocument2 pages1111 IfMithun NandanNo ratings yet

- Benzona 1511Document2 pagesBenzona 1511Dia Putranto HarmayNo ratings yet

- Belzona 1321: Instructions For UseDocument2 pagesBelzona 1321: Instructions For UserobertomaleoNo ratings yet

- Belzona 1341-3 - UnlockedDocument2 pagesBelzona 1341-3 - UnlockedimtiazNo ratings yet

- UK2211if 10143Document2 pagesUK2211if 10143MAMI RAKOTOMAHANINANo ratings yet

- Belzona 2211: Instructions For UseDocument2 pagesBelzona 2211: Instructions For UseMAMI RAKOTOMAHANINANo ratings yet

- Instructions For Use: 1. To Ensure An Effective Molecular WeldDocument2 pagesInstructions For Use: 1. To Ensure An Effective Molecular WeldQuy RomNo ratings yet

- Belzona 1121: Instructions For UseDocument2 pagesBelzona 1121: Instructions For UseMinhas ArshadNo ratings yet

- Belzona 4131: Instructions For UseDocument2 pagesBelzona 4131: Instructions For UsecodozinhoNo ratings yet

- 2 Belzona 1511 Instruction For UseDocument2 pages2 Belzona 1511 Instruction For UseNaveen Dev MadhavanNo ratings yet

- Belzona 1511 Instruction For UseDocument2 pagesBelzona 1511 Instruction For UseNitin AggarwalNo ratings yet

- Instructions For Use: 1. To Ensure An Effective Molecular WeldDocument2 pagesInstructions For Use: 1. To Ensure An Effective Molecular WeldQuy RomNo ratings yet

- Belzona 1391Document2 pagesBelzona 1391AsadAliNo ratings yet

- Belzona 3921Document2 pagesBelzona 3921Santosh Iim LucknowNo ratings yet

- Belzona 4341: Instructions For UseDocument2 pagesBelzona 4341: Instructions For UseSagysm Hotmarx MarvaugNo ratings yet

- Belzona 5111: Instructions For UseDocument2 pagesBelzona 5111: Instructions For UsePedro RuizNo ratings yet

- Belzona 2211: Instructions For UseDocument2 pagesBelzona 2211: Instructions For UseEnrique MurgiaNo ratings yet

- Belzona Fluid ElastomerDocument2 pagesBelzona Fluid Elastomergacm98No ratings yet

- Belzona 1321 (Ceramic S-Metal) - Instructions For UseDocument2 pagesBelzona 1321 (Ceramic S-Metal) - Instructions For Usevangeliskyriakos8998No ratings yet

- UK3111if 10134Document2 pagesUK3111if 10134VPN NetworkNo ratings yet

- Belzona 1341 (Supermetalglide) - Instructions For UseDocument2 pagesBelzona 1341 (Supermetalglide) - Instructions For Usevangeliskyriakos8998No ratings yet

- UK5892if 10106Document2 pagesUK5892if 10106mrashid286No ratings yet

- UK1391Tif 10034Document2 pagesUK1391Tif 10034Deepak YadavNo ratings yet

- 1391 T Belzona Instruction - UseDocument0 pages1391 T Belzona Instruction - UseSds Mani SNo ratings yet

- Gebruiksinstructie 7111Document4 pagesGebruiksinstructie 7111Achwan FebNo ratings yet

- Belzona 5831: Instructions For UseDocument2 pagesBelzona 5831: Instructions For UseVippin Kumar RanaNo ratings yet

- Belzona 1831 Instruction For UseDocument2 pagesBelzona 1831 Instruction For UseshambhoiNo ratings yet

- Belzona Know-How: For Bonding and Grouting Tiles and Wear PlatesDocument2 pagesBelzona Know-How: For Bonding and Grouting Tiles and Wear PlatesArthurNo ratings yet

- PDS-POLYKEN-1027-V1-AUG17 - AARPS-0972 PrymerDocument2 pagesPDS-POLYKEN-1027-V1-AUG17 - AARPS-0972 PrymerJoel SaucedoNo ratings yet

- 05.PFP - 261 (Rev)Document2 pages05.PFP - 261 (Rev)ChristinaNo ratings yet

- Belzona 1212Document2 pagesBelzona 1212faridNo ratings yet

- Interline 961 Eng A4 20081030Document4 pagesInterline 961 Eng A4 20081030Linnie McleodNo ratings yet

