Professional Documents

Culture Documents

Saic H 2011

Saic H 2011

Uploaded by

zuknesedriCopyright:

Available Formats

You might also like

- SAIC-H-2032 Rev 7Document4 pagesSAIC-H-2032 Rev 7Satheesh Rama SamyNo ratings yet

- Saic H 2011Document2 pagesSaic H 2011Ansar Ali VemmullyNo ratings yet

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection ChecklistSardar Muhamad RashidNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Application Insp of Intumescent Fireproofing Mat'ls SAIC-B-2006 30-Apr-13 MechDocument4 pagesSaudi Aramco Inspection Checklist: Pre-Application Insp of Intumescent Fireproofing Mat'ls SAIC-B-2006 30-Apr-13 Mechpookkoya thangalNo ratings yet

- Saic H 2014Document2 pagesSaic H 2014Ansar Ali VemmullyNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Application Insp of Intumescent Fireproofing Mat'ls SAIC-B-2006 3-Jul-18 MechDocument3 pagesSaudi Aramco Inspection Checklist: Pre-Application Insp of Intumescent Fireproofing Mat'ls SAIC-B-2006 3-Jul-18 Mechkarthi51289No ratings yet

- Saic H 1002Document4 pagesSaic H 1002NASIR SYEDNo ratings yet

- SAIC-H-1002 - Coatings and Repair Materials Receiving, InspectionDocument2 pagesSAIC-H-1002 - Coatings and Repair Materials Receiving, InspectionzuknesedriNo ratings yet

- Saic H 2024Document2 pagesSaic H 2024usmanNo ratings yet

- SAIC-H-1002 Rev 7 (Final)Document2 pagesSAIC-H-1002 Rev 7 (Final)ryann mananquilNo ratings yet

- Saic H 2015Document4 pagesSaic H 2015jerinNo ratings yet

- Saic-H-2028Document11 pagesSaic-H-2028mominNo ratings yet

- SAIC-H-2014 Rev 7Document3 pagesSAIC-H-2014 Rev 7mohammed siddiqNo ratings yet

- Saic H 1003Document4 pagesSaic H 1003NASIR SYEDNo ratings yet

- Saic H 1003Document2 pagesSaic H 1003Hussain Nasser Al- NowiesserNo ratings yet

- Saudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) SAIC-B-2009 30-Apr-13 MechDocument5 pagesSaudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) SAIC-B-2009 30-Apr-13 Mechpookkoya thangalNo ratings yet

- Saudi Aramco Inspection Checklist: Post-Application Insp of Intumescent Fireproofing Mat'l SAIC-B-2008 30-Apr-13 MechDocument2 pagesSaudi Aramco Inspection Checklist: Post-Application Insp of Intumescent Fireproofing Mat'l SAIC-B-2008 30-Apr-13 Mechpookkoya thangalNo ratings yet

- Saudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) 15-Nov-17Document5 pagesSaudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) 15-Nov-17Abdul HannanNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Inspection of Intumescent Fireproofing Mat'ls SAIC-B-2007 3-Jul-18 MechDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Inspection of Intumescent Fireproofing Mat'ls SAIC-B-2007 3-Jul-18 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- Liquid CoatingsDocument12 pagesLiquid CoatingsSUNIL RAJPUTNo ratings yet

- Saudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) SAIC-B-2009 3-Jul-18 MechDocument5 pagesSaudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) SAIC-B-2009 3-Jul-18 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Foam Generating Equipment - Installation Insp & Testing SAIC-B-2014 30-Apr-13 MechDocument5 pagesSaudi Aramco Inspection Checklist: Foam Generating Equipment - Installation Insp & Testing SAIC-B-2014 30-Apr-13 Mechpookkoya thangalNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Inspection of Intumescent Fireproofing Mat'ls SAIC-B-2007 30-Apr-13 MechDocument4 pagesSaudi Aramco Inspection Checklist: In-Process Inspection of Intumescent Fireproofing Mat'ls SAIC-B-2007 30-Apr-13 Mechpookkoya thangalNo ratings yet

- Saic-H-2027Document3 pagesSaic-H-2027momin0% (1)

- Saic M 1034Document3 pagesSaic M 1034Hussain Nasser Al- NowiesserNo ratings yet

- Saudi Aramco Inspection Checklist: Concrete Coatings Pre-Installation Inspection SAIC-H-1003 15-Nov-17Document2 pagesSaudi Aramco Inspection Checklist: Concrete Coatings Pre-Installation Inspection SAIC-H-1003 15-Nov-17Abdul HannanNo ratings yet