- Technical Proposal: (Application of Belzona Tank Preformed Patch Repair)Document8 pagesTechnical Proposal: (Application of Belzona Tank Preformed Patch Repair)Bambang IrawanNo ratings yet

- Abecote 341: Concrete Dust Proofer and Surface Hardening CompoundDocument2 pagesAbecote 341: Concrete Dust Proofer and Surface Hardening CompoundAshvin ParmessurNo ratings yet

- Nitocote SN511Document2 pagesNitocote SN511Gibbs PerNo ratings yet

- Quickmast 341Document2 pagesQuickmast 341osama mohNo ratings yet

- Enviroline 199+ds+eng PDFDocument4 pagesEnviroline 199+ds+eng PDFMohamed NouzerNo ratings yet

- Chemclad SC PDFDocument2 pagesChemclad SC PDFskNo ratings yet

- Ficha Tecnica Carboline Semstone - 110 - PDSDocument3 pagesFicha Tecnica Carboline Semstone - 110 - PDSUlises Sanchez PavianNo ratings yet

- Ceralusa 50-350 Technical BulletinDocument3 pagesCeralusa 50-350 Technical BulletinSayyed AliReza NematollahiNo ratings yet

- PDS-POLYKEN-1039 PrimerDocument2 pagesPDS-POLYKEN-1039 PrimerSenthilkumar NarayananNo ratings yet

- PFP-241-2K SB: Polyfloor Primer Multipurpose SBDocument2 pagesPFP-241-2K SB: Polyfloor Primer Multipurpose SBDodi Tri Wibowo100% (1)

- Fosroc Nitocote SN511 TDSDocument2 pagesFosroc Nitocote SN511 TDSmrameshceNo ratings yet

- Galvit EZ P40.01: Previous Suitable CoatDocument2 pagesGalvit EZ P40.01: Previous Suitable CoatDamian RoweNo ratings yet

- TDS Nitobond EP India4Document3 pagesTDS Nitobond EP India4SHIVANSHUNo ratings yet

- PDS Polyken 1033aDocument2 pagesPDS Polyken 1033aVijay KumarNo ratings yet

- Outstanding Chemical Resistance Apply by Brush, - Roller or Spray Unlimited Shelf Life - 100% Solids - Simple To Use - DurableDocument2 pagesOutstanding Chemical Resistance Apply by Brush, - Roller or Spray Unlimited Shelf Life - 100% Solids - Simple To Use - DurableAlfred GomoeliaNo ratings yet

- Abecote 340: Epoxy Resin Floor CoatingDocument2 pagesAbecote 340: Epoxy Resin Floor CoatingAshvin ParmessurNo ratings yet

- Ceilcote 2000 Flakeline+ds+engDocument4 pagesCeilcote 2000 Flakeline+ds+englivefreakNo ratings yet

- TDS - Nitobond PC - IndiaDocument2 pagesTDS - Nitobond PC - IndiaccNo ratings yet

- TDS - Starbond EP-SL1Document2 pagesTDS - Starbond EP-SL1EssamNo ratings yet

- Santisimo Rosario National High Schoo2Document47 pagesSantisimo Rosario National High Schoo2Kissarah B. VillanuevaNo ratings yet

- Physics Project On CapacitorsDocument16 pagesPhysics Project On CapacitorsIraban GuptaBasuNo ratings yet

- Kontrapunkt Egmont CaseDocument2 pagesKontrapunkt Egmont CaseFilt JohnNo ratings yet

- Critique Bryams Model ICCDocument34 pagesCritique Bryams Model ICCRachel Mestre MesquitaNo ratings yet

- D - Confidence - 13 PDFDocument152 pagesD - Confidence - 13 PDFMuhammad NasihNo ratings yet

- FSD PDFDocument19 pagesFSD PDFrambrahamNo ratings yet

- Astro SexDocument12 pagesAstro SexNitin Kumar Gupta100% (3)

- Iso 15504Document30 pagesIso 15504api-5754469100% (1)

- 3.2 Angles and Parallel LinesDocument20 pages3.2 Angles and Parallel LinesRonald L FisherNo ratings yet

- Automated Testing Tool QTPDocument2 pagesAutomated Testing Tool QTPvapapsNo ratings yet

- BPP October 9-13Document28 pagesBPP October 9-13Mariel San PedroNo ratings yet

- Meg Armstrong - The Effects of BlacknessDocument25 pagesMeg Armstrong - The Effects of BlacknessDaniel CorreaNo ratings yet

- Mid - Year Examinatin Timetable 2022 With InvigilatorsDocument1 pageMid - Year Examinatin Timetable 2022 With Invigilatorsb i z a r r o UnKnoWnNo ratings yet

- Educational Leadership - Personal Growth For Professional Development (Published in Association With The British Educational Leadership and Management Society) PDFDocument239 pagesEducational Leadership - Personal Growth For Professional Development (Published in Association With The British Educational Leadership and Management Society) PDFmili_mili100% (1)

- Plastic Yield LodeDocument9 pagesPlastic Yield LodesengozkNo ratings yet

- QuestionnaireDocument4 pagesQuestionnairegopi71190No ratings yet

- Assignment 1 - Basics of PythonDocument2 pagesAssignment 1 - Basics of PythonAshutosh SharmaNo ratings yet

- Qua Giang Sinh Day !Document9 pagesQua Giang Sinh Day !Quang Thinh PhungNo ratings yet

- Using Games To Teach ChemistryDocument4 pagesUsing Games To Teach ChemistryJohnNo ratings yet

- GranulationDocument37 pagesGranulationMuhammad Ali RizviNo ratings yet

- 2014 09 24 - LOINC and RELMA For Diagnostic ImagingDocument54 pages2014 09 24 - LOINC and RELMA For Diagnostic ImagingDaniel VreemanNo ratings yet

- Shakespeares Four HumorsDocument10 pagesShakespeares Four Humorsapi-248879977No ratings yet

- Progress Test3Document6 pagesProgress Test3botanurNo ratings yet

- Syntax Lesson 1Document8 pagesSyntax Lesson 1Nguyễn Ngọc Thảo VyNo ratings yet

- TXTDocument5 pagesTXTproman25-1No ratings yet

- Callable Bond and ValuationDocument13 pagesCallable Bond and ValuationDmitry PopovNo ratings yet

- Climate Museum ShowcaseDocument5 pagesClimate Museum Showcaseapi-403105736No ratings yet

- Guide On Construction of Industrial Developments in SingaporeDocument81 pagesGuide On Construction of Industrial Developments in SingaporeSuzaini ZaidNo ratings yet

- Io Rubric - English ADocument1 pageIo Rubric - English Asfscity07No ratings yet

Benzola 1311

Benzola 1311

Uploaded by

vanduongOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Benzola 1311

Benzola 1311

Uploaded by

vanduongCopyright:

Available Formats

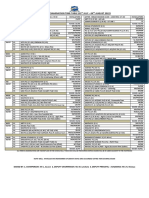

Belzona 1311

FN10133 (CERAMIC R-METAL)

INSTRUCTIONS FOR USE

1. TO ENSURE AN EFFECTIVE MOLECULAR 2. COMBINING THE REACTIVE

WELD COMPONENTS

APPLY ONLY TO BLAST CLEANED SURFACES Transfer the entire contents of the Base and Solidifier modules

a) Brush away loose contamination and degrease with a rag on to the Belzona® Working Surface.

soaked in Belzona® 9111 (Cleaner/Degreaser) or any other

effective cleaner which does not leave a residue e.g. methyl Mix thoroughly together to achieve a uniform material free of any

ethyl ketone (MEK). streakiness.

b) Select an abrasive to give the necessary standard of 1. MIXING AT LOW TEMPERATURES

cleanliness and a minimum depth of profile of 3 mils (75 To ease mixing when the material temperature is below 41°F

microns). (5°C), warm the Base and Solidifier modules until the contents

attain a temperature of 68-77°F (20-25°C).

Use only an angular abrasive.

2. WORKING LIFE

c) Blast clean the metal surface to achieve the following From the commencement of mixing, Belzona® 1311 must be

standard of cleanliness: used within the times shown below.