- Saudi Aramco Inspection Checklist: Concrete Coatings Pre-Installation Inspection SAIC-H-1003 15-Nov-17Document8 pagesSaudi Aramco Inspection Checklist: Concrete Coatings Pre-Installation Inspection SAIC-H-1003 15-Nov-17Abdul HannanNo ratings yet

- Saic D 2023Document2 pagesSaic D 2023razzak.me.enggNo ratings yet

- A A A A A A: Saudi Aramco Inspection ChecklistDocument2 pagesA A A A A A: Saudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- Apcs-113a Method StatmentDocument7 pagesApcs-113a Method StatmentNoman AhmedNo ratings yet

- Saudi Aramco Inspection Checklist: Foam Generating Equipment - Installation Insp & Testing SAIC-B-2014 15-Nov-17 MechDocument5 pagesSaudi Aramco Inspection Checklist: Foam Generating Equipment - Installation Insp & Testing SAIC-B-2014 15-Nov-17 MechAbdul HannanNo ratings yet

- Saic H 1004Document2 pagesSaic H 1004Anish V NairNo ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistAbdul Hannan100% (1)

- SAIC-B-2001 Rev 6Document6 pagesSAIC-B-2001 Rev 6pookkoya thangalNo ratings yet

- Saic B 2014Document5 pagesSaic B 2014mohammadNo ratings yet

- Saic H 1004Document4 pagesSaic H 1004NASIR SYEDNo ratings yet

- MST-CO-001-01 (MS For General Painting)Document9 pagesMST-CO-001-01 (MS For General Painting)Delta akathehuskyNo ratings yet

- Saic N 2026Document3 pagesSaic N 2026jerinNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Air-Cooled Heat Exchanger SAIC-E-2005 15-Nov-17 MechDocument13 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Air-Cooled Heat Exchanger SAIC-E-2005 15-Nov-17 MechmominNo ratings yet

- Saudi Aramco Inspection Checklist: Storage Handling & Presevation of Heat Exchangers. SAIC-E-2003 15-Nov-17 MechDocument7 pagesSaudi Aramco Inspection Checklist: Storage Handling & Presevation of Heat Exchangers. SAIC-E-2003 15-Nov-17 MechmominNo ratings yet

- Saic e 2005Document13 pagesSaic e 2005jerinNo ratings yet

- Saudi Aramco Inspection Checklist: Concrete Fireproofing Final Inspection SAIC-B-1004 3-Jul-18 CivilDocument2 pagesSaudi Aramco Inspection Checklist: Concrete Fireproofing Final Inspection SAIC-B-1004 3-Jul-18 Civilkarthi51289No ratings yet

- Saic-L-2010 Pmi Testing PDFDocument5 pagesSaic-L-2010 Pmi Testing PDFkarioke mohaNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldAnonymous 4e7GNjzGWNo ratings yet

- Saic A 1001Document3 pagesSaic A 1001Shazab NawazNo ratings yet

- Saic-H-2029Document12 pagesSaic-H-2029mominNo ratings yet

- Saic B 2014Document4 pagesSaic B 2014usmanNo ratings yet

- Larsen & Toubro Atco Saudi LLC: Procedure For Repair Touch-Up Paint of Equipment, Structural and PipingDocument10 pagesLarsen & Toubro Atco Saudi LLC: Procedure For Repair Touch-Up Paint of Equipment, Structural and PipingPrince Jose100% (1)

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saic D 2025Document12 pagesSaic D 2025Md ShariqueNo ratings yet

- Saudi Aramco Inspection Checklist: Post-Application Insp of Intumescent Fireproofing Mat'l SAIC-B-2008 3-Jul-18 MechDocument1 pageSaudi Aramco Inspection Checklist: Post-Application Insp of Intumescent Fireproofing Mat'l SAIC-B-2008 3-Jul-18 Mechkarthi51289No ratings yet

- Saic M 1012Document2 pagesSaic M 1012Hussain Nasser Al- NowiesserNo ratings yet

- SAIC-H-2001 Rev 7Document4 pagesSAIC-H-2001 Rev 7isslam elhoussanyNo ratings yet

- SAIC-H-2001 Rev 7Document3 pagesSAIC-H-2001 Rev 7Satheesh Rama SamyNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistWaleed MedhatNo ratings yet

- Optimization and Business Improvement Studies in Upstream Oil and Gas IndustryFrom EverandOptimization and Business Improvement Studies in Upstream Oil and Gas IndustryNo ratings yet