ISO 8501-1 Sa 2½ very thorough blast cleaning

American Standard near white finish SSPC SP 10 Temperature 41°F (5°C) 59°F (15°C) 77°F (25°C)

Swedish Standard Sa 2½ SIS 05 5900 Use all material 35 min. 25 min. 15 min.

within

d) After blasting, metal surfaces should be coated before any

oxidation of the surface takes place. 3. MIXING SMALL QUANTITIES

For mixing small quantities of Belzona® 1311 use:

SALT CONTAMINATED SURFACES 3 parts Base to 1 part Solidifier by volume

Metal surfaces that have been immersed for any periods in salt 5 parts Base to 1 part Solidifier by weight

solutions e.g. sea water, should be blasted to the required

standard, left 24 hours to allow any ingrained salts to sweat to 4. VOLUME CAPACITY OF MIXED BELZONA® 1311

the surface and then washed prior to a further brush blast to 25.3 cu.in. (415 cm³) per kg.

remove these. This process may need to be repeated to ensure

complete removal of salts. The soluble salt contamination of the

prepared substrate, immediately prior to application, should be

less than 20mgs/m².

WHERE BELZONA® 1311 SHOULD NOT ADHERE

Brush on a thin layer of Belzona® 9411 (Release Agent) and

allow to dry for 15-20 minutes before proceeding to step 2.

www.belzona.com Publication No. 03-07-23

3. APPLYING BELZONA® 1311 5. MACHINING OF SOLIDIFIED

BELZONA® 1311

FOR BEST RESULTS

Do not apply when: Belzona® 1311 is extremely difficult to machine down by turning,

i) The temperature is below 41°F (5°C) or the relative using conventional or carbide tipped tools. However, it can be

humidity is above 90%. machined using diamond tipped tool.

ii) Rain, snow, fog or mist is present.

iii) There is moisture on the metal surface or is likely to be Alternatively it can be machined by grinding, but this should be

deposited by subsequent condensation. carried out as soon as possible after the Solidified times shown.

iv) The working environment is likely to be contaminated by

oil/grease from adjacent equipment or smoke from

kerosene heaters or tobacco smoking.

6. APPLICATION OF A FURTHER LAYER OF

BELZONA® 1311

a) Apply the Belzona® 1311 directly on to the prepared

surface with the plastic applicator or spatula provided. Whenever possible the Belzona® 1311 should be applied in a

single layer to achieve the required thickness.

b) Press down firmly to fill all cracks, remove entrapped air,

and ensure maximum contact with the surface. Best recommendation when overcoating with suitable Belzona

products is to allow the Belzona® 1311 to reach the ‘Machining

c) Contour the Belzona® 1311 to the correct profile with the and/or light loading’ level of cure and then the surface must be

plastic applicator. roughened by abrading or grit blasting to achieve a frosted

appearance with a minimum surface profile of 40 microns before

CLEANING overcoating.

Mixing tools should be cleaned immediately after use with

Belzona® 9111 or any other effective solvent e.g. Methyl ethyl Alternatively, for service not involving immersion with a cold-

ketone (MEK). Application tools should be cleaned using a wall*, Belzona® 1311 can be directly overcoated within

suitable solvent such as Belzona® 9121, MEK, acetone or 90 minutes at 50°F (10°C), within 60 minutes at 68°F (20°C), or

cellulose thinners. within 30 minutes at 86°F (30°C).

4. COMPLETION OF THE MOLECULAR *Please contact Belzona Technical Service directly for

clarification, if necessary.

REACTION

Allow Belzona® 1311 to solidify as below subjecting it to the

conditions indicated.

Temper- Movement Machining Full Immersion

ature or use and/or light mechanical in

involving loading or thermal chemicals

no loading loading

or

immersion

41°F/ 5°C 4 hours 6 hours 4 days 5 days

50°F/10°C 3 hours 4 hours 2 days 4 days

59°F/15°C 2½ hours 3 hours 1½ days 3 days

68°F/20°C 1¾ hours 2 hours 1 day 2 days

77°F/25°C 1 hour 1½ hours 20 hours 1½ days

86°F/30°C ¾ hour 1 hour 16 hours 1 day

These times are for a thickness of approximately 0.25 inch

(6 mm); they will be reduced for thicker sections and extended

for thinner sections.

HEALTH & SAFETY INFORMATION

Please read and make sure you understand the relevant Safety Data Sheets.

The technical data contained herein is based on the results of long term tests carried out in our laboratories and to the best of our knowledge is Belzona products are

true and accurate on the date of publication. It is however subject to change without prior notice and the user should contact Belzona to verify the

technical data is correct before specifying or ordering. No guarantee of accuracy is given or implied. We assume no responsibility for rates of manufactured under an

coverage, performance or injury resulting from use. Liability, if any, is limited to the replacement of products. No other warranty or guarantee of ISO 9001 Registered

any kind is made by Belzona, express or implied, whether statutory, by operation of law or otherwise, including merchantability or fitness for a

particular purpose.

Quality Management System

Nothing in the foregoing statement shall exclude or limit any liability of Belzona to the extent such liability cannot by law be excluded or limited.

Copyright © 2023 Belzona International Limited. Belzona® is a registered trademark.

Belzona 1311 - Instructions for Use - (2) Publication No. 03-07-23

You might also like

- Denso Protal 7200 Brush Application SpecDocument2 pagesDenso Protal 7200 Brush Application SpecTino VelázquezNo ratings yet

- Belzona 1151: Instructions For UseDocument2 pagesBelzona 1151: Instructions For UseIrvansyah RazadinNo ratings yet

- Belzona 1311: Instructions For UseDocument2 pagesBelzona 1311: Instructions For UserobertomaleoNo ratings yet

- Belzona 1321Document2 pagesBelzona 1321GabrielNo ratings yet

- UK1111if 10132 PDFDocument2 pagesUK1111if 10132 PDFAdeImanudinNo ratings yet

- 1111 IfDocument2 pages1111 IfMithun NandanNo ratings yet

- Benzona 1511Document2 pagesBenzona 1511Dia Putranto HarmayNo ratings yet

- Belzona 1321: Instructions For UseDocument2 pagesBelzona 1321: Instructions For UserobertomaleoNo ratings yet

- Belzona 1341-3 - UnlockedDocument2 pagesBelzona 1341-3 - UnlockedimtiazNo ratings yet

- UK2211if 10143Document2 pagesUK2211if 10143MAMI RAKOTOMAHANINANo ratings yet

- Belzona 2211: Instructions For UseDocument2 pagesBelzona 2211: Instructions For UseMAMI RAKOTOMAHANINANo ratings yet

- Instructions For Use: 1. To Ensure An Effective Molecular WeldDocument2 pagesInstructions For Use: 1. To Ensure An Effective Molecular WeldQuy RomNo ratings yet

- Belzona 1121: Instructions For UseDocument2 pagesBelzona 1121: Instructions For UseMinhas ArshadNo ratings yet

- Belzona 4131: Instructions For UseDocument2 pagesBelzona 4131: Instructions For UsecodozinhoNo ratings yet

- 2 Belzona 1511 Instruction For UseDocument2 pages2 Belzona 1511 Instruction For UseNaveen Dev MadhavanNo ratings yet

- Belzona 1511 Instruction For UseDocument2 pagesBelzona 1511 Instruction For UseNitin AggarwalNo ratings yet

- Instructions For Use: 1. To Ensure An Effective Molecular WeldDocument2 pagesInstructions For Use: 1. To Ensure An Effective Molecular WeldQuy RomNo ratings yet

- Belzona 1391Document2 pagesBelzona 1391AsadAliNo ratings yet

- Belzona 3921Document2 pagesBelzona 3921Santosh Iim LucknowNo ratings yet

- Belzona 4341: Instructions For UseDocument2 pagesBelzona 4341: Instructions For UseSagysm Hotmarx MarvaugNo ratings yet

- Belzona 5111: Instructions For UseDocument2 pagesBelzona 5111: Instructions For UsePedro RuizNo ratings yet

- Belzona 2211: Instructions For UseDocument2 pagesBelzona 2211: Instructions For UseEnrique MurgiaNo ratings yet

- Belzona Fluid ElastomerDocument2 pagesBelzona Fluid Elastomergacm98No ratings yet

- Belzona 1321 (Ceramic S-Metal) - Instructions For UseDocument2 pagesBelzona 1321 (Ceramic S-Metal) - Instructions For Usevangeliskyriakos8998No ratings yet