Saic H 2011

Saic H 2011

Uploaded by

zuknesedriOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saic H 2011

Saic H 2011

Uploaded by

zuknesedriCopyright:

Available Formats

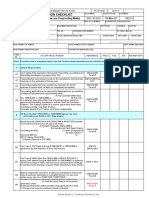

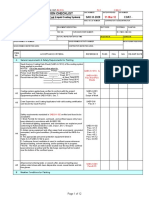

SAUDI ARAMCO ID/PIEU-31-Mar-2019 - REV.2019.03.00 (Standards Cutoff - March 31,2019) Rev.2019.03.

00 31-Mar-19

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Receiving Inspection of FBE Powder & Abrasive

SAIC-H-2011 10-Jun-19 COATING-

Materials and its Storage

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A COATING SYSTEM MATERIALS

09-SAMSS-089

FBE Powder materials shall have the manufacturer's name, product

Para. 6.1.5 &

A1 identification number, batch number, date of manufacture, and the

SAES-H-201

shelf life or the expiry date

PARA.6.10

FBE coating material conforms to the detailed requirements of

SAES-H-002. Materials conform to SAP code listed in APCS-104.

depending upon service temperature.

1) Conventional FBE (Temperatures not exceeding 65°C in subkha

soil or subsea, or up 93°C in dry soil condition, SAP M/N:

1000197745 (SAMS S/N: 09-697-820-00). SAES-H-002

A2 APCS-104

2) High Temperature FBE (Buried or immersion with temperature up Sheet

to 110°C in subkha soil or 125°C in dry ground , SAP M/N:

1000628582 (SAMS S/N: 09-000- 449-00).

Each batch of FBE coating must be tested and certified by the

Manufacturer in accordance with the requirement of Table 1. Vendor SAES-H-201,

A3

shall conduct the same tests to verify compliance with the Para. 6.11

requirements.

Prior to blast cleaning, all hydrocarbon contaminants within a 500 mm

wide band centered over the weld shall be removed from the pipe by

solvent cleaning per SSPC SP-1. Kerosene, diesel, or similar SAES-H-201,

A4 degreasers that leave an oily film shall not be used. Para. 8.2.1

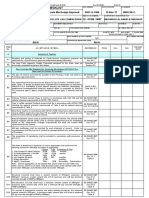

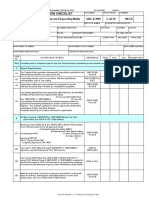

B ABRASIVES (NEW MATERIAL)

Blasting abrasives shall comply with paragraphs 6.3 and 8.2

requirements of SAES-H-001 and shall contain less than 50 ppm

chlorides and sulfates. They shall be stored in a dry condition and SAES-H-201,

B1 maintained dry during use. Contractor shall provide chemical Para. 8.2.5

analyses for all batches of abrasives used, to demonstrate

compliance with these requirements.

SAES-H-201,

Para. 8.2.5

Sand shall not be used as an apprasive as prohibitated by GI-

B2 & SAES-H-001,

0006.021.

Para. 6.3.2

Saudi Aramco: Company General Use

Recycled Mineral & Ferrous Mat'l Abrasives are prohibited.

SAES-H-001,

B3 Recycled Garnet is permitted if it meets the requirements of item B1

Para. 6.3.4

above and CSD approves the Recycling Equip & Procedures.

C COATING MATERIALS STORAGE

Coating material shall be stored and handled in accordance with the

Manufacturer's recommendations.

SAES-H-201

C1 Note: Improved storage, such as air conditioned buildings, shall be

Para 6.1

provided if and when the Consulting Services Department

determines that it is necessary.

Powder shall be transported and stored in a sealed container that

prevents the ingress of moisture or water. Powder shall be kept dry at

all times and not exposed to direct sunlight or used within 15 m of any SAES-H-201

C2 source of ignition. Para 6.2 & 6.3

Blasting abrasives shall be stored in a dry condition and maintained SAES-H-201

C3 dry during use. Para 8.2.5

REMARKS:

REFERENCE DOCUMENTS:

1. SAES-H-201: General Specifications for External and Internal FBE Coatings of Pipeline Field Girth Welds (31 May 2018)

2. SAES-H-001 : Coating Selection & Application Requirements for Industrial Plants & Equipment, (21 February 2018)

3. SAES-H-002: Internal and External Coatings for Steel Pipelines and Piping. (22 February 2018)

Contractor Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and

Name, Initials and Date:

Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and

Name, Initials and Date:

Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

You might also like

- SAIC-H-2032 Rev 7Document4 pagesSAIC-H-2032 Rev 7Satheesh Rama SamyNo ratings yet

- Saic H 2011Document2 pagesSaic H 2011Ansar Ali VemmullyNo ratings yet

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection ChecklistSardar Muhamad RashidNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Application Insp of Intumescent Fireproofing Mat'ls SAIC-B-2006 30-Apr-13 MechDocument4 pagesSaudi Aramco Inspection Checklist: Pre-Application Insp of Intumescent Fireproofing Mat'ls SAIC-B-2006 30-Apr-13 Mechpookkoya thangalNo ratings yet

- Saic H 2014Document2 pagesSaic H 2014Ansar Ali VemmullyNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Application Insp of Intumescent Fireproofing Mat'ls SAIC-B-2006 3-Jul-18 MechDocument3 pagesSaudi Aramco Inspection Checklist: Pre-Application Insp of Intumescent Fireproofing Mat'ls SAIC-B-2006 3-Jul-18 Mechkarthi51289No ratings yet

- Saic H 1002Document4 pagesSaic H 1002NASIR SYEDNo ratings yet

- SAIC-H-1002 - Coatings and Repair Materials Receiving, InspectionDocument2 pagesSAIC-H-1002 - Coatings and Repair Materials Receiving, InspectionzuknesedriNo ratings yet

- Saic H 2024Document2 pagesSaic H 2024usmanNo ratings yet

- SAIC-H-1002 Rev 7 (Final)Document2 pagesSAIC-H-1002 Rev 7 (Final)ryann mananquilNo ratings yet

- Saic H 2015Document4 pagesSaic H 2015jerinNo ratings yet

- Saic-H-2028Document11 pagesSaic-H-2028mominNo ratings yet

- SAIC-H-2014 Rev 7Document3 pagesSAIC-H-2014 Rev 7mohammed siddiqNo ratings yet

- Saic H 1003Document4 pagesSaic H 1003NASIR SYEDNo ratings yet

- Saic H 1003Document2 pagesSaic H 1003Hussain Nasser Al- NowiesserNo ratings yet

- Saudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) SAIC-B-2009 30-Apr-13 MechDocument5 pagesSaudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) SAIC-B-2009 30-Apr-13 Mechpookkoya thangalNo ratings yet

- Saudi Aramco Inspection Checklist: Post-Application Insp of Intumescent Fireproofing Mat'l SAIC-B-2008 30-Apr-13 MechDocument2 pagesSaudi Aramco Inspection Checklist: Post-Application Insp of Intumescent Fireproofing Mat'l SAIC-B-2008 30-Apr-13 Mechpookkoya thangalNo ratings yet

- Saudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) 15-Nov-17Document5 pagesSaudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) 15-Nov-17Abdul HannanNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Inspection of Intumescent Fireproofing Mat'ls SAIC-B-2007 3-Jul-18 MechDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Inspection of Intumescent Fireproofing Mat'ls SAIC-B-2007 3-Jul-18 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- Liquid CoatingsDocument12 pagesLiquid CoatingsSUNIL RAJPUTNo ratings yet

- Saudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) SAIC-B-2009 3-Jul-18 MechDocument5 pagesSaudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) SAIC-B-2009 3-Jul-18 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Foam Generating Equipment - Installation Insp & Testing SAIC-B-2014 30-Apr-13 MechDocument5 pagesSaudi Aramco Inspection Checklist: Foam Generating Equipment - Installation Insp & Testing SAIC-B-2014 30-Apr-13 Mechpookkoya thangalNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Inspection of Intumescent Fireproofing Mat'ls SAIC-B-2007 30-Apr-13 MechDocument4 pagesSaudi Aramco Inspection Checklist: In-Process Inspection of Intumescent Fireproofing Mat'ls SAIC-B-2007 30-Apr-13 Mechpookkoya thangalNo ratings yet

- Saic-H-2027Document3 pagesSaic-H-2027momin0% (1)

- Saic M 1034Document3 pagesSaic M 1034Hussain Nasser Al- NowiesserNo ratings yet

- Saudi Aramco Inspection Checklist: Concrete Coatings Pre-Installation Inspection SAIC-H-1003 15-Nov-17Document2 pagesSaudi Aramco Inspection Checklist: Concrete Coatings Pre-Installation Inspection SAIC-H-1003 15-Nov-17Abdul HannanNo ratings yet