- UK3111if 10134Document2 pagesUK3111if 10134VPN NetworkNo ratings yet

- Belzona 1341 (Supermetalglide) - Instructions For UseDocument2 pagesBelzona 1341 (Supermetalglide) - Instructions For Usevangeliskyriakos8998No ratings yet

- UK5892if 10106Document2 pagesUK5892if 10106mrashid286No ratings yet

- UK1391Tif 10034Document2 pagesUK1391Tif 10034Deepak YadavNo ratings yet

- 1391 T Belzona Instruction - UseDocument0 pages1391 T Belzona Instruction - UseSds Mani SNo ratings yet

- Gebruiksinstructie 7111Document4 pagesGebruiksinstructie 7111Achwan FebNo ratings yet

- Belzona 5831: Instructions For UseDocument2 pagesBelzona 5831: Instructions For UseVippin Kumar RanaNo ratings yet

- Belzona 1831 Instruction For UseDocument2 pagesBelzona 1831 Instruction For UseshambhoiNo ratings yet

- Belzona Know-How: For Bonding and Grouting Tiles and Wear PlatesDocument2 pagesBelzona Know-How: For Bonding and Grouting Tiles and Wear PlatesArthurNo ratings yet

- PDS-POLYKEN-1027-V1-AUG17 - AARPS-0972 PrymerDocument2 pagesPDS-POLYKEN-1027-V1-AUG17 - AARPS-0972 PrymerJoel SaucedoNo ratings yet

- 05.PFP - 261 (Rev)Document2 pages05.PFP - 261 (Rev)ChristinaNo ratings yet

- Belzona 1212Document2 pagesBelzona 1212faridNo ratings yet

- Interline 961 Eng A4 20081030Document4 pagesInterline 961 Eng A4 20081030Linnie McleodNo ratings yet

- Technical Proposal: (Application of Belzona Tank Preformed Patch Repair)Document8 pagesTechnical Proposal: (Application of Belzona Tank Preformed Patch Repair)Bambang IrawanNo ratings yet

- Abecote 341: Concrete Dust Proofer and Surface Hardening CompoundDocument2 pagesAbecote 341: Concrete Dust Proofer and Surface Hardening CompoundAshvin ParmessurNo ratings yet

- Nitocote SN511Document2 pagesNitocote SN511Gibbs PerNo ratings yet

- Quickmast 341Document2 pagesQuickmast 341osama mohNo ratings yet

- Enviroline 199+ds+eng PDFDocument4 pagesEnviroline 199+ds+eng PDFMohamed NouzerNo ratings yet

- Chemclad SC PDFDocument2 pagesChemclad SC PDFskNo ratings yet

- Ficha Tecnica Carboline Semstone - 110 - PDSDocument3 pagesFicha Tecnica Carboline Semstone - 110 - PDSUlises Sanchez PavianNo ratings yet

- Ceralusa 50-350 Technical BulletinDocument3 pagesCeralusa 50-350 Technical BulletinSayyed AliReza NematollahiNo ratings yet

- PDS-POLYKEN-1039 PrimerDocument2 pagesPDS-POLYKEN-1039 PrimerSenthilkumar NarayananNo ratings yet

- PFP-241-2K SB: Polyfloor Primer Multipurpose SBDocument2 pagesPFP-241-2K SB: Polyfloor Primer Multipurpose SBDodi Tri Wibowo100% (1)

- Fosroc Nitocote SN511 TDSDocument2 pagesFosroc Nitocote SN511 TDSmrameshceNo ratings yet

- Galvit EZ P40.01: Previous Suitable CoatDocument2 pagesGalvit EZ P40.01: Previous Suitable CoatDamian RoweNo ratings yet

- TDS Nitobond EP India4Document3 pagesTDS Nitobond EP India4SHIVANSHUNo ratings yet

- PDS Polyken 1033aDocument2 pagesPDS Polyken 1033aVijay KumarNo ratings yet

- Outstanding Chemical Resistance Apply by Brush, - Roller or Spray Unlimited Shelf Life - 100% Solids - Simple To Use - DurableDocument2 pagesOutstanding Chemical Resistance Apply by Brush, - Roller or Spray Unlimited Shelf Life - 100% Solids - Simple To Use - DurableAlfred GomoeliaNo ratings yet