- Saudi Aramco Inspection Checklist: Concrete Coatings Pre-Installation Inspection SAIC-H-1003 15-Nov-17Document8 pagesSaudi Aramco Inspection Checklist: Concrete Coatings Pre-Installation Inspection SAIC-H-1003 15-Nov-17Abdul HannanNo ratings yet

- Saic D 2023Document2 pagesSaic D 2023razzak.me.enggNo ratings yet

- A A A A A A: Saudi Aramco Inspection ChecklistDocument2 pagesA A A A A A: Saudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- Apcs-113a Method StatmentDocument7 pagesApcs-113a Method StatmentNoman AhmedNo ratings yet

- Saudi Aramco Inspection Checklist: Foam Generating Equipment - Installation Insp & Testing SAIC-B-2014 15-Nov-17 MechDocument5 pagesSaudi Aramco Inspection Checklist: Foam Generating Equipment - Installation Insp & Testing SAIC-B-2014 15-Nov-17 MechAbdul HannanNo ratings yet

- Saic H 1004Document2 pagesSaic H 1004Anish V NairNo ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistAbdul Hannan100% (1)

- SAIC-B-2001 Rev 6Document6 pagesSAIC-B-2001 Rev 6pookkoya thangalNo ratings yet

- Saic B 2014Document5 pagesSaic B 2014mohammadNo ratings yet

- Saic H 1004Document4 pagesSaic H 1004NASIR SYEDNo ratings yet

- MST-CO-001-01 (MS For General Painting)Document9 pagesMST-CO-001-01 (MS For General Painting)Delta akathehuskyNo ratings yet

- Saic N 2026Document3 pagesSaic N 2026jerinNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Air-Cooled Heat Exchanger SAIC-E-2005 15-Nov-17 MechDocument13 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Air-Cooled Heat Exchanger SAIC-E-2005 15-Nov-17 MechmominNo ratings yet

- Saudi Aramco Inspection Checklist: Storage Handling & Presevation of Heat Exchangers. SAIC-E-2003 15-Nov-17 MechDocument7 pagesSaudi Aramco Inspection Checklist: Storage Handling & Presevation of Heat Exchangers. SAIC-E-2003 15-Nov-17 MechmominNo ratings yet

- Saic e 2005Document13 pagesSaic e 2005jerinNo ratings yet

- Saudi Aramco Inspection Checklist: Concrete Fireproofing Final Inspection SAIC-B-1004 3-Jul-18 CivilDocument2 pagesSaudi Aramco Inspection Checklist: Concrete Fireproofing Final Inspection SAIC-B-1004 3-Jul-18 Civilkarthi51289No ratings yet

- Saic-L-2010 Pmi Testing PDFDocument5 pagesSaic-L-2010 Pmi Testing PDFkarioke mohaNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldAnonymous 4e7GNjzGWNo ratings yet

- Saic A 1001Document3 pagesSaic A 1001Shazab NawazNo ratings yet

- Saic-H-2029Document12 pagesSaic-H-2029mominNo ratings yet

- Saic B 2014Document4 pagesSaic B 2014usmanNo ratings yet

- Larsen & Toubro Atco Saudi LLC: Procedure For Repair Touch-Up Paint of Equipment, Structural and PipingDocument10 pagesLarsen & Toubro Atco Saudi LLC: Procedure For Repair Touch-Up Paint of Equipment, Structural and PipingPrince Jose100% (1)

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saic D 2025Document12 pagesSaic D 2025Md ShariqueNo ratings yet

- Saudi Aramco Inspection Checklist: Post-Application Insp of Intumescent Fireproofing Mat'l SAIC-B-2008 3-Jul-18 MechDocument1 pageSaudi Aramco Inspection Checklist: Post-Application Insp of Intumescent Fireproofing Mat'l SAIC-B-2008 3-Jul-18 Mechkarthi51289No ratings yet

- Saic M 1012Document2 pagesSaic M 1012Hussain Nasser Al- NowiesserNo ratings yet

- SAIC-H-2001 Rev 7Document4 pagesSAIC-H-2001 Rev 7isslam elhoussanyNo ratings yet

- SAIC-H-2001 Rev 7Document3 pagesSAIC-H-2001 Rev 7Satheesh Rama SamyNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistWaleed MedhatNo ratings yet

- Optimization and Business Improvement Studies in Upstream Oil and Gas IndustryFrom EverandOptimization and Business Improvement Studies in Upstream Oil and Gas IndustryNo ratings yet