- Abecote 340: Epoxy Resin Floor CoatingDocument2 pagesAbecote 340: Epoxy Resin Floor CoatingAshvin ParmessurNo ratings yet

- Ceilcote 2000 Flakeline+ds+engDocument4 pagesCeilcote 2000 Flakeline+ds+englivefreakNo ratings yet

- TDS - Nitobond PC - IndiaDocument2 pagesTDS - Nitobond PC - IndiaccNo ratings yet

- TDS - Starbond EP-SL1Document2 pagesTDS - Starbond EP-SL1EssamNo ratings yet

- Santisimo Rosario National High Schoo2Document47 pagesSantisimo Rosario National High Schoo2Kissarah B. VillanuevaNo ratings yet

- Physics Project On CapacitorsDocument16 pagesPhysics Project On CapacitorsIraban GuptaBasuNo ratings yet

- Kontrapunkt Egmont CaseDocument2 pagesKontrapunkt Egmont CaseFilt JohnNo ratings yet

- Critique Bryams Model ICCDocument34 pagesCritique Bryams Model ICCRachel Mestre MesquitaNo ratings yet

- D - Confidence - 13 PDFDocument152 pagesD - Confidence - 13 PDFMuhammad NasihNo ratings yet

- FSD PDFDocument19 pagesFSD PDFrambrahamNo ratings yet

- Astro SexDocument12 pagesAstro SexNitin Kumar Gupta100% (3)

- Iso 15504Document30 pagesIso 15504api-5754469100% (1)

- 3.2 Angles and Parallel LinesDocument20 pages3.2 Angles and Parallel LinesRonald L FisherNo ratings yet

- Automated Testing Tool QTPDocument2 pagesAutomated Testing Tool QTPvapapsNo ratings yet

- BPP October 9-13Document28 pagesBPP October 9-13Mariel San PedroNo ratings yet

- Meg Armstrong - The Effects of BlacknessDocument25 pagesMeg Armstrong - The Effects of BlacknessDaniel CorreaNo ratings yet

- Mid - Year Examinatin Timetable 2022 With InvigilatorsDocument1 pageMid - Year Examinatin Timetable 2022 With Invigilatorsb i z a r r o UnKnoWnNo ratings yet

- Educational Leadership - Personal Growth For Professional Development (Published in Association With The British Educational Leadership and Management Society) PDFDocument239 pagesEducational Leadership - Personal Growth For Professional Development (Published in Association With The British Educational Leadership and Management Society) PDFmili_mili100% (1)

- Plastic Yield LodeDocument9 pagesPlastic Yield LodesengozkNo ratings yet

- QuestionnaireDocument4 pagesQuestionnairegopi71190No ratings yet

- Assignment 1 - Basics of PythonDocument2 pagesAssignment 1 - Basics of PythonAshutosh SharmaNo ratings yet

- Qua Giang Sinh Day !Document9 pagesQua Giang Sinh Day !Quang Thinh PhungNo ratings yet

- Using Games To Teach ChemistryDocument4 pagesUsing Games To Teach ChemistryJohnNo ratings yet

- GranulationDocument37 pagesGranulationMuhammad Ali RizviNo ratings yet

- 2014 09 24 - LOINC and RELMA For Diagnostic ImagingDocument54 pages2014 09 24 - LOINC and RELMA For Diagnostic ImagingDaniel VreemanNo ratings yet

- Shakespeares Four HumorsDocument10 pagesShakespeares Four Humorsapi-248879977No ratings yet

- Progress Test3Document6 pagesProgress Test3botanurNo ratings yet

- Syntax Lesson 1Document8 pagesSyntax Lesson 1Nguyễn Ngọc Thảo VyNo ratings yet

- TXTDocument5 pagesTXTproman25-1No ratings yet

- Callable Bond and ValuationDocument13 pagesCallable Bond and ValuationDmitry PopovNo ratings yet

- Climate Museum ShowcaseDocument5 pagesClimate Museum Showcaseapi-403105736No ratings yet

- Guide On Construction of Industrial Developments in SingaporeDocument81 pagesGuide On Construction of Industrial Developments in SingaporeSuzaini ZaidNo ratings yet

- Io Rubric - English ADocument1 pageIo Rubric - English Asfscity07No ratings yet